How to make a countertop with your own hands

Any housewife dreams of a comfortable kitchen made in a modern style. The countertop is considered an irreplaceable kitchen attribute.

The work surface should be not only comfortable, but also practical. Not everyone knows how to make a beautiful kitchen countertop yourself quickly and efficiently. Although useful skills will be useful to many.

Today, many are trying to save money on the purchase of a kitchen set. Home craftsmen not only create a headset project on their own, but also order the cut of the necessary parts. At home, using ready-made tools, do-it-yourself assembly takes place. This is not only a cheap way, but also a great opportunity to create a furniture set that is ideal for a kitchen. Therefore, today we will consider an interesting stage in kitchen design - the manufacture and assembly of a kitchen countertop.

Types of kitchen countertops

The modern market offers a variety of materials for kitchen countertops. Quality material must withstand high temperatures and humidity, do not accumulate grease and any dirt must be easily removed from it. Let's consider the most popular ones:

Wooden countertops

Natural products are simple in design and match any interior. Manufacturing technology provides for the use of type-setting shields. Wood material undergoes thorough grinding and coating with a special composition, which provides characteristics such as strength and protection from mechanical stress. It is logical that such a top is highly flammable and cannot withstand high temperatures. Also periodically needs a special wipe to protect the surface.

Products from laminated chipboard

Were always the cheapest and most affordable. Manufacturing technology consists in facing the chipboard material with plastic. A special layer provides heat resistance, wear resistance, protection from mechanical stress. Laminated kitchen structures are highly durable, withstand high temperatures and do not discolor.

Stone countertops

Associated with luxury, high cost and durability. Stone countertops are made of hard rocks, the thickness of which is 2-3 cm. Manufacturing technology consists of grinding, polishing and processing. Holes for sinks and kitchen appliances are prepared in this plate.

Marble countertops

The main plus is the aesthetics of appearance. The marble top is suitable for any stylistic decision. This design can withstand high temperatures, but cannot boast of resistance to mechanical damage.

Artificial stone products

Recently, such designs have been quite popular. For this, a plywood sheet is taken, an artificial stone 12 millimeters thick is glued to it. The material itself is made of polymer glue with the addition of multi-colored granules.

All the advantages of artificial stone countertops are explained by the increased demand for such products. The structure is quite difficult to scratch and deform. She is not afraid of water and high temperatures.

How to make a countertop with your own hands

It has already been mentioned that artificial stone countertops are very popular. Therefore, if you are in doubt about which material to choose for self-production, then choose an artificial stone. Before starting work, you need a drawn diagram in which all the parameters and the cutting itself will be displayed. Further, according to the finished scheme, a blank is made. To do this, you need a standard set of tools that are in every home. Nothing supernatural is required for this.

Choice of design

An artificial stone countertop can be made of an unusual shape. It is worth noting that the L-shaped product is especially popular today. It will not do without the use of mirror milling of the ends. The joint after such processing will not stand out.

If there are bends on the product, the end strip will have to be heated to a certain temperature. To do this, you can take a building hair dryer.

The optimum temperature makes it easy to bend the product and keep its shape.

Many people try to make tabletops solid and reliable. And few people would think to choose a very thin design. After all, minimalism in such a case will add originality, while maintaining all the characteristics that the standard design has.

For those who prefer original models, you can make a liquid type of product. The self-leveling countertop will perfectly fit into any interior. The special characteristics make more and more consumers pay attention to such a popular product.

Material selection

The work of installing the countertop itself is not difficult, but in such a case, a lot depends on the material used. The standard set consists of:

- artificial stone;

- moisture resistant plywood;

- two-component adhesive composition;

- spatula;

- a bar with sandpaper;

- plunge saw.

By itself, the thickness of the artificial stone is small, so it will be necessary to make a plywood frame. This is done simply: a piece of certain parameters is taken. As a rule, the size of a standard table top is 760x600. Try to leave a small margin of half a centimeter.

Selection of tools

The process of installing a kitchen countertop itself is not difficult. But if we consider the issue from the technical side, then it is impossible to consolidate it without special tools. Therefore, for such a case, it will come in handy for you:

- tape measure;

- building level;

- set of screwdrivers;

- hammer, chisel;

- power tools;

- screwdriver;

- gun with silicone sealant;

- self-tapping screws of different calibers;

- skirting board with aluminum edge.

As you can see, a standard set of tools is needed for manufacturing. No exotic devices are needed in such a case. Therefore, armed with the right tools, you can start creating a special countertop.

Process of creation

You can create a sketch at any time. The main thing is to take accurate measurements of the kitchen space, where the furniture and work surface will be located.If your kitchen is angular, then you will have to make a corner of 90 º. This is not only considered a criterion for high-quality repair work, but also greatly simplifies the furniture installation along the wall planes.

Using a tape measure, we measure all installation sides. Quite often, you can find a work area in the form of a curved shape with an approach to an adjacent wall. Therefore, for an angular shape, it is better to divide the structure into several parts. Thus, each part will have its own work area. But in this case, the formwork will be a single structure with division into sections.

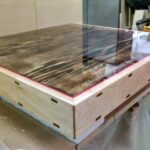

Assembling the formwork and frame

The plywood moisture-resistant sheet is installed evenly on a horizontal surface. Alternatively, a table will do. Further, all dimensions from the drawing are transferred to a sheet of plywood using a ruler and a pencil. Boards of 50 × 30 mm are placed along the extreme lines. Wooden structures help determine the height of the tops. The optimal size is 50 mm, because a reduced thickness leads to a decrease in strength, and an increase - to a large mass.

There are two options:

- use bars 50 × 50 mm for mounting;

- put metal corners.

The first option involves fixing the bars at the corners of the structure. When the board has a long length, then additionally you need to use several bars in the middle at the same distance from each other.

Countertop cladding

For those who are looking for non-standard solutions, ceramic tiles can be used for cladding. Any material is suitable for this: medium tile size, small, mosaic or a combination of several materials.

Be sure to wipe the seams, otherwise they will be the most vulnerable spot, therefore, take the utmost care when choosing a composition.

Features of countertop decor

It will not be difficult to decorate the countertop yourself. The most important thing is to have the right material at hand. Such actions do not require special skills in design skills. The main thing here is to come up with an interesting design. The cost of such work depends on the chosen technique and the material used.

How to care for your countertop

The worktop serves as the main work surface in the kitchen. Despite the material of manufacture of the countertop, the standard rules for caring for it will extend the service life of the useful element:

- do not leave hot or objects with a large mass on the surface;

- any work on the countertop should be done on a cutting board;

- do not keep near a chemically active liquid;

- remove all dirt in a timely manner.

These are the standard rules for caring for all types of countertops. Other differences depend on the material from which it was made.

Video: how to make a tabletop with your own hands