Children's bed-car with their own hands

Many parents who have small children know how difficult it is sometimes to put them to bed: either a bedtime story is needed, then the light of the moon interferes, then a thousand and one more reasons. Therefore, one of the options for simplifying this process can be an original children's bed, for example, in the form of a car.

Of course, the task is not easy, since making a car bed with your own hands will require knowledge, skills, and time. However, there is nothing super complicated here - any father will master this "science", if only his child is happy.

Types of cots

A baby bed must meet three basic requirements: strength, safety and attractiveness. If everything is clear with the first two, then the latter leads to ambiguity, especially when it comes to going to the store. On the one hand, there is no point in overpaying for extra decor and design, and on the other hand, it is worth taking into account the fact that children should be interested. Is always!

With this in mind, you can consider the main types of cots:

- Regular. The most common option is the most practical and equally uninteresting.

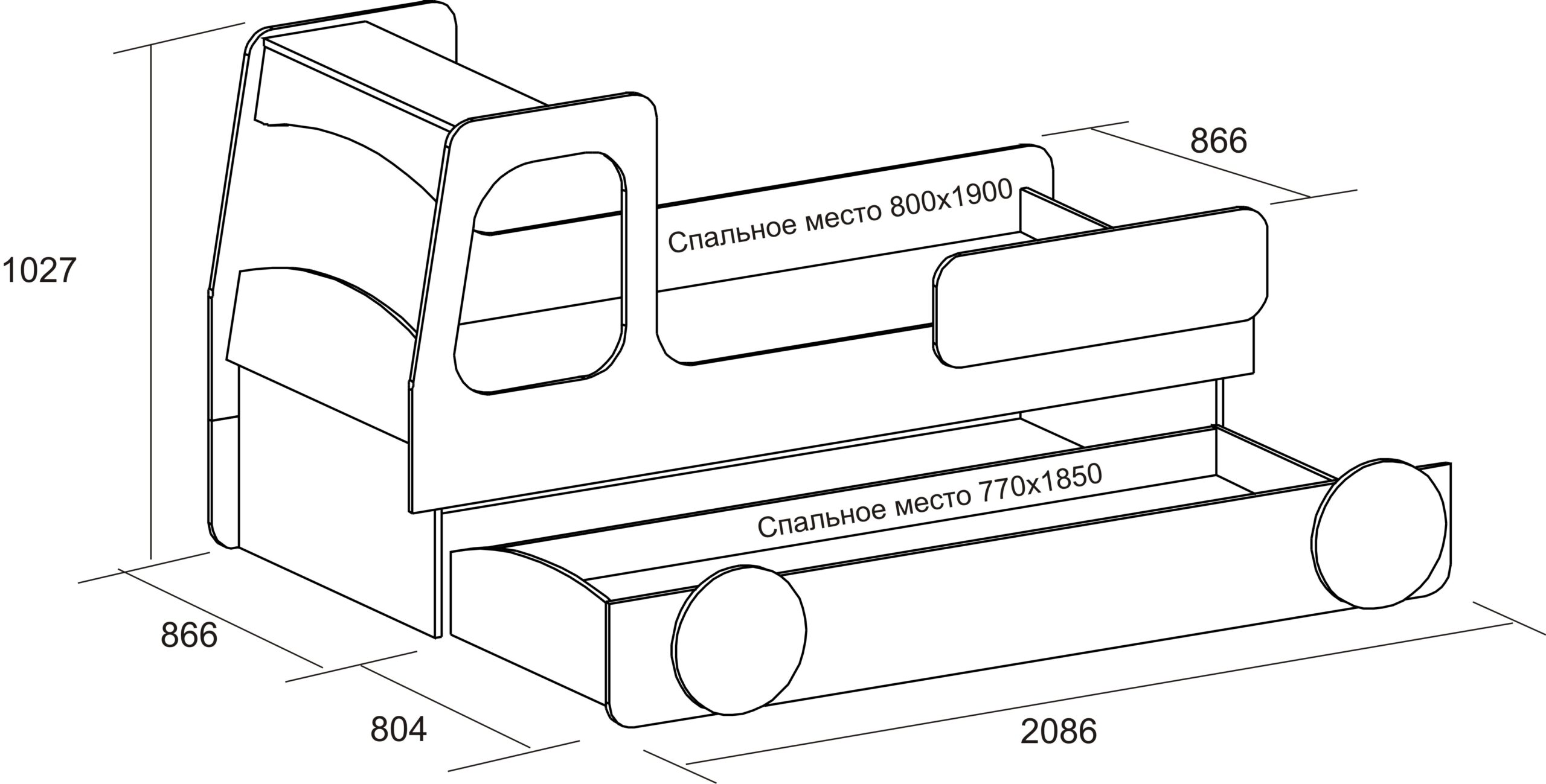

- Bunk. It is attractive because it is possible to sleep on the upper tier.

- Combined. A compromise option between, in fact, a bed and a table, wardrobe, cabinet. Good too.

- Homemade, stylized. For girls, these are butterflies, clouds or fabulous animals. For boys - of course, cars: sports, trucks, as well as buses and planes. The most interesting solution!

Note! If we talk about making by hand, then it is the variant with a typewriter that is most often found in modern houses.

How to make a baby bed in the form of a car with your own hands

You need to start with an idea. You should not take models with complex shapes and an abundance of small details as a basis. The contours of the future bed should be as simple as possible, with smooth contours, without sharp transitions and sharp corners. It is necessary to exclude options with volumetric surfaces, especially with curvature along all three axes - it is impossible to make this at home.

As the best option, they most often stop at the idea of styling for sports cars. Firstly, boys love racing and everything connected with it, and secondly, sports cars have laconic lines and have a good balance between attractive appearance and functionality. For example, the spoiler can be turned into a shelf and the hood can be turned into a clothes drawer.

Children's beds for boys with their own hands: a schematic diagram

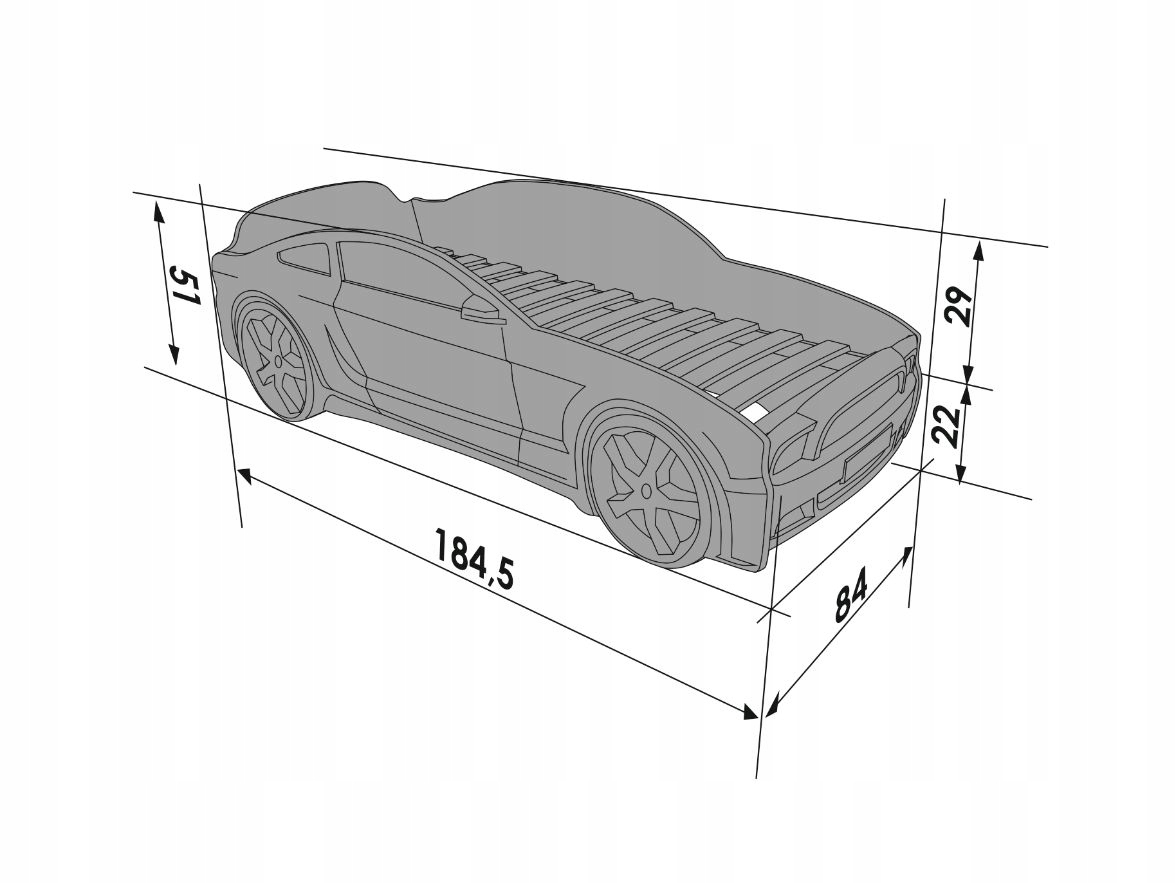

It will not be difficult to find a suitable drawing at the present time. Moreover, on the Internet you can find completely ready-made drawings, with assembly and cutting diagrams. Here, the main thing is not to miss an important point - the size and dimensions of the bed will be determined by the mattress.Therefore, it follows from what is available or, if you plan to do everything "from scratch", you can rely on the standard children's size: 140x70cm.

The next step should be the preparation of drawings. Ideally, it is desirable to have at least basic skills in CAD, CAM systems, but you can also make drawings manually. This is really important, since the depth of the drawing and the accuracy of the dimensions will determine what a do-it-yourself children's bed in the form of a car will turn out to be. Therefore, it is necessary to think over everything thoroughly, down to the smallest details.

Tools and materials

To make a bed, you need to divide the required tools into two categories (this will make it easier to understand what else you need):

- Common: hacksaw, screwdrivers, wrenches, breadboard and carving knives, a set of hex keys (for confirmations), sandpaper, markers, brushes and brushes.

- Special: jigsaw, grinder, grinder, building hair dryer, level, spray gun (airbrush).

It is assumed that the car bed for a boy with his own hands will be made only of wood. Plastic or metal should be used more for decoration. In general, the best option might be:

- Chipboard (chipboard). Differs in low cost, ease of processing and a wide range. Afraid of mechanical damage and moisture.

- Laminated chipboard (chipboard). The same chipboard, but with the so-called laminate - a coating that gives it color, texture and pattern. Less exposed to harmful factors.

- Fiberboard (not to be confused with fiberboard - MDF from English Medium-Density Fiberboard). Sturdy, good handling. The structure is closest to an ordinary tree.

Manufacturing

Ease and simplicity of manufacturing directly depends on the thoughtfulness of the concept and the accuracy of the drawings. Of course, a fair share of success depends on the "curvature" of the hands, nevertheless, the desire to surprise your child or the desire to bring everything to the end by all means will help here too.

Cutting blanks

For simple details, an ordinary hacksaw is enough, but since making a car bed with your own hands will not work without an interesting decor, the sidewalls will represent the greatest difficulty.

Firstly, it is difficult to make such a drawing without special equipment at a 1: 1 scale: you can try the coordinate grid method or print the contour in parts, on a printer, and draw them up directly on the surface of the sheet.

Secondly, curved lines are laborious to manufacture and process, and also require the ability to work with a jigsaw.

If there is such an opportunity, the best option would be to cut out the sidewalls at a company that provides such services - the result of the work of a milling machine cannot be compared with sawing by hand.

Important! When making sidewalls from a sheet with a laminate, you should select the appropriate operating mode and type of jigsaw blade so that when cutting you get smooth edges without chips.

DIY bed for a boy: frame

When designing furniture for a bedroom, two frame options are usually considered:

- Frame. The frame is the main power element, as it takes all the load. In this case, the sidewalls can be made from a thin chipboard sheet, no more than 16-18mm thick. It is advisable to take a beam thicker: usually a section of 50x70 is enough.

- Carrier. Here, the sidewalls themselves will play the role of power elements, and hold the entire load - they are made of chipboard or MDF, with a thickness of 18 to 22mm.In this case, it is necessary to consider additional fastening of the sidewalls to each other, if the panels are not solid, but have cutouts.

Assembly

It is recommended to assemble in two stages. The first, rough or trial, is carried out after the manufacture of all the frame parts and is intended for adjusting the joints, as well as correcting flaws in the design - since it is impossible to make a children's bed in the form of a machine with your own hands the first time without errors.

The second stage is considered finishing or final. It is being produced already at the final stage. Usually by this time all the details are finished: painted and decorated accordingly. As a rule, the "last" assembly takes place on site, directly in the nursery.

Laying the mattress

The mattress needs to be placed on a ready-assembled bed. However, you should take care of the type of substrate in advance. It also comes in two flavors:

- Lamellar or slatted. In this case, the "bottom" of the bed is a series of fixed-width slats, fixed at a certain interval.

- Solid. The base under the mattress is simply a piece of a sheet (usually chipboard), in one piece or with a number of holes to improve ventilation.

Final touches

After installation, the bed can be additionally decorated with overhead elements, for example, by installing wheels on the sidewalls or attaching a spoiler at the headboard, which will simultaneously act as a shelf for small things.

Also, if you have the necessary skills, you can organize the illumination along the perimeter of the bottom using an LED cord. In addition, LED spotlights will come in handy to simulate headlights, otherwise what kind of car is this - a bed for a boy made with your own hands!

Installing a baby bed: what you need to know?

Even at the planning stage, you should consider not only the design features, but also how such a bed will fit into the interior of the nursery. If repairs are not expected in the foreseeable future, you will have to develop a car design that best suits the style of the room.

In addition, the baby bed must be stable on its own. The child should not be allowed to injure itself as a result of its overturning or displacement. It is also not advisable that the furniture is in direct sunlight for most of the day - this can ruin the paintwork.

Do-it-yourself car bed for a boy: care rules

In general, caring for a handmade bed is not much different from caring for the same, but bought in a store:

- Avoid exceeding the humidity level in the room.

- Regular dusting and wet cleaning.

- The bed should not be placed near the radiators of the heating system.

- Don't forget to change your bedding.

As you can see, making a baby bed yourself is a completely feasible task. Of course, a lot depends on both the idea and the possibilities (including material ones). Nevertheless, if you really want to, then the sudden idea of how to make a car bed with your own hands can take on a completely real embodiment. Moreover, if she will give the child joy and healthy sleep.

Video: do-it-yourself children's car bed