Using edging in furniture

Since ancient times, people have tried to ennoble the space around them, give it coziness and make it as comfortable as possible for living. Thanks to this, furniture came into everyday use. It has undergone many changes, evolving from straw and stones to its modern appearance.

Furniture production, in our time, is put on stream. Automation of the manufacturing process allows you to stamp products in large quantities.

One of the components that made it possible to make this process real was the invention of modern accessible materials. Of course, precious woods, marble and forging still have their relevance and are highly valued, but nevertheless, they are not as in demand as chipboard, chipboard and MDF.

In the 30s of the last century, the market was flooded with products made of polyvinyl chloride, in other words, PVC or plastic. It was used to make pipes, dishes, toys, decorative elements and even furniture. It is a cheap and practical material that can be shaped into any shape.

Practically PVC is used in the manufacture of most types of furniture today. This material is used to make a furniture edge for framing the raw ends of shelves, tables, cabinets, etc.

Furniture edge

One of the most used materials in conveyor furniture production is laminated chipboard. Unfortunately, it also has its drawback. Lamination was carried out only on two wide sides of the canvas, while the other two have an unsightly appearance and can be very unsafe, having irregularities and roughness. The edge for furniture comes to the rescue, which masks nondescript ends, and makes the finished product aesthetically complete.

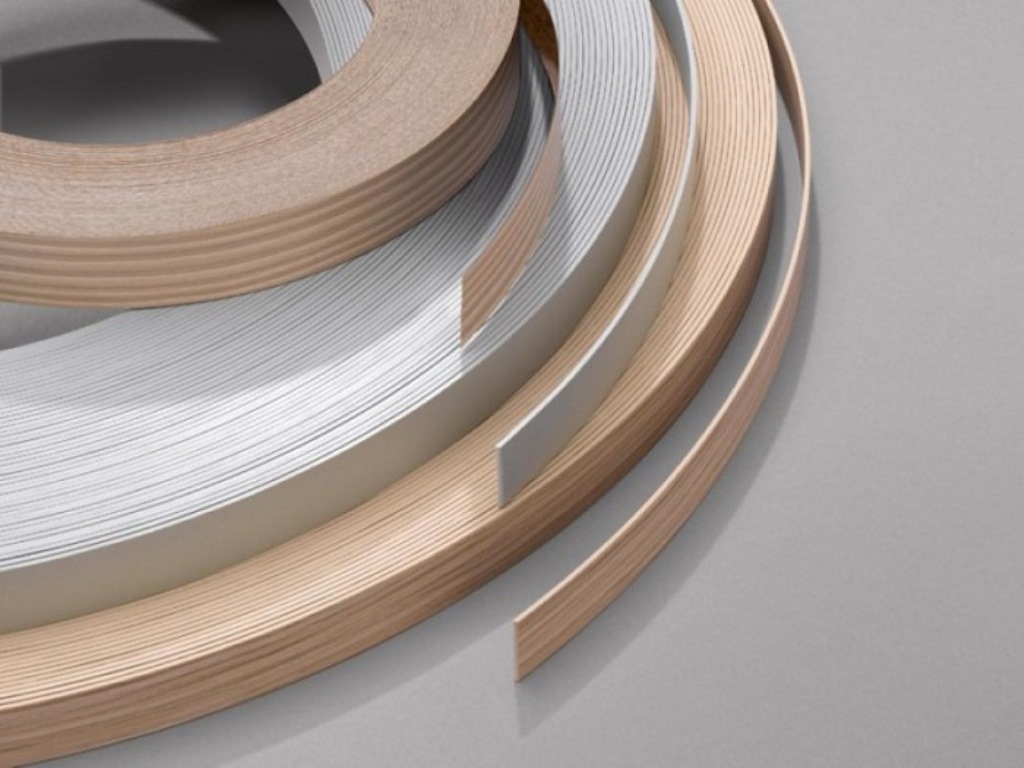

What is a furniture edge? This is a strip of small width, made of various materials, often impregnated with glue on one side and used for facing the edges of shield parts.

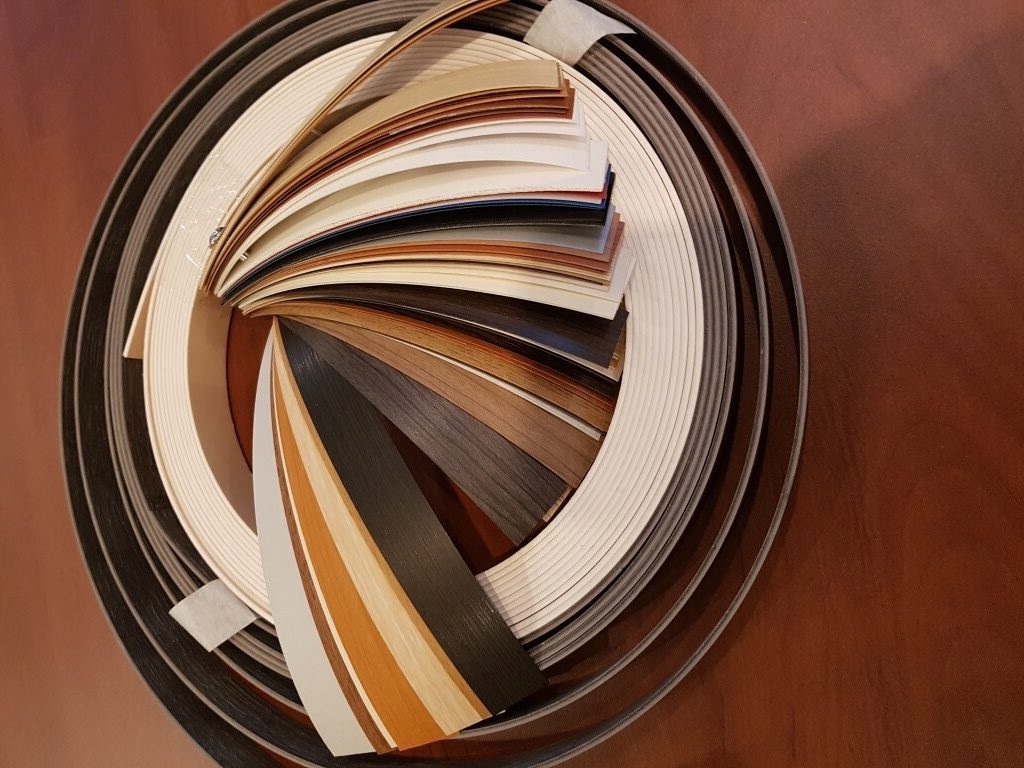

Varieties of furniture edge

There are several types of furniture edges. According to their form, they are divided into 3 main ones:

- Flat (in the form of a tape);

- T-shaped (built-in, requires a groove in the furniture board);

- U-shaped (overhead);

The last two options can be either rigid or flexible. They are considered practical and durable.

Edge dimensions

The thickness of the edging tape can vary from 0.2 to several mm. The choice of thickness depends on what kind of furniture you are using it for. For framing shelves and nightstands, kitchen worktops, internal shelves, you will need edges of different sizes and shapes.

The minimum width of the edges is 11 mm, the maximum is 110 mm.

What materials are they made of

It is important to know that thickness is not the only thing that matters when choosing an edge. One of the important indicators is the material from which it is made.

There are seven main and most popular ones:

- PVC edge - protects the ends from chips, mechanical damage, aggressive effects. It is often used by furniture industries, due to its low price, and the pliability of the material. Easy to install and reliable.

- Metal edge - used for the manufacture of commercial, industrial furniture. Reliable and durable.

- Veneer edge - thin strips cut from solid wood. Expensive. In most cases, they are used to decorate veneered products, doors. Natural veneered edge is not water resistant and is sensitive to various influences. The main advantage of such products is the aesthetics and environmental friendliness of the material.

- Melamine edging. It is based on tissue paper, on which decorative paper tape is glued and treated with various melamine resins. The final stage of its production is the coating of the tape with varnish. A special adhesive is applied to the wrong side of such an edge, which makes it easier to apply. Unfortunately, melamine edging is not very durable. Its thickness does not exceed 0.4 mm.

- Acrylic edge. Often it is also called a 3D edge, due to the peculiarities of its manufacture, it acquires a three-dimensional appearance. On the reverse side of the edging tape, images, patterns, drawings are applied, then they are covered with a special polymer coating, which gives the same effect. It is widely used when decorating furniture of various types of complexity.

- Polypropylene (PP) edgebanding is environmentally friendly. It has good performance and is easy to use.

- ABS edging is considered one of the most expensive. It has high anti-corrosion properties, it can withstand extreme temperature loads without changing its appearance and without losing its protective properties.

Where can you buy them

In Russia, there are four largest enterprises producing furniture edgebanding. Kaliningrad plant "Gagarindekor", "Izhevsk plant of furniture accessories", "Plant of furniture accessories" near Moscow and the famous "Nanoplast" in St. Petersburg.

Asian and European manufacturers also did not leave the Russian market aside and their products can be found in any store on a par with the domestic one.

In any furniture and hardware store, you can choose the right type of edge from the material you need and the right color for you, but try to give preference to a sample of well-known brands, with a ready-made adhesive base.

How to use correctly

Once you have chosen the edge that is intended for your piece of furniture, the time comes when you should use it for its intended purpose. How to do it right? First, decide what shape your furniture edge is. Next, investigate if it has a glue impregnation on the inside.

In order to apply an edge to the ends, prepare the necessary set of tools:

- Roulette or ruler;

- Any knife (clerical, construction);

- Iron or construction hair dryer to heat the surface;

- A rag, a piece of cloth;

- Fine sandpaper.

When decorating the ends with a plastic T or U shaped edge, a hammer may come in handy.

Prepare the workplace and fix the workpiece. Measure its length. Cut a piece of hem two to three centimeters longer. Apply to the end to be processed, and gradually warm up. Run periodically with a rag to level the surface. Wait until the glue hardens. After that, carefully cut off the excess edge and sand the cut with sandpaper.

If your edge does not have an adhesive component, glue the surfaces yourself.

Choose your edge responsibly, and it will protect your furniture and help keep it looking good for years to come.

Video: how to glue a furniture edge on a chipboard