Features of the lifting mechanism for the bed

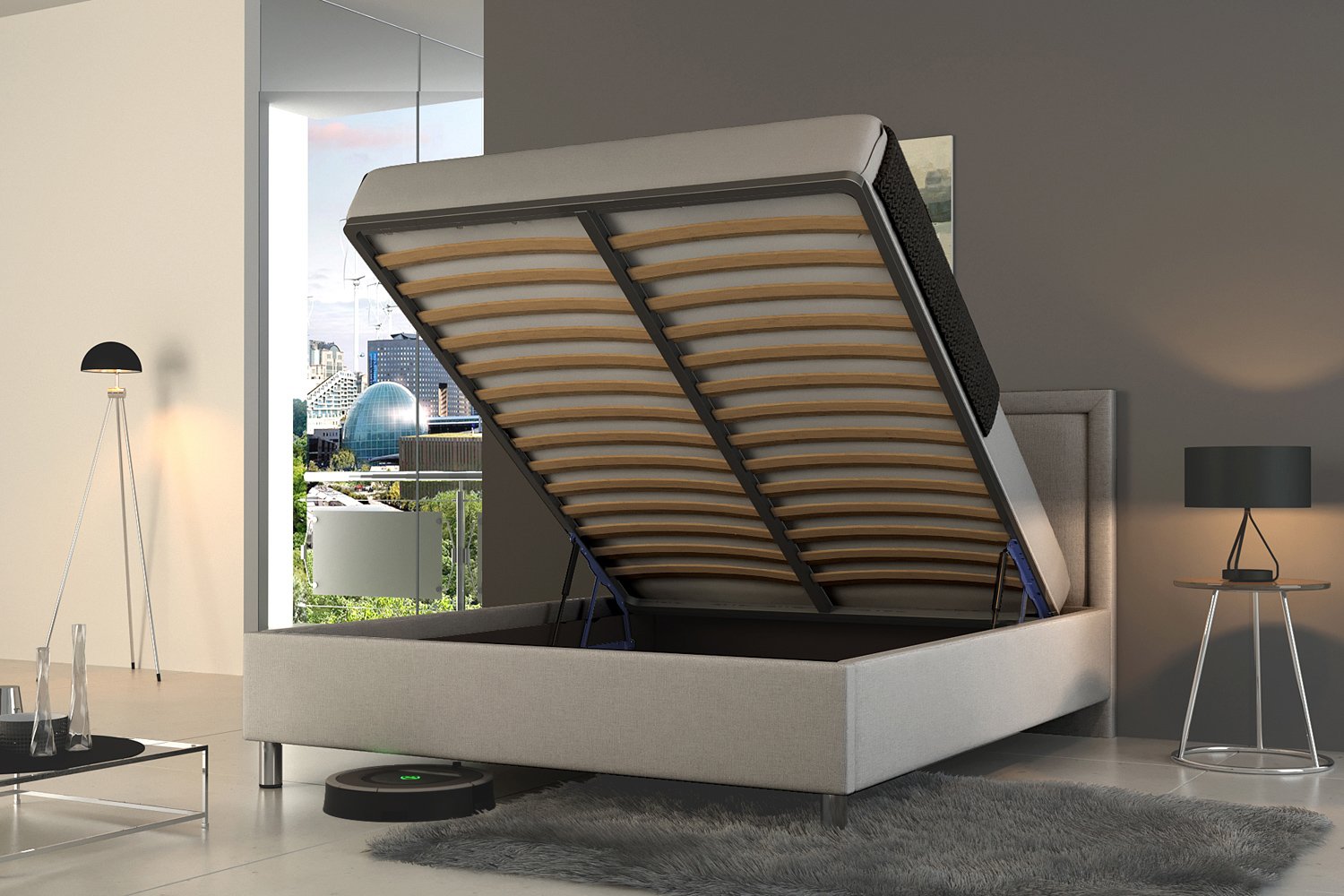

In an effort to optimize the free space in a modern apartment, it is not at all necessary to become an adherent of asceticism. It is much better to create a system in which each thing will be strictly in its place. However, in order to achieve this, you will have to use all available resources: a locker, a curbstone, shelves and even ... a sleeping place, which has a built-in mechanism for raising the bed on gas shock absorbers. Due to its large footprint, such a bed can be an excellent solution for putting things in order.

- Principle of operation

- Types and varieties

- Lift beds: advantages and disadvantages

- How Do I Pick a Good Gear?

- DIY mechanism: what is needed for this?

- Installation specifics

- The need for dismantling and its features

- Choosing a bed with a lift mechanism

- Video: installing the lifting mechanism on the bed

Principle of operation

All modern beds with a lifting function work on a similar principle - the base is pulled away, it is raised to a certain angle and the position is maintained using both muscular strength and special braces.

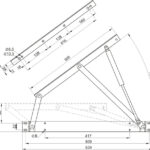

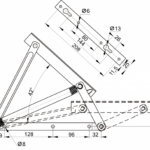

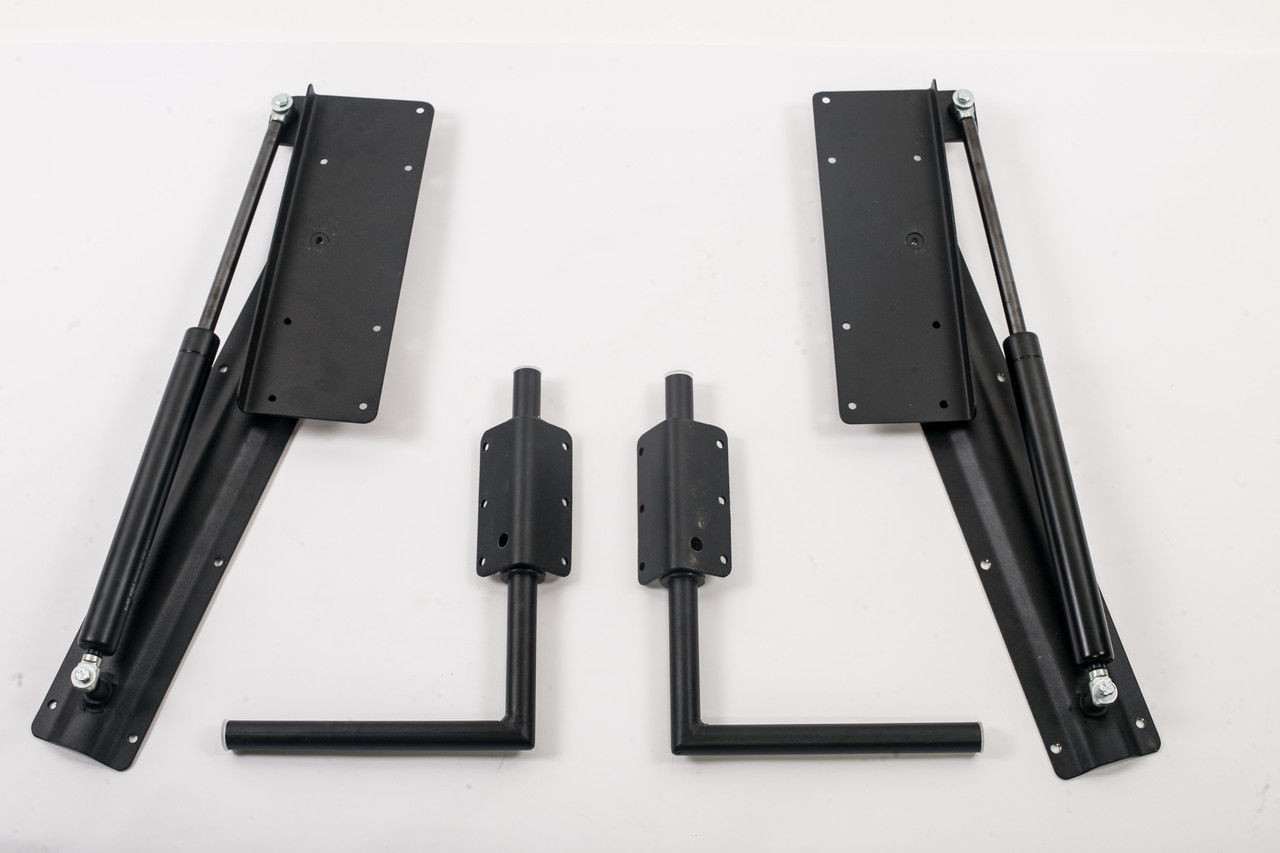

The structural scheme of most mechanisms is approximately the same: there are two metal plates, an upper and a lower one, which are attached to the base and side of the laundry box, respectively. The connection of these plates is carried out using a special rod (or rods - there may be several of them), the location of which forms an arc of opening.

Important! In most cases, such a mechanism is equipped with a force compensator to make the base easier to lift, but in the cheapest versions it is usually absent.

Types and varieties

Today, in many multifunctional beds, a mechanism can be built in, made according to one of three common design schemes:

Manual lifting hinges

This design involves lifting solely by muscular strength. Considering that on the base there will be a mattress, a bedspread and, often, pillows, then significant effort will be required. This solution assumes the presence of only a ratchet, which allows you to fix the opening angle - neither springs nor a shock absorber are provided here.

Spring compensator mechanism

This option is structurally similar to the manual mechanism. The key difference here is the presence of a compensating spring, which, when the substrate is lowered, is in working condition (stretched). In the process of lifting, the spring begins to compress, which partly reduces the amount of force applied.

Gaslift

So in professional jargon is called a gas shock absorber, which is installed to remove part of the force when lifting the base, as well as - as an end position lock. Unlike the previous case, this solution allows you to easily and smoothly transform the bed.

Lift beds: advantages and disadvantages

Most of the benefits of roll-top beds can be attributed to any type of opening mechanism.Therefore, it makes sense to highlight the positive points common to all structures:

- Compactness. Sheets, blankets, pillows and clothing are stored under the bed, freeing up space elsewhere.

- Low noise level.

- Ease of operation.

- Reliability. Especially in solutions where gas lift is used.

- A wide range of bed frames. You can choose a bed with a lifting mechanism for every taste and budget.

- Ease of maintenance.

There are also disadvantages, and they are characteristic of all options:

- Small clearance between bottom and floor surface. If dust accumulates under the bed, removing it from there is a rather laborious task without rearranging.

- Lack of mobility. Due to its dimensions, such furniture is placed in one place for a long time.

- Sagging. Cheap foundations begin to weaken over time, which affects the use of the structure as a whole.

Moreover, each version of the lifting mechanism has its own pros and cons.

Manual

The advantages include simplicity of design, reliability and ease of maintenance. As for the shortcomings, it is one here, but significant - the applied force required to lift the base.

Spring loaded

The advantage of this solution is the presence of a compensating effect that allows you to relieve some of the load (muscle strength) during the operation of the mechanism. The negative side will be the need to periodically replace the springs (over time, they lose their original stiffness, stretch), as well as the complexity of the installation, the adjustment of the compression force and the increased noise level.

Gas bed lift

The advantage of gas shock absorbers is smoothness during operation, lack of noise, unpretentiousness and durability. Of the minuses, it is worth mentioning a small stroke, a decrease in efficiency at low temperatures, the impossibility of repairing at home.

How Do I Pick a Good Gear?

If you are going to purchase a bed with a rising top, in addition to other selection criteria, you should also pay attention to the installed lifting mechanism. In doing so, it is recommended to consider the following:

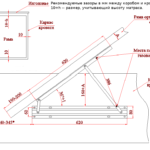

- Compression force. Determines the amount of force required to raise or lower the base, along with the mattress and bedding.

- Number of expansion joints. Usually mechanisms using springs or gas shock absorbers are installed on both sides of the box. This allows the applied force to be reduced at the moment of opening and the power requirements of the spring or gas lift.

- Opening angle. Most often, this parameter directly depends on the capabilities of the compensating element.

- Workmanship. The ease of use and durability of the mechanism directly depend on the reliability of the fasteners. Therefore, it is advisable to reject options using cheap designs. Better to give preference to German or Italian manufacturers.

Important! Usually, the power of the compensator is indicated in newtons (N), while for springs it is determined by its stiffness, and for gas lift - by the pressure in the cylinder. For a single bed, this value starts from 300N, however, depending on the design, it can reach 2kN.

DIY mechanism: what is needed for this?

The simplicity of the basic design suggests that such a mechanism can be made by oneself. This is partly true, but only if you have experience with metal, a drilling machine and a welding machine.

If we talk about manufacturing in the context of the general principles of work, several key points can be distinguished:

- Drawing. Design features such as the width of the flange of the base plates, the lengths of the rods and the distance between the holes are calculated depending on the point of application of the load, its nature (point or distributed), as well as the position of the axis relative to the center of mass of the entire structure. If such calculations are difficult to do on your own, it is recommended to look for the most suitable ready-made solution.

- Construction type. The manual version is the easiest in terms of manufacturing. However, if you want to install a compensator, here the choice is obvious - a gas shock absorber. Installing a spring implies an accurate calculation of its stiffness: weak - will not hold the base, and too rigid - will require significant efforts when opening. In addition, it may simply not be in the store.

- The nature of use (intensity). This will determine how powerful (reliable) the mechanism is needed.

Installation specifics

Based on the similarity of the schematic diagram and design features of most lifting mechanisms, we can offer a kind of universal approach regarding their installation:

- Frame preparation. First of all, you need to assemble the bed frame. In this case, it is enough to prepare the box (linen box) and the base for the mattress. At this stage, they will be separate elements.

- Assembly of the mechanism. If it is a purchased product, it may either already be assembled or must be accompanied by instructions. For a self-made mechanism, one should adhere to the considerations on the basis of which the design was developed (the assembly may include some nuances that are characteristic only for a particular case).

- Actually, installation. First of all, the mechanism is fastened to the sides of the laundry box. For the typical version, this is done on both sides. At this stage, it is necessary to strictly maintain the alignment along the landing points, otherwise, when opening, you can get not only vertical movement, but also rotation around the conditional center between the supporting side plates. The base is attached to the counterpart of the structure.

- Functional check. Here it is required to evaluate the operability of the mechanism as a whole: lifting the mattress pad, keeping it open, smooth running, the presence of beating or backlash.

The need for dismantling and its features

In most cases, disassembly of the mechanism as such is not necessary. Even when transporting furniture, it usually remains folded on one of the parts of the frame. However, there are a number of circumstances that may require intervention in the design directly:

- Spontaneous change in the position of the base.

- Jamming (jamming) of the mechanism, change in behavior during operation, different from the typical one.

- Squeaks, horizontal displacement, beating or friction in a certain place.

As a rule, such symptoms are signs of a malfunction of the lifting mechanism. To dismantle it, you need to free the bed from all that is superfluous, remove (unscrew) the base and, having gained access to the mechanism, conduct an inspection of the condition.

Choosing a bed with a lift mechanism

When choosing a bed equipped with a lifting mechanism, you need to pay attention to the following:

- Workmanship and construction. No beats, jerks, squeaks, backlash.

- Strength of the frame: matching the linen box to the base used. A good frame should not bend or sag.

- The type of the base itself. It is best to choose the option designed for an orthopedic mattress - it allows you to more evenly distribute the load.

- Materials and content.

- Ease of use.

The use of roll-top structures can be a great help for residents of small apartments or adherents of minimalism. It can also be a good option for those who live alone - everything you need will fit in a linen drawer. Therefore, if there is such an opportunity, it makes sense to give preference to just such a solution.

Video: installing the lifting mechanism on the bed