DIY furniture making tools

Is it possible to assemble a table or a chair at home? The answer is of course. Having at hand the necessary tool and the skills to work with it is not a tricky business. And if you have a country house, or at least a summer cottage, you will 100% assemble an excellent sofa. Having a lot of free space in the garage, it is possible to assemble decent machines from a hand tool in a simple way and "voila".

And if you don't know which furniture assembly tool you need, read this review. Here you will find how to hammer the dowel, how to screw in the confirmation, and how to make a jig for drilling holes.

Be sure to read the entire article. At the end of the bonus!

Pros and cons of self-assembly

Let's take a look at the merits first.

- Saving money. You are free to choose the material, fasteners and accessories yourself. Also no manufacturing costs by the factory.

- Design design. Independent choice of style, color, shape, material - all these factors will make it possible to make a real work of art without leaving your own walls.

- The quality of the product is in your hands. How long a chair or chair will last depends on meticulousness, attentiveness and addiction. Since the work is done for oneself, the approach will be appropriate.

- Possibility of manufacturing for individual conditions. You, like no one else, know what you want, where to put it and how this element of interior decoration should look like.

- An opportunity to discover new talents in yourself. What if things go further, and you decide to start assembling furniture professionally. The extra income hasn't hurt anyone yet.

Now let's talk about the cons. They are not here. If the decision is firmly made to independently make furniture, proper preparation has been made, a high-quality tool has been purchased, the business will certainly go well.

Is it possible to assemble furniture yourself

Definitely yes. The main thing in this business is to organize and carry out the work correctly. Start by sketching. This is done in the form of an outline on a piece of paper. The first step is planning. Development of several options for a future wall for clothes, open shelves for books or a wardrobe.

The second important question is the tool for making furniture. It's good if you still have handheld power tools after repairs or other work. But what if there were none? Do I need to buy a whole set of professional construction and woodworking tools. After all, their price borders on the purchase of a new kitchen set and an upholstered corner?

There is an answer to this question. You can borrow power tools from a neighbor, friend, brother, matchmaker, etc. Or you can contact a specialized company that issues rental tools with a symbolic amount and a deposit. In any case, this option will cost you less than buying a drill, screwdriver, jigsaw and other devices.

What tools are needed

For DIY manufacturing, you must have the following list of furniture tools:

- a set of screwdrivers and keys;

- set of drills;

- construction pencil;

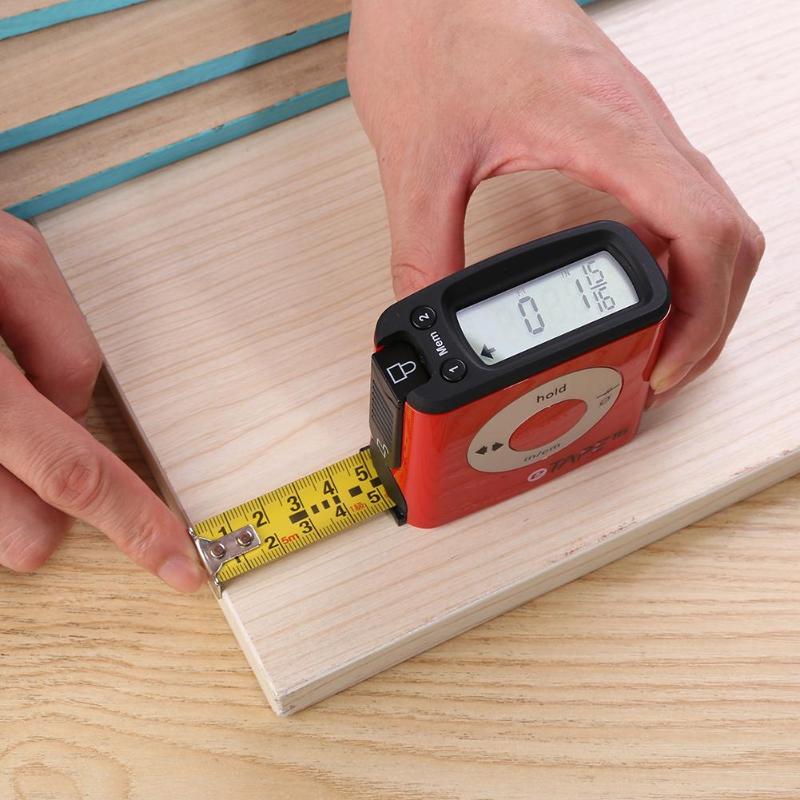

- measuring instruments (tape measure, level, square, joiner's ruler);

- surface treatment products (sandpaper, vibration sander, eccentric sander);

- drill;

- screwdriver;

- electric jigsaw;

- hand-held circular saw;

- conductor.

Each item listed above has specific requirements. This is due to the specifics of working with furniture sets, the processed material and the required quality of cutting products.

Let's consider each element required to complete the assembly work separately.

Screwdrivers and bits

To put together the structure, you must have a set of specialized screwdrivers. You will need:

- screwdrivers of various sizes with flat head;

- and also with a cross recess.

It is imperative to have screwdrivers with a long shank. This is necessary for tightening bolts, self-tapping screws and screws called "confirm" in hard-to-reach or recessed places. Sizes must be from 0 to 3 rooms. For a more precise choice, contact the seller in the hardware store with a request to provide you with a screwdriver size chart.

It is more convenient to buy a set of bits for a screwdriver. To tighten fasteners in hard-to-reach places, purchase a long extension rod. This will save you the cost of buying multiple screwdrivers as the bit set is cheaper.

Pay attention to the quality of the material from which the slot of the screwdriver or bit is made. Don't buy cheap Chinese products. The low price hides unsatisfactory quality. At the first serious tightening, the slot will "lick", fold the head. This is due to the raw metal used in the manufacturing process.

Good bits and screwdrivers, with a high-quality and reliable slot, are made with the addition of cobalt, chromium and vanadium. These metals are hard and elastic at the same time, which allows fasteners to be tightened securely. Such products are marked "CrV".

Drill

The selection of drills is carried out based on what material is used in the manufacture of furniture. This could be:

- natural wood;

- aluminum or other metal;

- slabs obtained from woodworking industry waste;

- plastic;

- glass.

Based on this, select drills for metal, wood and glass. For plastic, a wood drill is suitable, but you need to drill at low speeds.

If you plan on drilling steel, invest in cobalt-doped drills. Such consumables are more expensive than conventional products, but they are of high quality and serve for a long time. Co marking.

High-speed metal is used for wood. But for glass, specialized cutters are used, which have a working surface made of carbide metal.

Using the wrong drills for each material will inevitably affect the quality of the hole. And glass, due to its solid structure, simply cannot be drilled with other cutters.

Have drills in stock with a diameter of 2 to 10 mm.

Measuring

Accuracy of marking on workpieces for cutting to size is one of the main factors, observing which, you will get the perfect home product without flaws.

Measuring instruments are the main tool for assembling cabinet furniture. The dimensions of sliding-door wardrobes, built-in structures, or free-standing ones, require precise alignment in size. Therefore, pay special attention to the accuracy of the measurements. For this, there are classes of accuracy and degree of error of a particular measuring device.

Quality products have certificates of conformity for their products. You will need:

- building and carpentry ruler;

- level;

- elbow 90 degrees;

- roulette.

Some manufacturers produce measuring instruments with special clamps and engaging tips. This greatly facilitates the process of marking the material to be cut, as well as on the walls of an apartment or a private country house.

Grinding

To qualitatively process a wooden board glued from bars and spliced from a board is the main task in making furniture with your own hands. This process has a direct impact on the visual qualities of the finished craft.

The choice of grinding accessories is an important step in DIY manufacturing. External qualities depend on its implementation.

Sandpaper should be available in several grit sizes. If you are going to give a true aristocratic shine to the facades of cabinets, frames and panels, you must have an abrasive available:

- P300 brand;

- P600;

- P1200;

- P1500;

- P2000;

- P2500.

The latter grade provides gloss leveling. To speed up the production of work and improve their quality, use an eccentric sander. Thanks to the pendulum-rotational movements, not a scratch will remain on the surface of the furniture board.

For roughing the surface, you can use a conventional vibration sander as well as a belt sander.

For every sander in stores, sandpaper is sold in a specific shape. It happens:

- in the form of a rectangle with Velcro;

- solid tape;

- triangular in shape with rounded sides.

There is also a screwdriver attachment for attaching an abrasive wheel. The use of such a bond for home polishing of furniture is not allowed, due to rough processing and the appearance of obvious defects. And it is not convenient to work with a screwdriver with a grinding wheel.

Drill and screwdriver

If you ask any furniture maker: what tool is needed to assemble furniture, he will answer - a drill and a screwdriver. An ordinary man in the street, who does not deal with the manufacture of furniture on a daily basis, does not understand why two identical power tools are needed at once.

The fact is that they have different output rpm, as well as different power. And with only one device, you will have to constantly change bits for drills and vice versa, which will lead to a lot of time. Therefore, it is important to have both of these funds.

Choose drills with speed control. If high revolutions are good for wood with a small feed into the workpiece (ensures a clean cut), then for metal and glass, on the contrary - the lower, the faster and cleaner the hole is. And it will not be difficult to ruin a drill for metal or glass at 2000 rpm.

Drilling in metal and glass is carried out with the obligatory liquid cooling of the drill and the workpiece.

In addition, experts advise having an electric screwdriver available. It is convenient for screwing in easily accessible self-tapping screws. In the presence of these 3 devices, the work will be successful.

Jigsaw

A versatile tool with which you can cut various materials. The jigsaw allows you to cut:

- natural wood;

- chipboard, fiberboard, MDF and plywood;

- metal;

- glass and ceramics.

To get it done, you need to purchase a set of cutting files for a jigsaw. For each type of material, as well as depending on the required cutting frequency, manufacturers produce different cutting blades. They differ in:

- type of cutting element;

- the direction of the teeth;

- frequency of teeth;

- the angle of the tooth setting.

For wood and metal, high-speed steel blades with sharpened teeth should be used. Moreover, for steel, files are used that have a small and frequent tooth. For wood, depending on the required cutting frequency, both frequent small and large rare teeth are used.

Choose wood saws with opposing main teeth. This will allow you to make a clean cut without scoring on the face of the material.

For glass and ceramic tiles, specialized blades are used, which have a sprayed abrasive (diamond chips) as the main cutting element.

When buying a jigsaw, pay attention to the maximum and minimum number of revolutions, as well as the presence of a pendulum stroke. The latter is needed for cutting thick sheet materials such as:

- wooden shields;

- plywood;

- Chipboard;

- MDF.

The pendulum feed can have up to 4 positions. When it is turned on, the saw blade begins to swing and swing, which facilitates cutting and reduces the load on the engine.

Observe the heating condition of the saw blade while cutting. If it is overheated, the sharpening of the teeth will deteriorate, resulting in a loss of efficiency in the cutting process.

Choose jigsaws with electronic speed control under load. This will allow cutting the material with the set speed without scrap.

A circular saw

This tool allows you to cut out workpieces for assembling furniture in a perfectly straight line, eliminating the direction of the saw blade. This is achieved through the use of a hardfaced disc.

For a perfect cut of wooden boards and boards, it is necessary to install the guides with their clamping using clamps.

When cutting with a hand-held circular saw, reserve the material for the thickness of the saw, taking into account the soldering spread.

The use of a circular, unlike a jigsaw, is possible only with the use of exhaust equipment. A construction or ordinary household vacuum cleaner will do.

Manual frezer

Ideal companion in furniture making. With the help of a router, it is performed:

- cutting material;

- selection of grooves for cabinet door fittings;

- groove on the ends for splicing.

In addition, you can drill shallow holes with a router, and even apply all kinds of patterns to the surface of the facades. In the presence of special cutters, this tool will make it possible to make panels and frames for connection into a special thorn-groove.

The work of the hand router is carried out with a large emission of fine dust into the ambient air. Therefore, the use of a respirator and a construction vacuum cleaner is mandatory.

Conductor

A device such as a conductor is an indispensable thing in the manufacture of furniture at home. It allows you to drill holes at the ends of the workpieces and observe strict perpendicularity.

The jig is necessary when using dowels and adhesive (carpentry glue). You can buy it in a store or make it yourself at home.

For self-manufacturing of the conductor you will need:

- wooden blocks of the exact size or calibrated plywood;

- joiner's glue;

- metal tubes according to the diameter of the drills.

The jig is made individually according to the thickness of each workpiece. If the assembly is made of chipboard or MDF of the same thickness, 1 device is sufficient.

First, cut the top and bottom bars. Next, the intermediate bar is cut off and glued to the first two. Holes are drilled for tubes that are inserted there.

Assembly nuances

Furniture experts provide some tips for novice craftsmen.

- Consider the machining allowances for parts. When cutting, due to the thickness of the saw blades, the dimensions of the component parts are reduced.

- Cut on a flat surface with the part fully secured with the clamps.

- Use eye and respiratory protection. Some wood species, if inhaled, cause great damage to the body.

- Make a cutting scheme for the components of future furniture. This will save money by allowing everything to be cut exactly according to the markings.

- Buy quality, certified fasteners. The durability of your product depends on this.

- Be sure to place the ratchet on the screwdriver. If this is not done, you can easily damage the surface to be treated.

- From time to time, take control measurements of the dimensions and compare them with your drawing.

- The whole process of work must be carried out in strict accordance with the drawing.

- Make a build sequence. This will make the whole process much easier.

Video: instructions for assembling a wardrobe

And here is the promised bonus. Video lesson on the assembly of the wardrobe, conducted by experts.