Artificial stone countertop

A variety of finishing materials allows you to create a unique kitchen design. At the same time, it is important that they differ in strength, resistance to moisture. One of the most popular today is liquid stone for countertops.

The decorative element has good performance properties. A big plus is non-toxicity and resistance to mechanical stress.

- Advantages and disadvantages of liquid stone countertops

- Varieties of liquid stone for countertops

- What tools are needed for manufacturing

- Artificial stone countertop making process

- Repair of artificial stone countertops

- Video: artificial stone countertop

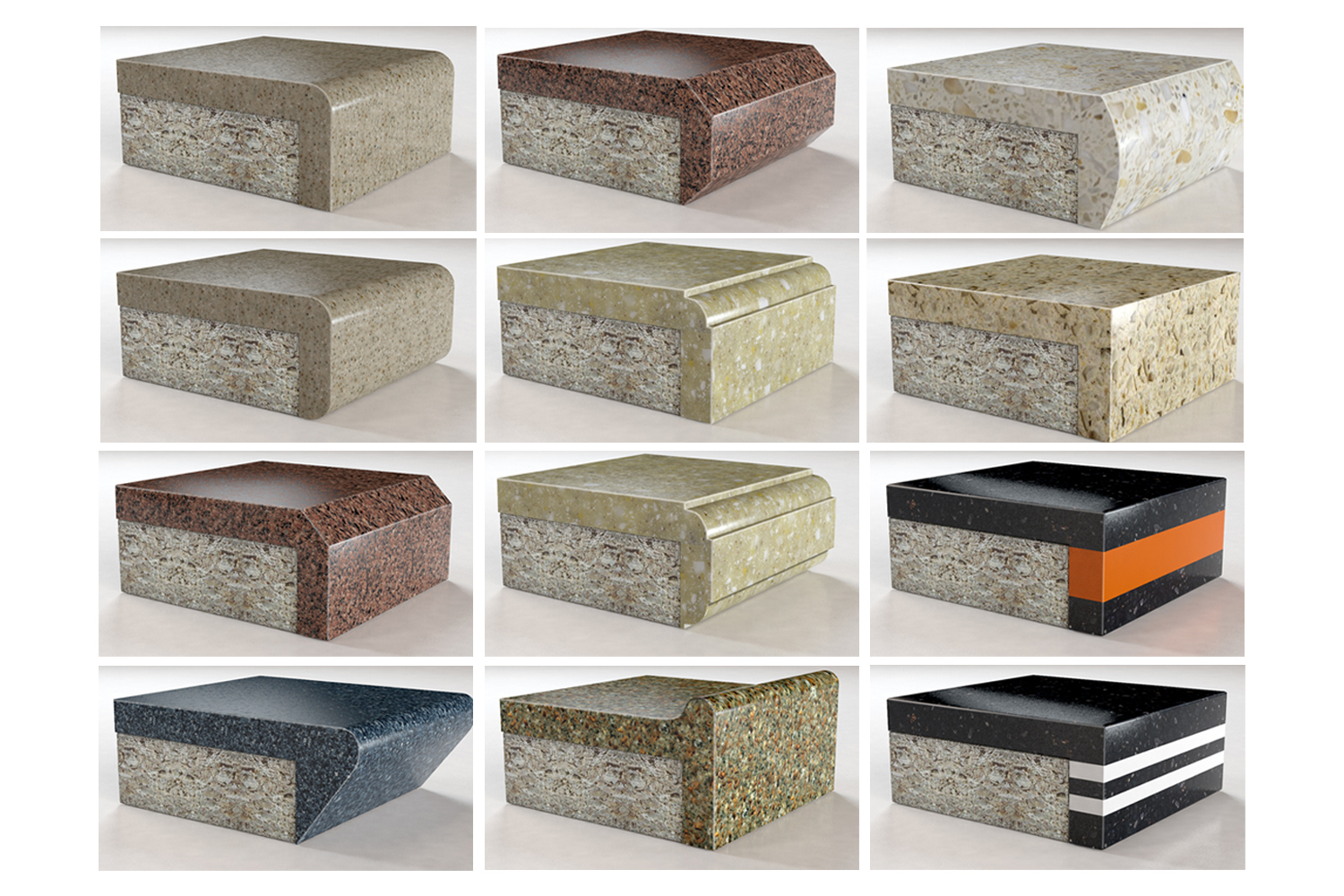

- Options for countertops made of artificial stone in the photo

Advantages and disadvantages of liquid stone countertops

A special feature of the composite material is its manufacturing process. Which involves the use of fillers, natural pigments and polymer resin. The popularity of acrylic stone is due to its strength, not susceptibility to various chemicals.

It is easy to use, so if you want, you can make a high-quality kitchen countertop yourself. The finished product has a number of advantages:

- uniformity of structure, impermeability - bacteria do not penetrate through such a surface, dirt does not accumulate;

- imitation of a natural breed;

- wide range of color palette;

- safety, environmental friendliness;

- the possibility of grinding, self-removal of scratches.

The material is warm to the touch and gives aesthetics to the room. A long service life can also be noted. It is easy to take care of such a tabletop, it is enough to wipe the surface with a rag. If you need to restore furniture with such a coating, you only need polish and sandpaper.

The disadvantages are not significant, but they are:

- the tendency to form abrasions, it is easy to scratch the surface;

- absorption of chemical dyes;

- not high heat resistance.

It is recommended to use such a surface with care, try not to knock or throw heavy objects on the surface.

In any case, if the countertop is deformed, you can carry out the repair yourself, giving it its original, attractive appearance.

Varieties of liquid stone for countertops

Depending on the use of the type of resin in and production, liquid stone comes in several varieties. Each has its own positive and negative sides.

At the same time, they are in demand on the market, more and more consumers are purchasing this particular material for the manufacture of countertops.

Acrylic

Thanks to the mineral filler, the material has a solid structure. Resins act as a binder. The presence of natural pigments gives the stone a different color. Therefore, you can often find a variety of shades, shapes.

Liquid stone for countertops can be monotonous, sandy in color, with marble stains, small veins, and translucent. Advantages:

- density, non-porous structure;

- does not stain, the stain that appears can be easily removed with a sponge;

- high wear resistance;

- allows you to embody the most original seamless designs;

- the ability to assemble from separate pieces;

- suitable for repair work;

- a huge range of colors.

Acrylic stone products can be glossy or matte. A big plus is that the material does not fade over time, the color remains for several years.

Agglomerate

No less popular, available in the price segment. Suitable for complex finishes. Possesses high strength. This material is obtained by combining individual particles of natural stone, polyester resins and additives.

Pros:

- resistance to high temperatures;

- durability;

- not toxic;

- easy to care for.

Despite its excellent characteristics, the material is suitable for creating simple geometric shapes.

Sheet artificial stone

Often sheet acrylic plates are large, allowing the manufacture of any designs of non-standard configurations. The canvases are connected with each other using acrylic glue, while there are completely no traces of butt seams. The sheets are easy to use, easy to install artificial stone.

Advantages:

- the ability to create any shape, looks like a monolith;

- when chips appear, they can be quickly sanded without disturbing the surface quality;

- easy to clean;

- does not emit harmful substances and odors;

- UV resistant.

Due to its low porosity, it does not absorb moisture, you can put it hot on the surface. Even after a long period of use, the appearance of the finish remains the same. The material retains its expressiveness while maintaining the richness of colors.

What tools are needed for manufacturing

Having decided to make the countertop with your own hands, you should perform all the steps in stages. But first you need to prepare the tool:

- electric drill, jigsaw;

- milling cutter and grinding device;

- thermal gun;

- screwdriver;

- sandpaper.

There are no specific recommendations for choosing a tool for working with an artificial stone. However, in order to achieve high-quality processing and durability of the product, it is necessary to use an electric tool designed for intensive use. The cutting blades must be made of tungsten carbide.

Artificial stone countertop making process

After preparing the tool and material, you can start working.

Phased execution:

- two blanks are made, five millimeters larger than the desired option. They need to be glued, the edges must be processed;

- then you need to cut holes for the hob, sink;

- the next step will be the installation of the mold on the work surface, the required plumbing is installed. Using plasticine, you need to cover up the places where the cracks have formed;

- now you can pour liquid stone, strictly following the instructions.

Important! It is necessary to work with the composition carefully and quickly, since it is able to quickly harden.

Also, before spraying the material, it is better to put glass cloth on top of the workpiece. This will give more strength to the structure. Next, the surface needs to be sanded, walk along the edges with a milling cutter.It is imperative to check visually how smoothly the structure is installed. If distortions are noticeable, the surface should be leveled.

The above process gives an understanding of how to make an artificial stone countertop with your own hands. There is nothing difficult in this, the main thing is desire and phased implementation.

Stone preparation

The simplest design is rectangular and easier to work with. The first step is to prepare the surface, stripes for finishing the edges, and you will also need a wall side. When planning a future product with smooth bends, first the acrylic sheet is heated to one hundred and sixty degrees using a building hair dryer.

It makes it possible to bend a stone of the desired configuration. A circular saw or cutting equipment is suitable for cutting artificial stone.

Manufacturing technology

Determining the desired dimensions and appearance is the first thing to do before making a countertop. Then, in the kitchen, the space near the sink is measured, followed by drawing a sketch on paper. It is not recommended to make the wall bumpers too high, five to seven centimeters will be enough. Using a router, it is necessary to cut out places for the hob and sink. Then all edges are carefully processed with sandpaper.

Next, you need to cut the plywood strips, about eight centimeters each. They are used as a framework. You also need to make a frame, a treated stone surface will be glued into it. A decorative tape is pasted over the ends.

Repair of artificial stone countertops

The material is aesthetically attractive, looks original, but requires careful handling. Even careful use of the countertop sometimes leads to the fact that various damage can appear on it over time.

As stated, artificial stone is easy to repair or refurbish. This will take a minimum of time and no special skills are needed.

Crack repair

If cracks and chips are visible on the surface, first degrease the deformed places. Then you need a two-component glue, which is used to fill the crack itself.

After waiting for it to harden, you should grind, then manually carefully polish the tabletop. Thus, it is possible to return the beauty and original appearance.

Scratches

The appearance of spots and shallow scratches on the surface does not look aesthetically pleasing. Therefore, it is better not to delay the elimination of this problem. You will need a piece of sandpaper that you can use to quickly sand the countertop.

It is recommended to first use coarse-grained material, then walk with fine-grained material. Some experts advise to additionally polish the stone using a drill with a felt attachment. The result is a smooth, even, scratch-free surface.

Bulges and stains

In addition to any chips, the surface can sometimes swell. In this case, the router will help out, with which you need to cut out the problem area. Then you will need a liquid stone for the patch, it must be poured into the place from where part of the swelling was cut. After curing, polishing and grinding are also performed.

A hand-made countertop made of artificial liquid stone will become a real decoration of the kitchen. Such a product will last for more than one year, delighting with its original look. Moreover, it is a pleasure to work on such a surface. It is easy to care for such a product, just wipe it with a sponge.

If cracks, scratches appear, the material allows you to restore the coating yourself, using a two-component adhesive. Also, regular sanding and polishing will help restore the original look.

Video: artificial stone countertop