DIY bed making methods

Self-made bed allows you to end up not only saving a considerable amount of money, but also getting one of the most important pieces of furniture in accordance with personal preferences and needs.

How to achieve the best result in making your own bed, this article will tell you.

Measurement and calculation of materials

Before purchasing material and starting work on assembling the bed, you need to understand how it will look in general. We start planning by taking measurements of the room.

At this stage, you need to have at least a rough idea of the rationality of placing the bed in the existing conditions. Having planned the approximate dimensions of the bed, try to designate them with improvised objects. This will help you understand how appropriate the selected dimensions will look in the room.

After the geometric length and width of the bed have been determined, you should proceed to planning its other parameters. One of these is the presence of a headrest. In this case, it is necessary to additionally increase the height of the wall legs, calculate the width of the upper bar, and provide for partitions. It is recommended to install 3-4 partitions-holders for a pillow 5-10 centimeters wide with a distance of no more than 15-20 centimeters between them on one berth.

If the bed for the bedroom is planned to be equipped with a mattress, it is imperative to take into account its dimensions when calculating materials and measurements.

It is also important not to overlook the calculation of the bed base. Most often, it is played by reiki. The main thing here is not to miscalculate with their load. Understanding what weight and size people will use the bed, you can plan the material for the bottom.

For an average person up to 180 centimeters tall and weighing up to 85 kg, rails with a width of 7-10 ci are enough. and 3-5cm high. with a distance of 5-7cm. between them. If you plan to accommodate larger people, it is better to increase both the width and the height of the slats. If the bed is planned to be a double, the calculation of the slats for the bottom is carried out separately for each sleeping part. It is not recommended to combine both berths with a solid bar, it is better to make them separate with a connector in the middle.

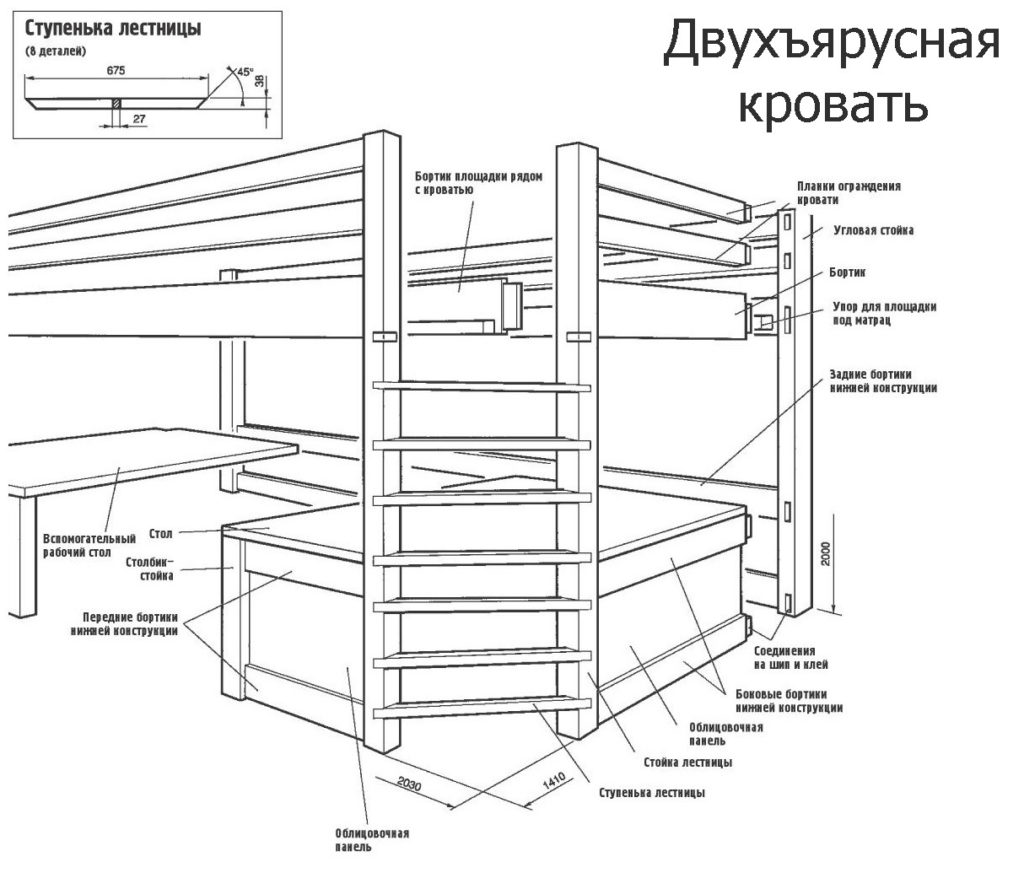

Drawing up drawings and diagrams for making a bed

Drawings will help you understand how to make a bed out of wood yourself. Before purchasing materials and based on the measurements obtained, we proceed to drawing up drawings. The main rule is that such a document must fully take into account the size of all components.

When creating a manufacturing scheme, one should take into account the methods of fastening parts to each other. The base planks are fastened together with furniture screws, the slatted bottom is most often fixed with construction brackets.

Timber selection rules

Properly selected wood is the basis of a reliable and durable bed, especially in the bedroom. Now you can find a great variety of offered breeds, it is customary to divide them into:

- soft;

- solid.

The most commonly used softwoods are pine, spruce, alder or linden. Solid - birch, ash, oak, beech. Alder and pine are low-price materials, when working with fasteners they can crack, therefore, when using them, it is not recommended to use nails, and for screws, pre-drill holes 1 mm narrower than the width of their turns.

Linden quickly loses its qualities due to the fact that this material is negatively affected by almost all external factors - humid and dry air, sunlight. At the same time, such wood is resistant to mechanical damage, therefore, it is most often used for the interior equipment of the bed.

Hardwoods are more expensive than softwoods. Solid oak is considered an elite material. However, when using these materials, you should take into account some features. Ash requires periodic treatment from pests, birch is often affected by a fungus and requires increased attention, beech does not tolerate temperature extremes and can deform from frequent stress.

The optimal choice is a combination of hard and soft rocks, and with a limited budget, of course, you will have to abandon more expensive materials. In any case, wood requires careful handling.

Important! Before purchasing any wood, it is imperative to carefully examine each individual element for signs of moisture and pests.

Necessary materials and tools

Before you start assembling the bed, you need to have the following tools on hand:

- jigsaw or circular saw;

- a set of self-tapping screws or furniture screws of different lengths (most often they combine fasteners with a length of 30 and 60 mm);

- a set of screwdrivers for twisting parts together;

- joiner's glue;

- acrylic varnish or wood stain;

- fine sandpaper;

- Sander.

If you plan to cut the material on a specialized machine, you can cross out the jigsaw and the saw from the specified list. You can also order grinding work.

Sandpaper is useful for finishing small irregularities. And stain and acrylic varnish will help to bring our bed to its final look.

What is needed for the fastening system

Most often, furniture screws are used as fasteners. This is the most reliable and durable method, but if such elements are not available, you can limit yourself to ordinary self-tapping screws. When using them, it is recommended to additionally strengthen the attachment points with metal corners.

The size of the fastener should correspond to the width of the fastened elements and be at least one and a half of the total width for each connection.

The procedure for making a bed

The general procedure for making a bed includes the following steps:

- Drawing creation

- Calculation of materials for manufacturing

- Purchase of materials, fasteners

- Marking, cutting and cutting of material

- Preparation of technological holes for fasteners

- Assembling the frame

- Additional finishing with a grinding tool

- Frame painting

- Bed decor

The stages before assembly were discussed earlier, after observing all the nuances, you can go to the finish line and start assembly.

Before starting work, it is recommended to additionally double-check the presence and sufficiency of the fasteners. To do this, it is enough to lay out on the floor in the order of collection all the fasteners and screws for their assembly. This technique helps to make the assembly in order of priority, excluding possible errors.

After assembling the sleeping frame, you should carry out the finishing sanding. If the bed material is not too rough, regular medium-grit sandpaper is sufficient. If there are areas that require significant efforts to bring to a smooth appearance, it is recommended to use a special tool.

Note! When working with grinders, it is necessary to observe increased precautions, protect hands with gloves.

Having processed the surface, we wipe it with a dry cloth from the remaining crumbs, which may interfere with us at the next stage - painting.

We paint the assembled frame with a brush or with a special spray. There are two options for painting materials - furniture varnish or wood stain. The latter has a watery structure and allows you to give the assembled furniture almost any color. To do this, you need to add the appropriate color scheme to its composition. We apply the resulting color composition of the stain on the surface and let it dry for at least 24 hours in a ventilated area.

Important! The color scheme must be suitable for use on wood surfaces.

When treating with varnish, you must use a respirator, the vapors of this dye are very toxic. Thus, it is recommended to protect yourself even when working in open space. Freshly painted varnish stops sticking after 3-4 hours, the time for complete drying of one layer can be up to 35 hours. In most cases, a single coat is sufficient.

Last of all, we upholstery our bed with decorative materials, if any.

Double bed made of chipboard

The assembly of a double bed has several mandatory requirements. The most important thing is to correctly calculate the maximum permissible load on each of the sleeping parts.

To assemble a bed from chipboard with your own hands, you need dimensional drawings, a project diagram and its sketch. Chipboard is not the most durable material, it is important to additionally strengthen it with wooden inserts. We do this over the entire area of the side walls. Additionally, we reinforce the attachment points of the side parts with metal corners.

We divide the bed into two identical parts, in the middle we start up a strong wooden bar along the entire length of the bed. It is also recommended to split the bed bottom into two parts to distribute the load. The legs of the bed can be made of metal or wood.

Particleboard beds are best suited for adolescents.

Plywood

Even before starting the assembly of a plywood bed, it is important to choose a material with a height of at least 2mm. We process the plywood sheet only with a circular saw, any other tools force the edges of the sawn material to crumble into separate chips.

We mill the plywood edges to avoid injury during operation on a sharp surface. In other respects, assembling a plywood bed is no different from using wooden blocks. In this case, furniture screws or self-tapping screws are used, depending on the width of the plywood used.

From a bar

To make a homemade block bed, it is important to pre-prepare the boards. They must be well sanded and free from the remnants of knots - they are clearly visible visually, and this negatively affects the strength of the bar.

The assembly of the bed should be done with furniture screws. Making a bed with your own hands will not be difficult, if you carefully follow all the tips and recommendations from this article, the main thing is to strictly follow all safety measures.

Video: how to make a bed with your own hands