How to make a chair with your own hands

Furniture made by yourself can take its rightful place not only in the country, but also in the apartment. In order to make a chair out of wood with your own hands, you do not have to be a master carpenter. Anyone can try their hand; to create a stylish piece of furniture, you need to choose the right array and have the right number of tools.

How to choose the right wood for your chair

The presence of natural material in the interior is applicable in many design directions and brings a touch of comfort and nobility to the house. When choosing wood for furniture, it is necessary to take into account the quality, texture and pattern of the raw materials. And in order not to be disappointed in a home-made chair in a few years, to know the type of wood that will last a long time without changes in state.

Different materials are used in the production of furniture - a combination of plastic, metal and wood elements. Self-production means only natural raw materials; it is impossible to make a glass or plastic part at home.

Chair Timber:

- pine, alder are the most affordable and soft types of wood, but products made from them are short-lived;

- cherry, beech, oak, birch - medium-strength raw material, has sufficient strength and moisture resistance;

- exotic, maple, larch - hard types of wood, resistant to moisture and durable, but difficult to process.

When choosing a material, you also need to decide on the finishing of the chair. If you mean a natural varnished texture, then you should pay attention to oak, walnut, Karelian birch and ash. This wood has a unique pattern. The paintable chair can be made from birch, pine and alder. This tree is susceptible to decay and needs to be impregnated with antibacterial compounds and paint coating.

Definition with chair size

The choice of furniture dimensions depends on the area of the room in which it will stand. For a small kitchen, it is better to choose an elegant model; massive structures are made for the family dining room, which will complement the interior and bring a natural element into the atmosphere.

Standard chair sizes:

- kitchen models: back height 80-90 cm, width 35 cm and height 50-55 cm, seating;

- for the dining room: back height 1 m, seat width 52-55 cm, depth 45 cm;

- a highchair is made based on the height of the child: 80 cm - 17 cm, then for every 5 cm of change in the indicator, 3-4 cm are added to the height of the chair.

The main thing is when choosing dimensions so that all family members feel comfortable. Homemade means individual sizes of chairs, take old comfortable furniture, take measurements and base on these indicators.

Chair designs

The shape of the back and seat determines the complexity of the work that a novice locksmith will have to face.The easiest option is to make a straight model from solid wood with square legs and a plywood back. Blanks for the future chair and fasteners can be bought at a hardware store.

In the traditional design, there are details:

- The frame consists of four legs and a frame that unites the chair into a single whole and bears the main weight load. Additional elements - projections, which are attached to the legs along the perimeter, their presence improves the stability and strength of the furniture.

- The seat can be straight - it is made of a solid wood, which is sanded and polished, or a plywood sheet. The concave shape is manufactured in factories with equipment and can be made to order. Curved, made with a soft seating position, upholstered in fabric or leather.

- The back can be lattice, through, when one wide element is mounted across. Also solid, made of solid solid wood, often carved and upholstered, when the back element is sheathed with fabric or leather.

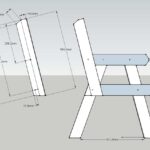

You can also make a folding version yourself, which is often installed in dachas and on the verandas of private houses, and in apartments such a chair will be comfortable on the loggia.

The most common way for self-production is carpentry, when furniture is made from solid wood by fastening and gluing individual parts.

Bent chairs are made of elements with a circular cross-section, sawn out according to a template and fixed with screws. And bent glued, when separate blanks are made from plywood and veneer and fixed to each other.

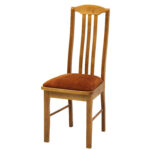

How to make a chair with a back and padded seat

Such models are more comfortable for long feasts, do not require special skills in the carpentry craft, and will look great in the interior of the living room, kitchen and bedroom.

The shape of the seat and backrest can be round, square and rectangular. And the upholstery material can be selected based on the style of the room and the color of the textiles.

Choosing material for the chair

Blanks for future furniture should have a flat surface, without knots, cracks and chips. Choose a tree that is dry and clean, free of wormholes and mold. If raw materials are selected from conifers, then there should be no protruding resin on the surface. Such wood is difficult to finish.

The upholstered seat and back are made of a wooden form and filler - it can be foam rubber, felt, batting and synthetic winterizer. The main thing is that the material has a height of at least 4 cm, otherwise several layers will have to be applied to the workpiece.

You can sheathe the soft parts of the chair with any material, but the most versatile are: leather or its substitute, jacquard, velor, velvet, tapestry and silk. When making furniture for the kitchen, it is better to give preference to upholstery that is easy to clean and does not absorb odors. A good choice is leather that has proven itself in high humidity conditions.

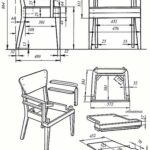

Measurements and drawing up

The easiest way for a home craftsman to make a chair is to take models and dimensions of furniture on the Internet and adapt them to your needs. Do-it-yourself drawings with dimensions for wooden chairs are freely available and will be understandable even for a novice carpenter.

The procedure for adapting the introductory dimensions to the required dimensions of the chair:

- Print the drawing on paper and replace the data.

- Draw up a new scheme according to the new input, observing the proportions.

- Draw each element individually with all dimensions.

- When drawing up drawings, you can start creating patterns at a scale of 1: 1 to complete parts.

Instrument preparation

To make a chair with your own hands, you can do with the presence that every owner has. You will need a drill-screwdriver for drilling holes and high-quality connection of elements. Jigsaw and fine-toothed hacksaw for trimming parts. Chisel them a hammer for assembling the structure and connecting fasteners: furniture nails, staples and a stapler for upholstery of the seat and back.

Step-by-step manufacturing instructions

It is necessary to make blanks for all elements of the chair - this is done according to the pattern, by tracing and sawing. When performing work, the dimensions must be strictly observed, the discrepancy and errors of more than 1 mm are unacceptable, otherwise you will have to adjust the parts to each other. The tree must be sanded and treated with an antiseptic compound.

Stages of making a chair with your own hands:

- Cut the required number of bars for the front and back legs. In the blanks, using a jigsaw, grooves are cut out to connect the structure.

- In the longitudinal and transverse bases, spikes must be made in the form of grooves. These will be the main connection points; during work, it is necessary to accurately maintain the dimensions.

- The chair is assembled in two stages. Applying furniture glue to groove joints. First, the front legs are assembled with prongs and the rear legs with a crossbar for the back. The workpieces are dried for 24 hours, then the whole structure is assembled. Additionally, the joints can be fixed with brackets and self-tapping screws.

- The sawn blank for the soft parts of the chair is placed on a sheet of foam rubber or other material and cut out with an allowance of 1-1.5 cm. The fabric is cut along the perimeter of the seat with the addition of 10 cm and evenly, without distortions, is fixed on a wooden base with a stapler.

After the frame has dried, the soft bases are fixed with furniture nails or self-tapping screws. - At the end of the work, the chair is turned over with the seat down and left to dry for another 24 hours.

Finishing

At the final stage, all protruding hats and wooden fasteners are cut off, the joints are sanded and putty. If the chair will be varnished, then the putty composition must be matched to the color of the wood.

Painting and decorating

If raw materials with a beautiful structure are chosen for the chair, then the best choice would be to cover the surface with varnish, which will protect the furniture from moisture and add shine. You can pre-treat the chair with a stain to create the desired shade.

Surfaces do not need additional treatment before painting. It is enough to sand the joints, putty and apply the composition twice with intermediate drying for 24 hours. Latex, acrylic and oil formulations can be used.

Additionally, new furniture can be decorated. For this, thermal stickers are used, which are easy to apply and remove from the surface.

Complement the chair with a cape or paint it in different colors.

When the owner is faced with the question of how to make a chair, it is enough to have a desire for its manufacture and a little imagination to create a beautiful piece of furniture.

Video: do-it-yourself soft chair