How to make a bed frame with your own hands

The bed is a place for a good rest. It should be comfortable, comfortable, of the right height and structure. WITH

making a base for a bed with your own hands made of metal is not only an opportunity to save money, but also create a solid and practical product made of durable material.

Varieties

Before proceeding to the creation of any product, you need to decide on its type, to decide what it will be. It should be borne in mind that making a bed is not as easy as it seems.

You need to think through everything to the smallest detail. There are two types of frame: wood and metal.

Wooden frame

Wood is an environmentally friendly material. It has strength, durability, practicality, and beautiful appearance. In addition, it is easy to process.

For a beginner, this is the best option.

Metal carcass

The second type is metallic, more laborious, requiring basic knowledge of working with this material. You can ask for a few metalworking lessons from a blacksmith and a welder. This will be required, if you wish, to create not only a metal frame, but also to diversify it with forged elements.

The iron base will last a long time if, after the end of the work, it is treated with anti-corrosion agents, painted. But it should be borne in mind that desire alone is not enough. You need to stock up on the necessary tools and equipment.

How to make a bed frame with your own hands

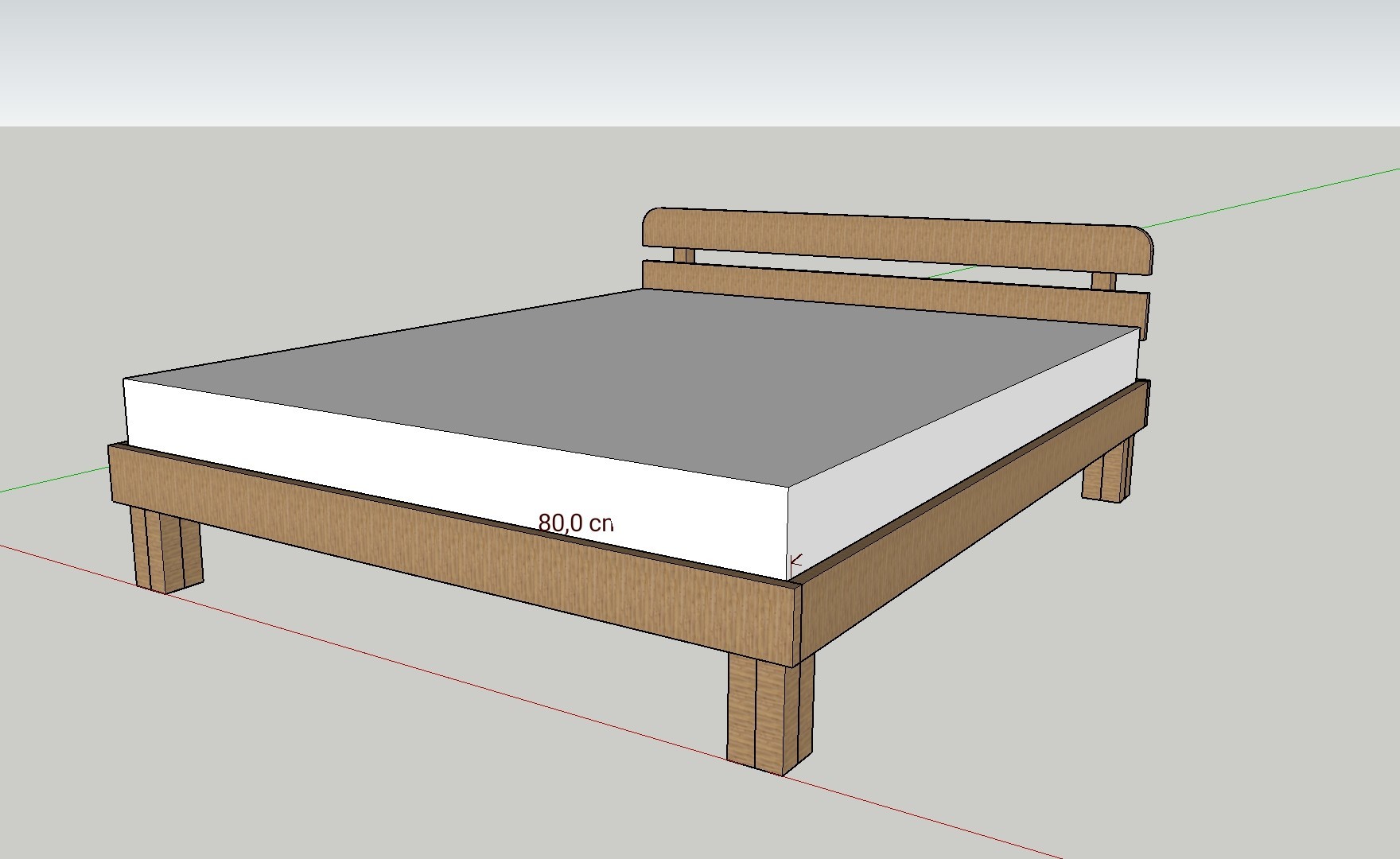

The initial step involves choosing a mattress. It is he who is the comfortable part that ensures good sleep. The base must be made according to the size of this part. When the choice is made and purchased, then you should create drawings of a metal bed with your own hands.

The most important indicator of a good bed is the optimal height from the floor. If it is too tall or too short, it will be uncomfortable to get up from it. Therefore, the selection of this parameter should be individual, in accordance with the height of the person who will sleep on it.

Design

The first stage is creating a project. You need to draw a diagram. All values and parameters are indicated on it. It is important to calculate them correctly in order to get a good-quality product in finished form.

The purchased mattress is taken as a basis. The frame will correspond to it + add an allowance of about 10-15 mm on each side.

You need to choose the type of bed: one, one and a half or double. The best option for sleeping should be 30 cm more than a person's height. The standard length is 2 meters. But you can choose an option from 190 to 215 cm.

The width can be like this:

- Bed for one person - 90 cm;

- For two - 138 cm;

- One and a half - 98 cm.

It should be borne in mind that the parameters of the frame must correspond to the place where the bed will be located.It must be measured beforehand. To these dimensions, you can add the size of the bedside table. It must be borne in mind that free movement along this berth and the ability to stand and lie on it without obstacles is a very important point.

The choice of design is necessary before creating a drawing. The bed consists of:

- frames;

- frame part;

- backs;

- legs or base.

You can add additional drawers or a niche for bed linen to the scheme. It is worth paying attention to the headboard. It carries decorative functions. If you need to forge it, then you need to have knowledge of the forging property. Forged structures can be hot or cold forged.

The final result will weigh about 50-55 kg. The welded bed is connected by welding. At the same time, you can create various types of products related to a specific style. You can create models in modern, loft or classic style.

Choice of materials

The second stage is the choice of materials. For a wooden product, boards should be prepared. For example, use a calibrated, planed board or take chipboard, MDF, pine beams.

Quantity:

- two boards 10x5 cm, length - 245 cm;

- four boards 15x5 cm, 245 cm long;

- thirteen slats 7.5x2.5 cm, length - 245 cm.

For a metal product, pipes made of steel or aluminum are required.

The first type will give the bed extra weight, but for the price it is not expensive. The second type will have a light frame, but it costs more than a steel counterpart. There are modern types of berths that involve the use of a bent metal rod. It can be colored at the end.

Required tools

Before starting work, you need to prepare the tools. For a metal product you will need:

- welding equipment,

- roulette,

- drill, drill bits for metal material,

- Bulgarian,

- square,

- metal brush,

- sandpaper,

- primer for metal surfaces,

- paint or varnish,

- anti-corrosion agent.

For a wooden bed:

- square,

- putty, wood glue,

- drill,

- circular,

- screws,

- self-tapping screws,

- sandpaper,

- paint, varnish, stain.

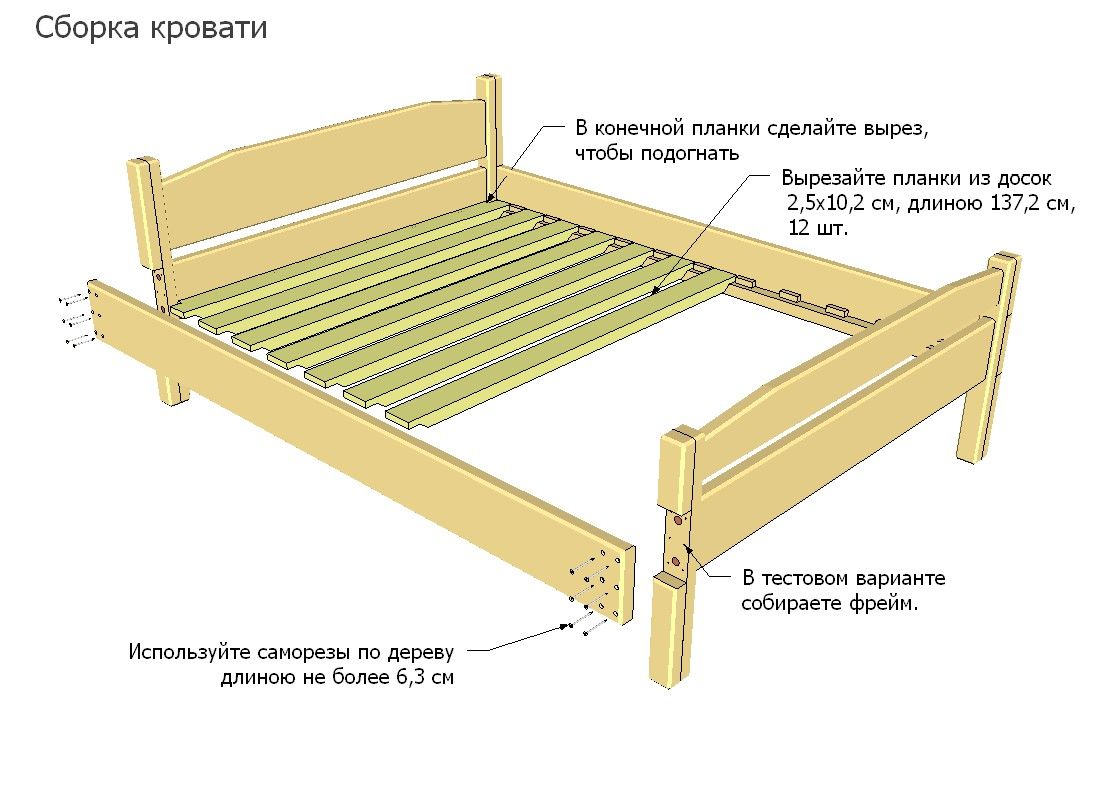

Assembly and installation of the bed frame

The process for a metal bed includes the preparation of pipe blanks according to the scheme. They should be laid out on a flat surface. then fasten these parts by welding. It is important to correctly monitor the angle of the connection, to maintain the desired degree. This will help to flatten the structure.

Next, the grinder is applied. Brackets need to be made. They can be used to mount frames: two central and four side frames. The slope should be maintained at 5 °. Using fasteners, connect the back and the base using a welding machine.

The frame is assembled in the following way: make blanks. For this, channels are cut and connected with a corner. Joints - weld. For the frame, you need to set the backrest vertically. Make grooves at the bottom. To do this, use a drill of about 9 mm. When the holes are made, they need to be adjusted to fit the tenon with a file. A connection to the headboard takes place.

Next, you need to weld the lattice on which the mattress will be installed. It is welded onto the frame. Legs or base are welded. All protruding parts are cut off with a grinder, cleaned with sandpaper. Paint is applied.

The wooden version begins with the fact that you need to retreat from the wall 1-1.1 meters. This will ensure that the mattress is properly positioned. Mark the sides of the end boards. When crossing the lines, you need to fasten the supporting view of the bars. Having created the frame, attach the headboard to it from the end side. For this you need to use slats. Clean everything with a plane, remove dust.

Coat all frame elements with stain. Then apply layers of varnish twice. Then you can attach lamellas or crossbeams. It is better to use self-tapping screws. Attach the legs. These can be planks or planks for a solid base. Paint the product.

Bed decor

The metal version can be decorated with a beautiful headboard. For this you need to use forged elements. If you have knowledge of blacksmithing, you can make graceful curls yourself. If there is no such knowledge, then you can order a ready-made version.

To sketch the finished version, you need to use your imagination or choose a ready-made scheme from the Internet. For a wooden product, you can use a carved headboard. Carpenter's talent can become an assistant in this matter. Painting in the decoupage style will add personality to the bed.

To do this, it is worth using acrylic paints of different colors and napkins specially used for this procedure. Also, to give an attractive appearance, it is worth using stain and varnish. This will make the tree more vibrant.

If you choose a matte varnish, then it will perfectly hide scratches. Glossy varnish will hide irregularities and add brightness to the product. It is also worth painting the product. It can be paint in the natural color of the wood, or you should choose your own option for the existing design of the room.

You can use fabric upholstery. For this, a dense material with a pattern or in one color is selected. Foam rubber can be nailed under the fabric base. To attach, you need to use a furniture stapler or glue.

Features of the frame for a baby bed

A sleeping place for a child should meet the following indicators:

- Environmentally friendly. To create the frame, you need to use only natural material that does not contain toxins, harmful impurities.

- Structural strength. Do not forget that children are very active. They can jump on the bed. Therefore, it must meet these conditions, not bend under the additional loads exerted on it.

- Additional elements. For small children, side walls can be attached to the bed. This will prevent them from falling while sleeping.

- Comfort. The dimensions should be such that the child during active sleep does not fall, does not knock on the walls. It must be borne in mind when choosing dimensions that children grow quickly. So an extra 30 cm in length never hurts.

When choosing a base, it is worth considering the development of the spinal column in a child. You need to choose it in accordance with the standards and orthopedic guidelines. How to select elements for the wireframe:

- It shouldn't creak;

- When choosing lamellas, you need to pay attention to their quality;

- The metal frame must be reliable, without rust, chips;

- In the manufacture of wooden products, they should be thoroughly cleaned, varnished, and made reliable.

You should take care of the quality of the fittings.If the bed will be a box for linen, then the lifting mechanism must be reliable, fixed in order to avoid injury.

Pros and cons of making a bed with your own hands

Making your own bed is not as difficult as it seems. But it should be borne in mind that this product will be made for individual needs - this is its main advantage. But is it worth trying without experience? You need to consider the merits and demerits.

Pros:

- Saving money. Everyone has come across the fact that a finished product sold in a store or salon is much more expensive than a hand-made one. This is due to surcharges for work, rent of premises for sale, salaries of sellers. When the bed is made in-house, then the cost is taken into account. You just need to spend only on the material.

- Originality and uniqueness of the product. Each result you get will be unique. You can take a ready-made version as a basis and add several elements to it, which your own imagination will tell you. Then such a bed will end up as a unique product.

- Pride in the handmade furniture. It is very important when you correctly approach the manufacturing process, preparation of drawings, the production of the bed itself, and now, finally, you can see what happened, then you can be proud that everything was done on your own. This is an opportunity to show your talents.

Disadvantages: You need to be patient, have a basic knowledge of wood or metal processing.

Video: DIY bed