Assembling the bed with a lifting mechanism

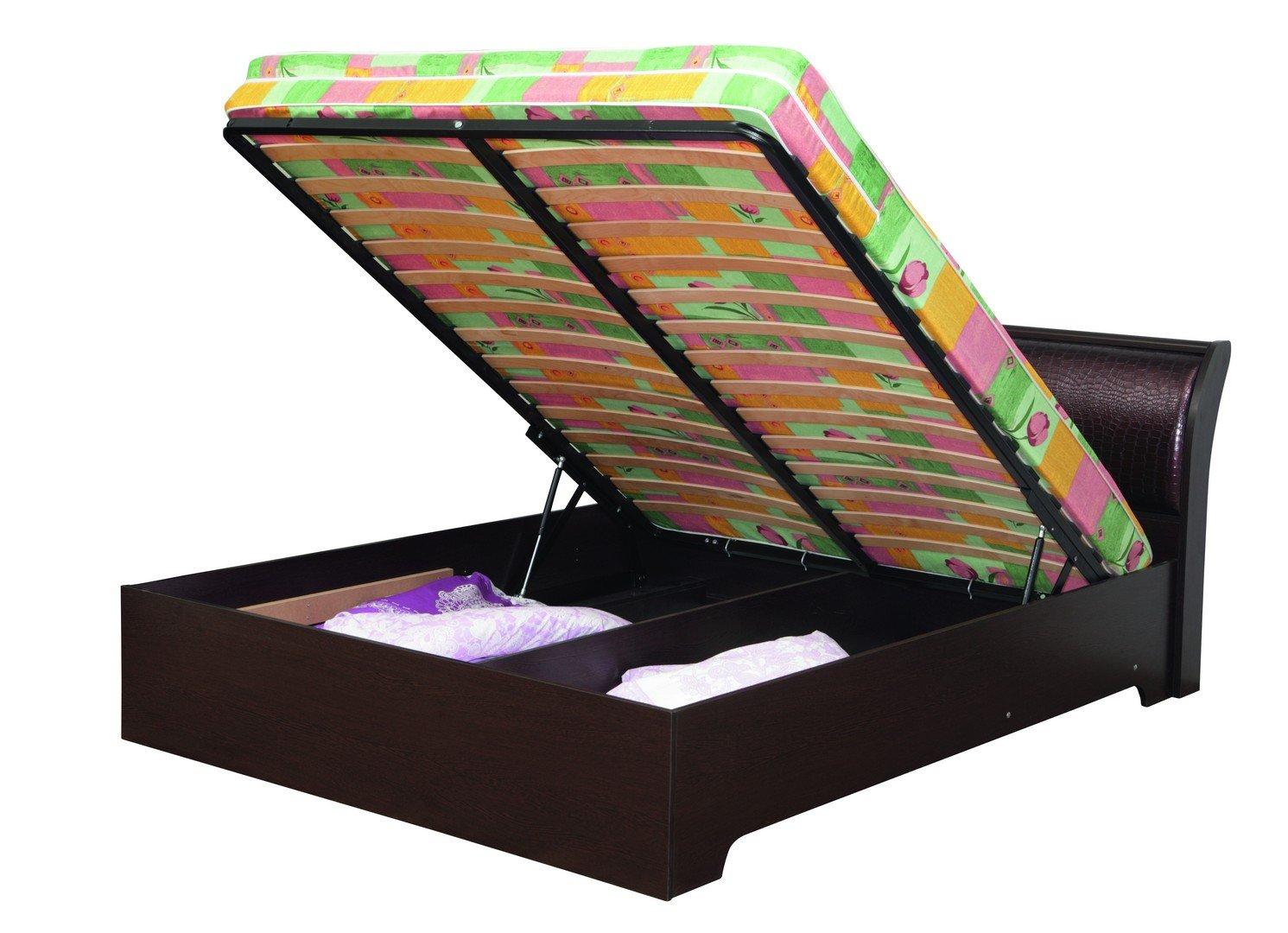

A real find for small apartments - beds with built-in drawers and a lifting mechanism. In the niches under the bed, you can store bed linen and other bulky items. And the most convenient thing is that you don't have to pull out the drawers and scratch the floor with the rollers.

After all, you can get access to the inner content with one movement of your hand. We will tell you how the bed lifting mechanism is assembled at home.

- Advantages and disadvantages of a bed with a lifting mechanism

- Features of the lift bed

- How the lifting mechanism works

- Varieties of lifting mechanisms

- How to choose a bed with a lifting mechanism

- How to assemble a bed with a lifting mechanism with your own hands

- Common problems and errors

- Video: assembling a bed with a lifting mechanism

Advantages and disadvantages of a bed with a lifting mechanism

The main advantage of these beds is space saving. There is enough space in the sections under the berth for storing bulky items. Partially such a bed can replace a wardrobe. Due to the fact that the access to the inner filling is carried out by raising the top bar, there is no need to free up space next to the bed in order to slide out the drawers without hindrance.

Plus, your flooring or carpet won't suffer from casters. Even if you do not use the bed as a storage place, the lifting mechanism will be convenient. Thanks to it, it is much more convenient to clean under furniture.

Do these beds have disadvantages? Alas, the cost of structures is much higher than the price of conventional models without a lifting mechanism. The second nuance is less significant. Dust will regularly accumulate under the bed, so things will have to be stored in boxes or containers.

Features of the lift bed

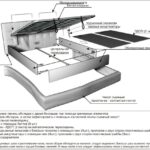

Usually, the most reliable components and durable slats are installed in such beds. That is, the structure was created taking into account all mechanical loads. The furniture consists of a flat base, a niche and a built-in mechanism, due to which the upper part is lifted up or to the side.

In most modern models, a gas lift is installed, but beds with a spring and manual mechanism are also found. Such furniture can be assembled with your own hands: it is not as difficult as it might seem at first glance.

How the lifting mechanism works

Depending on the type of mechanism, the base can easily be lifted or the process will require effort. The berth rises and leans to the side or perpendicularly (to the head).

When the bar is raised, access to the internal filling opens.

Varieties of lifting mechanisms

In modern models, a gas lift or a spring mechanism is more common. The manual system on hinges was popular several decades ago, now such furniture is rare.

Manual

The simplest mechanism without auxiliaries that make lifting the base easier.But at the same time, it is the most durable. Powered by the movement of the furniture hinges. During the lifting, all the weight falls on the hands, so not everyone can access the inner contents.

For a child, this task will be difficult to accomplish. Rough handling may cause deformation of the case. Especially if the bed is made of inexpensive chipboard that cannot withstand frequent use.

Spring loaded

This is a budget option, which is installed in an economy class bed, as well as in some models of the middle price category. When lifting, the weight of the body partially rests on the springs, thanks to which even a person who does not have developed physical strength can cope with it.

However, it will be difficult for the child to lift the base. A serious drawback of the mechanism is its short service life. Typically, manufacturers claim 5 years for the device to remain usable. Then the springs are stretched.

On gas shock absorbers

Gas lift is the most advanced mechanism. Lifting a berth practically does not require physical effort: the bulk lies on the device. Works silently, the base rises and falls smoothly, securely fixed in an upright position.

The mechanism can be installed in any bed. Manufacturers claim 10 years of device life. The only drawback is the high cost compared to other models. But in the long term, the acquisition will be profitable.

How to choose a bed with a lifting mechanism

To choose the right furniture, you should focus on the operating conditions:

- if you do not need to regularly raise the base (for example, things that are rarely used are stored in the bed), you can purchase a model with a manual mechanism;

- spring installations or a model with gas shock absorbers are suitable for regular use;

- for a children's room, it is better to choose a bed with a gas lift, but it is also suitable with a spring mechanism if you plan to change furniture within a few years.

It is important to pay attention to the materials of manufacture, namely, the strength of the lamellas. In budget models, inexpensive chipboard is usually used, which can quickly deteriorate. The best in relation to them will be MDF beds. This material is durable and safe.

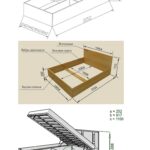

The larger the furniture, the more weight will be placed on the mechanism. According to the standard, such beds are 2 m long and 90 cm wide (single) and 2 m (double). Product dimensions must be taken into account when choosing a mechanism. It is worth checking with the manufacturer for what loads it is designed for.

How to assemble a bed with a lifting mechanism with your own hands

If you select high-quality materials and accurately calculate the drawings, you will be able to assemble a bed with a lifting mechanism with your own hands. For manufacturing, chipboard, OSB, MDF or plywood are used. The body can be made of solid wood, if opportunities allow.

But the lifting bar should be made of lighter materials so as not to put a high load on the mechanism. It is better to opt for MDF: these are safe boards based on shavings and resin, they are durable and easy to work with. It is also important to choose upholstery fabric and filler.

Required tools and fasteners

Before proceeding with the assembly, you need to prepare the materials of manufacture and the necessary set of tools:

- screwdriver;

- grinder with a disc for metal;

- welding machine;

- jigsaw;

- construction hair dryer;

- furniture stapler;

- roulette;

- level;

- pencil;

- steel strips;

- screeds, corners, brackets.

Stages of work

The first step is to cut out the details according to the drawings.

Further instructions for assembling a bed with a lifting mechanism are as follows:

- body assembly;

- installation of legs, corner braces;

- installation of the lifting mechanism;

- frame attachment.

In the first stages, the work is carried out in the same way as the assembly of a regular bed. The only difference is in the installation of the lifting mechanism.

Assembling the base and box

The perimeter of the body consists of a headboard and 3 drawers, which must be connected together with furniture ties or corners and brackets that are fastened with screws. The work is best done with a partner who will hold the parts to be joined.

It is important to check the evenness of the floor: if the bed is installed skewed, the mechanism will not be able to function normally. How to assemble the base and body:

- parts are connected on the floor to avoid distortions;

- use a construction square to align the corners;

- the screed is carried out with building corners, the caps of the self-tapping screws should be slightly drowned in the thickness of the plate;

- the joints are additionally glued;

- cuts are processed from burrs;

- for double beds, it is recommended to make an additional longitudinal stand in the middle.

After assembling the box, you do not need to tighten the bolts immediately. This is done only after leveling the structure. And checking the accuracy of the angles. In the finished box, transverse partitions are mounted, which will create sections for storing things.

This stage can be started if there is no need to create separate “boxes”.

Important! Wooden materials must be pre-treated with wood stain, sanded and varnished after assembly.

The lifting box is assembled according to the same principle as the base. For manufacturing, 3 drawers are used. The base of the bed frame and slats are attached to them.

Installation of legs and installation of corner braces

The legs are attached either to special platforms that are located on the frame elements, or the bars (40x50) are screwed into the structure with screws.

Important! Using the level, you need to determine the height of different sections in order to align the legs in height.

The most important stage in the assembly of the body is the connection of parts with corners. Before fastening, it is necessary to check that all angles are strictly 90 degrees. After joining the joints, it is better to treat with glue, and remove the excess immediately.

Installation of the lifting mechanism

Important! The weight of the lifting bar rests not only on the arms and shock absorbers, but also on the fittings. Therefore, it is necessary to choose the most reliable mounts.

The lifting mechanism can be made by hand, but it is better to order a ready-made one in furniture production or in specialized stores.

How is the installation of the mechanism:

- the upper bar of the mechanism is mounted to the base of the box and the crate of the berth; this will require a metal stiffening bar made of rolled angles;

- to facilitate sliding of the hinges, a lower support bar is attached to the box.

After installation, check the strength of the fasteners and tighten (but do not overtighten) the bolts.

Fastening the frame and mattress holders

With the help of self-tapping screws, slats (approximately 20x80 mm) are attached to the inner side of the lifting bar. They are aligned to the bottom edge of the perimeter.

Slats are laid on the yards, the length of which corresponds to the length of the furniture. They are mounted on support rails in 15 cm spacing. Plywood can be used if the optional center post is installed.

Common problems and errors

The main problem when assembling a bed with a lifting mechanism is non-compliance with calculations and inaccurate connection of corners. It is very important to respect the dimensions of the planks. If it is not possible to cut sheet material at home, it is better to order a cut.

Accurate joining of the corners will ensure the reliability of the structure and the exact fit of the lifting bar to the base. If a lifting mechanism with a gas lift is selected, it is necessary to clarify its reinforcement: for which bed models it is suitable. It is mounted using nuts with a retaining ring and fluoroplastic washers. The cylinder of the mountings should be facing up.

It may be difficult to lift the lifting bar. It could be because the fasteners are too tight. When installing, they must be screwed in all the way, and then slightly loosened in order to obtain a minimum backlash. Then check that the mechanism is working properly.

For the convenience of lifting the slats, it is worth mounting handles on the frame, as well as a mattress stopper. This simple method will make the use of the bed even more convenient. A hand-assembled bed with a lifting mechanism is much more reliable than factory models.

It's all about the ability to choose materials yourself. Such furniture will cost less. Considering that the assembly process is not that complicated, this can represent a significant savings on the budget.

Video: assembling a bed with a lifting mechanism