Contemporary style kitchen sideboard

The tradition of setting up a kitchen buffet was forgotten for some time, but now it has found a second life. Beautiful and durable furniture is suitable for storing utensils and food. You can choose the right model for any kitchen style. Even a master with little experience will be able to make a buffet with your own hands. The most important thing is to choose high-quality and safe materials that are comfortable to work with.

Kitchen cupboard designs in a modern style

The old sideboards were always elegant: with carved elements, engravings on glass.

Modern types of furniture strive for minimalism. This does not mean that the visual design of the buffet fades into the background: it just shifts the emphasis from unnecessary decor to details, shades, and shapes.

Buffet options in modern styles:

- hi-tech - “smart” solutions in the choice of accessories, simple shape, the facade can be made of laminated material of a bright shade, chrome parts, glass are appropriate;

- eco-style - made exclusively from safe wood (approx. bamboo), facade with natural texture, minimal finishing;

- minimalism - laconic form, emphasis on functionality, roomy compartments;

- kitsch - bright colors, non-standard or simple shapes, furniture can be made with a hint of retro style;

- Scandinavian - massive, with an emphasis on the ecological component, can be decorated with cross beams;

- shabby chic - ornate design with decorative elements, artificially aged finish.

The sideboard can be roomy or narrow, for installation in a corner. You can find the right model for every kitchen size.

Advantages and disadvantages

Any buffet for the kitchen has a number of advantages:

- practical - it can partially or completely replace other storage systems;

- stylish - beautiful utensils, seasonings can be stored on open or glazed shelves;

- durable - most often kitchen cupboards are made of solid wood or high-quality plywood, such furniture remains stable for decades.

The disadvantage can be the high cost of products made of precious wood species, as well as the complexity of assembling models with a non-standard design.

Varieties of buffets

The most important thing is what material the buffet will be made of. Form, organization of internal space and storage systems are secondary features.

Based on materials

Modern sideboards are made from solid wood or particle boards. Let's consider the most popular materials and their properties.

- Fiberboard. Heat and moisture resistant, lightweight, durable and inexpensive material, easy to process, most often used for the manufacture of back walls, drawers and hanging drawers.

- Chipboard. Reliable, budget material that comes in a variety of shades. It has a significant drawback: when heated, it emits formaldehyde into the air, therefore, it is not quite suitable for installation in the kitchen, especially near a heat source.

- MDF. Strong, reliable and environmentally friendly material (natural resins are used instead of synthetic glue). Resistant to moisture, easy to process.

- Solid wood. The safest, most environmentally friendly material. With proper preparation (drying, sanding, staining) it does not lose its shape for many years, it is resistant to moisture. Pine, larch, oak are used in the manufacture of furniture. These are the most durable and hydrophobic types of wood. The only drawback of the material is the high price.

By design

The most popular are direct buffets. They can be long or short, deep or as narrow as possible. This is a classic furniture model. The facade can be made straight or rounded.

Corner models are narrower and are suitable for small kitchens. In spacious rooms they are used for storing decorative utensils.

By storage type

Internal filling of dressers:

- swing sections - can be decorated with glass or blind doors, often separated by 2-3 shelves;

- drawers - often located at the bottom of the chest of drawers;

- open niches and shelves - a large open space is located in the center, the upper shelves can be made without doors.

How to make such a buffet yourself

To make furniture on your own, you need to calculate the size of the sideboard, choose what it will be made of, and think over the design.

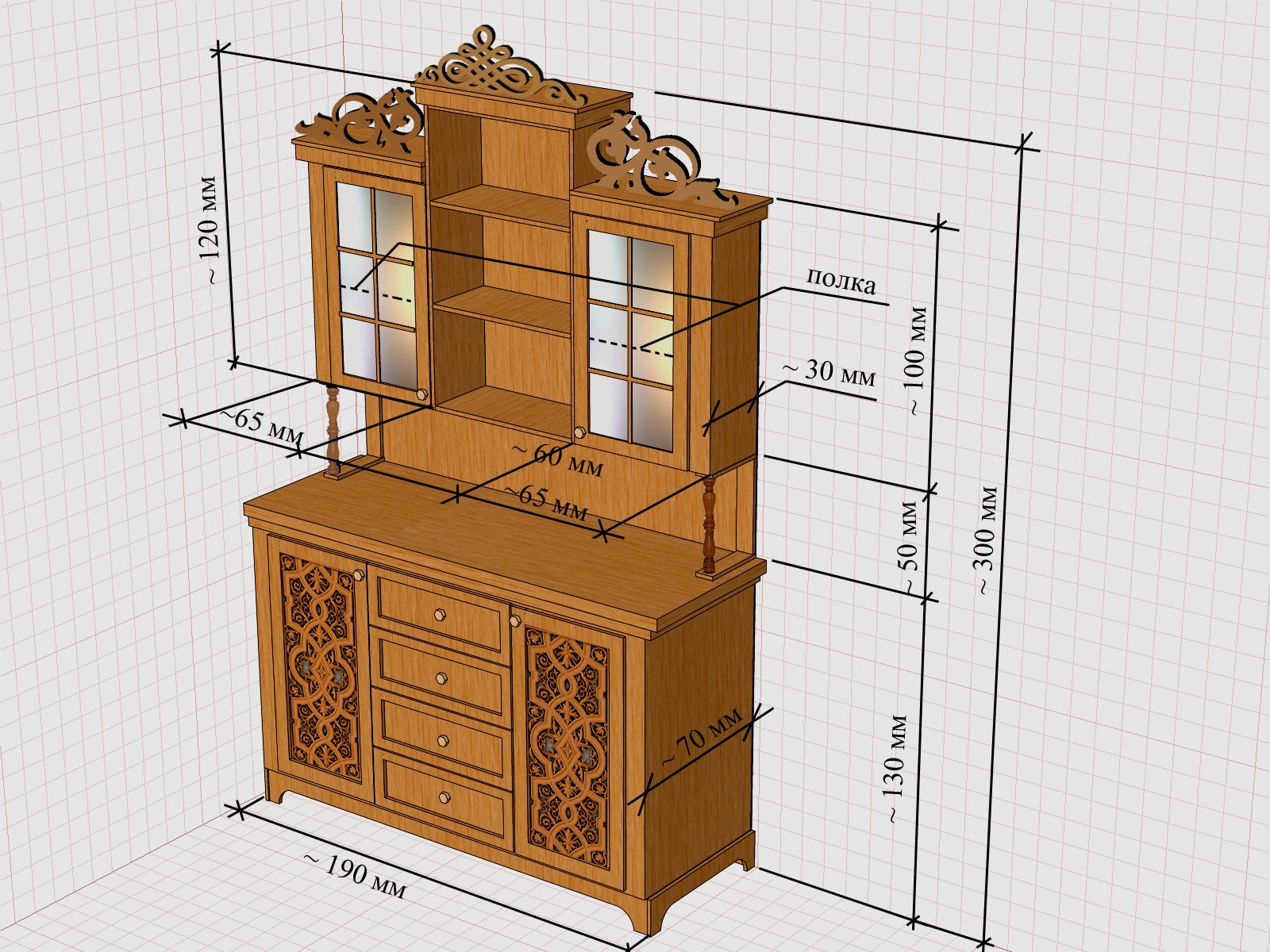

Drawings and diagrams

It is very important to choose and think over the internal content of the buffet. If you design furniture according to a scheme that involves drawers, then you need to buy high-quality fittings. They fix it strictly along the axes, parallel to each other. It is better for a novice craftsman to choose simpler drawings with open shelves and swing doors.

Attention! Drawings are made taking into account the parameters and dimensions of the future product. Experienced craftsmen recommend numbering the details so as not to get confused, and to collect accessories in separate organizer cells.

Required materials and tools

For manufacturing, you will need solid wood boards or sawing sheet material. If it is not possible to prepare parts at home, it is better to order them in production. This will save work and avoid sizing errors.

What tools are useful for making a sideboard:

- drill with a drill for wood;

- screwdriver;

- a grinder or sandpaper of varying degrees of grit;

- jigsaw;

- a circular saw;

- building level;

- corner ruler;

- tape measure, pencil.

To process the details, you will need wood stain and varnish or putty on wood, primer and paint, as well as brushes and rollers.

Buffet creation process

First you need to prepare the parts or order them. Saw boards or sheet material are divided into segments, and they are given the desired shape with a jigsaw. Then the work is carried out in accordance with the following stages:

- preparation of large body parts - side strips - holes for fasteners are drilled in them;

- depending on the design, the supporting base is assembled. It can be a plinth with legs or strong side posts that will serve as a support;

- if the lower bar is the carrier, the pins are unscrewed into it, on which the side panels are mounted;

- if load-bearing - side panels, lower and upper planks of the basement part are screwed with self-tapping screws;

- then the upper part is assembled, it can be designed separately, and then fixed with self-tapping screws directly to the lower pedestal or to the corners to the side supports. In the second case, there will be a niche between the lower and upper parts;

- the back panel is mounted to the finished case; for this, the case can be laid on its side;

- before installing the doors, it is necessary to put the sideboard, measure the accuracy of its angles, tighten the fasteners;

- markings are applied to the parts and side racks, holes for the hinges are drilled in the marked places, fittings are installed;

- doors are hung on it, then the operation of the mechanism is checked, if necessary, the hinges are tightened or loosened.

After assembling the main body, the product is processed and coated with paint or varnish. Painting or varnishing can be done immediately after marking the mounting holes.

During the assembly process, it is very important to focus on the building level so that the buffet turns out to be even, without distortions.

Video: how to make a buffet with your own hands