Do-it-yourself TV stand

Until recently, it was impossible to imagine that there will be such flat, light and neat TV models that they can be attached to the wall with the help of a small bracket. However, this is not always possible even now due to the peculiarities of the room, for example, because of windows or thin walls.

Also, many people often place other equipment next to the TV. As a result, TV cabinets are still popular with customers.

However, when choosing furniture on the Internet site or in a salon, it is not always possible to find exactly what will fully meet your expectations, since everyone has different ideas about the future acquisition.

The bedside table should harmoniously fit into the interior of the room, have a certain size, style and color. Sometimes a buyer finds a suitable model, but the cost stops him.

Therefore, people who are not afraid to try to do something on their own often wonder if they can make a TV stand in a modern style with their own hands.

What you need to make

A do-it-yourself TV stand is not at all difficult to make. It is enough to have a clear understanding of what kind of model you want to make. If you do not have a certain level of skill, it is worth considering rectangular or angular shapes of furniture, which are much easier to make than other non-standard types of models.

Also, you need to decide whether you want to make a bedside table in the form of an ordinary table or add functionality to the product, for example, drawers, open shelves or closed drawers with doors that can be equipped with ordinary handles or a modern "push mechanism".

It is important to take into account the size of all the items that you plan to place on the bedside table, because it is usually because the capacity of the bedside tables available on the furniture market does not meet the needs of the buyer, he thinks about making it himself.

You should also define the style and color of the product so that it matches the rest of the furniture and the overall interior of the room.

Materials (edit)

An important point is the choice of the basic materials that will be used for the manufacture of the cabinet. It can be one kind of material or several. Note that some of them are easier to work with than others.

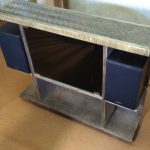

How rich the product will look also directly depends on the material.For example, for a country house, you can choose the remains or scraps of old furniture as a basis, and for a luxurious living room interior - real wood. The sash or countertop is sometimes made of glass or plastic.

Let's consider the types of materials in more detail:

- Particleboard and plywood are the most economical options and are the easiest to work with. However, their disadvantage is their fragility and simplicity of appearance.

- Drywall - this material is an easy-to-use material, often used to make unusual furniture models. However, it is unable to withstand heavy objects.

- MDF is a higher quality material that looks attractive and has a longer service life.

- Natural wood is a costly but environmentally friendly option that is highly durable and luxurious. Maybe, as in the form of a solid wood array or in the form of glued wood panels, timber.

Important! When buying wood, be sure to pay attention to the dryness of the material, moisture can deform the cabinet during the manufacturing process or later, during operation.

Instruments

The assembly of any furniture is not possible without a certain set of tools. you need to prepare them first. It is easiest to order a cut of the material in the appropriate workshop, but if you plan to make the parts yourself, then you will definitely need an electric jigsaw with suitable blades.

In addition, you will need:

- pencil or chalk for marking;

- cardboard or whatman paper for cutting out templates of cabinet elements;

- roulette;

- clamps for pressing parts;

- glue suitable for your material;

- edge tape;

- building level;

- sandpaper or sanding machine;

- fasteners (screws, guides, etc.).

If the product is of a more complex format, then another tool may be required.

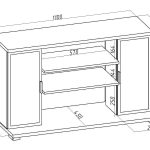

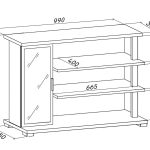

Drawings and assembly diagrams of TV stands

When you have decided on the model of the future product, its dimensions and functionality, you need to prepare a drawing. If you know how to draw, then do it yourself, otherwise you should find a ready-made scheme on sites with relevant topics.

Important! When choosing a drawing, you need to pay attention to the weight and dimensions of the TV, as well as to what additional accessories, decorative elements, etc., you plan to place on the nightstand.

DIY cabinet assembly technology

The technology for assembling a TV stand is not complicated, the procedure is always the same, regardless of the complexity and functionality of the structure. To begin with, individual parts are made and processed, then they are connected to each other, legs are mounted.

At the end, the product is decorated with decorative elements. Let's consider each of the manufacturing stages in more detail.

We prepare materials

First, you need to make patterns for the main parts. To do this, concentrating as much as possible, depict them on thick cardboard in accordance with the drawing. Then the ready-made templates are cut out, applied to the material, the contours are outlined along them and the cut is made.

This allows you to save materials and accurately, without errors, make individual parts of the bedside table. The sawn part is subjected to the following processing:

- when working with chipboard, the parts along the edges are sanded and glued with tape.

- when working with natural wood, all surfaces are sanded;

- drywall is not processed, only covered with a primer and painted.

Putting all parts together

The second step is to assemble the prepared parts.A level is used to level the structure. Legs or side walls are attached to the tabletop, if necessary, with pre-screwed rails for the cabinets, and then the bottom.

After that, the product is supplemented with cabinets, shelves, drawers.

Installation of legs

The second step is to assemble the prepared parts. A level is used to level the structure. Legs or side walls are attached to the tabletop, if necessary, with pre-screwed rails for the cabinets, and then the bottom.

After that, the product is supplemented with cabinets, shelves, drawers. Before you finally connect all the parts, you must once again carefully check the product for evenness of their fit.

Curbstone decor

It is necessary to decorate the bedside table depending on the material used.

The laminate will look beautiful right after assembly. Solid wood must be primed and treated with stain, this protects the material from water and dirt. After that, you can apply artistic carving, varnish or paint.

You can also stick a decorated film on the finished product, apply images using a stencil. Stylish decor elements can be beautiful handles on cabinets, glass or stained glass doors.

Thus, a do-it-yourself TV stand is an excellent choice. A smart approach to work can save you money, bring warmth and comfort to your home, and even prevent the purchase of additional furniture, such as a table.

The furniture manufacturing technology is quite simple, and by connecting creativity and talents, you can make a self-made piece of furniture unique, a kind of "highlight" of the interior.

Video: do-it-yourself wooden TV stand