How to make garden furniture with your own hands

Every gardener at one point inevitably faces the need to select and purchase furniture for his site. You can, of course, spend an impressive amount of money on the purchase of all the necessary items of street interior. However, many people choose a more creative approach for themselves - creating garden furniture on their own.

In this process, there are many subtleties, carefully observing which you can achieve an amazing result. This article will tell you about all the rules and tips for making garden furniture.

How to choose the right material

As a rule, the question of choosing a material is the easiest to solve. Many garden owners choose to use wood. Someone makes individual elements from pallets, others use such improvised materials as stumps, or a vine from the branches of trees growing nearby. It all depends on the desired result and the availability of free time.

If you pay enough attention to planning, preparing and assembling garden furniture, the result can be just as good as commercial samples.

Definition with construction

Before you start creating garden furniture with your own hands, you need to have a clear idea of the final look of the entire structure. Even a small sketch is enough to roughly calculate the required amount of material.

Most often they make with their own hands:

- tables

- chairs

- beds or sun loungers

- storage racks and shelves

Required tools and additional materials

On the one hand, for the manufacture of many pieces of furniture, you can completely do with the material at hand, however, to create more reliable and durable furniture, you may need a specialized tool:

- jigsaw (or hand saw), circular saw

- Sander

- screwdriver

- drill with a drill for wood to fit the size of the screws

To create a simple piece of furniture, it will be enough:

- hammer

- screwdriver

- self-tapping screws

- sandpaper

- roulette

- pencil

- fixing furniture corners

The beauty of garden furniture is that even in its unbridled form, it looks quite appropriate. What can we say about a professional approach to business - such a homemade garden interior will surprise even the seasoned.

Design and drafting

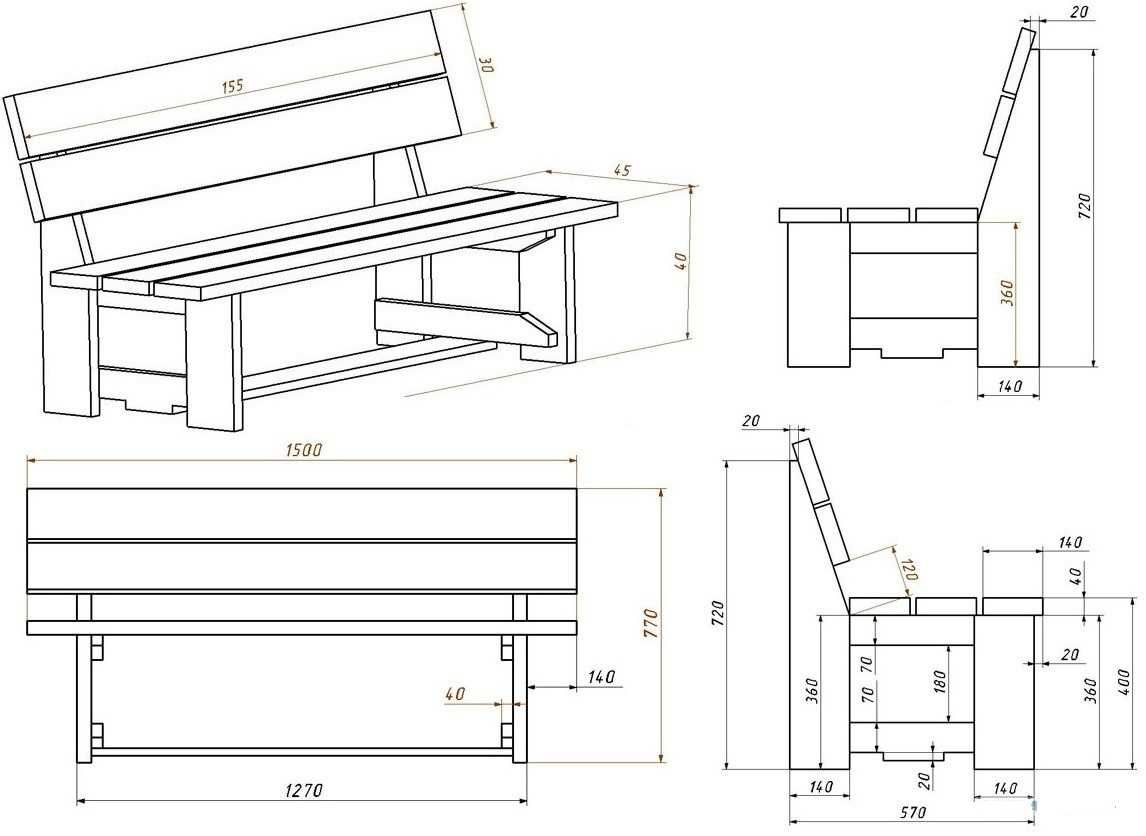

When creating garden furniture with your own hands, drawings and diagrams should first of all be based on its appearance. Having decided on the future look of our furniture, we proceed to the next important stage - drawing up drawings.

Note! The more thoroughly you approach this process, the better the final result will be.

When drawing up a drawing, we carefully calculate every detail, this will not allow us to lose sight of even the smallest nuance.

The first step is to draw the frame.

We are working on the methods of fastening, we calculate the amount of necessary fasteners.

After completing this process, it is recommended to take another close look at the resulting plan - if you do not make adjustments to it now, then it will be problematic to do it. Well, if the drawn up scheme is completely satisfactory, we proceed to the embodiment of our plans.

DIY workshops on making garden furniture

As already noted, the process of making garden furniture from wood with your own hands is very responsible and exciting. Next, we will take a closer look at the most popular and often self-assembled interior items.

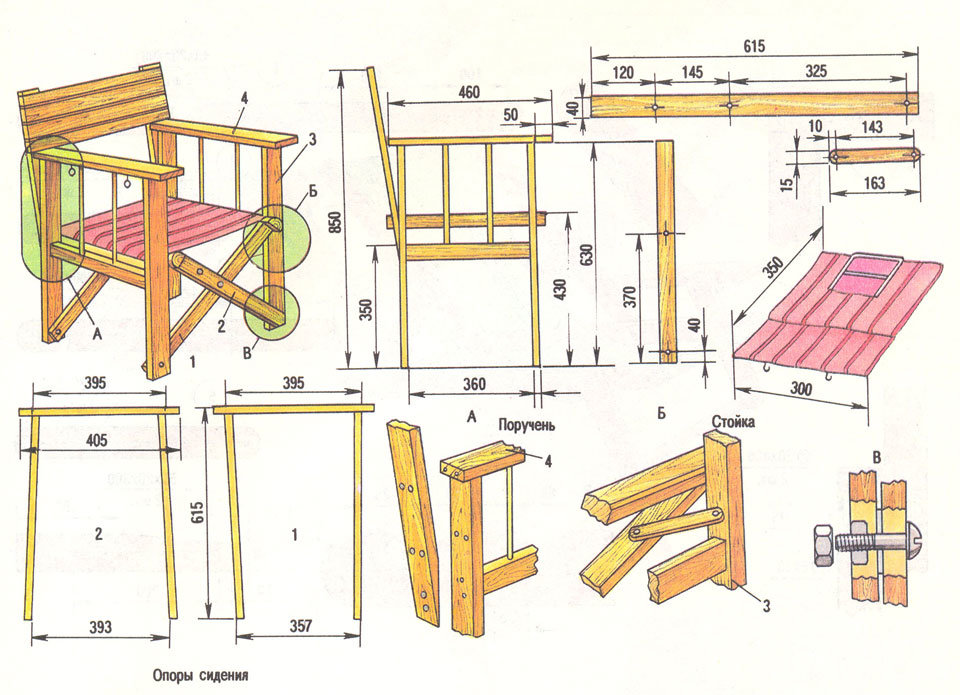

Making a garden chair

A chair for a garden can be made both in the simplest form of a base for a seat screwed to a stump, or you can approach this process more thoroughly.

To assemble a garden chair, we use a pre-selected type and size of wood. It is recommended to purchase a bar of at least 40mm on one side. This will provide reliable support for a person with an average weight of 80-90kg. If it is required to place people of more impressive dimensions on such furniture, we increase the size of the timber to 60 or even 80 mm.

We mark the material with a tape measure and a pencil according to the drawn up drawing.

Let's move on to sawing. In this process, you can use a hand tool, but a faster and better result can be achieved with a jigsaw or circular saw.

For the frame, it is customary to use square bars, for the back and base - rectangular.

It is better to grind the surface of the wood well before starting the assembly, this will save you from the risk of getting a splinter under the skin both during the assembly process and in the further operation of such furniture.

We mark with a drill the places where the fasteners will land and proceed to the final assembly.

Note! If you plan to use our furniture outdoors, the tree must be covered with protective compounds against moisture - special paint or varnish.

Instructions for making a table with benches

The final appearance of such a product directly depends on the intention and capabilities of the person himself. In its simplest form, such a table and benches can be stumps covered with a wooden base. More often they take this issue more seriously, because such a street headset will be used for large companies, and the more thoroughly you approach the issue of its creation, the better the final result will be.

A very common option is with a rectangular table closed on all sides.

To create it, we make a frame of beams, and we upholstery with wood over the entire area of the lateral surface.

We pre-prepare the material - we grind and carry out processing with compounds that allow the use of furniture in outdoor conditions, which can be purchased at furniture and hardware stores.

We assemble benches according to the size of the table. Their length should be commensurate with the table, the width may vary depending on the planned budget and the materials on hand. To make it comfortable for a person to sit on a bench, it is recommended to make it at least 15-20 cm wide.

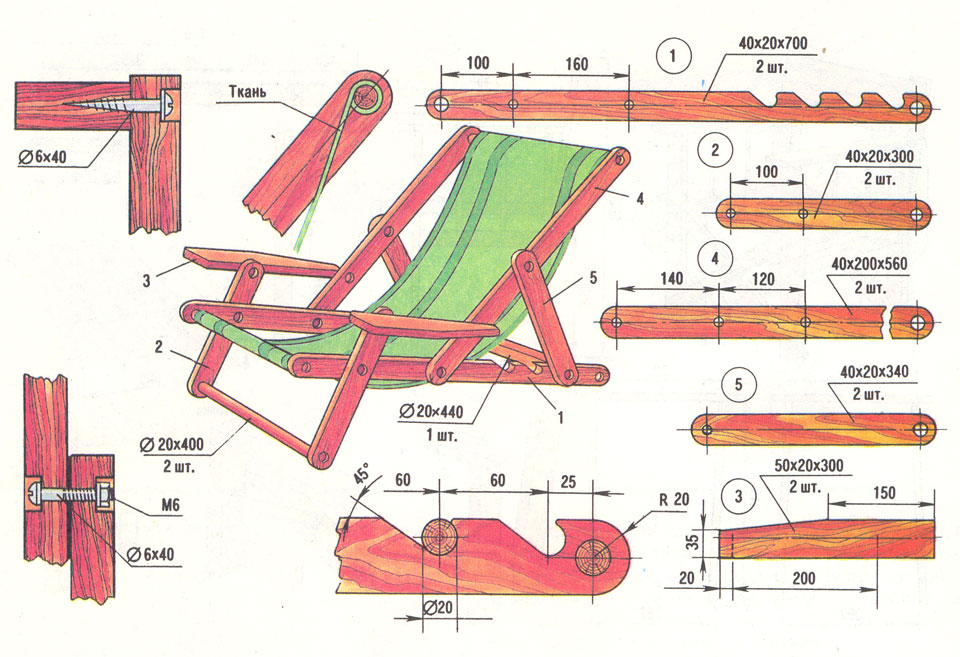

Do-it-yourself chaise lounge

Before assembling a sun lounger, it is also important to have an understanding of its final look. It can be an easy-to-make chair with a wooden base and a fabric that acts as a back and seat. Or you can make a monolithic reclining version of the chaise lounge. The first is more acceptable for those cases when it is planned to change its location, while the second, due to its high weight and inconvenience of movement, is installed in a certain place and is rarely rearranged.

In both cases, we make a wooden frame. For a small sitting chair, a 25 * 30cm bar is suitable. It is necessary to make two long legs and two short ones. We connect them together, if necessary, we leave the structures to be assembled - in the simplest form, for this, it is enough to fasten the fastening screws with nuts with lugs. We connect the legs to each other with strips, and we pass the fabric through them, it is better if it is burlap - it is more durable when used outdoors. It is recommended to additionally reinforce the upper and lower legs with metal spacers - for this, it is enough to insert a metal rod into both legs on each side.

For a large lounger, first of all, we collect the base, which is then closed with rectangular slats. We grind the front part of such a structure and cover it with a protective layer - furniture paint or varnish.

Pallet table

When creating a table, you should pay special attention to the quality of materials. Old pallets look rather unassuming and do not differ in quality, especially those that have been exposed to moisture for a long time. Therefore, the main advice is to use new pallets.

To collect the simplest possible option, three pallets are enough - two for the legs and one for the lid.

More often, pallets are used as a lid, fastening together, and the legs are made of additional materials - a wooden bar, high stumps, or tree trunks left after a saw cut.

The main rule when assembling a table is high-quality grinding of all its parts, especially the surface of the lid. We fasten pallets together with long screws.

It is also recommended to additionally process the surface of the resulting product with paint or varnish to protect it from the influence of negative environmental factors.

Wicker furniture

Wicker garden furniture without drawings and diagrams is very problematic to assemble. Therefore, if it is decided to make such an interior item, first of all, it is necessary to correctly think over the drawing, and based on it, calculate the amount of required material.

If there is no experience in making such furniture, you can find ready-made schemes on the Internet and, according to them, purchase the necessary material.

As a basis for such furniture, you can use a vine or rattan.

When individual elements are interwoven with each other, continuous weaving is most often used - with this method, individual rods are woven into the posts perpendicular to them, alternately bending around the rod from one side or the other. The resulting weave is very reliable and durable.

It is customary to make the back and seats with openwork weaving, since this type is quite beautiful in itself.

By purchasing high-quality weaving material, you can guarantee your furniture high durability. As a rule, wicker furniture does not require any additional processing.

Examples of creative and stylish garden furniture design

In order for the furniture not only to perform its functions for a long time and with high quality, but also to be an aesthetic decoration of the garden, it is often decorated with additional elements.

One of the most striking examples of decor are fresh flowers, field flowers look especially bright.

Another way to make your garden furniture a piece of art is to decorate with an attractive accessory like a blanket or pillows.

Decorating garden tables with glass or plastic countertops looks no less attractive.

Having studied and carefully applied the recommendations for making country furniture out of wood with your own hands, the drawings and assembly diagrams should not be thrown away, they may be useful in the future .. If you also apply the decoration techniques with additional accessories presented earlier in the text, the furniture will become an excellent place for a family recreation.

Video: DIY wooden garden chairs