Features and purpose of lamellas

Beds with a mesh base today have almost completely given way to a more comfortable alternative - beds with an orthopedic frame. The basis of such models consists of straight or curved lamellas, which have a beneficial effect on the health of the spine.

What is lamella

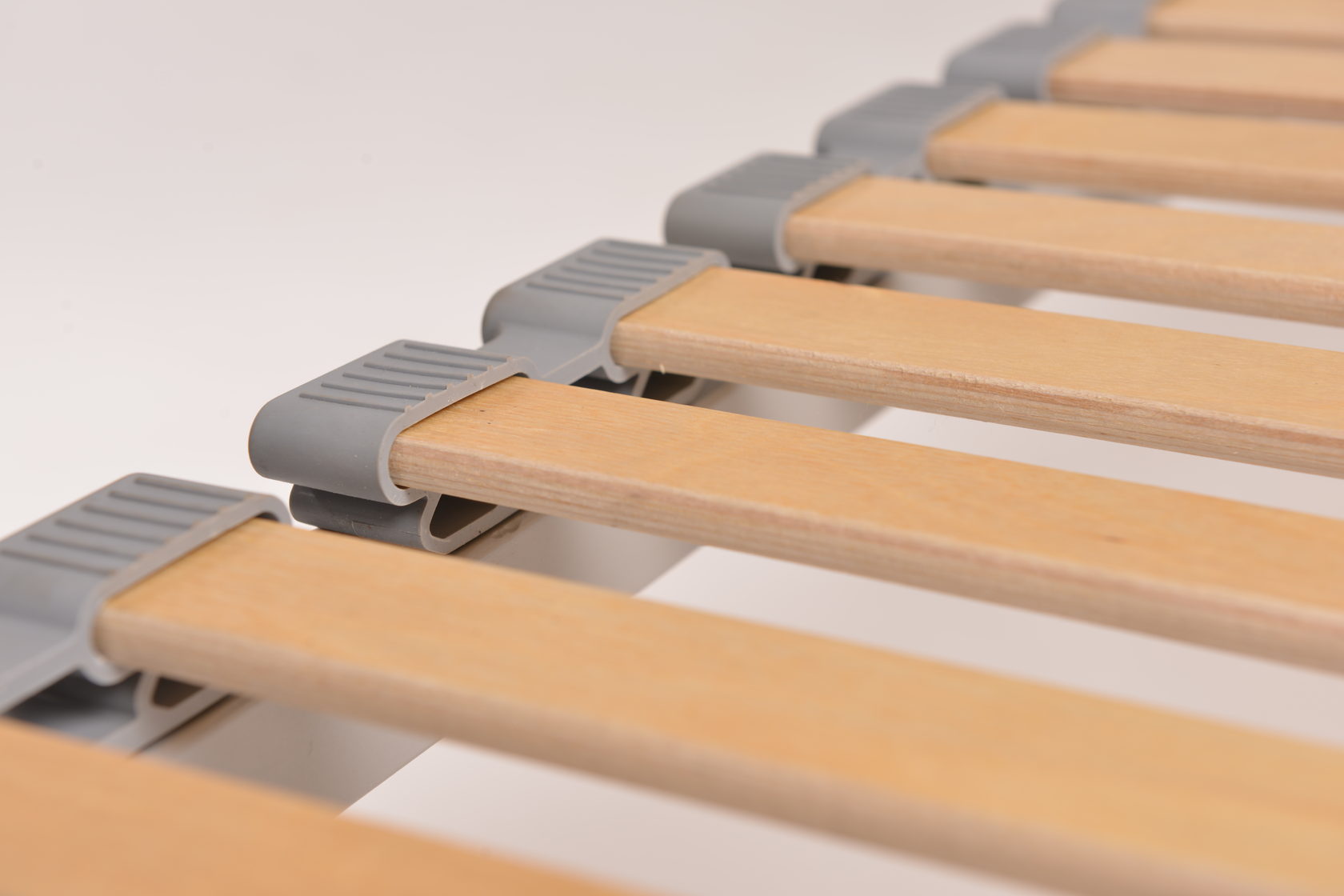

Otherwise, the lamellas are called lats or slats and look like a set of slightly curved planks. This design forms an elastic lattice with a springy effect, on which the orthopedic mattress is placed. Parts can have various fasteners, although most often rigid fastening elements or strips on the tape are used.

Note! The orthopedic bed base, which has a rigid structure, significantly extends the life of the mattress.

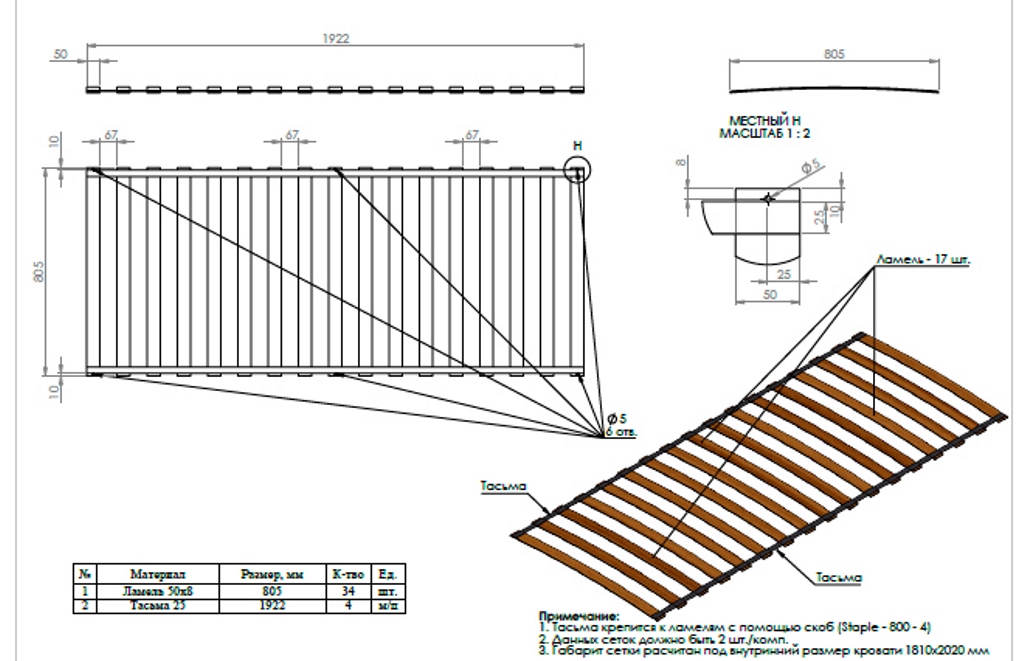

The thickness of the plates varies from 1 to 10 mm, the width is from 25 to 120 mm. During laying, their distance can reach from 2 to 6 cm. In the designs of double beds, two rows of slats are provided for each of the sleeping people.

The use of frequent stacking allows you to ensure maximum reliability of the structure, so that the bed can be used even by people with significant weight. The greatest distance left between the lamellas is chosen in case of light loads on the mattress. A standard structure for a double bed frame with dimensions of 160x200 cm is a structure with 30 crossbars. With a smaller number of them, the required strength is often not achieved. The minimum number is 22 lamellas in the case of a double base.

When choosing a bed or a base for it, it is necessary to study the possibility of purchasing accessories in case of damage or breakage of any elements. The fittings consist not only of lamellas, but also of lat holders, transformation mechanisms and gas lifts. In case of improper use of the orthopedic base, it can be damaged, and then the lamellas can be replaced with your own hands.

Note! Often the breakage of lamellas occurs in the case of overdried indoor air, which leads to the drying out of the wood. To avoid this, you can regularly clean the surface of the battens with a damp cloth.

What slats are made of

For the manufacture of lamellas, only well-dried high quality wood is used. During production, the wood mass is sawn into separate layers, which are impregnated with glue at a specific temperature, which gives them a slightly curved shape. A significant characteristic of the products is their elasticity, which is ensured by the homogeneous distribution of wood fibers.

For this reason, not any tree is used for production, but only:

- Birch. It has a white wood with a slight red or yellow tint. For production, an array of 15-40 years is used.Fibers with a high uniform density are arranged confused, which provides a high decorative effect of the texture. Birch products have high strength, bend easily and undergo various treatments.

- Beech. This is a fairly expensive material. Its array is white with a yellow or red tint, while the annual layers are clearly visible. The wood is distinguished by its high resistance to deformation and the ability to firmly hold fittings. Due to its natural elasticity, it is often used in the production of bent elements. Beech is resistant to changes in temperature and humidity, medium-resistant to decay.

- Ash. Differs in durable and resilient wood, products from which it is difficult to split. The color of the array is light, the heart-shaped rays are not visible. Subject to high-quality drying, the material is almost unaffected by external factors and is easy to process. It has low thermal conductivity, which makes it possible to place it next to heating devices. Ash products are quite expensive, and the massif is mainly used in exclusive products.

Note! Ash is often used to make additional decorations, such as a carved headboard or bedside lamps.

- Poplar and linden. They have similar characteristics. Wood of both species has a low cost, medium strength and softness. The dried massif is well exposed to various treatments and staining. Linden and poplar products are impregnated with special protective agents, which ensure the possibility of operation at high humidity.

- Maple. This is a noble variety that is actively used in the manufacture of furniture. It is used for the manufacture of the headboard, frame and slatted base. The density and strength of the material is determined by the type of maple. Wood has elasticity and toughness, which allows processing products in various ways. Due to the significant hardness of maple, fittings and fasteners are extremely secure in it.

To further protect products from moisture changes, they are opened with varnish.

There is also an alternative to wooden lamellas - metal slats. They retain their rigidity throughout the entire period of operation, but they have significant weight. Metal slats hardly bend under the weight of the mattress, which reduces its orthopedic properties.

Note! When using a metal base, the problem of squeak of lamellas is completely eliminated.

If the steel has an anti-corrosion coating, then the base can be used at different temperatures and humidity. Metal bars are required less than wooden ones: 8-10 pieces are enough for a single bed, compared to 14-15 in the case of wood. Metal battens are almost never used for beds equipped with a lifting mechanism, due to their significant weight.

Pros and cons of slats

The following advantages of lamellas can be distinguished:

- strengthening of the orthopedic and anatomical effect of the mattress due to the elastic base;

- ensuring natural air exchange due to the gaps between the slats;

- an increase in the service life of the mattress due to the acceptance of a significant part of the load by the lamellas;

- the possibility of easy replacement of strips;

- long period of furniture operation;

- noiseless design, provided by special holders used to fix the plates;

- low cost of slats, which has little effect on the final price of the bed;

- ease of cleaning due to the high base.

There are also a number of disadvantages:

- the possibility of conflict with mattresses, which are equipped with thin flooring protection and springs of small diameter, since in this case the springs can be pressed into the gaps between the slats;

- small selection of models;

- lack of protection from the bottom of the mattress from the smell of things from the pencil case, moisture and dust accumulated under the furniture.

What are lamellas for?

The main functions of the rack base are as follows:

- Ensuring high-quality ventilation of the mattress. Due to the large amount of air entering the gaps between the battens, it is possible to constantly maintain the optimum temperature at the points of contact between the mattress and the body.

- Providing the most physiological position of the mattress. This is achieved due to the elasticity and flexibility of the slats, as a result of which a person is guaranteed sound sleep and quality rest.

- Even distribution and reduction of the load on the mattress. This allows you to significantly extend the period of its operation.

Note! The use of a slatted frame reduces the likelihood of the growth of pathogenic microorganisms that can appear inside the mattress.

How to choose the right one

When choosing a bed with a slatted bottom, consider the number of slats. The wider the bed, the more planks should lie at the base. The optimal number of slats for a bed with a length of 190-200 cm is 20-22 pieces. If there are more slats, then the bed will become more plastic, softer and more functional, it will be able to withstand the greater weight of the mattress.

It is also important to choose the material of the slats. The most affordable option is birch, which is not inferior in strength to harder wood. Birch slats are installed in economy-class products, less often in the middle segment.

Note! When buying a double bed with a width of 140 cm or more, you should choose a model with a slatted bottom, divided into two halves. This will allow you to create your own base for each berth. In this case, shorter strips will be used.

Anchor

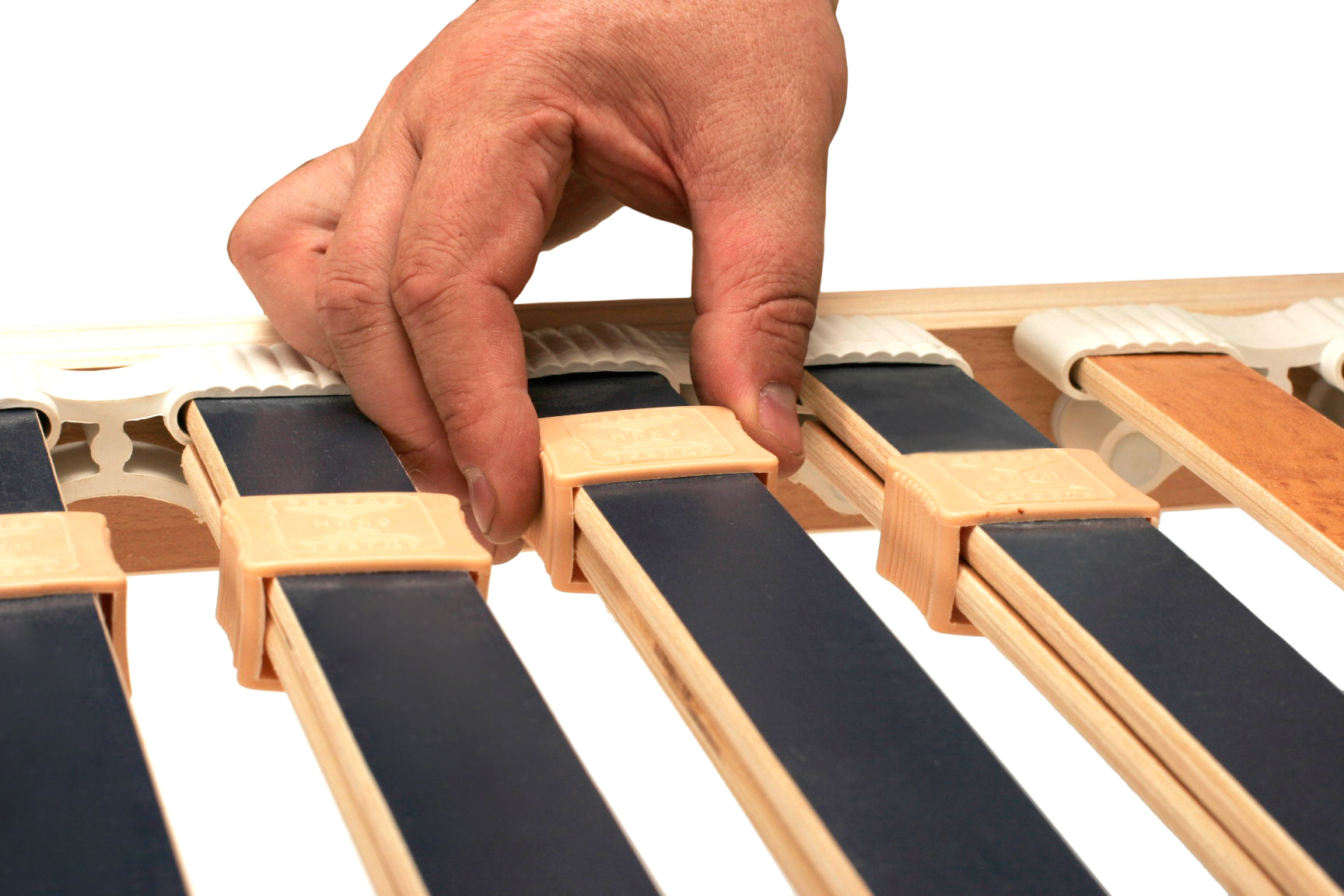

The bed slats are attached using a tip holder, which can be made of plastic, rubber or polypropylene. The holder is fastened using rivets and staples. In some cases, fixation is provided in special pockets, which are made at the base of the frame.

Take off

If it is necessary to repair the bed frame, then to dismantle the plank, it should be bent towards the bend until it leaves the groove, and then moved to the side.

Note! In the event that the rail breaks, it should be replaced, rather than trying to glue it.

To dismantle the lamella fixed by the holders, you will need pliers, a hammer or a screwdriver. To facilitate removal of the holder, first remove the damaged rail. Dismantling is carried out based on the type of holder and the method of fixation: it may be necessary to remove the brackets, remove the pins or unscrew the screws.

Change

New lamellas should be purchased from specialized stores. It is important that these planks are the same size and material as the others. Installation of new parts is carried out in the same way as installation.

Which slats are better - narrow or wide

All lamellas can be divided into:

- Wide strips (from 50 to 70 mm). They are optimal for mattresses equipped with spring blocks or latex springless products. They are mounted at a distance of 4 to 6 cm from each other. Wide lamellas are convenient to use on the tape, since, in the event of a change in the length of the frame, they can be brought closer or removed.

- Narrow beams (30 to 40 mm). They are used for mattresses with independent springs with high density. The lattice of frequent narrow slats is used for folding beds, cots and transforming beds.

Important! The distance between the narrow strips should not exceed their width.

How to make lamellas with your own hands

To make lamellas you will need:

- birch plywood or mounting rails with a thickness of 1.5-2 mm;

- cutting tools;

- fastenings for lamellas, preferably polypropylene or rubber.

Note! Choose smooth birch plywood with no roughness or knots to avoid the need for additional processing.

Before you make the slats for the bed with your own hands, you need to create a drawing and cut out parts of the same size. After that, a fastening cap is put on them, together with which the slats enter the base of the bed.

The base with lamellas is a comfortable orthopedic construction that provides complete rest. With the right choice of the number of slats, you can significantly improve the quality of sleep and recovery of the body.

Video: what are lamellas and what types are there