How to make furniture facades out of wood with your own hands

Wood is a classic for room design at all times, it will always look elegant. Do-it-yourself wood furniture facade is an interesting, attractive solution for the interior. Don't forget to save money as well. Custom products will always cost more. In this publication, we will focus on the basic principles that will make it possible to make original products for the home.

Varieties of wooden furniture facades

When making a facade for do-it-yourself furniture, you need to take into account several aspects:

- the door must be an integral part of the furniture, open and close normally;

- to match in style to a wardrobe, bedside table, any object;

- high-quality products can be quite expensive (considering that they are handmade);

- the craft should be easy to maintain, cleaning should not be a heavy undertaking.

Any carpenter has his own preference in the production of facades. There are several of the most popular types of products that have their own unique characteristics.

Facade from MDF

Boards made of wood (fibrous) shavings are MDF. The composition also includes: lignin, paraffin, which are safe substances that do not affect human health. Plates are environmentally friendly raw materials.

Product advantage:

- moisture resistance;

- sufficient density for the facade;

- easy to operate and work (it is possible to cultivate with a cutter);

- plastic (you can give relief to the object).

MDF is a basic form, but different materials can be used for coating:

- PVC film). Sometimes people immediately choose slabs with film elements. This design is reminiscent of objects made from solid or processed wood. PVC engraving is very diverse: matte, glossy options, illustrations, large paintings, etc.

- Enameling or painting. A popular way to decorate the front. The range of colors is quite large. If you wish, you can make a creative image with paints. The general drawing of the sea coast on cabinets, bedside tables in the bedroom or in the kitchen, a collage of beautiful sakura and other plants.

- Plastic. May have a glossy, matte texture. Quite often you can see it in modern style solutions.

- Veneer (thin sheets). The designs are popular for kitchen decoration. An ideal, and most importantly, a popular option is an imitation of natural wood. Imagine expressive hazel or exotic wood in your kitchen. Visually - it is bright, pleasing to the eye!

Note! MDF in facade elements can be used in any room: kitchens, bedrooms, private offices, children's rooms, etc. Designers love to apply material in a modern style, futuristic genre.

Chipboard

Chipboard is a chipboard.The structure of the material does not allow for milling. Such objects are always smooth and clear. The front part of these facades can be connected with plastic, aluminum cladding. Most often, laminated chipboard (laminated) is used for such structures. The assortment of goods is huge: original colors, stylization.

For the kitchen, it is better to use chipboard with a moisture-absorbing structure. A similar option is suitable for the bathroom.

Additional Information. Particleboard is a budget but bright modification. Used for any style projects.

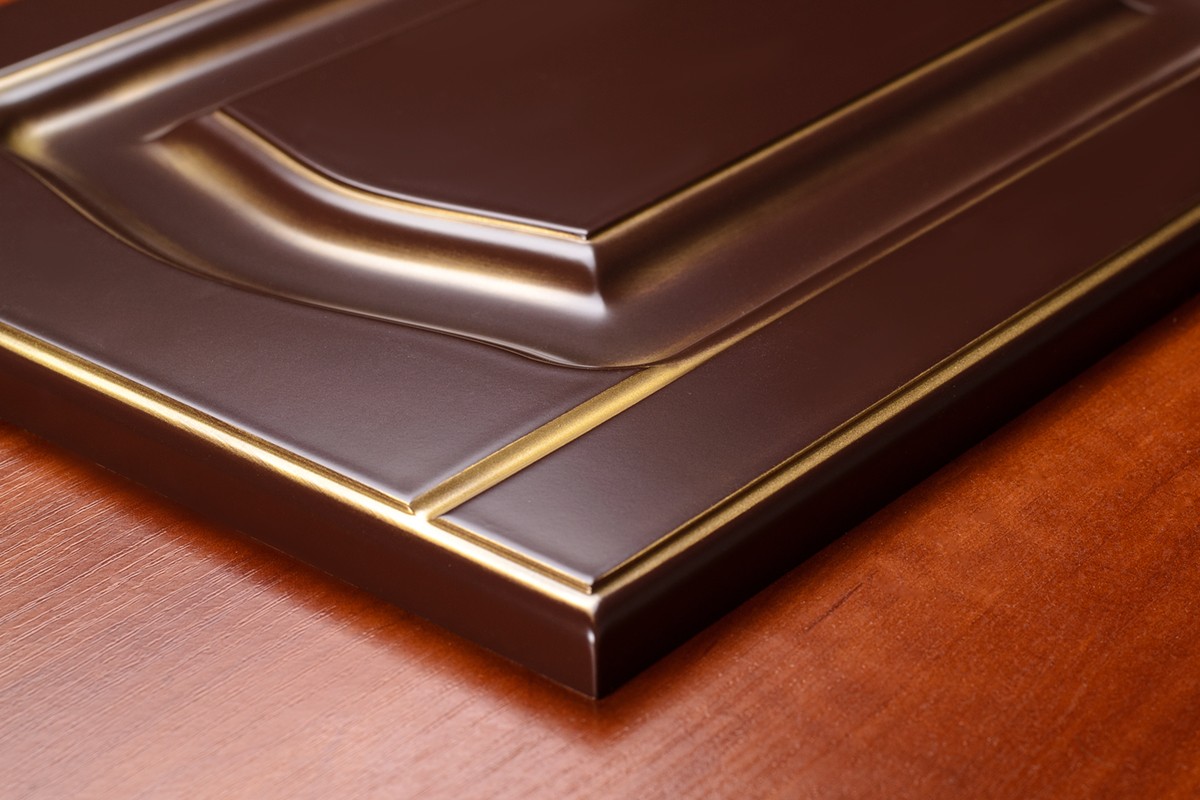

Solid wood

The production of furniture from wood is a whole art. The most environmentally friendly material. Craftsmen most often stop at the following breeds:

- Birch;

- oak;

- Pine;

- beech;

- some masters order "overseas" samples: red, lemon tree, rosewood.

To work with this material, it must first be dried. Then the array is processed by different means. Special fluids protect wood from harmful bacteria and fungi. They also help to make the raw materials resistant to temperature changes or indoor humidity.

The array is suitable for milling. Engravings, original images make these products the best for design developments.

When the sample is ready, it must be treated with varnish or paint, other special tinting agents, the creation of decorative coatings, and the aging of objects.

There are several types of solid wood: typesetting (from picturesque elements), veneered construction.

Important. The products are often used in the Classic, Baroque style. Ensembles Country, Eco also cannot do without a magnificent array.

What tools will you need to make a do-it-yourself wooden facade

In order to make a furniture facade, you need to have the appropriate tools:

- materials: wood, board, plywood, plastic, MDF glass, chipboard and other raw materials (it all depends on the layout of the structure);

- tape measure, ruler, square, pencil;

- electric jigsaw;

- different screwdrivers;

- screwdriver, drill;

- glue for carpentry needs;

- a set of brushes;

- clamps (clamps);

- spray gun;

- cutter, grinder, discs.

Anyone can make the sample you want, you just need to listen to the working guidelines.

Step-by-step manufacturing guide

To make furniture facades with your own hands, you need to follow the step-by-step universal instructions:

- Development of drawings. Material base preparation.

- We make a frame from wood. It requires a rail. She, in turn, is divided into 4 parts. In the end part of each of the four parts, grooves are made.

- Preparing the frame insert. A groove is made from the inner base for insertion.

- Grinding of all elements. It is better to use a grinder with a sanding disc, but you can get by with sandpaper.

- Assembling the object. At this stage, it is better to take measurements again. You must make sure that everything is in order with the dimensions and correspond to the declared values. For gluing, you need to choose a professional glue, strictly adhere to the instructions for gluing items. The elements of the facade can be tightened with clamps.

- Painting (varnishing). Before work, the surface must be cleaned of dirt, degreased, primed. You can quickly paint with a pneumatic spray gun, if it is not possible to use this equipment, you can limit yourself to brushes.

- Installation of door hinges.

Recommendations may vary for different products.

Instructions for the manufacture of solid facades

Such structures are made without joints from a solid cut, more often it is painted. Then comes the surface cladding.

Several advantages of such structures can be emphasized:

- resistance to moisture, temperature changes;

- reliability;

- durability;

- environmental friendliness;

- aesthetics.

Making solid doors is similar to the universal instructions:

- Preparatory stage: measurements, purchase of materials, tools.

- Working phase: preparation of individual parts, assembly. grinding.

- The final stage: painting or varnishing, fittings are attached.

One-piece doors weigh quite a lot, very dimensional products, the price is also not cheap.

How to make a paneled facade

These doors are assembled: wood, plywood insert or veneer (there can be many variations).

Detailed instructions for the production of paneled facades:

- Project calculations. A tape measure will help you measure the openings. Here you need to remember that the doors themselves should be smaller by a few millimeters (usually three mm.)

- Raw materials. Suitable for work: solid wood, MDF, chipboard, aluminum, glass, etc.

- Markup. Schematic markings on samples.

- Production of individual parts. Parts of the doors are cut in accordance with the drawings.

- Grinding of elements.

- Working with paneled grooves (cutting).

- Openings are made for further assembly.

- Creation of a complete design. Use of biting aids.

- Drying of the surface.

- Sandpaper cleaning (grinder).

- Primer.

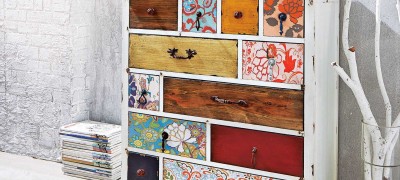

- Finishing. There is an opportunity to be creative and create a decorative masterpiece. Door insert, photo collages, mosaics, simple painting.

Paneled structures have the biggest advantage - affordable cost.

Patience, precision are qualities that will help beginners create works of art.

Installation of facades

Even at the manufacturing stage, certain installation procedures are performed:

- marking of areas with fittings;

- openings for parts;

- hinges are attached;

- now the facade is placed in the doorway;

- adjustment of fittings.

Recommendations and tips for making

Any person faces difficulties in woodworking, especially at the initial stage. There are several recommendations that will help novice craftsmen:

- Product diagrams can be found on the Internet at specialized sites. Start light projects first, then complicate tasks.

- Explore theoretical information on the subject: articles, training videos.

- Buy carpentry tools. It's good when the equipment is always at hand.

- The easiest way to decorate is self-adhesive film. Using wood stain. It brings out the natural structure of the wood. Looks original and elegant.

Making a facade with your own hands is just the beginning in woodworking. At first, a person is always not easy. In the future, everything will turn out better.

Video: manufacturing of furniture facades