What materials are furniture made from?

Furniture is a key element of the interior that determines the comfort of being in the room. It can be different not only in appearance and functionality, but also in raw materials. Knowing what materials the furniture is made of, what are their advantages, you can choose the option that is optimal in terms of price and quality.

The importance of raw materials cannot be underestimated, because the durability, functionality, practicality, and style of the finished item depend on it.

Materials for the manufacture of furniture and their properties

Conventionally, the raw materials from which the goods that make up the furniture market are produced can be divided into:

- the main one used for housings, frames, bearing blocks;

- additional, used for upholstery, decor.

You can make functional interior items from classic materials:

- wood;

- metal alloy;

- plastic;

- glass;

- rattan;

- residues of wood processing.

Additional Information. To decorate furniture, to make it pleasant to the touch, durable and resistant to wear, artificial leather and textiles are used. Frameless functional interior elements are made of the same materials.

Solid wood

Natural wood is the best furniture can be made of. It costs a lot, lives for a long time, attracts with its appearance, functional qualities, durability. So that the raw materials do not disappoint, when choosing they are guided by hardness, density, pliability in processing.

Exclusive varieties for the best furniture:

- hornbeam;

- bog oak;

- boxwood;

- merbau (intsia);

- mahogany.

This material is the densest, heaviest, most durable, expensive. Not so rare, but very valuable varieties - walnut, maple, oak. In terms of density, oak is comparable to a hornbeam.

Cherry, birch, ash are slightly softer. Linden, alder, willow massifs are considered soft, suitable for furniture. The softest are conifers. They are rarely used for a high-quality interior, since they contain a lot of resin.

It is known what material high-quality furniture is made of: natural wood. It looks presentable, has the greatest strength and durability. Wood can be painted in any shade, fit into the interior, regardless of style.

Quality raw materials are safe and do not emit toxins. If necessary, it is subject to restoration. Another advantage is the unique woody pattern that is inherent in a particular plant variety. Most often, natural massifs are used in the facades of cabinets and kitchens, in the manufacture of chairs, tables.

Chipboard

The material for making the slab is sawdust formed during the processing of natural wood. For chipboard, low-quality logs and waste from forest sawing, processing of trunks are suitable.

For the production of chipboard, coarse fractions are dried, sorted, heated, pressed, adding synthetic glue, antiseptics and substances that prevent water absorption.

The finished board is a durable, durable product that can be sanded, coated with a decorative layer. The main disadvantage of chipboard is the presence of resins with formaldehyde in the composition. To control the content, technological standards of safe concentration have been developed, which make it possible to classify wood sheets as safe materials.

The camera method is used to check for the presence of a dangerous connection. If the result shows no more than 0.02 mg of formaldehyde per cubic meter, the specimen is suitable for the manufacture of children's interiors.

MDF

Medium density fibreboard is made from crushed shavings, the size of fractions of which is comparable to dust. It does not contain resins, toxic substances, since safe lignin is used as a binder.

Such a plate appeared in the course of experiments on the creation of DPV by the dry method. MDF is easy to process; an object with unusual shapes and bends can be made from the slab. It is a waterproof, durable material. The strength of MDF exceeds that of chipboard.

Advantages:

- applicability in bathrooms;

- resistance to microorganisms;

- security;

- ease of cutting, milling;

- low price.

The main disadvantages are the danger of fire, the complexity of the restoration.

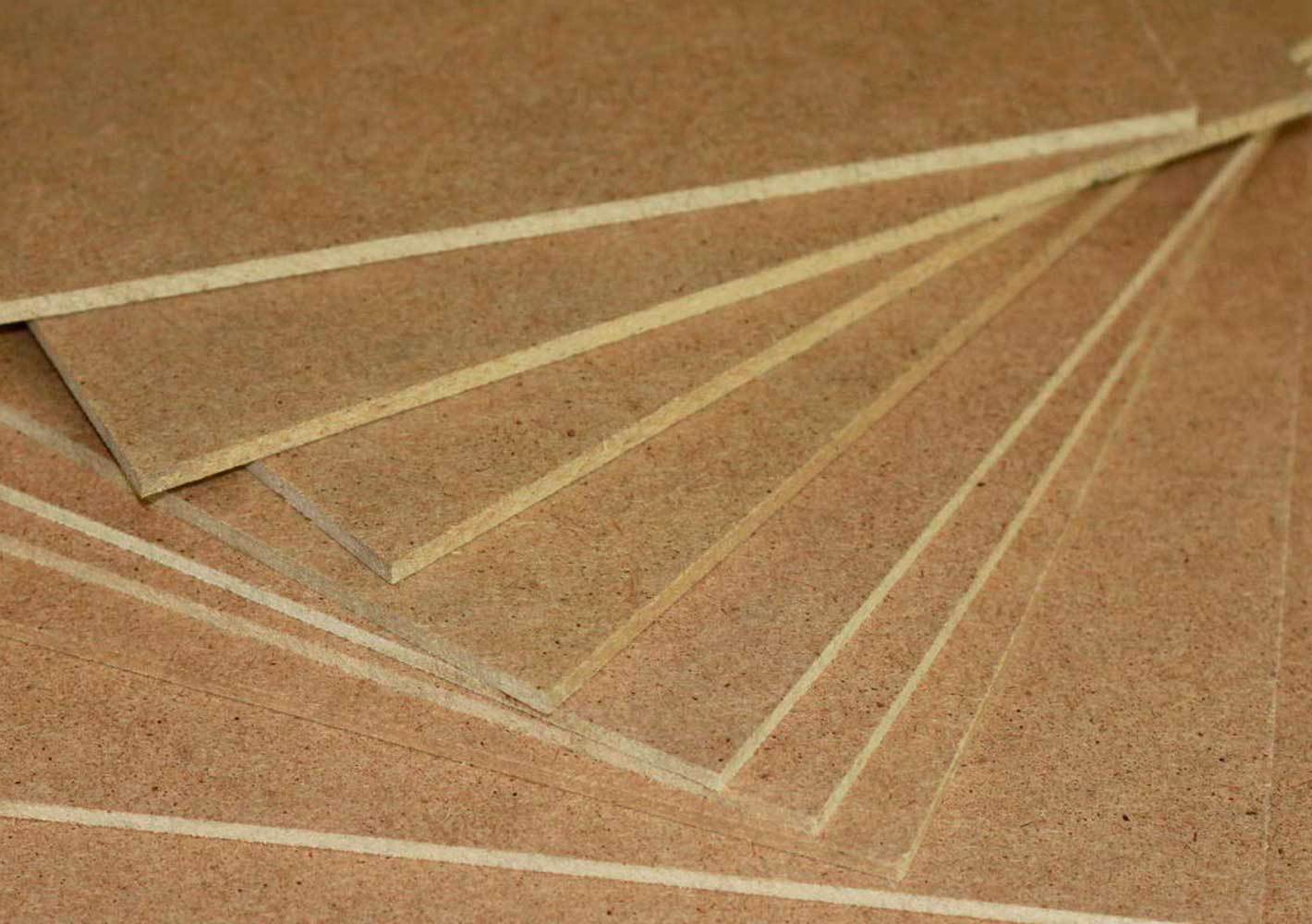

Fiberboard

Fiberboard is usually used for the production of back walls, bottoms of interior items made from more durable and attractive raw materials (chipboard, MDF). For the manufacture of fiberboard, the shavings are carefully crushed, mixed with resin, and heated. An alternative production option is wet, without auxiliary additives.

The first method is chosen if you need slabs smooth on both sides, the second - if one smooth surface is enough. In the manufacture of sheet raw materials, antiseptics are used. The front surface is decorated, laminated. Fiberboard is an inexpensive, reliable sheet material. The main disadvantage is the complexity of the fastening.

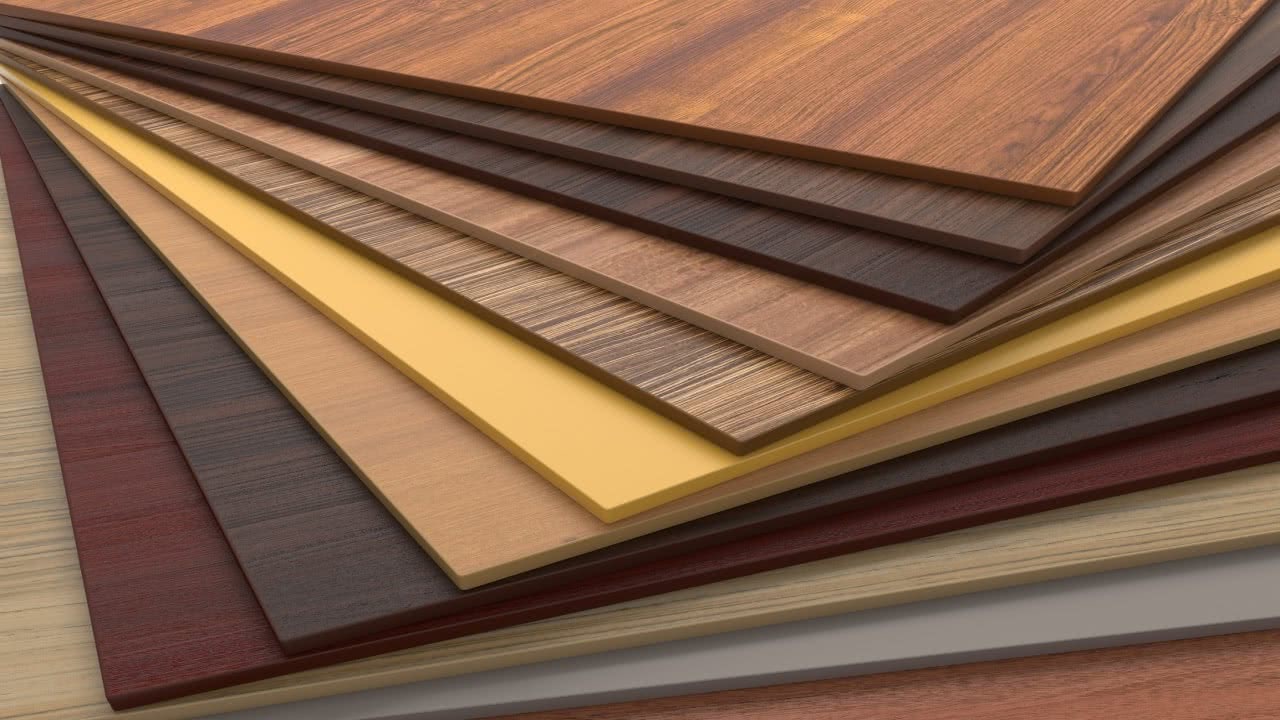

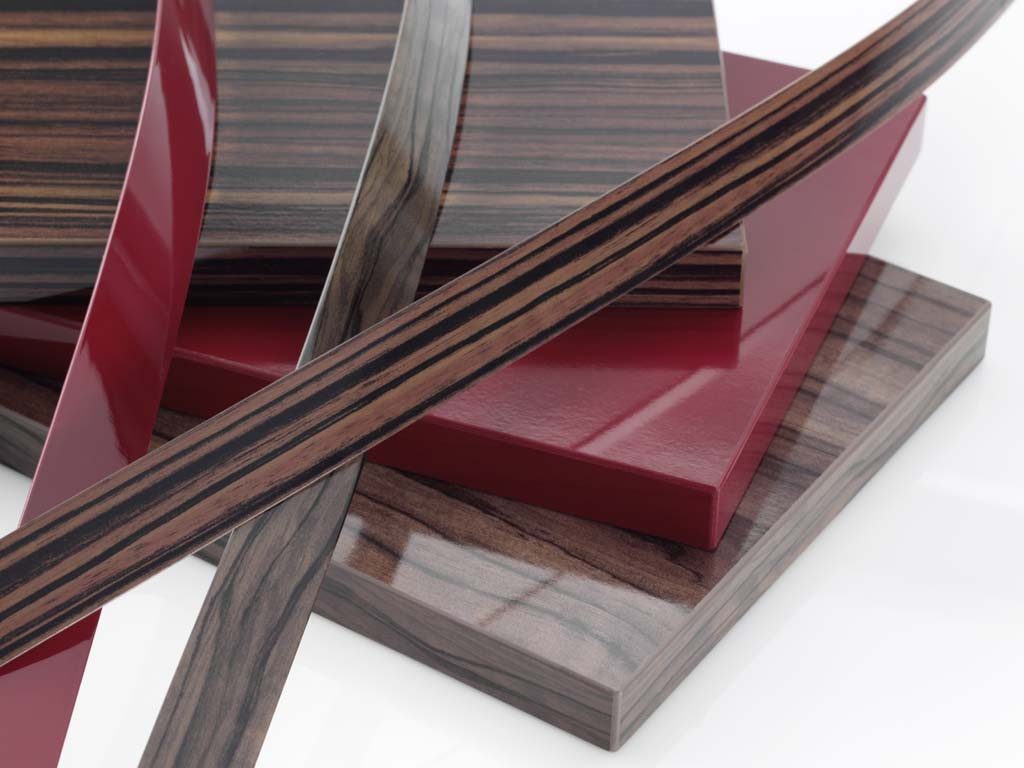

Chipboard

Laminated chipboard is an improved version of chipboard sheets with greater strength and better appearance. The material is resistant to temperature extremes, externally imitates natural wood, is durable and applicable for the production of kitchen furniture.

Finished specimens weigh a little, are cheap, attract with their external characteristics and variety, hold fasteners securely, do not attract dust thanks to a special coating. Among the disadvantages are the ability to absorb water, inapplicability for milling, making unusual shapes.

Sheets can be deformed. If the fasteners fall out, the connection cannot be restored due to the specifics of the structure. Another disadvantage is inapplicability for children's rooms, since toxic resins are used in production.

Metal

Metal furniture is durable, stylish and expensive. This will decorate any home and office. Elegant forged items are real objects of art, showing the taste and wealth of the owner. There are also more casual interior elements.

These are used in hospitals, offices, shopping centers. The latest technologies for the use of alloys make it possible to make not only heavy, impressive specimens, but also light, practical ones.

Advantages of metal furniture:

- strength (it is very difficult to break the forging);

- durability (service life is measured in decades, centuries);

- unpretentious care.

Among the disadvantages is the high cost, sometimes - a lot of weight.

Plastic

Plastic is an artificial raw material from which various household items are made. Furniture is no exception. Plastic products are cheap, lightweight, durable and practical. Most often they are used to decorate bathrooms, terraces and verandas, cafeteria halls. They are easy to wash, easy to reach and clean.

Attention! Plastic is not afraid of bad weather, does not suffer from moisture, wind. You can make an object of the most intricate shape out of it. True, the material is fragile. A cheap variety is short-lived, ugly; aesthetic and reliable is expensive.

Glass

Glass furniture has appeared relatively recently, but has won the love of buyers. Transparent, translucent cabinets, tables, shelves are widely used by designers in the development of stylish interiors. They are appropriate in living quarters, offices, restaurants; visually increase the space, bring a feeling of weightlessness.

This is especially useful when decorating small rooms. Glass objects do not interfere with the luminous flux, are strong and durable, non-toxic. Among the special advantages are moisture resistance, environmental safety, non-flammability.

The disadvantages of the glass interior are fragility, resistance to mechanical damage, high price.

Laminate

Laminate is to some extent a revolution in the furniture industry. It is a durable, beautiful material that visually imitates natural wood. It withstands heat, does not allow moisture to pass through, does not swell or deform.

Laminate is suitable for kitchen interior decoration, as it can withstand heavy loads. Among the advantages are beauty, long service life, safety for the environment. Among the disadvantages is the impossibility of fine processing.

Melamine

Melamine is a polymer film covering suitable for large areas. Often used for processing MDF, chipboard; allows you to get a flat surface that is impervious to water. Melamine is suitable for creating a kitchen interior, different parts of cabinet furniture.

The polymer film increases the resistance of the material to mechanical stress. It is strong, flexible, durable, aesthetic, makes particle boards safe for humans, since the polymer prevents the evaporation of resins.

The toxicity of melamine is less than that of food. The main disadvantage is susceptibility to solvents, household chemicals. Film can be scratched. Of the advantages, an affordable price, pickiness in care stand out.

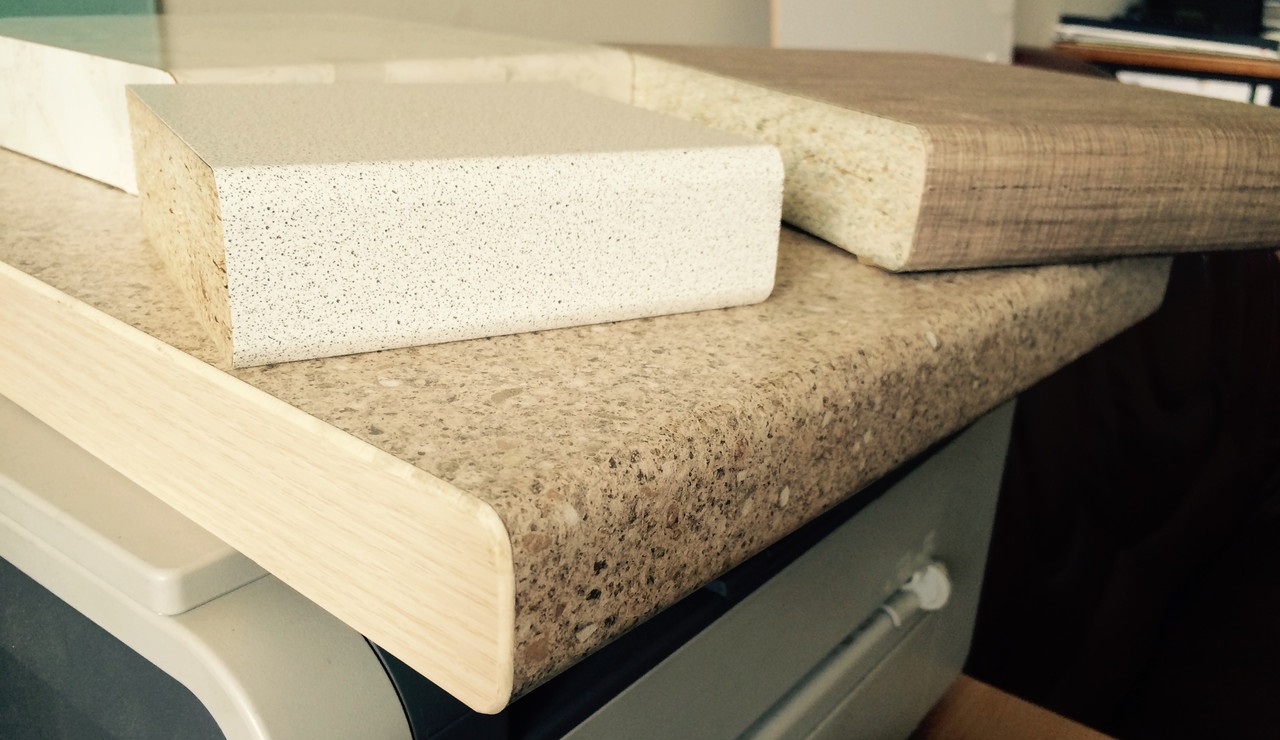

Other materials for making furniture

The brightest, most impressive raw material for furniture is stone. Benches, tables, counters, window sills are made of it. The material is durable and hygienic. It is difficult to scratch it; damaged surfaces must be restored. The main disadvantage is the high price.

Sometimes furniture is made of plywood. It is a cheap material, mainly used for interior elements (drawers, shelves). Plywood is lightweight, easy to process, safe for humans.

There are interior items made of rare materials:

- grown crystals;

- volcanic lava;

- cardboard.

What tree is it recommended to make furniture from?

When choosing a material, the purpose of the interior item, the style of the room, and financial capabilities are taken into account.

Designers advise:

- pine for the facade of the kitchen, for rooms in the style of loft, rustic, country;

- birch for classic style, curly elements;

- ash for rocking chairs, decorated with ornaments of objects, for decorating play, living, sleeping areas;

- oak for rooms in the style of seasoned classics;

- beech for dry spaces;

- larch for carved elements, wet rooms.

Cladding methods and materials

Veneer imitating expensive woods is often used as a facing material. It is a thin sheet of wood that is attached to the surface with an adhesive. Veneer can be natural and artificial. The first one is more expensive, it is made of valuable wood; the second is much more accessible.

An alternative to veneer is a polymer film. It gives the surface strength, visual appeal. It is a paper impregnated with synthetic substances. There are 4 groups: relatively thick PVC and ABS, thin PP and PET. There are fluorescent, metallized, decorated with patterns that mimic the texture of the natural material of the variety. They are attached with glue (laminating) or under high pressure (lamination).

How to choose quality furniture

The main factors when choosing furniture:

- material;

- manufacturer;

- price;

- ergonomics.

Important! When buying, it is recommended to pay attention to the style of the interior, the color scheme. So, dark furniture suits light walls (and vice versa).

For small rooms, modular designs, glass items are appropriate. To assess how long the vending specimen will last, they study the quality of the fittings. They check how the doors open, drawers slide out.

If you need durable, practical, maintenance-free furniture, pay attention to plastic, metal pieces.

Video: MDF or chipboard - which is better?