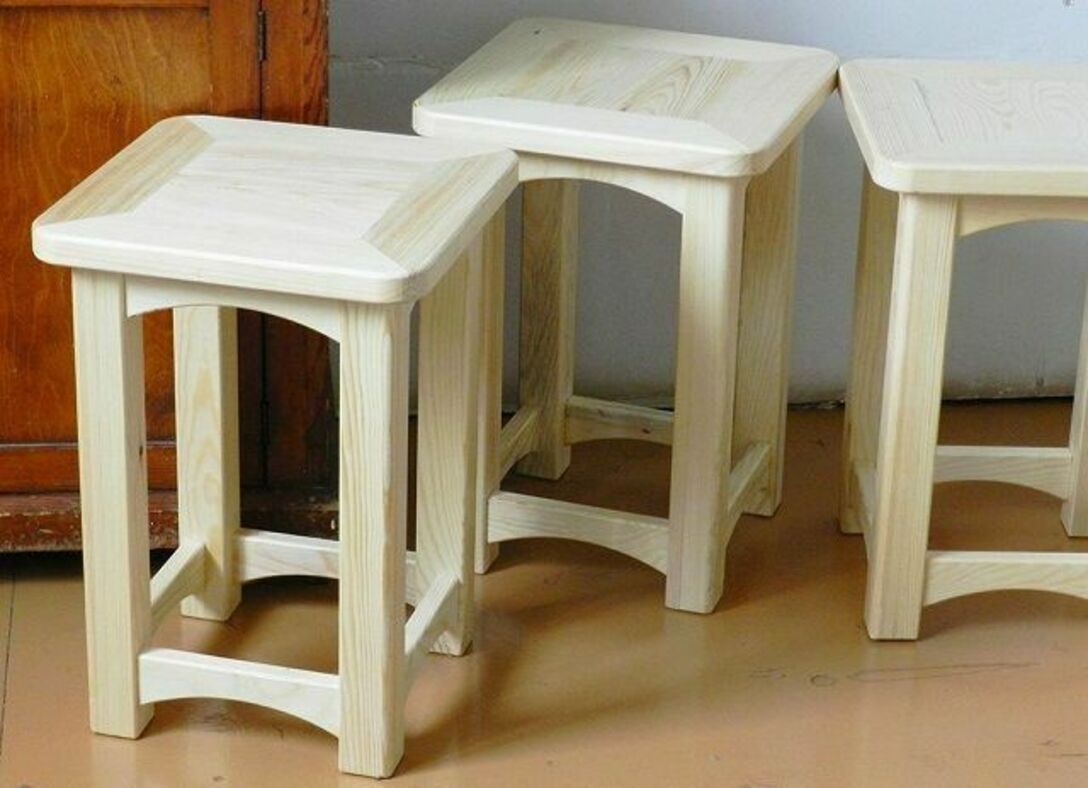

Making a stool from chipboard with your own hands

A stool is an indispensable furniture attribute of every home. Some prefer ready-made, purchased products, others want to make their own. The manufacturing process does not take much time and requires a minimum of materials.

You can use waste wood, plywood. An ordinary chipboard stool will become a work of art and will delight family members for many years.

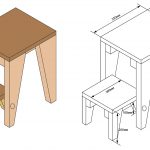

How to make a chipboard stool

First, you need to decide on the design of the future model. At the same time, the basic set of tools and materials remains almost the same. In most cases, stools are made from available chipboard.

Due to the excellent properties of the chipboard, the products retain their original appearance for a long time and are resistant to moisture.

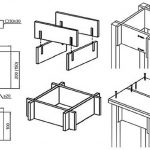

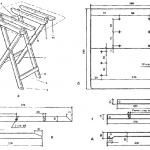

Drawing and diagram

After making the final decision on creating a specific configuration, you need to draw up a sketch. Such a drawing contains a schematic illustration, according to which you need to make a chair. The scheme must be performed taking into account the correctly calculated dimensions of all elements.

In this case, you do not need to draw everything perfectly, just draw by hand. Most importantly, the figure should show the dimensions, the principle of connecting parts. When you have a plan at hand, it will be easier to work and less time wasted. At each stage, you can check whether everything is being done correctly.

It should be borne in mind that the upper part is made smaller than the base for the stability of the structure. When drawing up a drawing, in addition to the calculated parameters of the parts, the size of the internal connecting elements should be taken into account. This includes spikes, projections, grooves in which parts are installed.

Selection of tools

Armed with a set of devices, it will be easier to make a stool from chipboard with your own hands. For this you will need:

- ruler, marker or pencil;

- drill;

- electric or manual jigsaw;

- furniture stapler;

- screwdriver;

- sandpaper, PVA glue.

It is necessary to prepare all the tools in advance, put them in their places for convenient use. Having these components, you should select the necessary materials for the furniture structure.

Choice of materials

The main raw material is a chipboard sheet. You will also need upholstery fabric, leather substitute, filler. Foam rubber, synthetic winterizer will do. Giving preference to a fabric cloth, it is better to take a material of good density, which is not subject to rapid abrasion.

You also need a finishing tape glued around the edges of the stool. It is selected according to the width and shade of the chipboard. If you plan just a stool, without upholstery, you will need varnish to cover the surfaces.

Manufacturing

To create a stool, not only a new piece of chipboard is suitable, you can use any old furniture. Having a drawing with the dimensions of the structure, they begin to act.

Material preparation and sawing

The first step is to cut the prepared blade. The work uses an electric jigsaw with short teeth. With its help, it is easier to cope with the assigned tasks.The tool is turned on at high speed to get even and clean cuts.

Then the process itself begins:

- using the prepared template in the form of a cardboard blank, you need to attach it to the wood board and circle it strictly along the contours with a pencil. This will help to accurately and accurately cut all the elements;

- after cutting, the resulting roughness is removed with an abrasive cloth;

- grinding and fitting of cut bars.

It is not recommended to skip the grinding stage, because all household members will have to sit on such a product. When the parts are cut and prepared, the holes need to be drilled.

Note! All of them are performed at exactly the same level.

Assembly

The next step will be to assemble the structure, having previously processed the sections with a ribbon. This material must be applied as accurately as possible to the edge of the seat, legs.

Use a hot iron to fix the tape. Actions should be short and quick. Use a soft piece of cloth to press down on the heated tape.

Important! The adhesion of the adhesive on the back of the coating occurs instantly. Therefore, it is recommended to perform manipulations promptly.

Using confirms and self-tapping screws, you need to assemble all parts of the stool. For convenience, you can first glue the elements, then connect them with self-tapping screws. If you plan to make a seat with a soft structure, the top is upholstered with foam rubber and upholstery fabric.

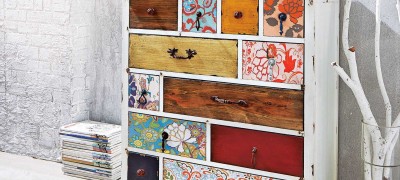

Decorating

Various decorative details will help to give the product completeness and originality. Such a chair can be trimmed with oilcloth, leatherette or dense jacquard. There is already a free flight of imagination. Foam rubber is best suited for filling.

The lacquered stool looks elegant. For this, 2-3 layers of paint and varnish are applied to the surface. The main thing is that the work should be done in a well-lit and ventilated area.

Chipboard scraps stool

If there are unnecessary pieces of old furniture or chipboard panels left in the house, there will be a use for them. They are great for creating a practical stool. On the scraps, you first need to apply a graphic marking of the parts.

Then along the lines it is necessary to cut out templates of the future product. After completing the cutting process, all edges must be cleaned. The model should not have chips or protruding fibers.

To connect the jumper to the rack, you will need self-tapping screws, sometimes spike grooves are used. Using a drill, a hole of the required diameter is made.

In order for the groove to fit snugly into the spike of the lintel, you may need to align it with a file. When fixing parts, it is better to use a clamp to fix the gluing. The drying time of the glue can be read on the packaging.

Also, before starting work, you should read the instructions, then there will be no questions about how to make a plywood stool with your own hands. Having decided to make a stool with your own hands, you can take a new sheet of chipboard for the product or use any scrap from old furniture.

When completing the drawing, the main thing is to maintain a balance between the bottom and top of the structure, in order to end up with a stable stool. You can decorate in different ways, for example, equip with a soft seat that is firmly attached. You can also make this top removable.

Video: do-it-yourself stools from chipboard scraps