Plywood on the bed under the mattress

When buying a bed, few people think about how the mattress pad is organized in it. Most do not even know what it is. Nevertheless, there is an important point here, since not only comfort, but also the state of health itself depends on how the base of the bed is organized.

Even an orthopedic mattress will not help if the design is designed with mistakes! Therefore, the lamella plays an important role here.

What is lamella in furniture?

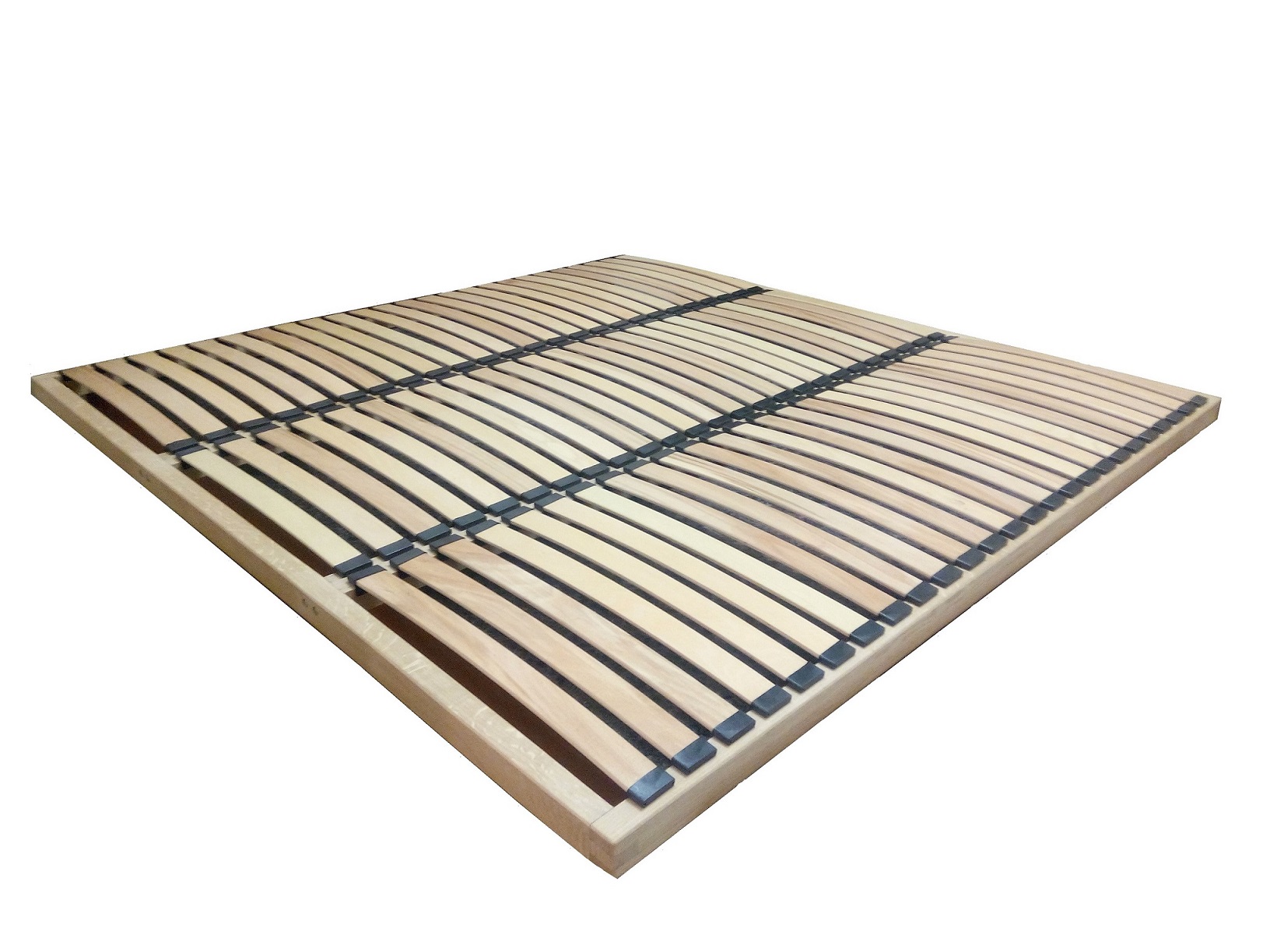

In a general sense, a lamella (latoflex) is a rail. It has a certain range of length and width, just enough not to become a board.

The slats used in the manufacture of furniture are of two types: straight or curved. Straight lines can be made from solid wood such as beech. Curved - are a kind of "pie" made of glue and birch veneer.

The advantages of furniture frames using latoflex include:

- Providing an orthopedic effect even when using conventional mattresses.

- Good resistance to external loads.

- Formation of necessary and sufficient conditions for optimal air circulation in the mattress.

Note! Recently, slats with adjustable stiffness have become popular. In terms of design, they are most reminiscent of vehicle springs.

Optimal distance between bed slats

Since the battens or latoflexes are installed in the frame at regular intervals, a reasonable question arises - what size should they be? Part of the answer to it can be obtained by starting from the design features of the mattress.

So, for models based on springs, the width between the lamellas should not exceed the diameter of these springs. As for orthopedic mattresses, the distance between the batts can be increased.

As a rule, the width of one lamella can range from 3 cm to 7 cm, with a thickness of about a centimeter. Thus, for a single bed in the "lorry" type, about 20 - 25 slats are enough. Although, the principle is often applied here - the more the better.

In the general case, the distance between the battens is taken equal to or slightly larger than the width of the rail.

Additional Information! Sometimes, to enhance the anatomical effect, the base can be made using slats of different widths. Then the distance between them will be floating and is determined by the dimensions of the frame.

What are the slats: the main differences

Most of the frame slats differ in size, material of manufacture and rigidity.

However, there are other qualities that can affect their application in a particular design:

- View. Straight or arched.

- Base type. It can be either plastic or metal.

- Fasteners material.

- Length.

- Colors.

- The ability to adjust the rigidity.

The main thing is that the selected lamellas provide the necessary strength and be flexible enough.

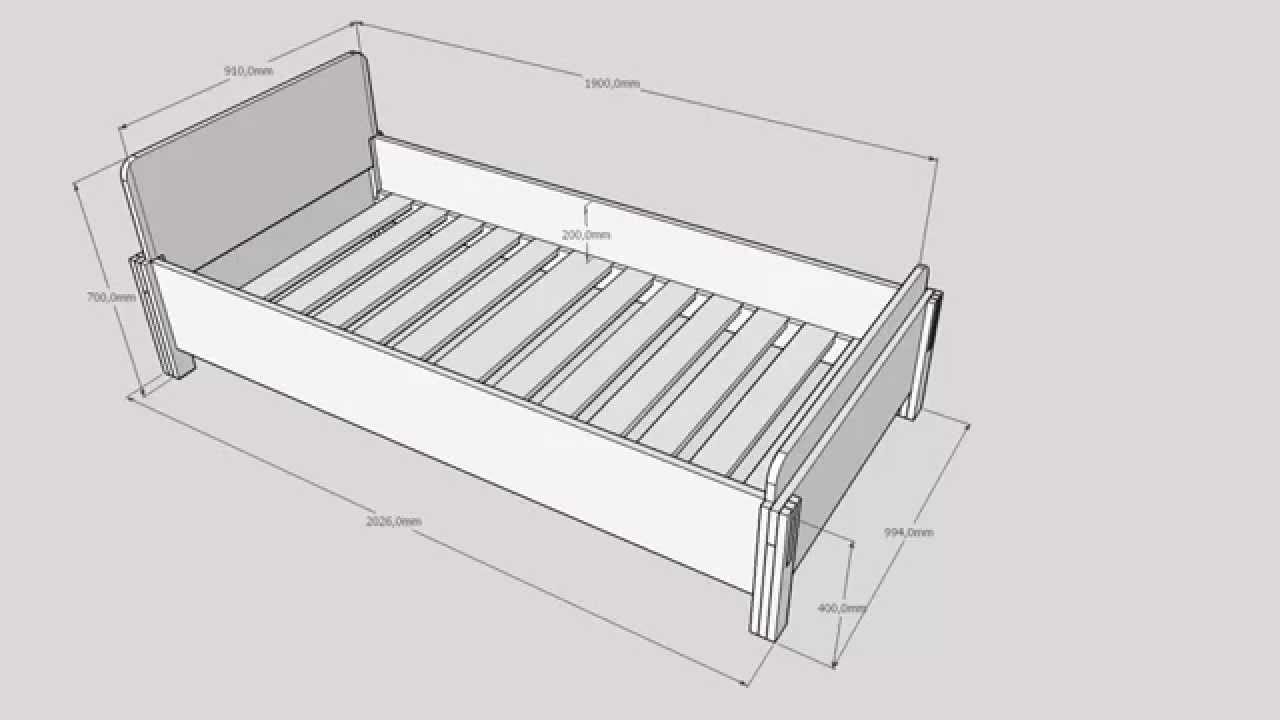

This is especially true for wide double beds, since the permissible load, based on a standard single bed, is no more than 150 kg. Therefore, both the size and the material used are of such importance.

By material

Usually lamellas are made of wood: either birch (flexibility, elasticity, cheapness), or beech (strength, appearance). Pine latoflexes are sometimes found.

By size

Most frames use two types of lamellae: narrow and wide. The former are perfect for almost all models of mattresses, while the latter are mostly for orthopedic.

A typical size for a narrow lath is considered to be a range from 3 cm to 4 cm. A wide lamella can have a width of up to seven centimeters.

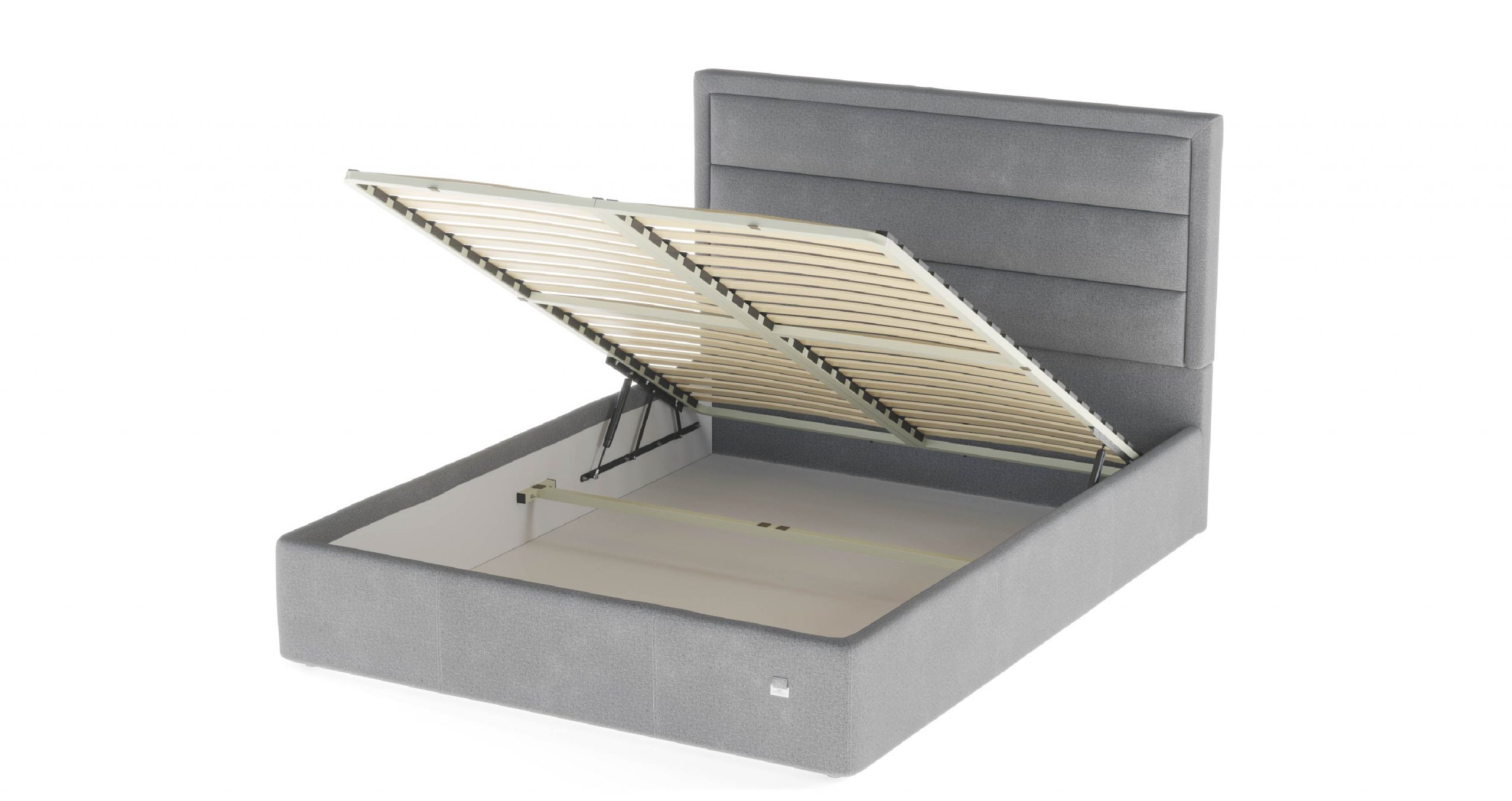

Plywood as a mattress pad

The classic version of the bed base. Differs in both ease of manufacture and greater strength. Therefore, it is used in structures where the lamellae "lose" in ultimate load.

In general, the thickness of such a substrate can vary from 6mm. for single beds, up to 20mm. for structures of the "euro" type.

Additional Information! In the manufacture of the bases, only special plywood is used. Since it is a composite material, it is necessary to exclude the possibility of evaporation of the adhesive layer.

Location features

As a rule, the installation of a plywood base is carried out on longitudinal side arms (long slats), which are attached to the sidewalls. Actually, a plywood sheet is laid on top of them, and a mattress is already placed on it.

If the bed is so large that the size of a standard sheet is not enough, the missing part is added in addition. To ensure ventilation, holes of different diameters and mesh are punched in the plywood, depending on the model of the mattress.

Thus, such a simple thing as a lamella, which is used in the bases for an orthopedic mattress, will provide not only comfort during sleep, but also enable the body to assume a natural position.

Ultimately, this minimizes the risk of all kinds of chronic diseases that arise for this very reason!

Video: do-it-yourself plywood bed