How to make a do-it-yourself plywood chair

In the modern era of the abundance of building materials and tools, more and more people are faced with the desire to independently manufacture furniture for their home. Firstly, this is cost savings, and secondly, the ability to manufacture according to the required non-standard dimensions. Once you spend on tools, you can use them for many years.

Making furniture with your own hands gives you the opportunity to fly imagination, you can come up with, design and assemble your attribute yourself, while it will be original, unusual and just the way you want it.

In the case when you do not want to reinvent the wheel, you can use the schemes of ready-made samples, since there are a lot of them on the world wide web. Your task will be to copy the sketch and complete all stages of the work, following the instructions.

- What are the advantages of making a chair with your own hands

- Varieties of plywood armchair designs

- What tools and materials will be needed for DIY making

- How to choose the right plywood sheet

- Drawing preparation

- How to make a plywood rocking chair

- Chair model with three legs

- Plain stool

- Tips and tricks for making

- Video: do-it-yourself plywood shell chair

- Photo 50 design options for stylish plywood furniture

What are the advantages of making a chair with your own hands

Important components in the manufacture of a chair with your own hands are:

- Selection of quality, natural materials;

- Adjusting the chair to fit your size and preferences;

- The choice of color scheme is yours;

- The ability to fit into your interior;

- Saving financial resources;

- Improving your own skills in working with building materials;

- Formation of design skills;

- Pleasant pastime;

- Development of imagination, thinking, attention;

- Development of design taste.

When buying a chair in a store, you cannot know 100% what materials were used to make it, what adhesive components the manufacturer used. Most likely, to reduce the cost of production, they could have taken low-quality and toxic analogues. You will not have the opportunity to reveal this when buying, since everything is skillfully disguised, and only what is profitable will be written in the composition.

Varieties of plywood armchair designs

There are a large number of modifications of plywood chairs, but basically they are divided into two types:

- Rocking chair;

- A chair in the form of a chair or stool.

The British ascribe to themselves the authorship of the rocking chair. It is believed that one of the craftsmen created it after the model of a baby cot on runners.

Americans dispute this version, believing that it was Benjamin Franklin who invented this element of the interior. By the way, he is the owner of the rocking chair patent.

It happens:

- on runners;

- on the spring mechanism;

- on the pendulum mechanism.

Chairs, like a chair or stool, may differ in the presence or absence of armrests and backrests.

Designers annually come up with many variations of this furniture, sometimes not always suitable when used for its intended purpose.

What tools and materials will be needed for DIY making

If you have a desire to try yourself as a carpenter-furniture maker and you decide to make your own chair, prepare the following materials and tools:

- Plywood. For reliability, the frame and supporting elements are best made of plywood with a thickness of at least 18mm, and for backs with a seat, you can use 15mm sheets;

- Hacksaw and electric jigsaw. If available, you can use a circular saw;

- Screwdriver, drills, self-tapping screws;

- Hammer, small nails;

- Grinding machine, or ordinary sandpaper and file;

- Roulette, pencil, scissors, corner;

- Joiner's glue, if possible, take transparent so that you don't have to, then sand the yellow streaks;

- Paint, varnish, stain;

- Materials for decoration (various fillers, fabric for making pillows, or for the upholstery of the chair itself).

How to choose the right plywood sheet

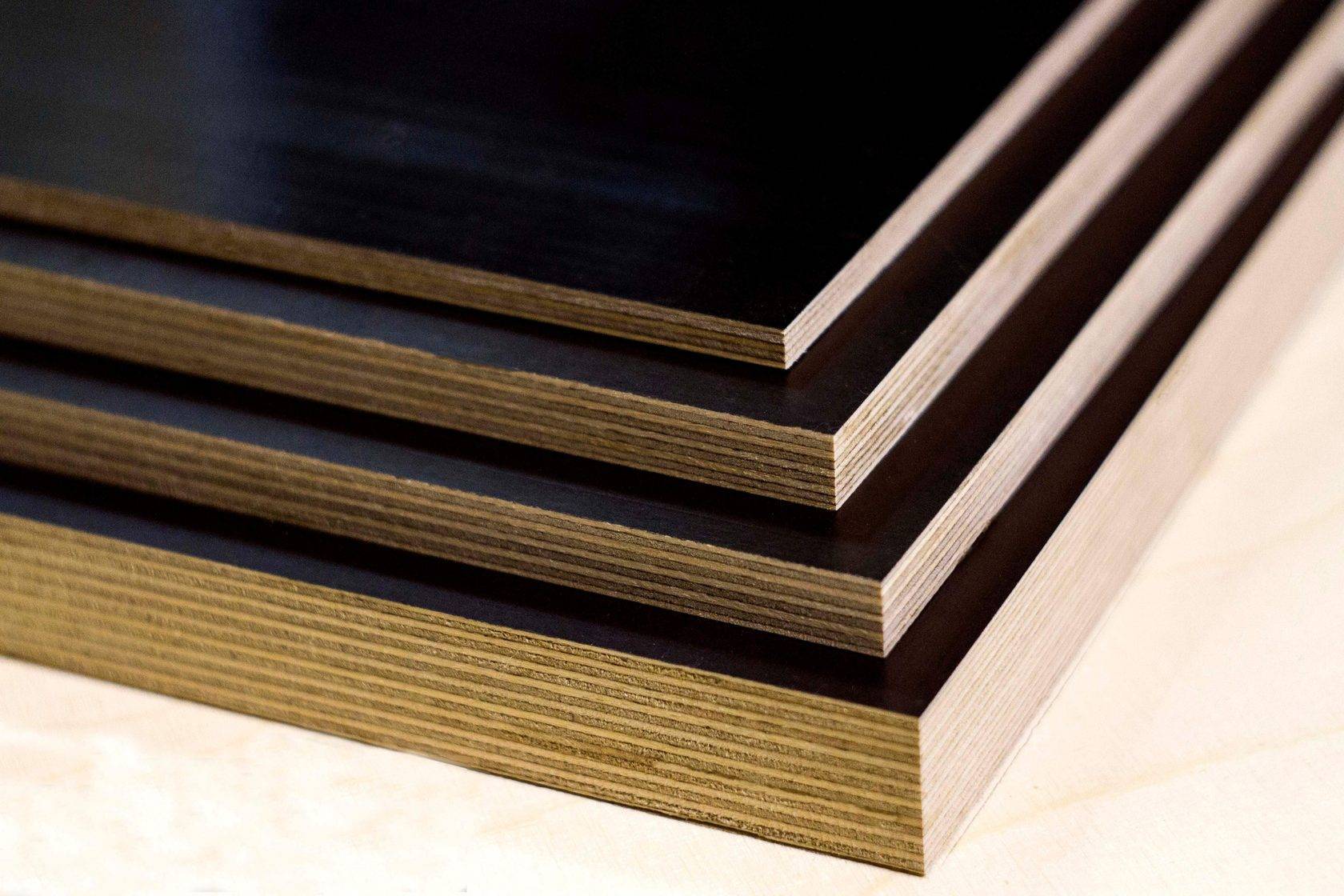

Plywood is thin wood panels glued together. The number of layers varies. It is distinguished by its strength, flexibility, low weight and, unlike wood, does not require complex processing, and its price is quite attractive.

In most cases, manufacturers choose plywood sheets for the manufacture of furniture. This is a fairly popular material, strong and durable.

In order to choose the right FL, we will analyze what types and varieties it has. Species are classified in relation to the wood used in their manufacture.

| Deciduous

They have a light shade, smooth texture. Most often made from birch, but poplar, aspen, alder and maple can also be used. |

Combined

Differs in high moisture resistance. Made from coniferous wood such as spruce, cedar, pine and larch. |

Coniferous

The outer layers of the composite plywood are made of hardwood, and the inner layers are made of coniferous, which provides a pleasant structure and high moisture resistance. |

Also, plywood sheet is divided into grades:

- Elite plywood:

- free from chips, cracks, knots, residues and glue drips;

- it is almost impossible to find in stores, since all products from factories are bought by furniture factories;

- has a minimum number of flaws, suitable for making furniture at home.

- First grade.

- Second grade.

- Third grade.

- Fourth grade.

Plywood is also classified into:

- unpolished;

- sanded on one side;

- polished on both sides.

For making furniture at home with your own hands, it is better to use FBA or BV plywood sanded on both sides. In their production, natural adhesive components are used, they do not have toxicity and are highly durable. Unfortunately, interior items made from such materials are not suitable for outdoor use, as they have a low level of moisture resistance.

FBS, FB and BS brands are durable and moisture resistant.

There is a universal option that is suitable for both indoor and outdoor use - this is film faced plywood. It is not afraid of mechanical stress, aggressive external factors and does not require finishing.

Based on the purpose for which you will be making your furniture, choose the kind of plywood that suits you best.

Drawing preparation

Surely, the diagram of the chair you like is freely available on the Internet. It contains the exact dimensions, materials required, and tools for manufacturing. If you are not satisfied with the presented models, you can study several of the most attractive ones and model your own scheme.

To get the drawing right, design your chair on paper, ideally from multiple angles. Divide it visually into main parts and draw them. You may need templates, pencil or marker, ruler, tape measure, corner, scissors. Select the sizes based on your own requests.

Step-by-step manufacturing instructions:

- Transfer your drawing from paper to a sheet of plywood;

- Saw the details of your chair;

- Grind the cut points;

- Pre-assemble your chair without using any fasteners. Use helpers. This is necessary for the deliberate elimination of shortcomings.

- Glue the necessary details;

- Drill holes for self-tapping screws.

- Connect all the parts together.

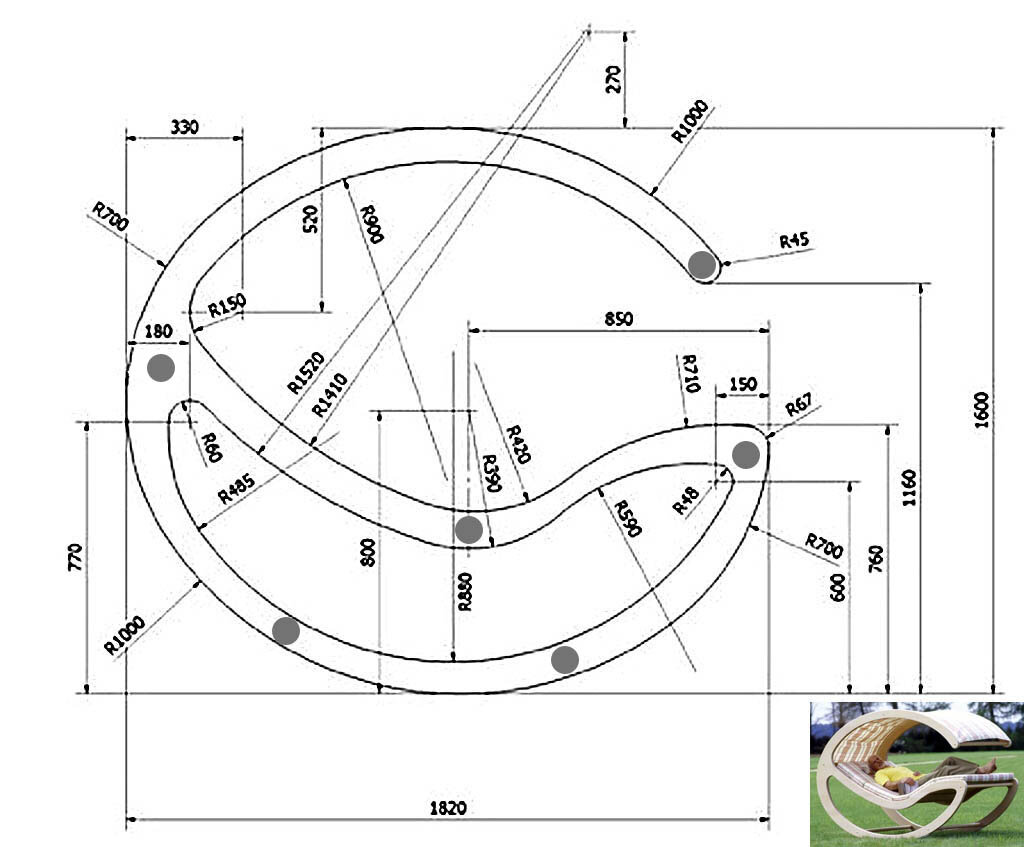

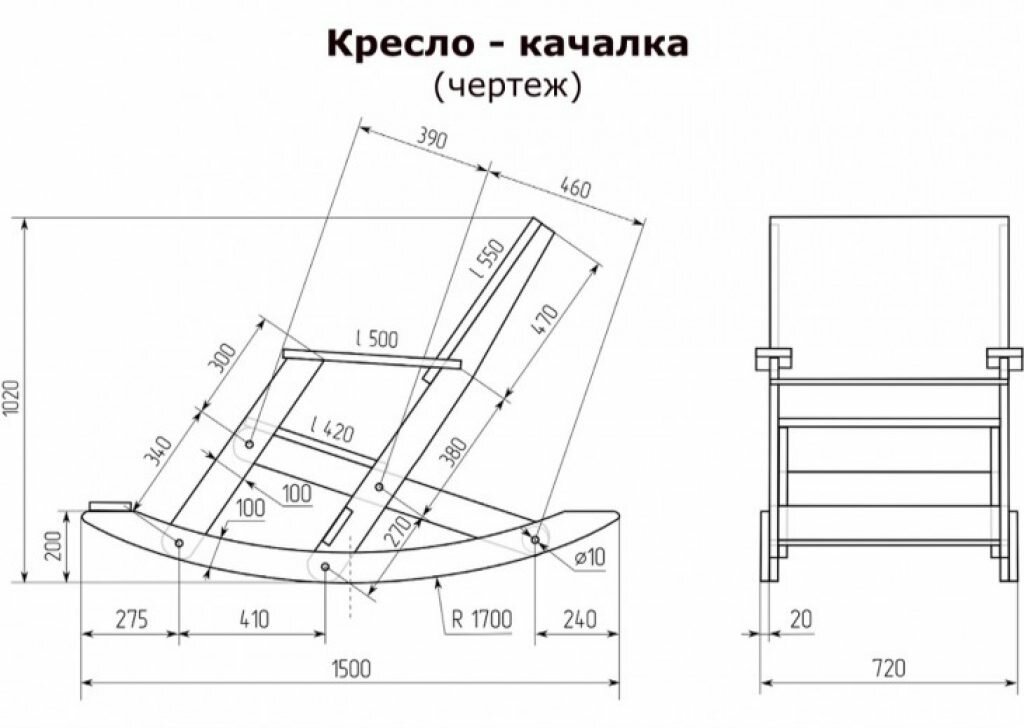

How to make a plywood rocking chair

Choose the model you like or draw your own. Most often, a rocking chair consists of two solid side parts, reinforcing slats and the lounger itself.

- First, we transfer your drawing to a plywood sheet;

- We cut it out;

- We grind;

- Next, cover the necessary elements with glue, wait for drying;

- Grinding may be required after gluing;

Let's go to the assembly:

- we install one of the side parts on a flat surface;

- the holes for the reinforcing rails (there are 3 of them) are greased with glue and the rails themselves are placed there;

- cover the opposite edges of the rails with glue and connect to the second side piece;

- if your side parts require runners, then install them. (For some models, runners are not required, since the shape of the side parts allows you to swing without them);

- we fix the back and seat with self-tapping screws;

- mask the caps of the fasteners with wood putty. After drying, sandpaper;

- Varnish the resulting product.

Once completely dry, your rocking chair is fully usable for its intended purpose.

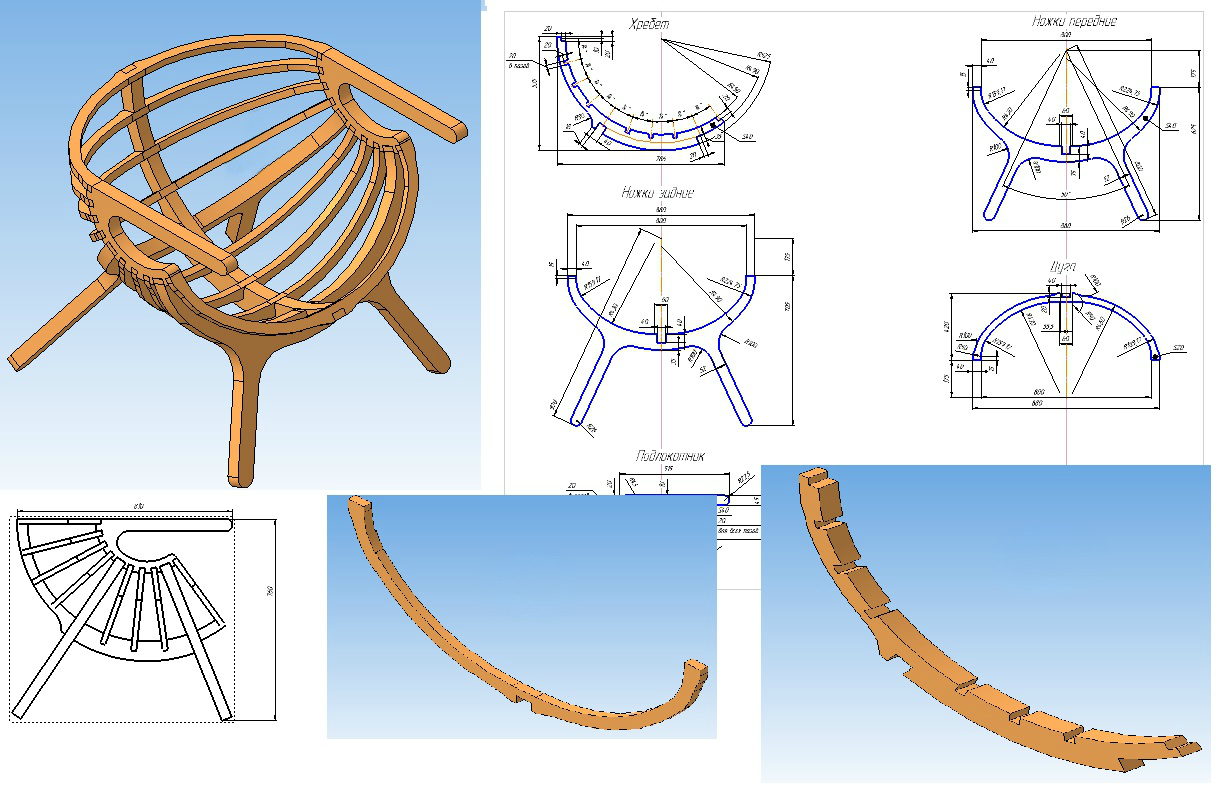

Chair model with three legs

Recently, unusual models of chairs with only three legs have gained popularity. Often such chairs are called seashells, for the involuntary resemblance.

The whole structure includes one piece with two legs, one piece with one rear support leg, armrests, and nine semicircular pieces that make up the back and seat.

For the manufacture of such chairs, self-tapping screws or nails are rarely used. The main function of bonding the entire structure is taken over by glue.

For the comfort of this type of chair, it is advisable to use pillows.

Plain stool

Before stools were invented, man sat on the ground. It was the first piece of furniture that Homo Sapiens invented.

An ordinary stool has a simple structure. Consists of four legs of the same length and the seat itself. Sometimes, for reliability, closer to the bottom, the legs of the stool are interconnected with wooden planks. The stool does not have a back and armrests. Includes only one person sitting.

There are also three-legged stools. One of the most famous three-legged specimens is considered the Alvar Aalto stool.

In Moscow there is a museum dedicated to the history of furniture, in front of which there is a monument to a stool, which is considered the ancestor of all furniture art.

Tips and tricks for making

In order to produce any piece of furniture with high quality, you need to take a responsible attitude to all stages of its manufacture.

To begin with, carefully consider the choice of material from which you are going to make your furniture, be it a stool, chair or armchair. Prepare all the tools in advance and purchase the missing ones. Take all measurements accurately. Be sure to study the information on this issue. Consider all the nuances, do not neglect the little things.

Use assistants whenever possible, especially when assembling a three-legged chair.

Use the resulting product strictly for its intended purpose. If the furniture is for home use, then it may not withstand aggressive environmental influences (rain, sun, heat, cold, etc.).

Don't overload.

Video: do-it-yourself plywood shell chair