What is eurozapil countertops, what is it for

Factory countertops are made only straight. But to implement some design ideas, at times, you need to assemble an L-shaped or U-shaped structure. Several parts have to be joined.

Those who want to assemble such a headset on their own will need to carry out euro-sawing of countertops at home. We will tell you how to do this and what are the advantages of the method.

What is Eurozapil

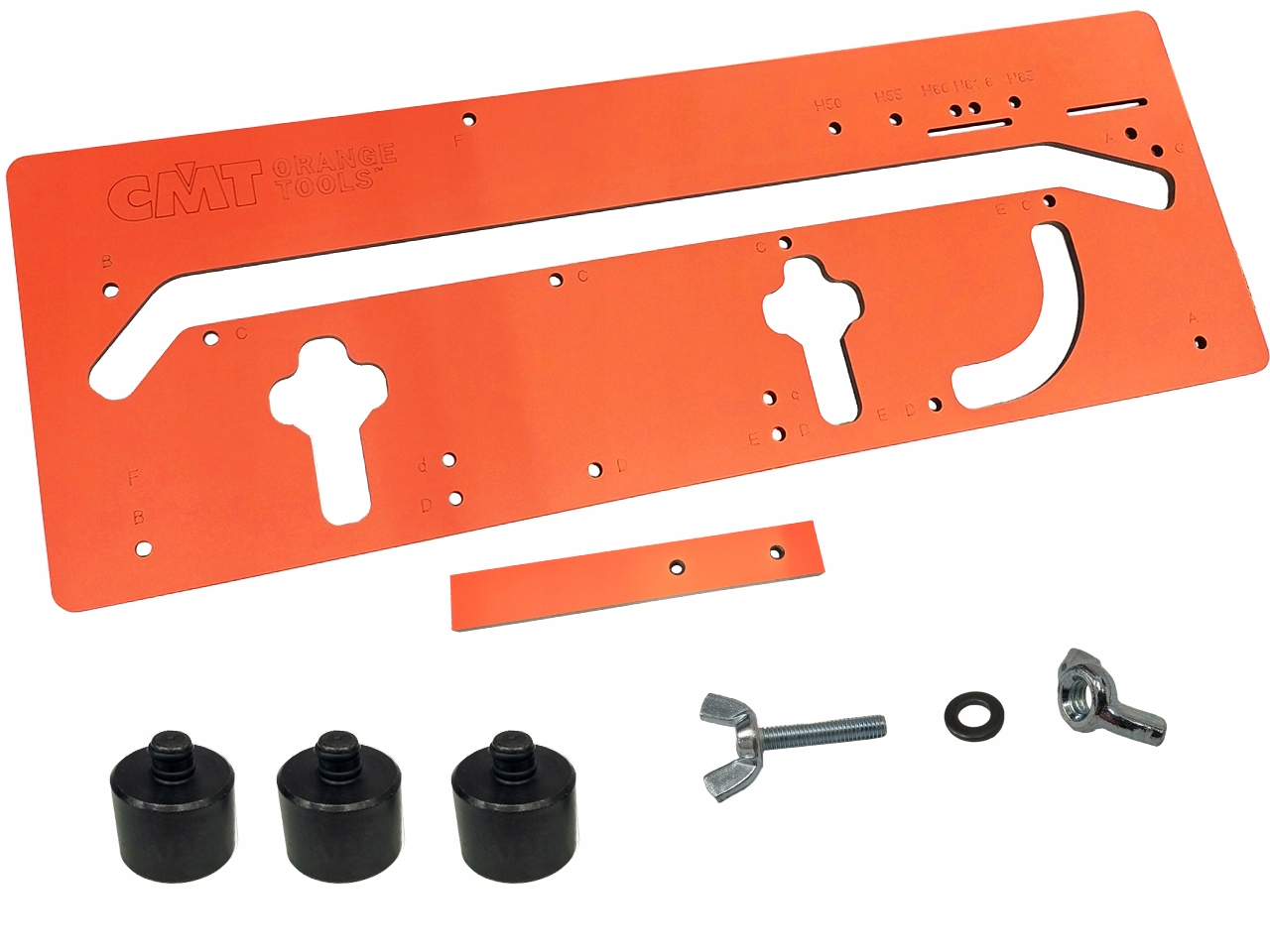

This method is necessary in order to join parts in a seamless way according to pre-compiled templates. A milling machine is used to create the parts.

Attention! Some manufacturers perform Euro saws on a cutting machine in order to reduce the cost of production. But in this case, the joint may not turn out even, but with a height difference of 1 mm or more.

What is it for

Through eurozapil, a tabletop connection is made without bending and height differences.

There are three mounting methods:

- right angle - canvases are placed at an angle of 90 degrees;

- with a T-shaped aluminum profile;

- with a turn through the segment.

The most important thing in this method is to carefully grind the joints with a milling machine. If all the conditions are met, the difference in height will be no more than a hundredth of a millimeter, and the joint is quite difficult to notice with the naked eye with the naked eye.

Advantages and disadvantages

The connection of countertop parts through euroform is appreciated not only because of the decorative feature of the method.

- Thanks to the precise joining of the parts, the surface becomes waterproof.

- Drops of water do not fall on the untreated edge of the countertop, as a result, it does not swell and lasts much longer.

- The surface is smooth and uniform, the headset looks much more expensive.

Disadvantages:

- the shape set during processing cannot be changed; when rearranging, you will have to change the tabletop;

- for the countertop to get used to the walls close, they must be aligned, the same applies to the floors of the house. Only a small inconsistency will be disguised, a strong curvature will be noticeable.

Eurozapil countertops at home - instructions

To make a euro-cut on the tabletop, you need a template and a suitable milling cutter. Better to buy quality tools: cheap fakes are dulled after 10 cuts.

The home craftsman should purchase a canvas with a margin of length, since with this method the slabs are not immediately cut off. First, the components are washed down, the joints are tried on, and only after adjustment is the cut made.

The next step is to form the screed holes. Their depth should not exceed ¾ of the thickness of the part. If this indicator is higher, deformation of the material and damage to the decorative coating is possible when the fasteners are tightened.

Attention! The grooves are made with a width of 8 mm, and the diameter of the holes should be 25 mm. The step between their centers is 68 mm.

Sizes of templates for sawing - 20, 25, 30 mm. From the side on which the sink will be mounted, screeds are made of lesser depth, from the opposite - more.

To process the joint, use a silicone sealant or hermetic adhesive. It prevents moisture from penetrating inside, has antiseptic properties, so that fungal forms do not develop between the plates.

Helpful hints and tips

For an even cut, take a new cutter. The grooves must be cleaned of dust after milling.

Before installation, the parts are laid face down strictly at the same level. This is necessary for height adjustment.

The sink is installed 2-3 days after the worktop assembly. If you do this earlier, the glue will not have time to set, and the design will be unreliable.

Use paper towels to remove excess sealant. Cloths are not suitable as fibers can get caught in the joint.

To prevent construction dust and small debris from getting into the joint during further work, it is covered with masking tape. Once the process is complete, the paper tape must be removed so that it does not interfere with the drying of the glue.

If debris or construction dust gets on the uncured sealant, you need to wait until it dries, and only then remove the contamination.

Video: how to make eurozapil countertops