The device and the choice of table-bed

For small apartments, transforming furniture is the perfect invention. The main goal pursued by the developers of transformers is to save living space. It is very convenient in all respects, the room is not cluttered with unnecessary interior items, but comfort remains.

Versatile furniture is produced in various variations with functionality that matches a specific room. The peculiarity of the transformation lies in the fact that through simple manipulations one piece of furniture turns into another. Many have long been familiar with the armchair-bed, they have probably heard of wardrobes, but the table-bed will surely arouse your genuine interest.

What is a table-bed

Versatility is the main fad of such an interior find as a table and a bed. Two in one, a work area and a place to rest and sleep. Transformation occurs at will, at any time of the day or night, in a simple way, depending on the design of the device:

- transferring the bed from a horizontal position to a vertical one and lowering the working surface of the table;

- by turning the tabletop and bed together, while the writing utensils on the table remain intact;

- pulling out the bed from the niche located under the table top;

- the constituent parts of the transformer change their position and purpose.

The main advantages of the universal convertible table are:

- Rational use of living space.

- Multifunctional purpose.

- The presence of an orthopedic mattress.

- Extraordinary design.

- Reinforced, durable frame.

- Effortless transformation.

- Reliable fixation of the mechanism.

How does it work

The design of transformable miracle furniture for rest and work includes two functional elements:

- The working surface of the table.

- A complete place to sleep.

The table in this design can be of different sizes, but its length is limited by the width of the bed. A table with a length of at least 1.2 m is considered convenient for work. Its height is important, the right choice will provide comfortable working conditions and will not lead to curvature of the spine.

At the base of the bed there is a solid support on which the mattress is fixed. There are two types of bases:

- In the form of a lathing made of wood, metal or plastic. This design is called lamella, it provides good air circulation in the mattress.

- A solid base is made of a solid sheet of chipboard or plastic, it is stronger, but prevents normal ventilation.

Standard bed width - one and a half or double.

Varieties

Furniture transformers for work and leisure, depending on the folding method, are conventionally divided into categories:

- vertical models;

- with horizontal opening.

A characteristic feature of vertical transformation is the combination of 2-3 structural elements. Assembled horizontal models look like a cabinet or chest of drawers.

In addition, there are other transformation formulas, for example, a table with a superstructure. Taking into account the layout, the add-in can perform various functional purposes. Another interesting type of construction is a table with shelves and an attic-type bed.

Transformation options

The main difference between the models of bed-tables from each other is in the variants of their transformation. The main groups include:

- lifting - the table top rises up in such a way that the bed remains under it;

- folding - in such models the bed will rise and the table is folded back instead;

- swivel - transformation occurs by simultaneous rotation of the table and bed;

- roll-out - in this group, the berth is unfolded by rolling it out from under the table top.

There are models in which the transformation, as such, does not occur, and the sleeping place is stationary above the table. To get on the bed, you need to use the ladder, which is either fixed to the body, or unfolds, or attached. The options for such furniture may be different, it all depends on your preferences and how you want to furnish the room.

Can I do it myself

This type of transformable furniture is especially suitable for furnishing a children's room. And space is saved for games, and the unusual design will surely please the child. But even more interest will be aroused by spending time with children in the process of making a transformer in a home workshop.

If you have certain skills in working with wood and a certain amount of diligence and patience, then you can try to assemble such a "folding bed" yourself. It is important to remember here that you will have to combine two pieces of furniture with different functionality. The main difficulties are associated with the correct installation of a complex transformation mechanism, without which the structure will not work.

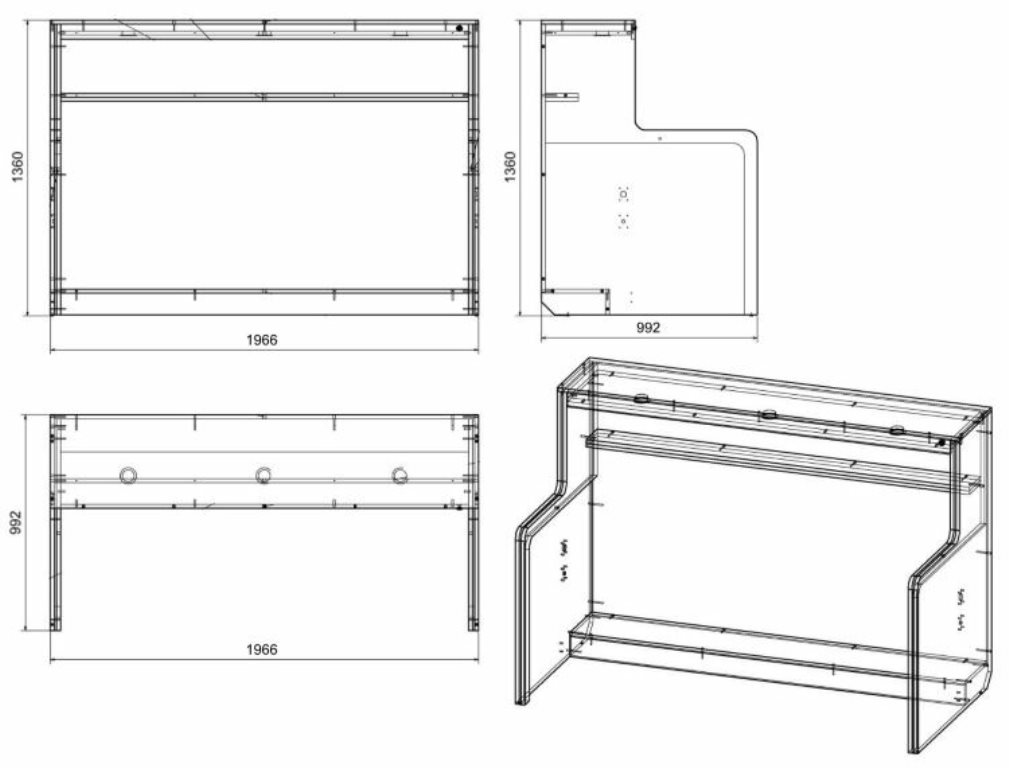

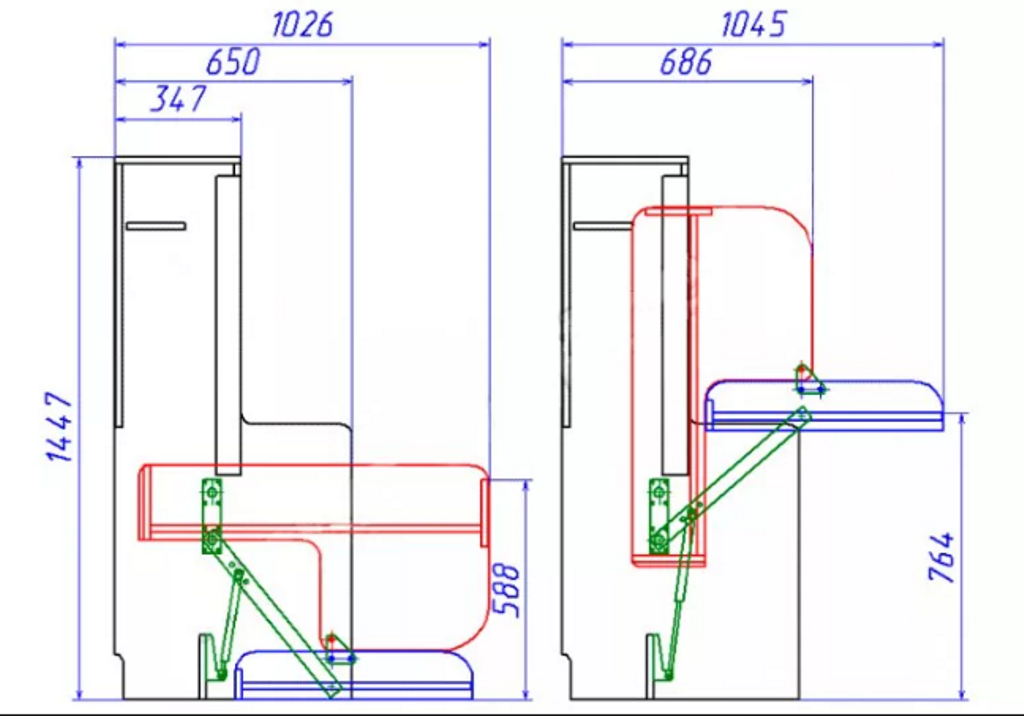

Diagrams and drawings of the table-bed

For self-assembly of a smart bed, you will need construction drawings and a detailed detailing diagram. All this is thought out in advance at the stage of preparation. You can use ready-made developments, which are freely available in sufficient quantities on the Internet.

In addition, the basis of simple options for transformation models of a bed-table is based on the same principle of operation, according to the same scheme.Differences, only in additional accessories: cabinets, folding, side tables, shelves for books. If desired, the finished structure can be equipped with additional elements later.

Necessary materials

The final appearance of the finished product largely depends on the quality of materials and components used in production. To assemble the frame, use the following materials:

- wood is the most expensive option;

- Chipboard - lightweight with a wide range of colors;

- MDF - with characteristics inherent in wood, but cheaper in cost;

- metal profile - high strength, but nondescript appearance.

The main furniture components include:

- The transformer mechanism must be selected taking into account the weight of the person, the functionality of the furniture and the size of the room. Pay attention to the material, all lifting devices must be made of hardened steel with increased wear resistance. Use gas shock absorbers for a smooth ride.

- The mattress for the table-bed should be made of lightweight material that can easily fold, and then return to its shape. Spring blocks are not suitable for this purpose.

How to assemble a table-bed with your own hands

In accordance with the drawings, it is necessary to prepare all parts of the structure for assembly. After that, proceed with the installation, observing the scheme and sequence of actions:

- We mark, draw and cut out the details of the frame.

- We mount the bed base using fixing fittings.

- We collect the rest of the body parts.

- On the lower part of the base, we install the table-bed transformation mechanism.

- On the sides, on both sides of the lifting device, we make two oval-shaped holes for the subsequent installation of the mattress fastening straps.

- We mount the table parts and fix the parts of the folding device from below.

- We connect the tabletop and the bed through a transformation mechanism.

- We put an orthopedic mattress on the base and strengthen it with straps.

Decor

In addition to their main purpose, pieces of furniture are designed to decorate the interior. The table-bed is no exception, its aesthetic component varies depending on the room where it will be located. The nursery is best decorated in bright colors for the development of imagination and a relaxed atmosphere. You can try a combination of subtle tones for coloring the countertop and brighter, accentuating ones for the upholstery of the bed.

Photo prints on the facade of the structure will look spectacular. When it comes to other rooms, the style of furniture should not fall out of the overall concept of the interior. Usually, materials such as veneer, MDF panels, polished chipboard are used for facing the front elements of cabinet furniture. As decorative elements, if necessary, LED-backlighting and original fittings can be installed.

Features of the choice of a finished structure

The first and foremost requirement for transformable furniture, given the constant mechanical stress it experiences, is reliability. Only high-quality materials and components should be used in production. When choosing a transforming table with a bed, you should pay attention to the following points:

- environmental friendliness of materials;

- reliable installation of frame elements;

- parts of lifting mechanisms must be steel with an anti-corrosion coating and a minimum number of nylon inserts.

- metal elements of the bed frame must be all-welded without flaws.

For better resistance to dirt, wooden elements are treated with a durable paint and varnish coating or laminate is used. The main purpose of the bed is to ensure good rest. Therefore, it is better that it be equipped with slats and an orthopedic mattress.

Top manufacturers

Modern furniture manufacturers offer a wide range of multipurpose serial products. With a slight movement of the hand, bulky, filling the entire space of the room, the beds are transformed from a sitting area into a work desk, an elegant chest of drawers or hides a furniture facade from view. Smart transformable furniture from leading manufacturers is an innovative method of creating modern interiors in living spaces. The best of them guarantee high quality and service throughout the entire warranty period.

Belitec

German quality guarantee. German manufacturer of exclusive bed mechanisms with electric remote control. The company offers a wide range of high quality products. The furniture of this company is distinguished by its high stability and structural stability. The beds are equipped with cold foam mattresses that have five comfort zones. They provide a comfortable sleep and support for the spine in the correct, natural position, completely repeating the body contour, thereby preventing diseases of the musculoskeletal system.

Clei and Colombo 907

An Italian home furniture manufacturer combining craftsmanship and quality with innovation and research. The company is the market leader in smart beds with a vertical transformation method. Furniture from Colombo 907 is distinguished by such characteristics as:

- operational safety;

- structural reliability;

- ease of use;

- increased comfort;

- modularity;

- aesthetics and ergonomics.

These parameters are reflected in the models of the SmartBeds collection.

IBed

In its activities, the company uses innovative approaches and production with modern technologies. A special attitude to the manufacture of folding furniture allows you to create incredibly comfortable bed-tables, characterized by an excellent balance of the mechanism. The dimensions of the work surface of the table top allow you to organize a place for both writing and for installing a computer. IBed transformers are equipped with a number of additional accessories in the form of shelves and drawers.

Transform

A domestic manufacturer of multifunctional furniture that ensures the rational use of the living space of houses and apartments. The company firmly holds its positions in the price segment for consumers with an average income level. The offered products are made from environmentally friendly, high-quality materials using high-tech transformation mechanisms.

"Smarti-furniture"

The Penza Furniture Factory produces folding beds with a lifting mechanism both in series and on an individual order.The company is not the first year on the market, its transforming furniture fully complies with the requirements of world standards and is designed for small rooms Smarti furniture uses high-quality components and will provide the consumer with:

- the uniqueness of the setting;

- saving living space;

- easy use;

- reliability, practicality and comfort.

The products of the factory are developed and designed by creative designers and highly qualified engineers.

As you can already see, furniture transformers, in addition to their direct purpose, can also become a real interior find. Especially if you get down to business with your own hands, choosing the necessary materials and attributes to your taste. A table-bed is a good solution that allows you to combine an office, a living room and a bedroom in one room for the price of one.

Video: assembling the table-bed transformation mechanism