Manufacturing drywall shelves

The plasterboard shelf fits well into any interior because of its unusual appearance and large capacity. You can make it yourself at home. Let's take a closer look at how to make drywall shelves with your own hands.

Pros and cons of drywall shelves

This material is quite versatile - almost any product can be made from it: for the kitchen, living room, bedroom and even a bathroom.

The advantages of drywall are expressed in:

- Easy handling. Any shape can be cut from it;

- Low weight. The design will be practically weightless;

- Possibilities of decoration in any way;

- Long service life;

- Low cost;

- Opportunities to use both whole sheets and small pieces that could be left over from repairs.

Like any material, drywall has its drawbacks. These include:

- Fragility. In case of mechanical damage, it begins to break;

- Under heavy load, deflections may appear;

- Cannot withstand too high humidity levels.

The material gained such popularity due to its low weight: the structure can be easily moved, and it does not give too much load on the walls.

Varieties of shelves

In order to determine whether built-in or corner drywall shelves are best done, you need to understand the features of each of them.

Corner

They are perfect for a room with a small area, they will make the interior more attractive. Corner shelves are built into the corner of a room, most often used for storing books, figurines, etc.

They can be open or closed. The latter are used to store more hidden things. You can equip the shelf with lighting, then the overall composition will look even more attractive.

In addition, the shelf rack can perform two functions: decorative and functional. It is recommended to combine them into one.

Built-in

This option is built into the wall. It can also be equipped with lamps and decorated. Such a shelf will take up enough space, so it will not be suitable for small apartments.

How to make a drywall shelf with your own hands

Having decided on the type of product, you can start manufacturing. Let's take a closer look at this process.

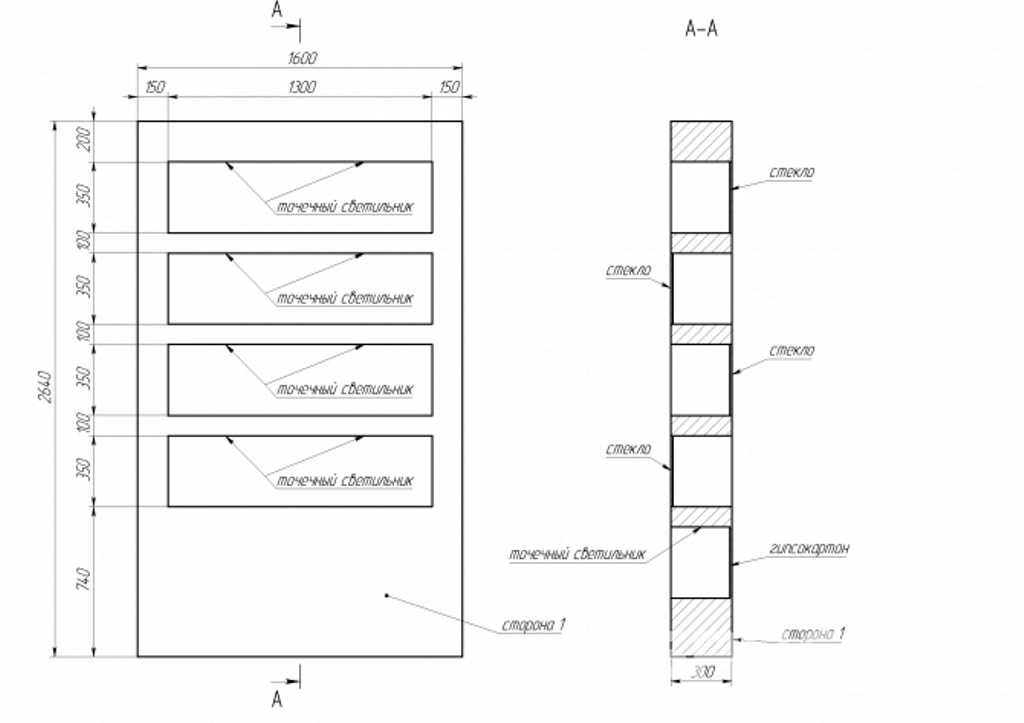

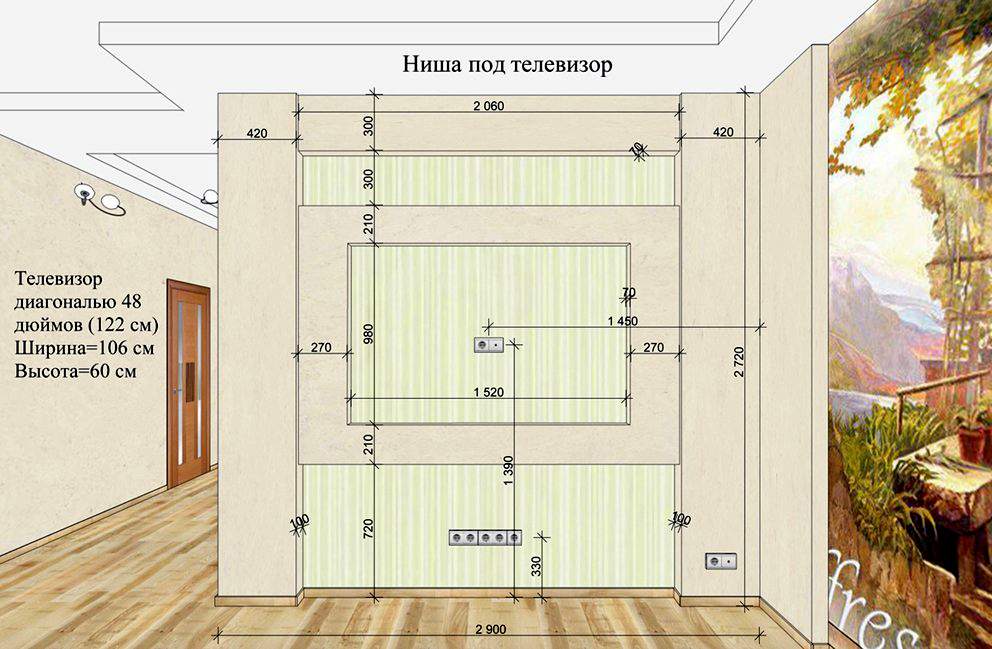

Drawings and assembly diagrams

The first step in manufacturing a product is to create a drawing. It needs to reflect the appearance, exact dimensions, tools and step-by-step execution of work.Editing is much easier with a sketch.

You can draw up a drawing yourself on graph paper or just on A4 sheet. You can also use a special program on your computer that will help you create a correct and clear drawing. You can use the Internet.

Preparing the wall

In order for the product to be durable and of high quality, you need to prepare the wall to which the structure will be attached.

First you need to remove the old coating. It can be wallpaper, a layer of putty, and so on. If there are any defects in the wall, then they must be eliminated. For this, all cracks and roughness are filled with foam or putty. Cover the wall with mortar for extra strength.

After the mortar has dried, the wall must be primed.

Note! In order for the surface to be smoother, you need to level it with a spatula.

Now you can proceed directly to the manufacture of the shelf.

The process of installing shelves from a profile

Initially, you need to decide on the shape, placement and whether the backlight will be built in, as this has a direct impact on the overall design.

The frame of the entire structure is a profile made of wood or metal. If the shelf is to be used as a storage for things, then it must be strengthened as much as possible. If she has only a decorative purpose, then strengthening is not needed.

For manufacturing, you will need the following materials and tools:

- Construction knife;

- Scissors for metal (if its use is provided);

- Pencil or marker;

- Corner;

- Plumb line;

- Self-tapping screws;

- Dowel;

- Drywall;

- Screwdriver;

- Drill;

- Reinforcement tape;

- Putty knife;

- Putty;

- Primer.

For processing, you will need paint, wallpaper, glue and a protective coating.

Note! The dimensions of a drywall sheet are about 3 meters by one and a half, with a thickness of one and a half centimeters. These parameters must be taken into account during manufacture.

Now let's look at the stages of work. First you need to mount the frame. As a material, you can take wood or welded into a single metal. The shelves are fixed with metal dowels for greater reliability.

Next, you need to attach sheets of drywall with self-tapping screws. Now you need to start puttingty. Ready.

If necessary, you can install the backlight: for this you need to attract the LEDs with screws. You can also decorate the surface with paint or patterns. Patterns can also be made from drywall.

Plasterboard shelves fit perfectly into almost any interior, giving it a zest. For self-production, you must follow the instructions and strictly follow the drawing.

Video: installation of drywall shelves in the bathroom