DIY sofa - how to make, step by step instructions

Making furniture at home is a laborious process, of course. But what could be better than the embodiment of your own unique ideas. Fortunately, nowadays any materials and tools are freely available for this. And how to make a sofa with your own hands - read the step-by-step instructions in this article.

Varieties of sofas for making at home

Before starting work, it is worth deciding on the design of the sofa and you will definitely have to make a drawing of it. Design is the most important stage, but not the most difficult. You can make a sofa with your own hands using homemade drawings and assembly diagrams, without professional skills. The main types of sofas are as follows:

- Angular. It comes with a square and rounded corner insert.

- Book. conveniently unfolds, but manufacturing will require welding skills.

- Modular. Consist of several separate blocks.

- Transformers. This is a great option for those looking to save valuable space.

To make any type of sofa, you will need approximately the same set of materials and tools. However, each design has its own characteristics.

Additional Information. If it is difficult to independently design a sofa design, you can use the help of a special constructor: PRO-100, Kitchendraw, Woody.

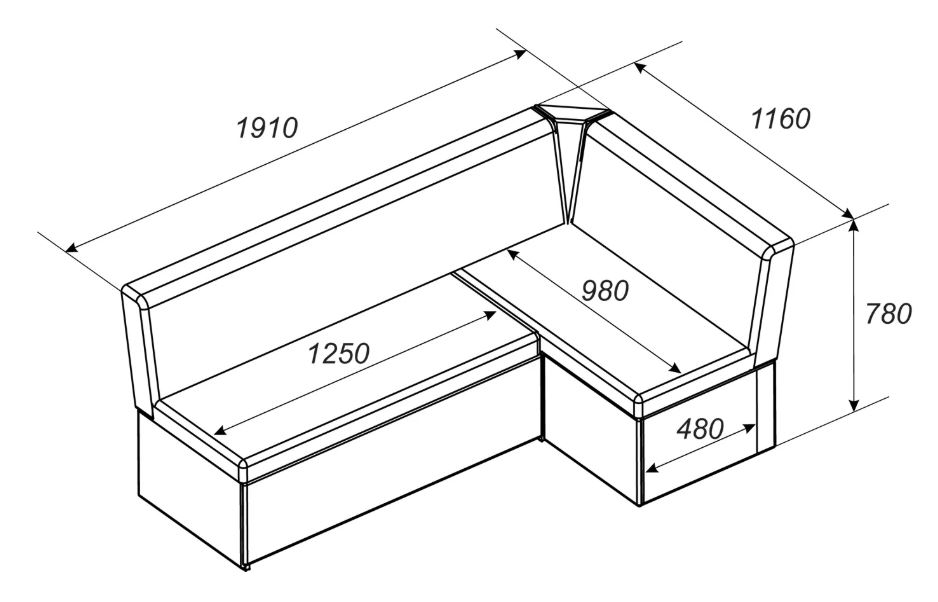

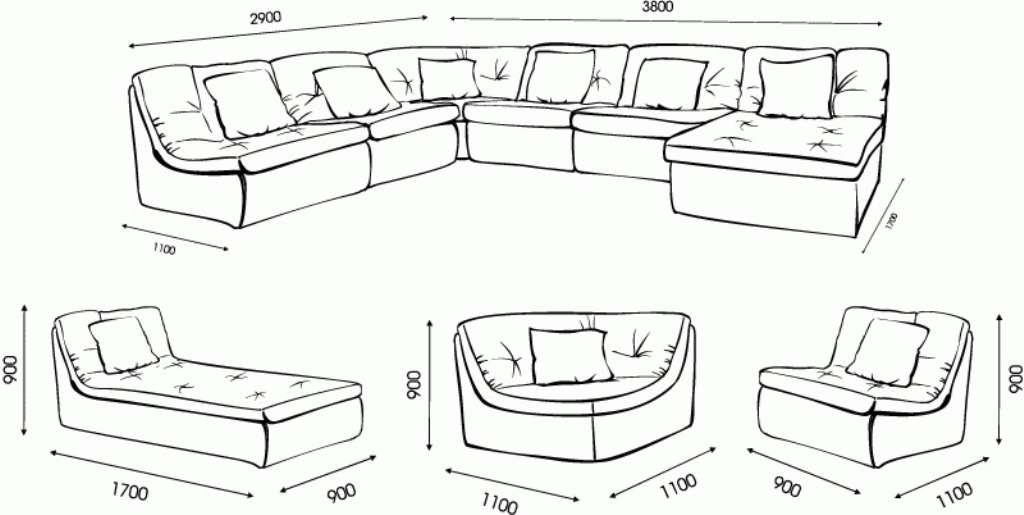

Corner sofa

A corner sofa is installed in the living room or in the kitchen, if the dimensions of the room allow. It may be somewhat difficult to make a corner sofa with your own hands, simpler designs are performed faster and easier. It is a very comfortable and practical design that looks impressive and can accommodate a large number of guests.

Like any other, a do-it-yourself corner sofa involves the creation of drawings and assembly diagrams that will help to accurately transfer the dimensions of the product to the material. First you need to make drawings of the future product on paper.

Next, a detailed drawing of all the elements, their attachment points, partitions and internal boxes is created. This must be done as accurately as possible, so that later all the parts can be easily mounted and interconnected.

- Materials: plywood, fiberboard, upholstery, synthetic winterizer, fasteners, sliding mechanisms, wheels.

- Tools: screwdriver, electric saw or jigsaw, furniture stapler.

- Construction glue, double-sided tape, a pencil, tape measure, sandpaper and a hammer are also useful in the work.

First of all, the dimensions of the parts are transferred to the chipboard and beams.Then they are cut and adjusted to size to each other. Then you can start assembling the product:

- A frame is made, for which long and short bars are connected into a rectangle. First, the first frame is assembled, then the second. The base is connected to the bars with bolts or screws.

- The lower part is sewn up with fiberboard. Nails are used for fastening.

- A corner square insert is made in the same way. If a rounded corner part is assumed, for it the material is bent 90 degrees and attached to the frame beams.

- Boxes are made and connected to the base.

- The side ones are attached to the corner part.

- The back of the sofa is fixed to metal corners.

- The facade is covered with a sheet of chipboard or plywood.

- Next, the seats are made and foam rubber is glued to them.

- Hinges are mounted to connect the seat to the module.

Additional Information. The thickness of the filler is chosen depending on the desired softness. It is better if it is at least 5-10 cm.

After the foam rubber is attached to each structural element with glue, you can start trimming with decorative material. Details are cut from jacquard, flock or any other fabric according to the size of the elements. In this case, you should leave a few centimeters for the allowance. Finished products are attached to the modules using a stapler.

For an attractive look and convenience, you can decorate the sofa with pillows and bolsters. You can fill them with the remains of foam rubber, and sheathe them with any bright fabric. For contrast, you can take a fabric of a different color, or choose a color for curtains and wallpaper.

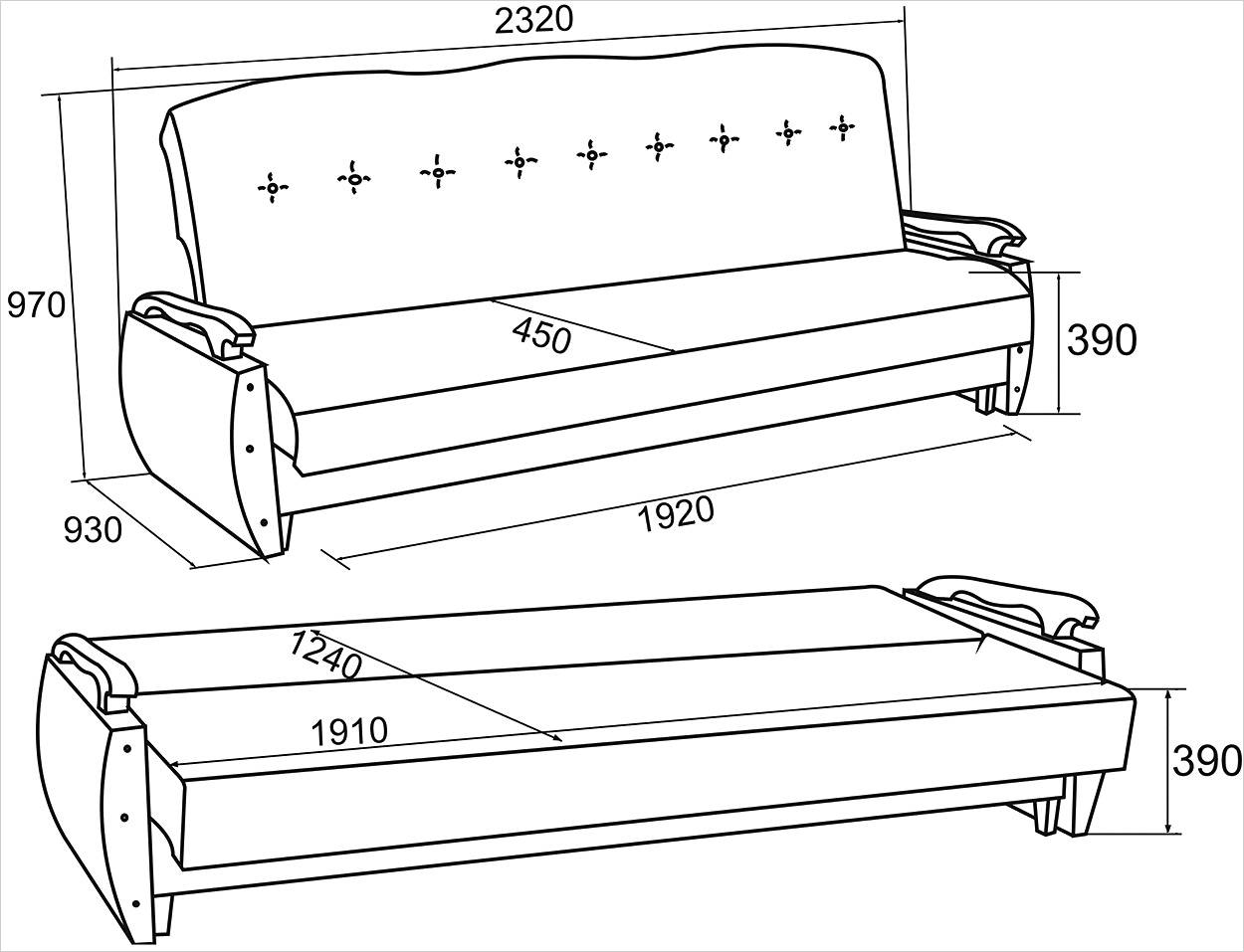

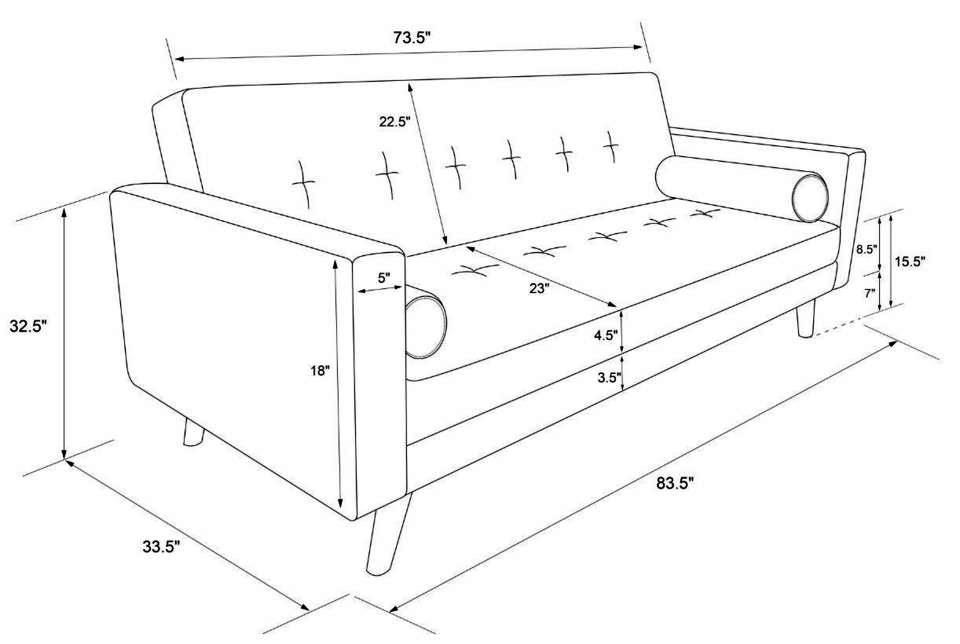

Folding sofa

The fold-out sofa can be made in several versions: a fold-out sofa, a fold-out sofa and a roll-out sofa. The difference between them is not significant, so making any of them is not difficult if you have the skills to make furniture. To begin with, they make a diagram of the product, draw up drawings of each element, cut out the necessary blanks and make holes. You will also need:

- Frames or furniture boards for the seat and backrest.

- Fiberboard boards, beams, spring blocks, sheathing material, foam rubber, hinges.

- The tools should be as follows: jigsaw, screwdriver, screwdrivers, grinder, furniture stapler.

- Tools at hand: nails, screws, door hinges, construction glue, staples.

The step-by-step instructions for making such a sofa are as follows:

- The back of the sofa is made of furniture board. Saw out a diamond-shaped opening and the upper edge of the back with a jigsaw along the markings.

- A support bar is made and attached to the wall.

- A wooden rail is placed on the support and the seat is hinged.

- Marking is performed for the hinges of the side supports of the seat, which will fold inward. The hinges are fixed with screws and the side supports are installed.

- Mount the back of the sofa to the finished structure.

Important! The sofa folds and unfolds thanks to specially designed hook loops. Correct installation will ensure the sofa functions properly.

Foam rubber is placed on the finished structure and covered with upholstery fabric. You can decorate such a sofa with decorative pillows and cover with a blanket. Better to sew a removable cover - it can be removed and washed if dirty.

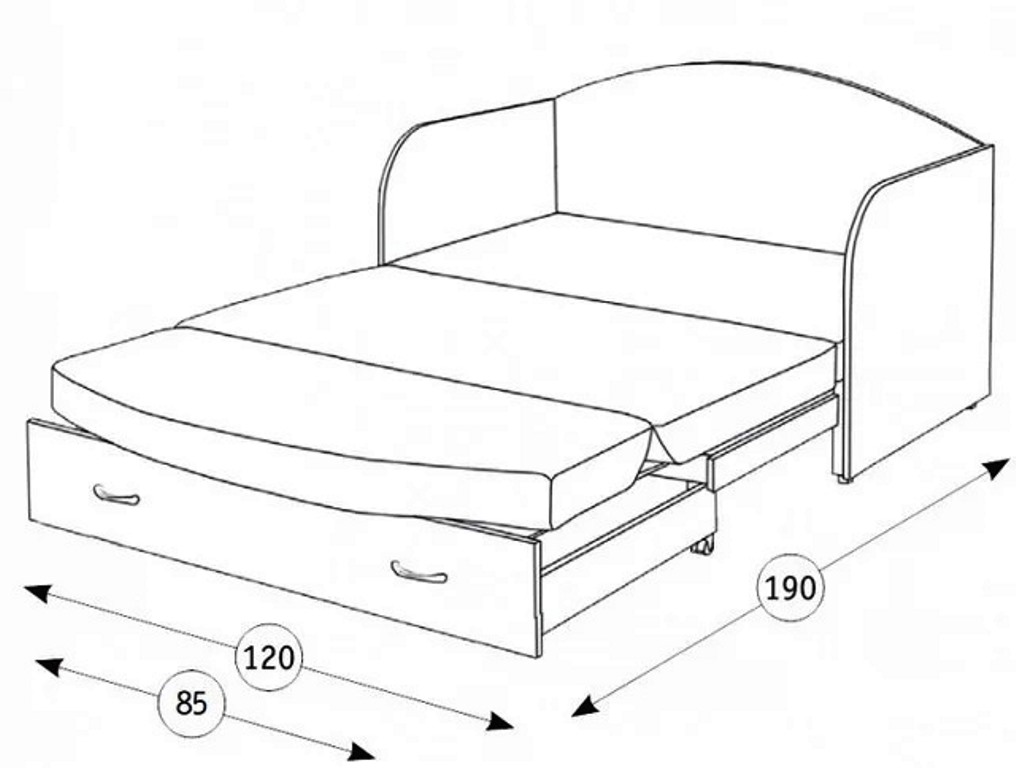

Making a children's sofa

The sofa in the nursery should be small and functional. Any kind of design can be used, but the most popular is the sofa ottoman. It takes up little space, is convenient and folds easily. To make it you will need:

- Materials: lumber, upholstery fabric, filler.

- Tools: electric saw, screwdriver, jigsaw.

- Auxiliary tools: fasteners, tape measure, pencil.

The technique for assembling the sofa-ottoman is as follows:

- Execute product drawings and cut parts from them.

- Make a frame from the boards and fasten them with corners.

- Attach the wooden canvas with self-tapping screws.

- The back is made of plywood or boards.

- Sawed out, assembled and assembled drawers. If they are not provided, the facade is covered with slats.

- Connect the structural elements together.

Important! The structure must be strong and safe. All wooden elements are thoroughly cleaned with sandpaper, covered with stain or varnish.

All parts of the product are sheathed with foam rubber and glued with wood glue. The upholstery material is fixed with a stapler with staples. The fabric is chosen natural, bright colors. The soft back can be made in the form of a house or a car, which will undoubtedly delight the child. Decorate with animal-shaped pillows.

Modular sofa

A feature of the modular design is that they are assembled from separate blocks. Depending on the area of the room, you can supplement the product with any elements. To make such a sofa you will need:

- Plan in advance which modules and parts the product will consist of and choose a transformation mechanism.

- Draw up a drawing of the general structure and each element separately in accordance with the dimensions.

- Prepare materials: wooden beams, chipboard sheets, upholstery, foam rubber, fasteners.

- Tools: grinder, screwdriver and furniture stapler.

- Materials at hand: construction glue, tape measure, screwdriver set.

If all this is available, you can start manufacturing individual elements and assembling the structure. Since such a model has several parts, you can start with any of them. The stages of work for everyone will be the same:

- Assemble the frame according to the drawing from the beams and fix them with self-tapping screws. Do it for each block.

- Make a back from bars and chipboard, attach to the base.

- Make armrests, if provided.

- Lay the foam rubber on separate elements and secure with glue.

- The pre-cut trim is fastened with staples with a furniture stapler.

- Attach the transform engine to the wireframe and moving elements.

Now you can connect separate parts of the sofa and install it in any room: living room, bedroom or room.

Important! If a roll-out mechanism is provided, you will need to screw the roller guides to the inside of the frame. The rollers are attached to the sides of the movable part.

Such a sofa can be successfully decorated with pre-sewn covers. This is very convenient because you can sew a different color for each part.

Leather sofa made of wood

Furniture made of wood is particularly durable, and leather upholstery gives solidity and serves for many years. But the manufacture of such a sofa will require a certain skill and endurance from the master, since it is quite difficult to work with such materials. For manufacturing you will need:

- Materials: natural or eco leather, timber, foam rubber.

- Tools: hacksaw, spirit level, mounting stapler, screwdriver.

- Additional tools: self-tapping screws, corner, scissors, tape measure, wood glue, varnish, stain, paint.

Manufacturing of the structure takes place in several stages:

- A frame is assembled from wooden beams.

- A frame for a sofa is made from boards.

- A rectangular back and side parts are made. Sheathed with wooden planks.

- The wood is treated with varnish, creating a protective layer against damage and moisture.

- A structure of springs is laid on the seat.

- Sheathed with foam rubber and begin to tighten the skin.

Leather is a tough but capricious material. Its cost itself is not small, but the process of sheathing with such material is painstaking. For this, special needles and thin, but strong threads are used. The previously marked parts are cut with a sharp knife, if necessary, the parts are sewn together, then the patterns are attached to the elements of the sofa. You can use a glue gun for this.

Important! When cutting, take into account the direction of stretching of the skin. It stretches better laterally than longitudinally.

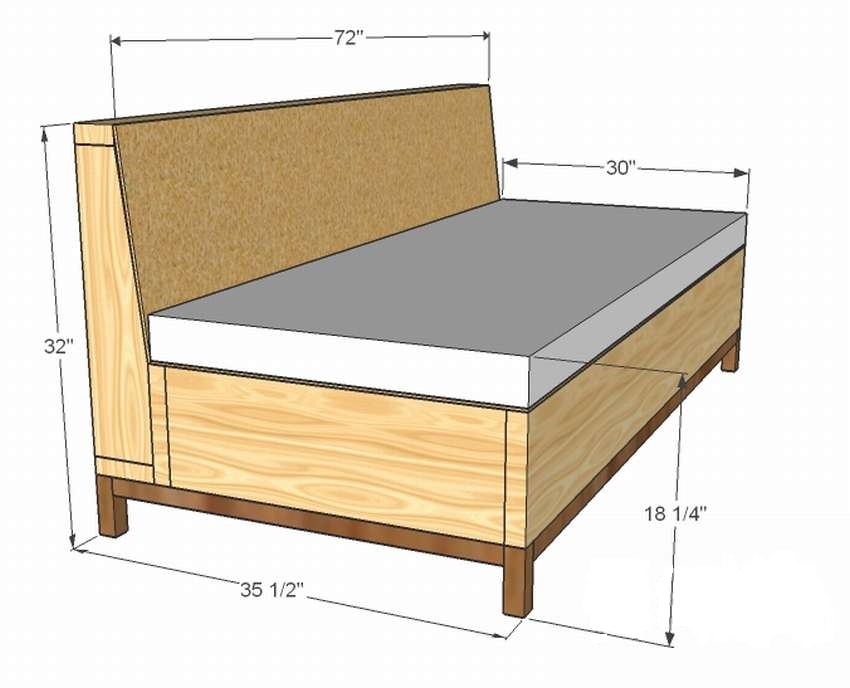

Plywood

This is an original and incredibly simple design that will perfectly fit into the interior of an apartment or summer house. It is especially good for beginners to start with such sofas - it will take a minimum of time and financial investments, but they will be able to gain experience. For such a design, it is necessary:

- Materials: plywood, chipboard, foam rubber, upholstery fabric.

- Tools: electric drill, assembly stapler, screwdriver.

- Additional tools: self-tapping screws, corners, paint brush, marker, scissors, tape measure, wood glue.

The manufacturing process is as follows:

- They choose the design and dimensions of the sofa, draw up detailed drawings of all parts.

- Transfer the dimensions to plywood, cut out the details.

- For the frame, take plywood or laminated chipboard. The edges are sanded with sandpaper.

- The frame is assembled using the joint-to-joint technique. The frame consists of longitudinal and lateral parts and is tightly sheathed with sheathing.

- For the rigidity of the frame, a wooden spacer is installed on top.

- Foam rubber is laid on plywood and fixed with wood glue.

In conclusion, the product is sheathed with an upholstery fabric. For a summer cottage or kitchen, it is better to use eco leather: it is easier to care for and more durable. Covered with a fleecy blanket and decorated with soft decorative pillows.

How to make a folding convertible sofa

Such a model is incredibly practical, and it will not be difficult to make it. With this design, every square meter will be used. At night it is a comfortable sleeping place, and during the day it is a small but functional sofa. To make it you will need the following:

- Draw up a detailed design drawing. The main elements are the carrier box and the base.

- Materials: MDF boards, plywood, furniture nails, hinges and upholstery.

- Tools: saw, screwdriver, grinder, sandpaper, drill and drill bits.

All parts of the structure are prepared in advance, then they proceed to assembly. To begin with, two load-bearing boards are connected with screws, and from below they are fixed with a transverse board. The upper part is reinforced with a transverse beam, attached to the side of the bearing racks. They also do with the front part of the box. Further, the following steps are performed:

- The side cladding is mounted to the end and upper parts of the box using fasteners.

- Secure the front pillar. First, a cross bar is mounted, then an end board relative to it on top of the box.

- The plywood sheet is reinforced with vertical boards so that it does not bend, and then installed to the box.

- A folding part of the structure is made of plywood, on the sides of which there are triangular crossbars.

- The parts are fastened with a horizontal board at the end part. For this, self-tapping screws are used.

In the end, separate parts of the transforming sofa are connected to each other.You can decorate such a transformer with a cape or cover. Faux fur or long-piled fabric will make it even cozier.

Video: how to make a sofa with your own hands

Examples of do-it-yourself sofas in the photo

Already many craftsmen who have tried to make furniture with their own hands have appreciated its advantages. This is cost savings, quality materials and the ability to create unique and practical things with your own hands. Below are examples of sofas that even novice craftsmen can make with their own hands.