Features and varieties of furniture drill for confirmation

Confirmates became popular in the 90s and still have not lost their relevance in furniture production. These mounts are great for DIY designs. Their correct name is a one-piece screed, and “Confirmat” or Confirmat is the name of a German trade mark that produced hardware of this type.

We will tell you which drill bit for furniture screed is suitable for work.

What is a furniture drill for confirmation

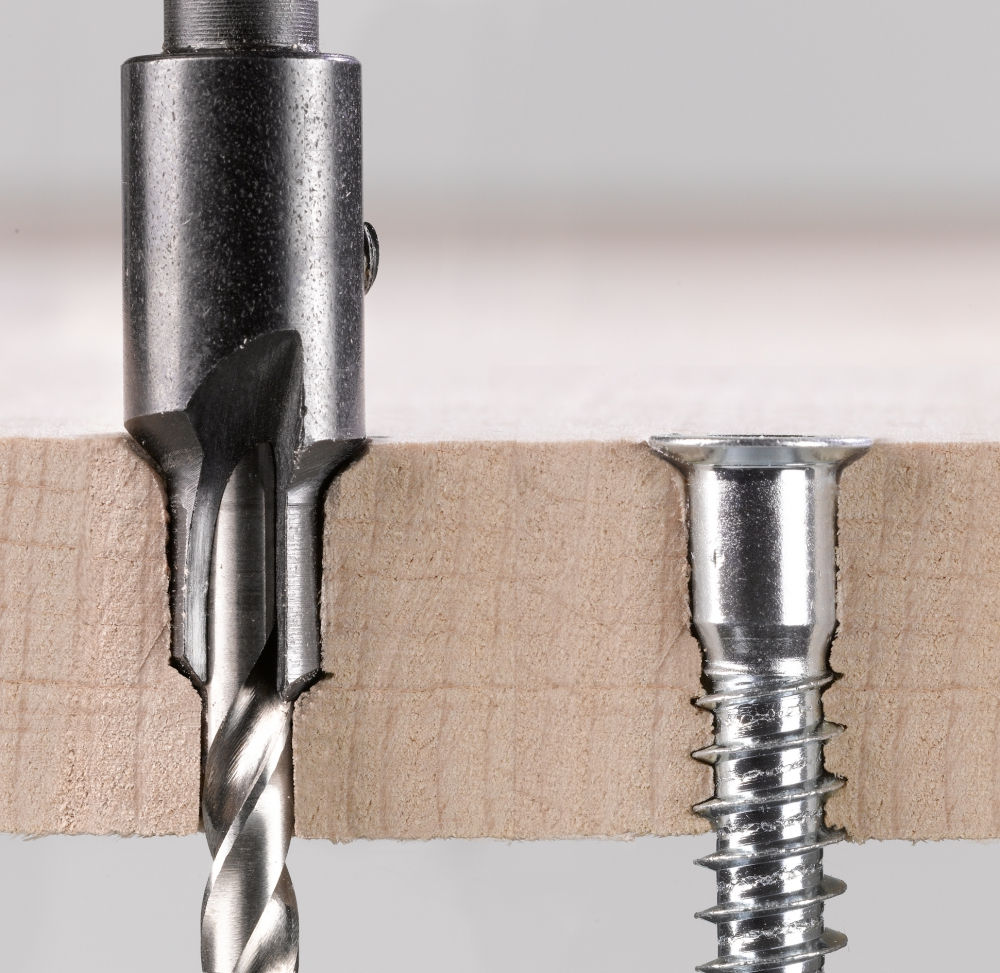

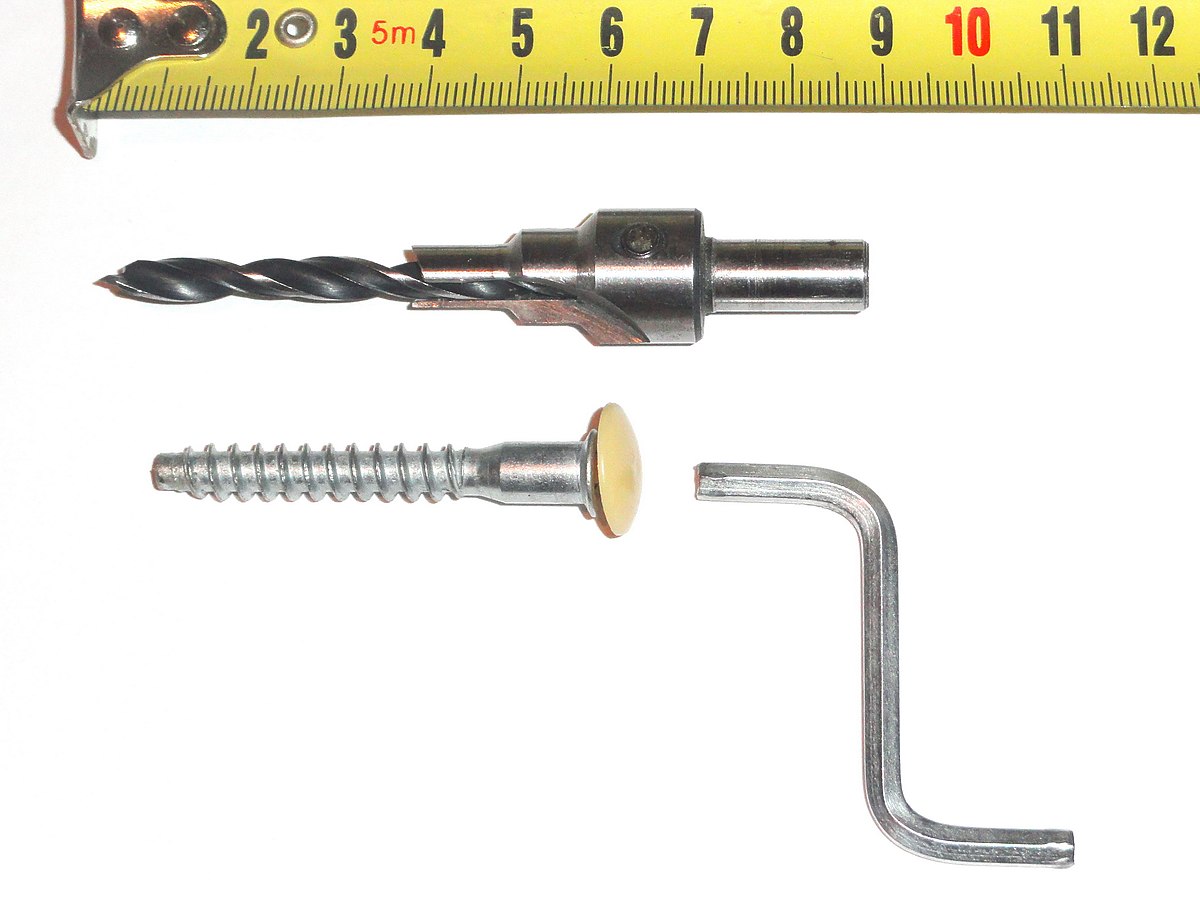

The most suitable for installing confirmations are drills that are equipped with a working head. One side of the device makes a hole along the diameter of the neck, and the other countersinks the place where the cap will be located.

Types and benefits

For work, ordinary furniture drills and equipped with a stepped mill are used. In the first case, small chips may remain on the surface, which will be covered by the screw head.

Drills equipped with a step cutter are more suitable. With their help, you can immediately chamfer for the location of the screw head.

Using such a tool allows you to get a hole of the desired diameter in one go.

For your information. The stepped cutter forms a suitable surface for the confirmation head. It does not chip away.

When buying, you need to check the hardness of the drill. It should be 61-64 Rockwell. This value can be found on the product packaging.

If it is impossible to see the information (the factory packaging has been lost), then you can see the data that is indicated on the drill body.

On Russian products, a steel grade is indicated. Products made of alloys P18 and P9M5 have the best performance characteristics. On European drills, you need to look for the HSS 4341 marking, which indicates that the product is made of high-speed steel.

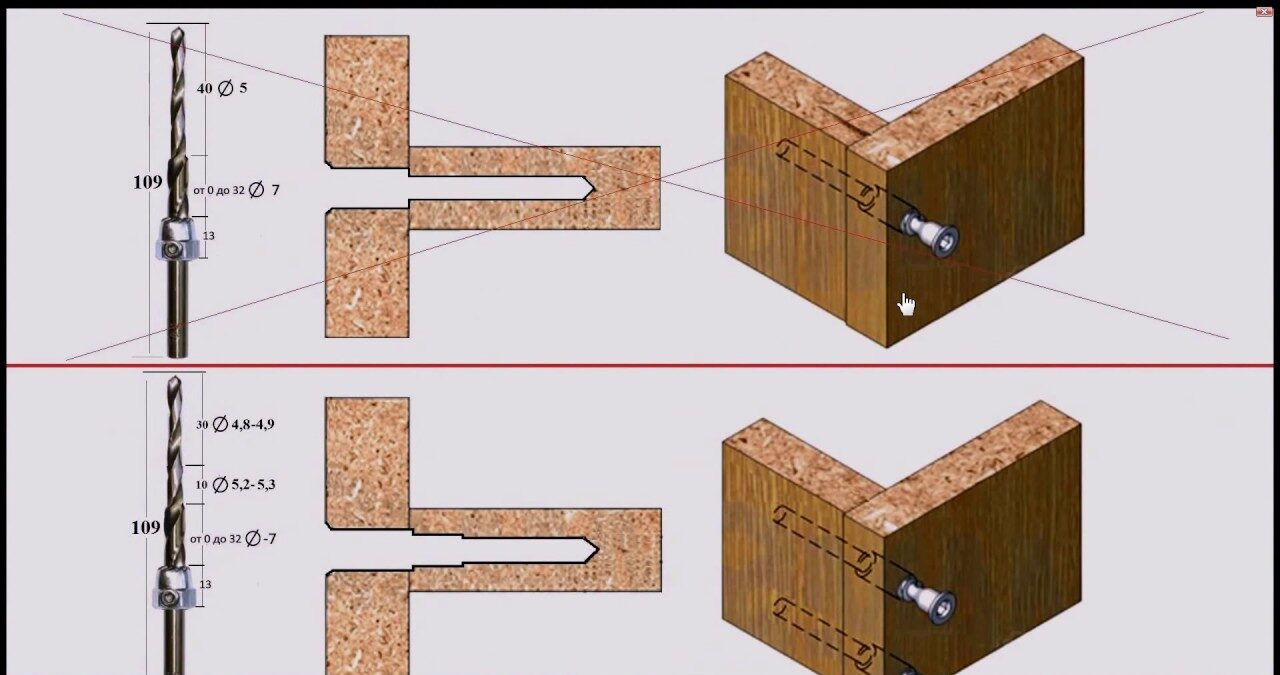

Drill dimensions

The dimensions of the drill bits for furniture are determined, depending on the material and dimensions of the confirmation.

At home, craftsmen are advised to use smaller diameter drills.

Correspondence of models and thread sizes:

- 5x40 and 5x50 - thread for the bottom hole - 3.4 mm, outer - 4.7-5 mm;

- 7x40, 7x50, 7x60 and 7x70 - thread for the lower hole - 4.7, outer - 6.3-7 mm.

How to choose the right

To make a choice, you need to measure the head of the Euro screw (its inner part). The indicators may differ from manufacturer to manufacturer.

If the value obtained is 6.3 - 7 mm, a 7 mm drill is suitable. It is universal for fastening models 7x40 - 7x70 mm.

Even if a slight backlash is formed during drilling, it's okay. In extreme cases, you can loosen the connection, adjust the location of the parts and tighten the confirmation again.

The same goes for models 5-40 and 5x50. Drills 5-6 mm are suitable for them.

Top manufacturers

The unrivaled leader in production remains Hafele, the brand that pioneered the supply of these fasteners to the market. The company's products are made of high-quality steel and are excellent for mounting hardware.

Products of the German company Hammer Werkzeug GmbH are also trusted. Among the Russian manufacturers, we can mention the Praktika company.

Recommendations and tips for use

To get a reliable connection of parts, you need to follow a number of rules:

- select a drill that meets European certificates;

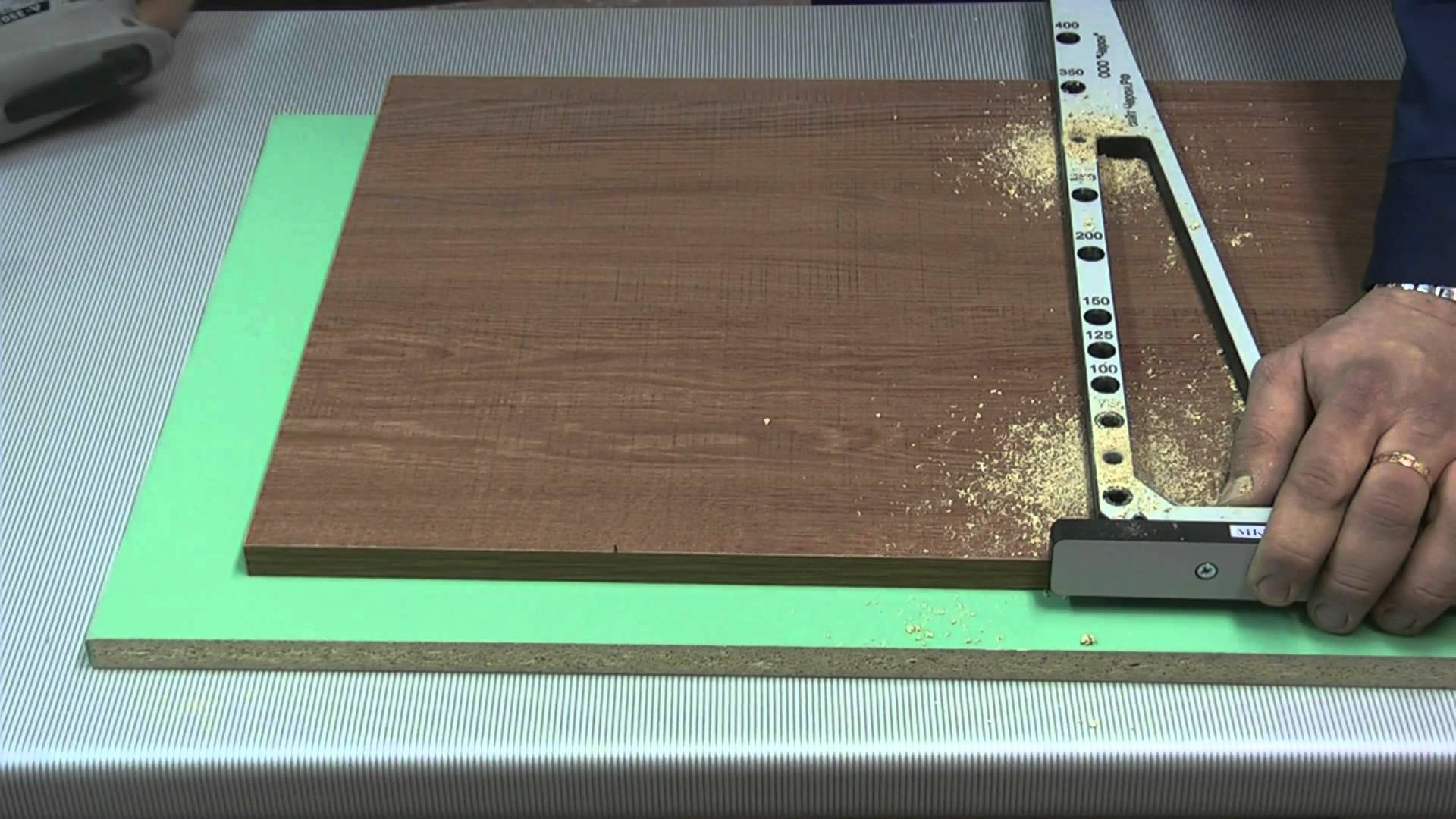

- apply precise markings on the component parts (take into account allowances);

- fix the details;

- control the tool while drilling.

For more convenience, you can get a special tool. You can buy a ready-made one or make it yourself: cut out a wooden template with a metal sleeve for a drill inside.

Versatile part additives help you get the job done faster and maximize build quality. With their help, preliminary holes are made smaller in diameter.

Video: Confirmation Drill