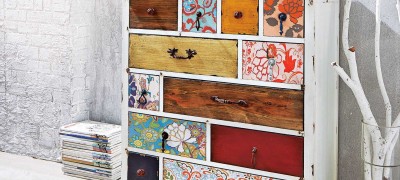

Antique wood furniture

Wooden furniture has excellent characteristics, the main of which are environmental friendliness and durability. Often, when creating such interior items, they are artificially aged, giving a more monumental look.

We will tell you about all the intricacies of this process and the manufacturing scheme in this material. Making semi-antique furniture with your own hands is a very exciting process, the result of which can be a unique element of the interior.

What tools and materials are needed for work

For the manufacture of furniture, a wooden base is required, and here the toolkit is as follows:

- Beam, or solid wood, or a combination of both. It is important to correctly calculate the amount of material required before starting work.

- Tools for woodworking and preparation of individual parts

jigsaw or circular saw- sander (or the corresponding drill attachment)

- a set of screwdrivers or screwdriver

- fasteners for connecting furniture - corners, screws and screws

- sandpaper

Special tools or materials are also needed to give the assembled furniture an antique look:

- special chemical compounds

- metal brushes, including in the form of attachments for a drill

- soldering iron and hair dryer

If you plan to age the existing furniture, the process is greatly simplified, which we will talk about later.

How can you make furniture old

With all the necessary tools at hand, we proceed to create a drawing. After that, having prepared the material, we assemble the furniture using the tools described above. You can also age existing furniture.

In any case, there are many nuances in this issue, and we will consider them further.

Chemical processing

An aged piece of furniture looks elegant, and this process can be accelerated with the help of chemical compounds.

Note! It is strictly forbidden to carry out such work in poorly ventilated rooms and without eye and hand protection.

With the help of chemical elements, the following aging effect can be obtained:

- cracking

- creating wear or fading

- darkening of tone

- uneven coloration

Craquelure varnish is a special substance that, when it hits the surface of a tree, causes the top layer to crack. When the inner layer is painted in dark tones, and the lower one in light tones, an excellent antiquity effect is obtained.

To give the furniture a beautiful shabby or faded surface, the double staining technique is used. The first dark layer is applied first.After it dries, a second staining with light paint is carried out and the dried surface is sanded unevenly in different places. This technique creates a stunning visual effect of old furniture.

Darkening of individual pieces of furniture is the simplest of aging techniques, and it can be achieved with the help of ordinary stain. We process the surface, let it dry - and voila.

Uneven staining is a special case of a scuff effect, also called a dry brush effect. As the name implies, paint with a brush slightly moistened with paint over the surface of the wood, getting the visual appearance of old furniture.

Mechanical restoration

For machining tools, the most commonly used are:

- chisel

- metal brush

The most famous and commonly used machining technique is brushing. When using it, the upper soft layers of wood are removed, while the opened inner ones must be painted in a dark shade.

Thermal

Heat treatment is rarely used due to its specificity. With too much exposure, such furniture looks like after a fire, and is not suitable for every interior. Another thing is drying with a construction hairdryer, or the effect of a soldering iron.

In this case, irregularities or visual traces are created on the surface, creating the effect of antiquity.

Furniture preparation

The better the furniture base is prepared for the aging process, the better the effect will be. At the same time, it is not recommended to completely remove the top layer of the material, from such processing the furniture will seem only newer, and the applied techniques will not have the desired effect.

Before chemical exposure, we treat the furniture with a degreaser to improve the effect of penetration of the composition into the depths. For mechanical aging, it will be enough to wipe the front part from dust; with the thermal method of aging furniture, you can do without any preparation at all.

Before starting work, it is recommended to completely remove all fittings from the surface.

Manufacturing technique

Soft woods, such as pine, are best suited for artificial aging. You can, of course, work with hard ones, but such processing will require much more effort.

In any case, regardless of the piece of furniture being created, be it a chair, a table or a wardrobe, we first draw up a drawing, according to which we prepare individual parts and their further assembly. Having collected any of the pieces of furniture, we prepare it for further processing. Next, let's look at the most popular techniques.

Artificial pollution

The artificial pollution effect of all existing ones has the strongest visual effect. We wipe the wood with wax, and the darker its shade, the stronger the effect will be. The wax fills in the hollows in the surface of the wood, thereby enhancing the desired effect.

Note! To obtain aged furniture, we recommend waxing in one direction over the entire surface area.

Patina

The patina effect (visual aging of the surface, when the veins remain intact) is suitable for wood with an appropriate texture.

In furniture stores, you can even find special paints that create a similar effect. Before starting work, the top layer of the selected furniture is well varnished. After the varnish has dried (usually within 24 hours), a special paint with a patina effect is applied.

The dried layer of paint is processed with sufficient force with medium-hard sandpaper. And thus the desired result is achieved.

Crackle

Crackle effect - artificial cracking of the surface. Produced by chemical compounds. We apply a special craquelure varnish to the surface, and wait for the effect to appear.

Note! Before starting such work, the surface must be well cleaned.

Then we apply a pre-selected color scheme on top of the varnish, which will visually enhance the effect. And at the end of the entire procedure, we cover the resulting surface with a layer of protective varnish in order to preserve the resulting aging for a long time.

Coloring

In this case, the wooden surface is painted with several layers of color, more often from the lightest to the darkest, the further to the final layer, the less effort is applied and the smaller the surface is painted.

Between adjacent layers, an additional sanding is usually carried out, which makes it possible to enhance the effect.

As you can see, semi-antique wooden furniture created according to the above recommendations with your own hands is an exciting activity with the expected result of aging of the selected interior items.

Video: how to make semi-antique furniture