How to make a chair with your own hands

Doing something with your own hands, on your own is not only an opportunity to save money, but also a pleasant and practical way to spend time.

Learning new things, becoming experienced in the production of wooden furniture - all this can be done if you make the necessary efforts, fully understand the production process.

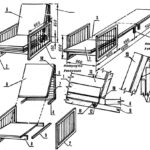

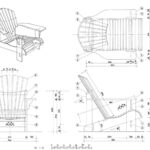

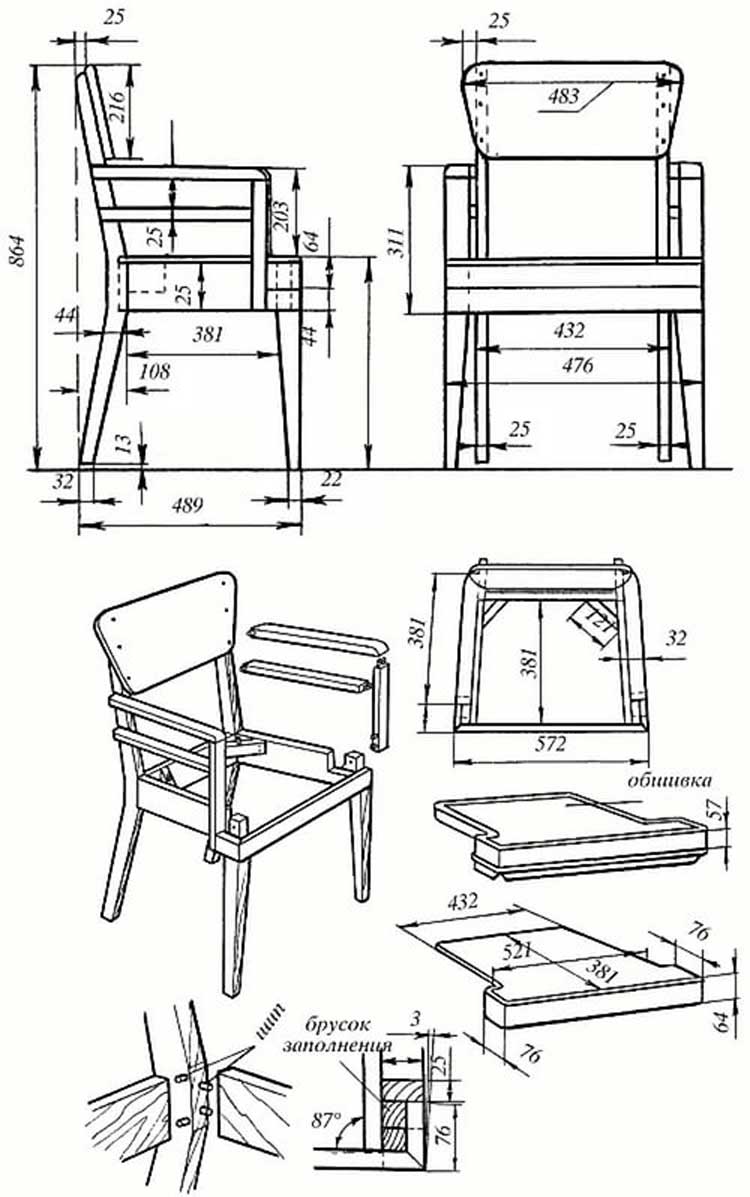

Drawings and diagrams of the chair

It should be borne in mind that when choosing a suitable drawing, the frame depicted on it is important. If you change it, you can get a completely different product. For example, removing the armrests creates a comfortable chair. By extending the seat to a certain length, you can change the design and make a garden bench.

Before making a do-it-yourself chair out of wood using drawings and selected dimensions, you need the end result to match the preferences of the master. The structure consists of:

- Backrests,

- Seats,

- Legs,

- Armrests.

The diagram may contain additional details for folding the chair. Such fasteners are installed after the preparation of the main parts according to the drawing. It is also worth paying attention to the manufacture of an upholstered chair. To do this, you need to prepare foam rubber, upholstery fabric.

It may be necessary to make seams on the material so that the soft base matches the original on the diagram downloaded from the Internet. To do this, you need to have an experienced sewing assistant or have basic knowledge yourself.

Preparation of materials and tools

In order to make a chair with your own hands, you need to do everything in stages. In accordance with the selected drawing, it is necessary to prepare materials. If the base is wooden, then you should purchase or choose from the available raw materials: plywood, timber, boards, chipboard.

The tree for the frame is the best option, environmentally friendly and inexpensive. Choose wood carefully. The presence of bark, splits, cracks, uneven texture on the boards is not encouraged.

Additionally, you may need fasteners, wood glue, varnish or paint for application to the surface of the product, foam rubber, filler, textile fabric: velor, jacquard, tapestry, flock, leather (natural, artificial).

Tools to prepare in advance:

- Screwdriver;

- Furniture stapler;

- Jigsaw, grinder, necessary attachments;

- Machine for sanding boards;

- Staples or screws;

- Chalk;

- Hammer;

- Scissors, upholstery sewing machine.

The components of a wooden chair can be prepared independently or ordered at a special enterprise, where they can make blanks according to the presented samples.

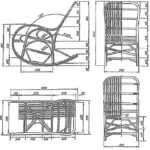

Varieties of armchairs

You can choose any type of chair on the Internet. It can be made from improvised and unnecessary materials. For example, recently, copyright works using wooden pallets have been gaining popularity. They are held together. You can put a square cushion on the seat.

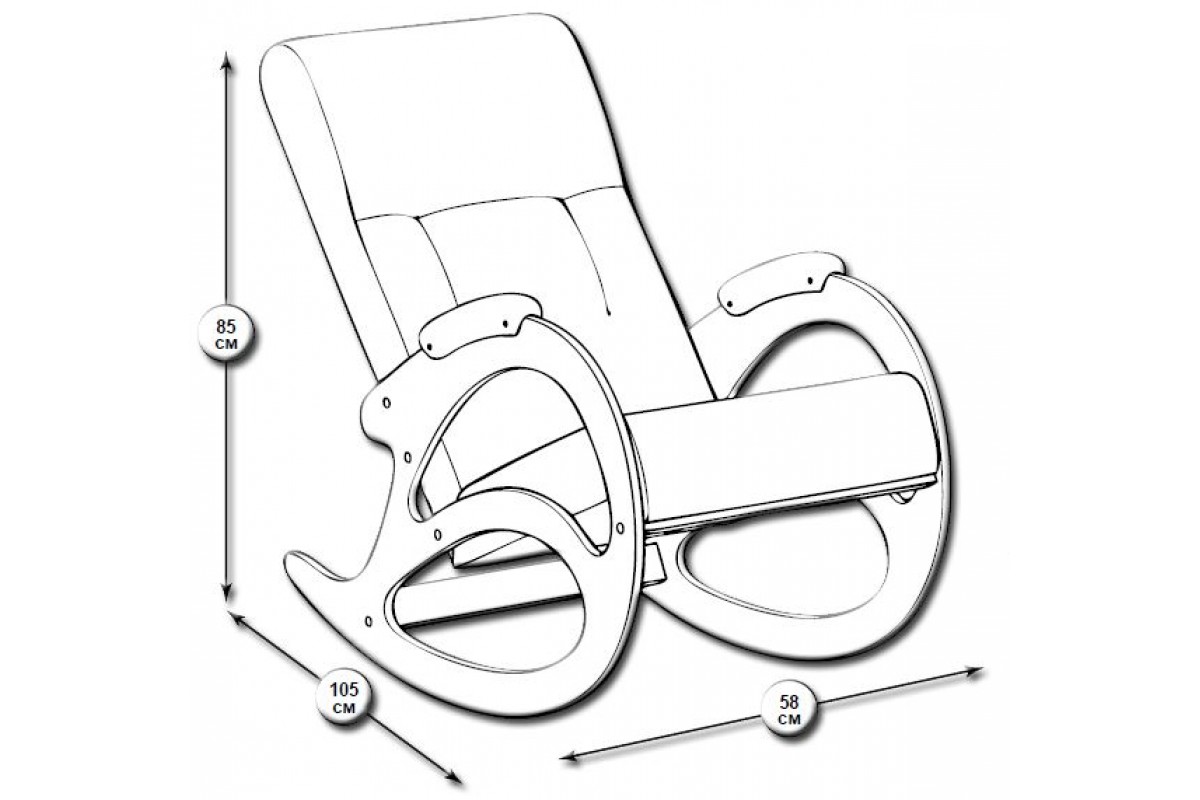

If desired, you can make a small version of the glider. This is a high-comfort chair. It can be placed both in the house, in the country, and on an open veranda. But for its production, it is important to use a ready-made drawing, watch a training master class or be present during its production.

Sadovoe

Solid wood can be used for a country chair or rocking chair. The composition of the tree is ecologically acceptable for human use, does not harm health. The first condition is to determine the consumption of material, to fully imagine in what sequence the work will be performed.

This piece of garden interior can be without soft elements, which simplifies the installation of this structure.

Baby

A feeding chair, children's swing or a miniature chair is best made of wood. After choosing a scheme, you need to pick up the material and start production. A highchair is useful at home and in the yard.

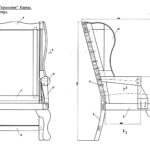

"Shoe"

When you look at the photo, where the depicted is another version of the chair - a shoe, many people think that its manufacture is heavy. But with a phased installation and sewing skills, you can build this type for home use. The curved silhouette and unusual design will be a worthy decoration for any home.

DIY chair making process

Instructions for making a classic model are provided.

This is a comfortable and at the same time easy-to-install chair. Wood material should be used for it. At the first stage, you need to prepare raw materials, tools, choose a place where work will be done.

Important! It is necessary to carefully choose a place for the preparation and cutting of parts with the subsequent assembly of the structure. It should be spacious. A lot of waste, shavings, debris will accumulate.

The prepared frame parts must be laid out in the correct order. This will help to quickly carry out all subsequent work. If welding is carried out in the manufacture of a metal base, then the place where it is manufactured must correspond to the required fire safety.

Stages of work:

- Transfer the prepared templates of the elements of the product to the wooden material with the help of chalk.

- Using a grinder, with a jigsaw, cut out the elements along the drawn line.

- If there are rough spots on the timber or boards, you need to walk over them with a sander.

- Using a screwdriver, welding machine or hammer, connect the parts together. If there are fasteners for folding the chair, attach them with screws.

- Go to a soft base. To do this, make a pattern on the fabric, cut out individual parts, fasten on a sewing machine. It is worth considering! When cutting fabric elements, you need to make a seam reserve of 1 cm.

- Cut the foam components.

- Wrap the seat and armrests with foam rubber. Attach it with a construction, furniture stapler. If the armrests do not have a soft base, and decorative elements are being established on top of a regular board, then they need to be attached with glue or a screwdriver.

- At the last stage, the surface of the product should be treated with bio-protective substances, varnish or painted with paint. Once dry, the chair is ready for use.

Decorating can be done in various ways: sew buttons on a fabric seat in a staggered arrangement, process with several shades of paint, attach additional curls to a metal frame, etc.

When creating, you must use your imagination, stage-by-stage work.

Video: how to make a chair with your own hands