DIY sofa making methods

Home craftsmen create beautiful and reliable sofas on their own. In specialized stores, such furniture is offered at a high cost. If you create a sofa bed with your own hands, it will be much cheaper.

Varieties of sofas for making at home

To create furniture, it is important to use a simple design that allows you to create a high-quality and reliable product. Manufactured sofas can fit in with modern living, but they must be of high quality and beautiful design.

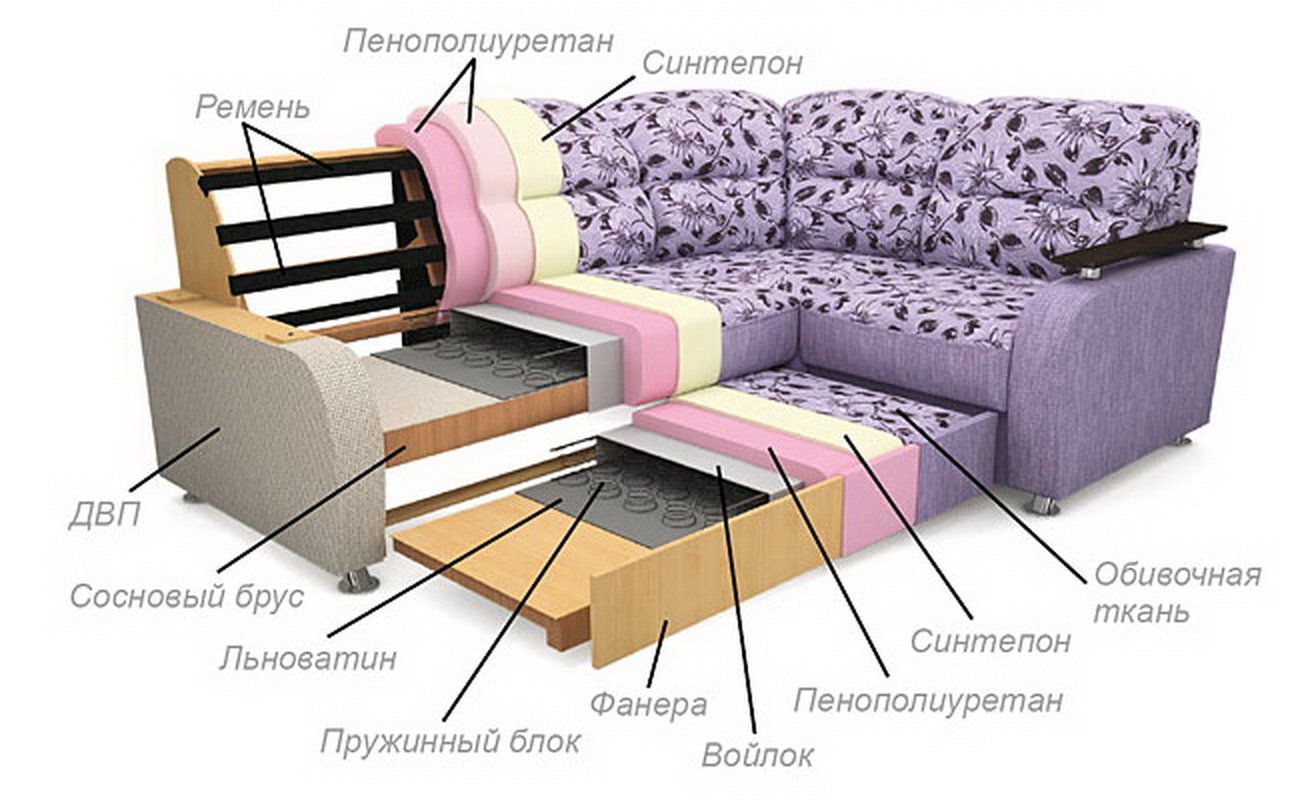

Sofas can vary in shape and size. Natural wood and high-quality beams are used to create structures. For greater rigidity, plywood sheets, chipboard will be required. However, in each case, it is important to choose high-quality materials, beautiful upholstery and take into account the peculiarities of the drawings used.

Note! Assembly is usually done using a screwdriver. The existing joints are initially greased with wood glue, after which the wooden parts are pulled together with self-tapping screws. Metal fasteners are used to secure the joints.

The frame for the mattress is created on the basis of the boards. The support area assumes the presence of cross belts for furniture, which are fastened vertically, then perpendicularly and with a horizontal binding.

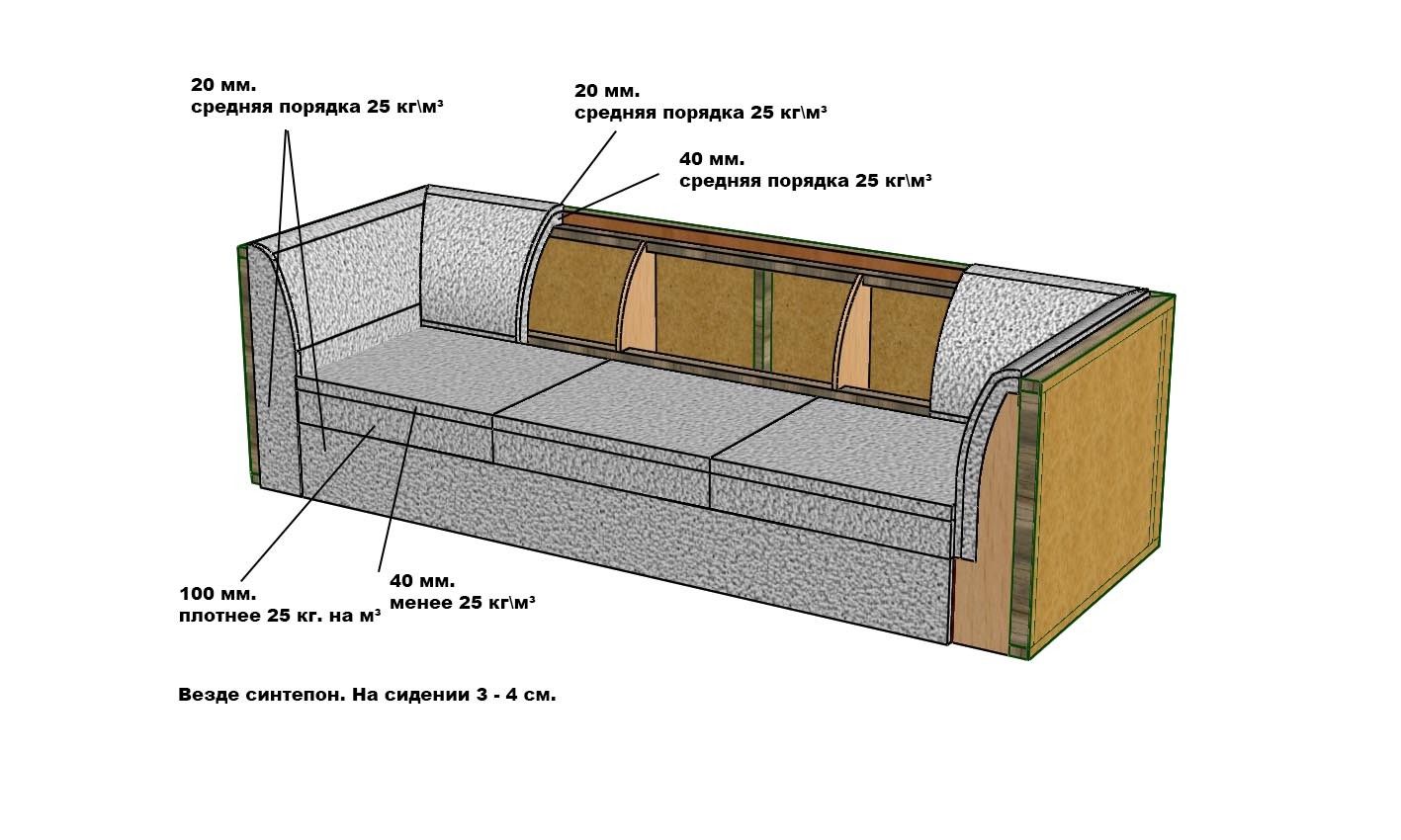

The back often remains hollow inside. Its shape can be rectangular or sloping. The upper and front parts are covered with foam mats. It is also suitable for efficient side trimming.

Sheathing material can be made according to special patterns to save money on the purchase of finishing fabric or leather. The selected textile fabric must be tried on for each element of the sofa, and then the required cuts must be made.

It will take a few days to create a simple model. In other cases, the workflow will be longer and more specific. For example, rounded models are created using wood or plywood panels, which are reliable and of high quality.

To create a sofa bed with your own hands, drawings and assembly diagrams are always needed, because without them it will not be possible to implement a project.

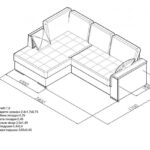

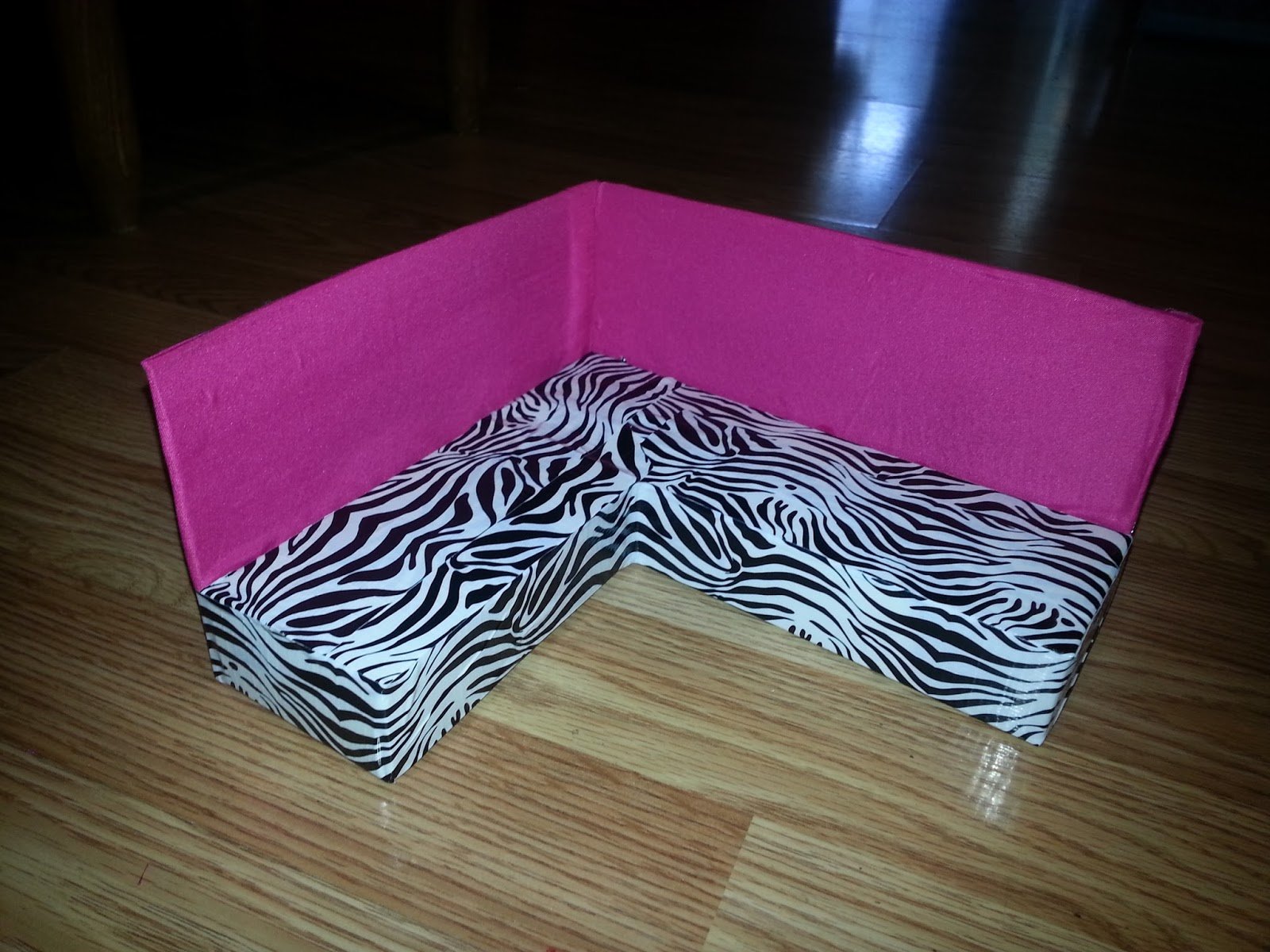

Corner sofa

Initially, cushions are created that will be used as seats. The boards are fastened to each other using self-tapping screws and plates. Chipboard sheets are attached to the created box at the bottom. The wooden frame will allow you to make a support that needs to be protected from external factors with plywood. The back of the sofa can be upholstered with heavyweight fabric.

An additional structure is created in a similar way. To connect the individual elements, an angular structure is required, created from the base material. When creating this part of the sofa, the angle of rotation is taken into account.

The back and seats are covered with batting, and the back with thick cotton. The legs are created from wooden blocks in which holes are drilled. Long screws are required to screw them to furniture. Structural design is essential to prevent deflections and deformations of the sofa.

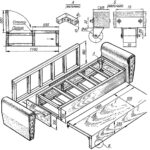

Do-it-yourself folding sofa

This model is considered one of the easiest to perform. It is more difficult to create a roll-out sofa. For work, you will need a furniture board, timber, chipboard, natural wood.

Stages of creating a folding sofa:

- Initially, you need to cut out the armrests and glue them with high quality foam rubber.

- Now you need to assemble the right and left sidewalls.

- Foam rubber is suitable for creating parts for frame sheathing.

- You can pull the textile cover over the sofa frame.

Such models are suitable even for small spaces. Among the advantages are convenience, functionality.

Most of the parts are created from natural wood, because it will last a long time if properly processed. Plywood is suitable for cladding the frame of the frame and creating drawers. For cheaper furniture, chipboard, MDF are suitable.

When creating such functional furniture, it is important to choose a durable and beautiful upholstery material.

The design of the seats should be simple, and the backrest should be rationally installed vertically from the beginning, although then it can be folded. The box can be created from chipboard, but at the same time it can be of different dimensions, if you choose the right size of the material. First, you need to screw the legs to the sides of the future furniture with self-tapping screws, as well as the main guide. Now you need to assemble the frame of the box, and in its middle you need to install, sew to it the bottom, created from special plywood.

All frames, which determine the reliability and geometry of the model, are made of timber. The assembly algorithm will be similar for every part. A rectangle by the size of the seats is twisted with self-tapping screws so that the frame is strong, followed by checking the diagonal.

The back frame is sewn on from the back using a suitable fiberboard sheet.

The sofa should "stand" on legs. You can buy them or make them yourself. A good material for them will be a bar, which can be additionally trimmed to emphasize the beauty of the furniture. Correctly finished legs will be in harmony with the color of the upholstered furniture.

The frame of the sofa must be sheathed with plywood, taking into account the thickness of the bar, using self-tapping screws.

After that, the furniture is treated with upholstery. It is advisable to start with the box and then move on to the main part. Moreover, the back side of the bed box does not have to be trimmed. Using the fabric, you need to make sure that there is enough of it for the fold and secure it with a furniture stapler to the walls. Remains of fabric upholstery are suitable for facing the ends and side parts. The cover can be sewn and bought by securing it at the bottom and back with furniture staples.

The assembly of the sofa ends by screwing 3 loops to the back of the drawer: 1 above the center, and the other two on both sides. The second shelf of the loops is screwed to the bottom of the back. The sofa is set in the unfolded position and the markings are made in order to correctly install the back.

Taking into account the design features of the sofa, it is important to understand the importance of starting work from the box, because it will be the basis of the furniture.

Making a children's sofa yourself

To successfully create a simple children's sofa, it is important to draw up a project.It is advisable to decide on the inclination of the back, the height of the legs, the dimensions, the thickness of the pillows. The legs must be stable as they face significant stress.

Note! The main elements of a children's sofa are the base, legs, backs and seat. Armrests are optional.

The frame of a sofa is usually made of slats. Self-tapping screws and metal corners are used to fasten the parts. To create a furniture frame, slats, boards, beams are suitable, because the load on the product can be different. The base must be 4-sided.

The legs can be installed in the frame. Sometimes they serve as a decorative detail, and in this case, the perimeter of the base will be the support. It is advisable to use reliable legs.

The frame of the sofa is sheathed in chipboard with the bottom and the side. Then they can be painted, toned, varnished.

The seat and back are made of plywood panels, padding polyester or batting, foam rubber. A stationery knife and special scissors will help to facilitate the work with materials. For fastening parts, special staples and a functional gun are suitable. Plywood sheets will be the base, after which you need to glue thick and thin foam rubber.

Upholstery must be used to cover all furniture.

Advice! The main part of the process is attaching the seat to the base and the back of the sofa to these pieces of furniture. For this, metal corners and self-tapping screws are suitable.

After that, you can create a beautiful cover, which should be bright to make the furniture beautiful and original.

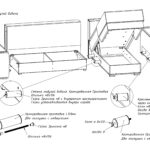

Making a modular sofa

Interested in how to make a sofa bed yourself, you can give preference to a modular model. You can create such furniture with your own hands and make sure of its practicality and reliability. Drawings will help to implement existing ideas for creating furniture.

To create a frame and a box, plywood and chipboard are suitable. Pillows are created using foam rubber and padding polyester. High-quality upholstery is also required. A sofa cannot be created without furniture legs and lifting mechanisms.

For the manufacture of a sofa, it is advisable to cut out the armrests of a beautiful and original shape.

The first stage is the assembly of the sofa frame. Initially, you need to create armrests, and they should be beautiful and symmetrical, so it is important to focus on the instructions provided. All elements are connected using self-tapping screws and a screwdriver. It is advisable to use bars of the same characteristics so that they can be firmly connected.

The base of the board is also created, because the back of the furniture will be held on it. After that, the sofa is sheathed with plywood sheets. After creating the frame, the legs are screwed to the product. The drawer is assembled, but temporarily left aside.

It will need to be sheathed with material and a soft layer. All parts are fastened with self-tapping screws. Then the backrest is installed on the frame, after which the armrests and the drawer are installed.

Furniture must be decorated so that it is soft and comfortable. How the sofa will look depends on this stage. The armrests need to be given sophisticated curves. Foam rubber is used for cushions and seats to keep pieces of furniture soft. Now you can make fabric upholstery, and the material should last for a long time.

A self-created sofa will surely fit into the existing room.

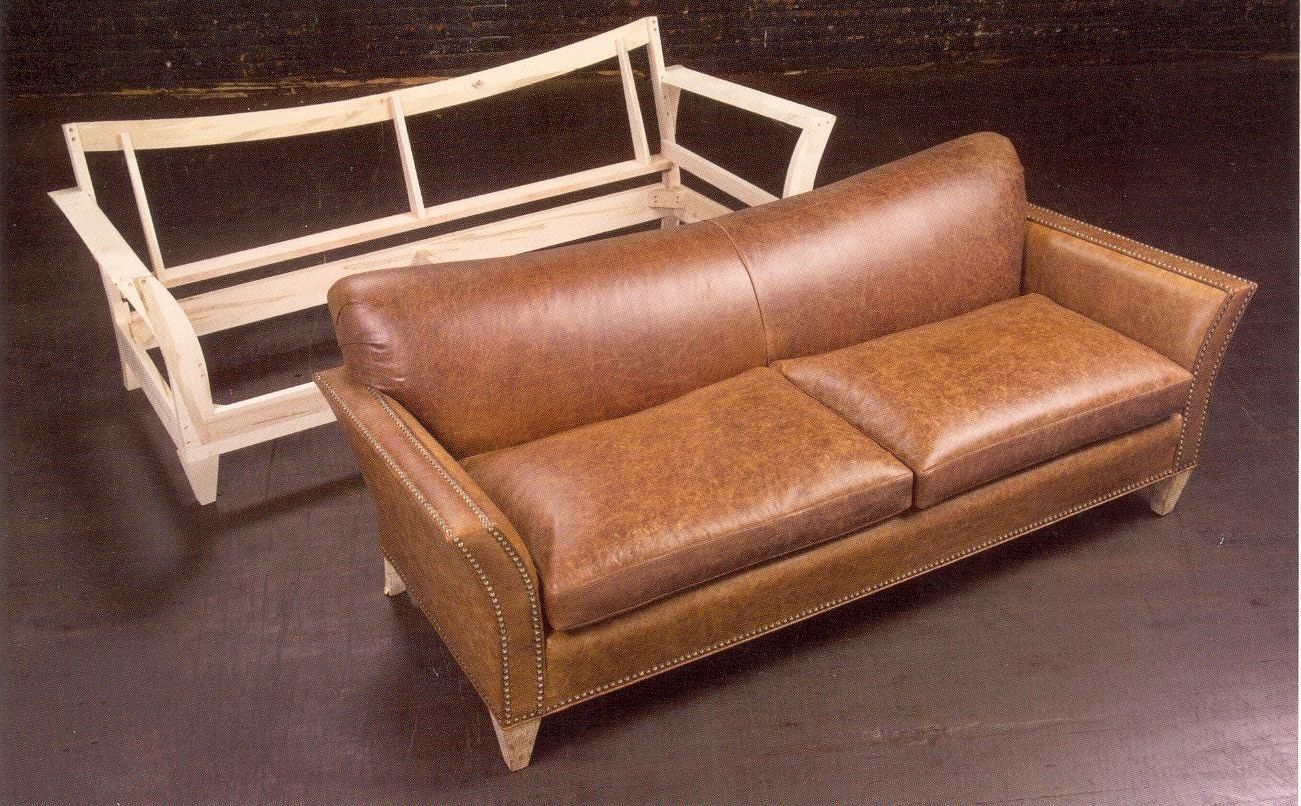

Leather sofa made of wood

The frame is made of high quality natural wood. The filler must be of high quality and durable so that the upholstered furniture retains its original shape for a long time.It is advisable to choose leather as upholstery. Elegant legs are necessarily created for the sofa.

The first step is to create a rectangular drawer that is suitable for storing bedding. To strengthen it, transverse slats are used. With the use of self-tapping screws, you can create the base of the box thanks to plywood. Wooden slats are attached to these frames.

Then armrests are created. Plywood is a good base material. A timber is installed along the perimeter for strengthening. At the next stage, the frame of the sofa is pasted over with foam rubber, and its thickness is taken into account to create tightness.

Now you can start the creative stage of work. Furniture covers can be sewn by yourself. By creating such a sofa, you can make leather upholstery of the desired color, which will be seated with zippers. The leather can also be nailed to the frame using staples and a furniture stapler so that the material fits flawlessly.

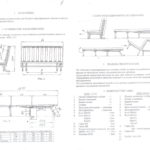

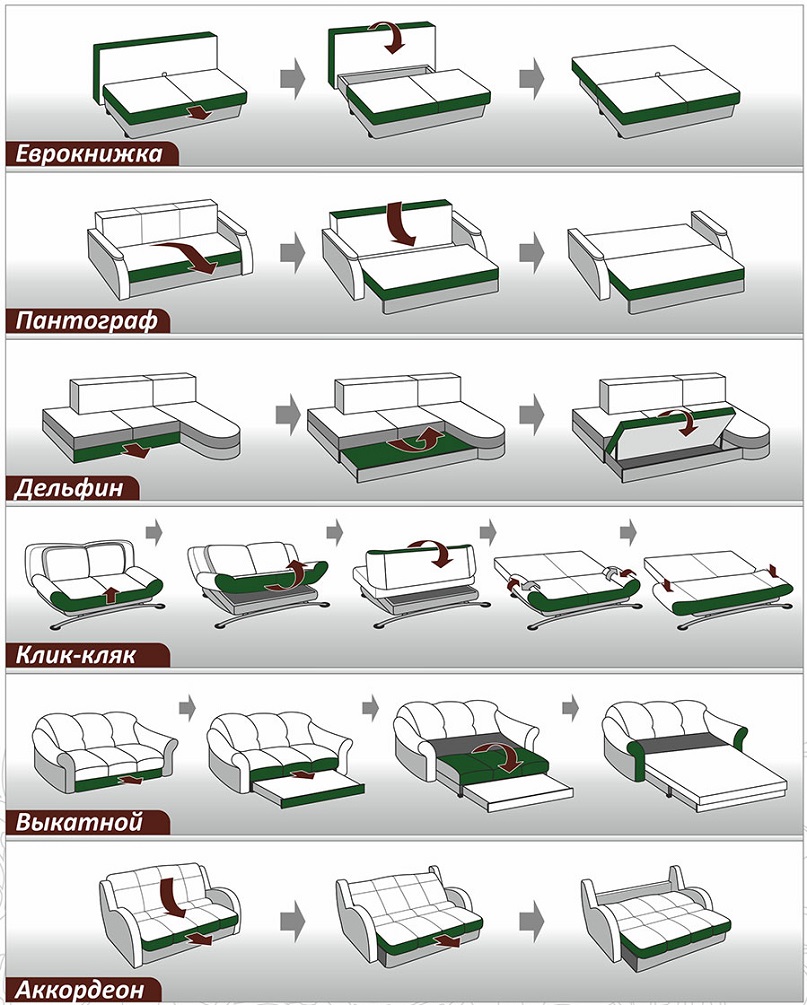

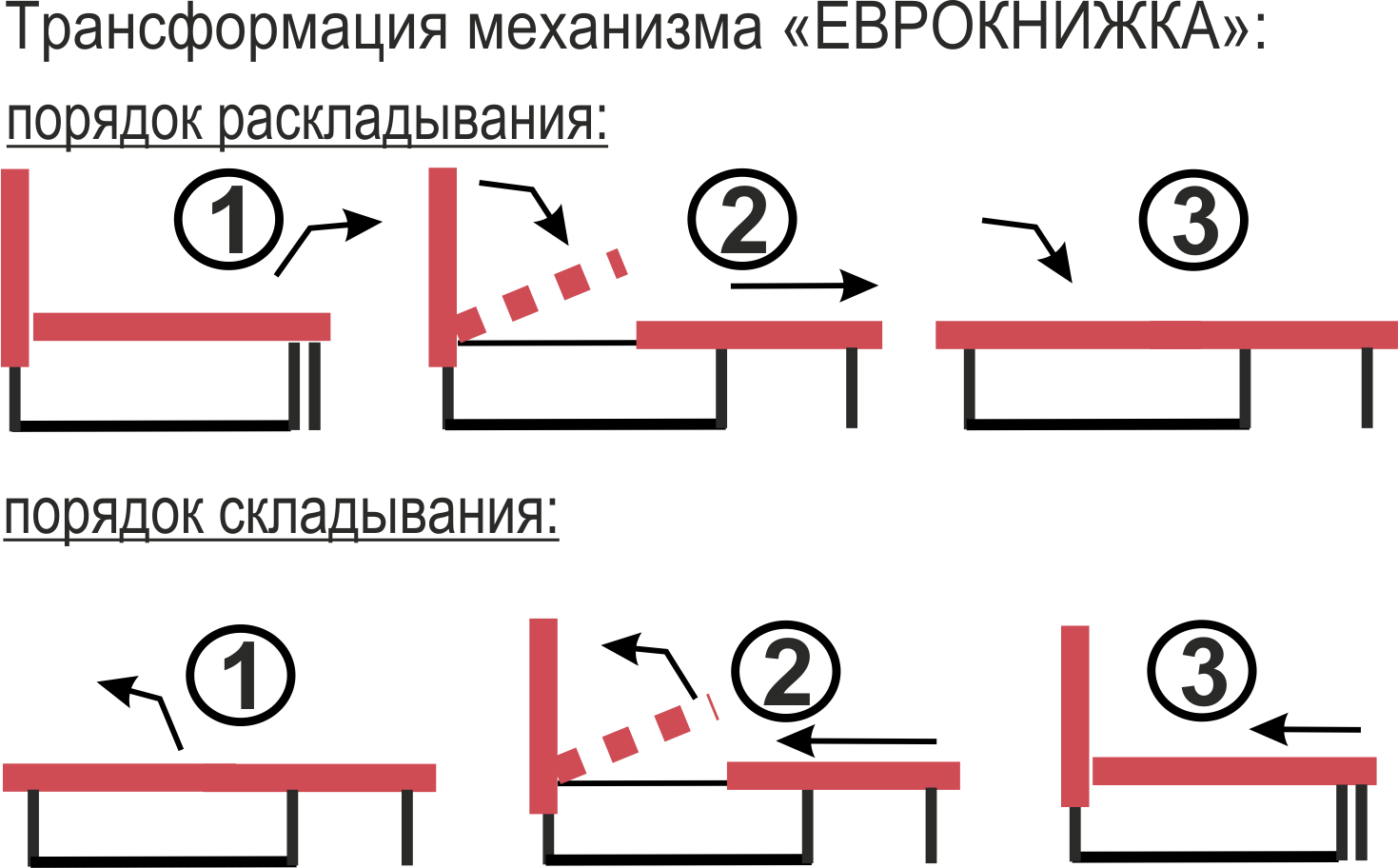

Roll-out or folding convertible sofa

You can also create a bed that is a transformer and can turn into a sofa. The instruction can help in the implementation of the existing idea.

The convertible folding sofa is becoming a classic. Despite numerous modifications from manufacturers, such furniture is still considered expensive and it is more advisable to make it yourself.

Assembly does not require any special skills, so minimal experience is sufficient. Drawings will help in the implementation of the idea.

Note! The main components are the frame, base, lifting mechanism and decorative elements.

- Initially, the frame and power parts of the box are assembled, and the maximum deviations are 5 millimeters per meter.

- The side panels are drilled into the plane of the sofa. The rest of the elements are drilled into the end. Euro screws are used to tighten the box.

- For resistance to load, stiffeners will be required, which are located at a distance of 700 millimeters from the base and top of the furniture.

The base depends on the size of the bed and the mattress. Two side walls and backrests can be assembled into one frame. The front panel is attached with self-tapping screws to special furniture corners. It is advisable to fasten the wall to 4 corners, then align it on all sides and fix it completely to avoid skewing.

Now the box is installed and the lift mechanism is fixed. The base is the axis of rotation of the mechanism and the upper horizontal. The box and the bed are connected by joining parts.

For the correct operation of the structure, a power mechanism based on a gas spring is used.

The final stage is decoration. For example, the façade of a product can be decorated with false doors. The legs are installed in special holes. Knowing how to make a beautiful and reliable sofa out of a bed, you can successfully implement the idea.

Examples of DIY sofas

Having studied modern models of sofas and understanding the features of their creation, you can successfully implement an existing project, taking into account your goals. Self-production of furniture involves taking into account the nuances and differences of structures, understanding the design differences.

A sofa that you create yourself should fit perfectly into the existing space.

Video: DIY sofa making