DIY furniture from logs

Interior items made from natural materials are gaining more and more popularity. With a competent approach, you can make real masterpieces from them, which will proudly become part of even the most modern and pretentious interior. In addition, wooden furniture is very strong, so it will be able to serve its owners for more than a year.

What can be made from a log

To add more naturalness to the interior, log furniture can be used to decorate your permanent residence. At the same time, it will look most harmoniously in a country setting. Tables, chairs, benches can be varnished or painted in color. In each of these options, they will look eclectic and stylish.

How to make furniture from a log with your own hands

Even a person with a minimum set of building skills can make a summer cottage set for himself. The key is the desire to create and the willingness to follow the instructions. It all starts with choosing a model and creating a drawing. Only after that it will be possible to purchase material and implement your project.

Scheme and drawing

For people who start making furniture for the first time, it is advisable to borrow ready-made drawings for furniture from a log with their own hands, which can be easily found on the Internet. You can find a ready-made project with the same dimensions or adjust it to the required ones. Taking into account the ratio of the parameters of the elements, of course.

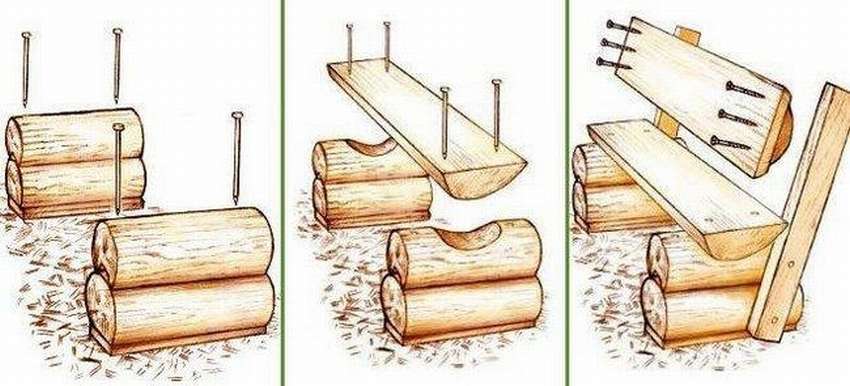

The scheme for making a bench with a back from a log:

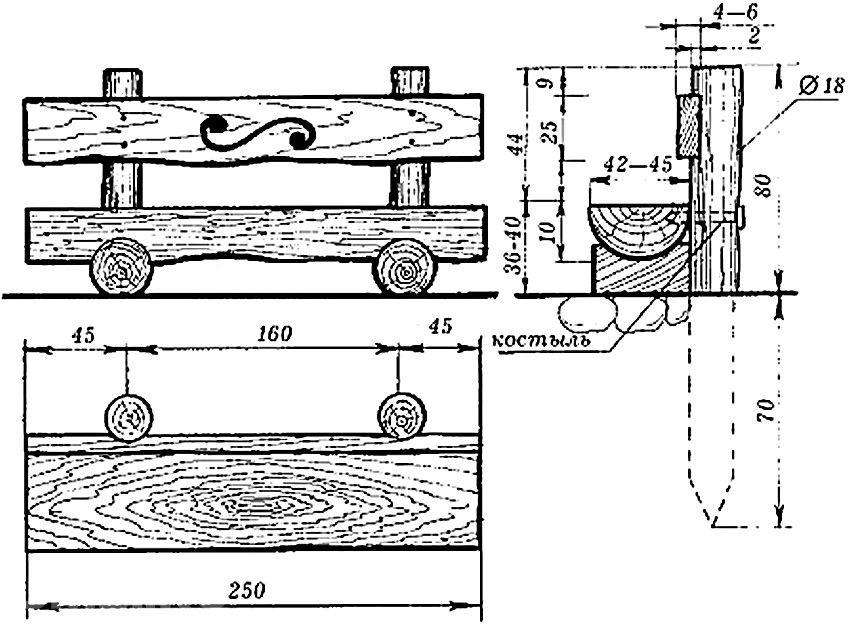

Bench drawing:

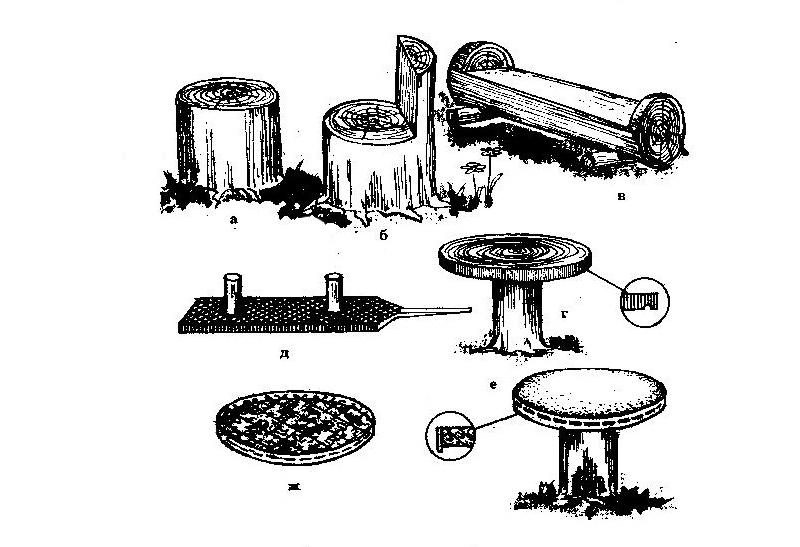

Scheme for the manufacture of country furniture from a log:

Choice of wood and other materials

The cheapest raw material for furniture is pine, but it must be handled with great care. The material is malleable in work, but very soft in itself: the slightest physical impact contributes to the formation of cracks and chips. Therefore, pine furniture is categorically not suitable for a children's room. The most durable, albeit not cheap, materials are oak and walnut.

The high price will be justified by the following advantages:

- Durability. Wooden furniture can last for decades. The main thing is that the technology of its production is not violated.

- Environmental friendliness. The material is of natural origin and is completely safe for humans.

- Minimum processing. The cut of wood is beautiful in itself, so it does not need additional decorative elements. It is enough just to open it with varnish to protect it from external factors.

At the same time, another component of long-term operation is the correct choice of materials for manufacturing:

- The wood should be flat, without knots and chips. The presence of the latter will not allow high-quality processing of the material. It is better to refuse to buy wood with cracks on it in layers. Most likely, the material is old and a high-quality product cannot be made from it.

- When choosing coniferous woods, it is important to pay attention to the location of the annual layers. The closer they are to each other, the stronger the material will be.

- If possible, ask the seller when the tree was cut. Autumn is more flexible than winter.

- When it is planned to use several types of wood in the work, it is better to choose options that are similar in structure. Then they will have approximately the same drying out.

It is advisable to buy wood from trusted sellers with a good reputation. Buying in a spontaneous market at an attractively low price can come as an unpleasant surprise in the form of overdried or underdried produce.

Furniture making tools

In order to make the furniture manufacturing process as comfortable and simple as possible, it is necessary to take care of the "correct" inventory. For work you will need:

- screwdriver;

- drill;

- electric jigsaw or circular saw;

- stationery knife;

- fasteners;

- square;

- measuring tape.

Additionally, it will be necessary to purchase fittings, fasteners and guides for the drawers, if any are suddenly provided.

Manufacturing process

If you have a drawing, appropriate materials and tools, you can assemble garden furniture in 1-2 days. If the object being created is bulky, you will need the help of third parties.

Benches

You can make a model with or without a back. The first option is definitely more comfortable, so it is worth stopping for the suburban interior on it. After a hard day, you want to rest in comfort.

For the manufacture of a bench with armrests, it is advisable to use an edged board with a section of 25x100mm. The height of the product will be 74.2 cm, the seat will be 40 cm, and the armrests will be 62.5 cm, the height of the backrest will be 33 cm, and the length of the bench will be 1 meter. These values are averaged, but the master for himself can change them up or down.

Assembly procedure:

- Initially, it is necessary to assemble the legs with ties. To do this, 4 parts 60 cm long must be placed parallel to each other. The distance between the elements should be 32 cm. The first tie is fastened perpendicular to the legs, the second - along the edge of the parts. You can immediately attach boards that will act as armrests. Here you need 2 elements 52.2 cm long and 7.5 cm wide.

- The assembled part of the bench must be placed vertically and the base for the back must be attached to it from the inside. Here you need 2 elements 52.2 cm long and 5 cm wide.

- It remains only to make a flooring of boards with a gap of 10 mm between the frame elements.

To make the bench look more spectacular, you can open it with varnish and cover it with a decorative mattress.

Tables

The principle of implementation is similar to assembling a bench - it all starts with fixing the legs with ties. There is no optimal size here - every master makes a table based on the needs, the growth of household members, etc.

It is better to make the legs from well-polished timber or very thin logs. If it is not supposed to disassemble the table, it is better to connect all the elements together with self-tapping screws. The table top can be made of edged board or OSB sheet.

Chairs

A do-it-yourself log table usually turns out to be slightly rough and uncouth. For city apartments, such a product is unlikely to be suitable, but for a summer residence it is just that. The length of the legs is 45 cm, as is the width of the seat, while the height of the back is 60 cm as standard. However, the dimensions can also be adjusted for yourself.

In the logs intended for the legs, grooves are cut, where the projections will then be attached. Of course, you can do without it, just fastening them with ties. The backrest frame is also made of two logs, which are attached to the base with self-tapping screws. Several planks can be placed between them as spacers.

The space under the seat can be sewn up with a single sheet, but models lined with a thin board look best. The design turns out to be spectacular, but rather bulky and heavy. It is easier to use such a chair permanently, without rearranging it from place to place.

Garden furniture

In addition to the standard bench, chairs and table in the garden, there is probably not enough and a small locker - storage for daily used equipment. The frame is knocked out of an edged board, fastened together with self-tapping screws or staples. On one side, the cabinet can be sewn up with a thin sheet of OSB or left like a shelf.

How to make a flower bed from a log

One of the most spectacular garden design options is cutting a cavity at the base of the log, where the flowers will be placed. This process is laborious: you will need both a jigsaw and a drill.

To begin with, the log should be marked and placed on small "legs" made of metal or plastic - this way the tree will be less exposed to dampness and moisture. Only after this can the markings be made: the sides should remain at the flower bed so that the ground does not erode during rain.

Note! Flower-bed logs quickly lose their appearance, therefore, before using, it is advisable to open them with varnish and treat them from pests.

Where can I put the furniture

Garden furniture made of logs is very afraid of moisture and dampness, therefore it should be placed in a sunny and well-ventilated place. An excellent solution would be an open veranda, where all elements will be reliably protected from rain. For the winter, it is better to remove wooden furniture from the street or, at least, to cover it with polyethylene.

Anyone can make garden furniture from logs with their own hands. The main task is to choose the right or make a drawing on your own, to buy really high-quality materials. If all the preparatory steps are completed, the final assembly can be completed even in 1 day.

Video: DIY table