How to make a computer chair with your own hands

It is especially convenient to work at a computer when there is a comfortable environment that contributes to the correct position of the body at the workplace. Making furniture with your own hands is actually not difficult. You need to acquire the necessary materials, have skills in working with tools and some free time.

Design features of a computer chair

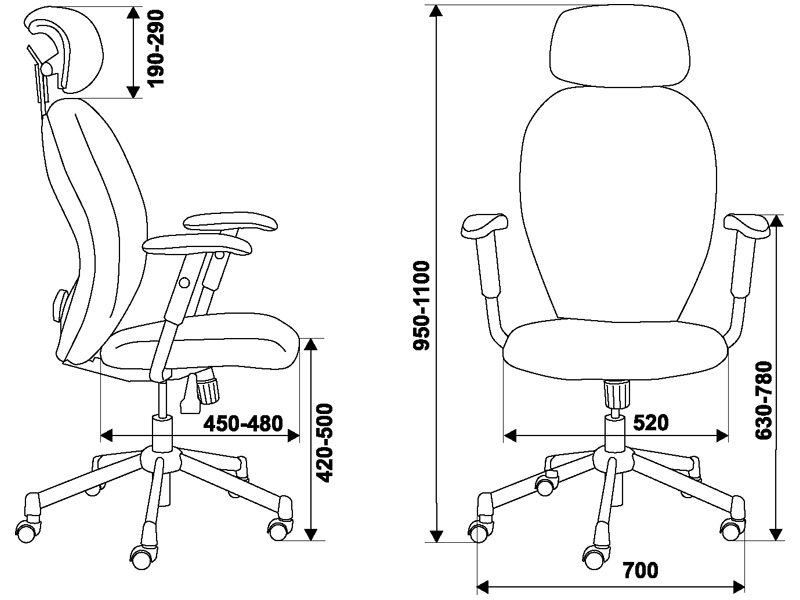

There are universal parameters of the chair, which can be varied depending on the person's physique. Before figuring out how to make a computer chair, you need to familiarize yourself with the features of its design.

- Computer chairs and chairs are made according to the same principle. There should be reliable back support, comfortable armrests, good shock absorption and a height adjuster. The latter can be discarded if furniture is made in advance in accordance with the height and weight of a person.

- If the furniture is designed for an average adult, then the total height of the chair will be 110 cm.The width of the seat balances within 52 cm with a backrest size of 60 * 51 cm.The space between the seat and the floor will take 50 cm.The size of the cross is 70 cm.

- Artificial and natural leather, acrylic material or nubuck are suitable for upholstery.

How to make a computer chair with your own hands

It is better to start making an office chair with your own hands by getting to know the diagrams and drawings. They provide a basic understanding of how the entire installation should work and what to look for when assembling.

Scheme and drawing

The more careful and thoughtful you draw the scheme, the better the furniture you create. Take measurements from yourself, measure your height and weight. Calculate a comfortable seating area.

Materials and tools

The frame for a computer chair is made of wood or metal. Less common is the steel case. If you have opted for a wooden chair, buy an antiseptic in advance to treat these surfaces. This will prevent the wood from rotting and drying out.

Depending on the model you choose, you will need the following tools:

- Welding machine. With it, you will weld the main structural parts.

- The sander is needed for processing wood and chipboard surfaces.

- The jigsaw copes with small work in hard-to-reach places.

- With a drill, you will make holes in the right places for the fasteners.

- Furniture stapler.

- Screwdriver.

- File.

- Sandpaper, bolts, screws and screws.

Manufacturing steps

A small instruction on how to make a do-it-yourself computer chair from scratch is divided into stages. Do you have unwanted office or car seat parts in stock? Then you already have a frame ready.If you purchased plywood or wood planks, then the furniture must be made from the very beginning.

- Draw back, seat and armrest drawings onto a sheet of plywood. Previously, the scheme must be carefully worked out, adjusted to the individual parameters of the one who will be sitting in the chair.

- Using a jigsaw, cut out the parts, process the edges with a sander. Sand especially small areas. All surfaces must be smooth so that no chipping or chipping remains.

- Assemble the base of the product immediately using welding, a drill and steel profiles. It must be stable, since it is the base for the entire structure. Assemble the backrest and armrests.

- Grind, prime, paint and varnish all parts. After they are completely dry, the chair can be assembled.

The final stage

When the structure is assembled, the final stage will be its comfortable and decorative components. It's time to sew the seat and back cushions. To make it comfortable to sit on such furniture for a long time, put soft foam rubber between the seat and the upholstery fabric.

Attach the rotating wheels to the base. This will make your chair mobile and will not scratch the floor.

How to properly repair a chair

You already know how to make a do-it-yourself office chair. How to fix it if some part is out of order? First of all, divide the breakdowns into specific ones and those that can be repaired at home. It is better to entrust complex repairs to a professional. Sitting on a faulty chair affects your health in the first place. Therefore, take the repair very seriously.

Simpler parts are usually subject to replacement or repair, for example, castors, cross piece, armrests.

- The crosspiece breaks most often, especially if it is plastic. The main thing is to carefully pull it out of the gas lift. It is convenient to do this with a hammer.

- Often the legs need to be replaced. To do this, remove the backrest and armrests so as not to break them during repairs. Turn the chair over, loosen the fixing screws, and slide the cover out. Knock out the gas lift with a hammer and replace the crosspiece with a new one. Craftsmen recommend lubricating parts for best performance during assembly.

- Often the piastre, the metal mechanism that adjusts the height of the chair, breaks down. It is taken out of the pseudo cartridge, disconnected from the gas lift with several hammer blows.

Hand-made furniture is pleasing to the eye and adds to productivity. It is so pleasant to sit every day in a chair designed solely for your comfort and convenience.

Video: do-it-yourself computer chair