How to make a clamshell with your own hands

Do you need an extra bed in the house or a weightless crib for a summer cottage? You can do it yourself with a minimum of cost. You will need quality wood, a standard DIY tool kit, and suitable blueprints.

We will tell you how a clamshell is made of wood with your own hands, what types of furniture can be made, what are their advantages.

Pros and cons of a homemade clamshell

An important advantage is the budgetary cost of the product. There is no need to overpay for a unique design, tax and duties. Of course, the material also needs to be purchased, but in most cases, this is less waste than the finished product.

The second plus is the ability to make furniture according to individual measurements and design. Depending on the skills of the master, the clamshell can be simple and functional or original, with a complex decor.

And one more advantage is the guarantee of the quality of the materials used. There are few shortcomings, and for an experienced craftsman, they are completely insignificant. You will have to spend time on manufacturing, a certain set of tools will be required, which may not be in the house.

Varieties of clamshells

You can find several types of clamshells on sale and make yourself:

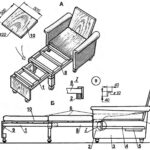

- American - folds in half, reliable and convenient. At the base of the berth there is a spring block. The headrest folds into the back;

- French - a three-part design, in appearance it resembles an orthopedic lattice. The set includes foam rubber and a mattress, 6-10 cm thick, does not have folding headrests, is made of steel pipes;

- Italian - double fold, equipped with a mattress 14-18 cm thick, the most comfortable, equipped with an orthopedic sleeping base made of metal mesh, belts.

The easiest way is to make two-section clamshells yourself. A mattress is bought or sewn separately for them. It is fixed with Velcro or fasteners. When properly assembled, the clamshell can hold up to 150 kg.

How to make a clamshell with your own hands

To make a clamshell with your own hands according to the drawings, you need to choose a model that will be more convenient to make. It is also worth considering in advance what materials the furniture will be made of, choosing a comfortable mattress and finding all the necessary tools.

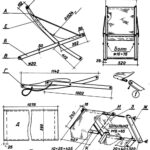

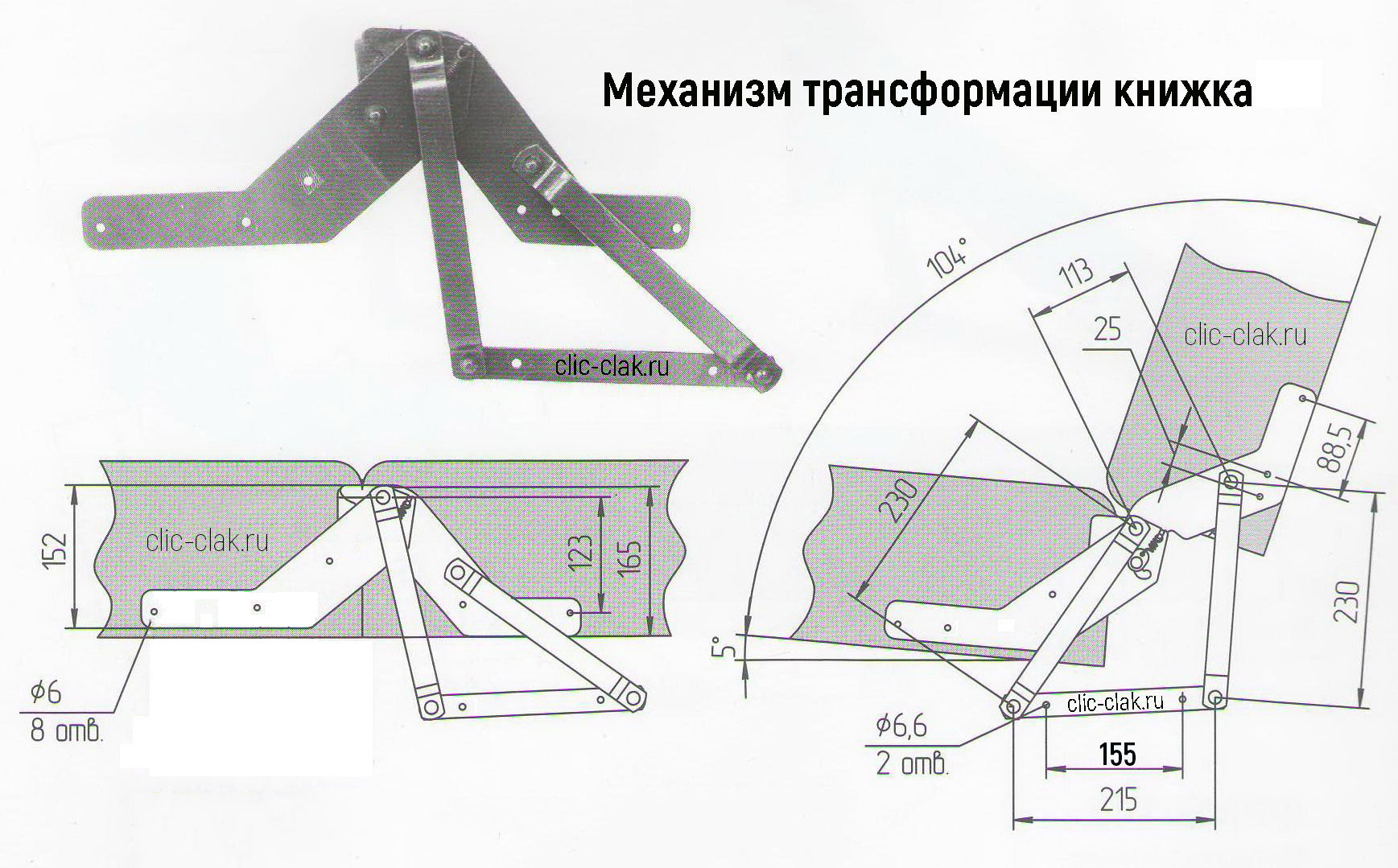

Drawing

The easiest way to make your own folding beds is from MDF or wood. You don't need complicated equipment and tools to work.

The drawings show the standard dimensions of the product, but if necessary, they can be changed to suit individual needs.

Selection of tools and materials

Folding beds are made from metal pipes, wood or chip materials.

Among the latter, preference should be given to MDF. It is malleable in work, inexpensive and suitable for a novice master.

What tools will be needed:

- circular saw;

- grinding angle;

- sandpaper;

- drill;

- tape measure, pencil.

Important! Use personal protective equipment - gloves and goggles.

Manufacturing process

Work begins with the preparation of the study of drawings. Ready-made templates need to be printed or transferred to paper by hand, to make calculations of materials (with a margin). Only after that you can start assembling the structure.

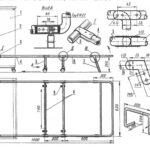

The first to go to work are supporting boards equal to the length of the mattress. They need to be cut out in accordance with the dimensions of the berth. The sides of the folding bed are made of them.

Important! The cross bars should be slightly longer than the width of the mattress.

The lamellas (slats) of the bed base are connected to the sides with self-tapping screws. Then the back wall is attached to the structure. The next stage is the manufacture of a shelf to which the base will be attached. It is mounted inside the box with props.

The box for the mattress is made of MDF with dimensions of 10x145x198 cm, you will need 2 end and side boards, pre-connected with self-tapping screws. Attach the frame to the middle of the bottom. After completing the assembly, sheets of plywood for the base are mounted to the box.

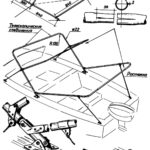

The next stage is the manufacture of supports. They are made of a bar with a section of 40x100 mm. The legs are attached with loops to the bottom of the structure. Any convenient folding mechanism can be chosen in such a folding bed.

Important! At the assembly stage, check the serviceability of the folding mechanism.

The clamshell can be considered finished. All that remains is to decorate and add useful accessories.

Advice. You can hide the supports from the timber with the shutters of the blinds. Another option is to make extendable legs.

In order for the folding bed to take up a minimum of space when closed, not to unfold and to be convenient during transportation, it is recommended to install a decorative latch.

The finished product can be painted, varnished or decorated using one of the decorative techniques (painting, decoupage). A ready-made folding bed will serve as an additional place to sleep at home, as well as a comfortable chaise longue for a summer residence.

Video: do-it-yourself compact clamshell