Corner shelf - how and from what you can make

To properly organize the space and save space, various devices are used that you can make yourself. Ergonomic and multifunctional furniture with an interesting design will emphasize the features of the room, and with good imagination it will become a unique design solution.

Consider how to make a corner shelf with your own hands.

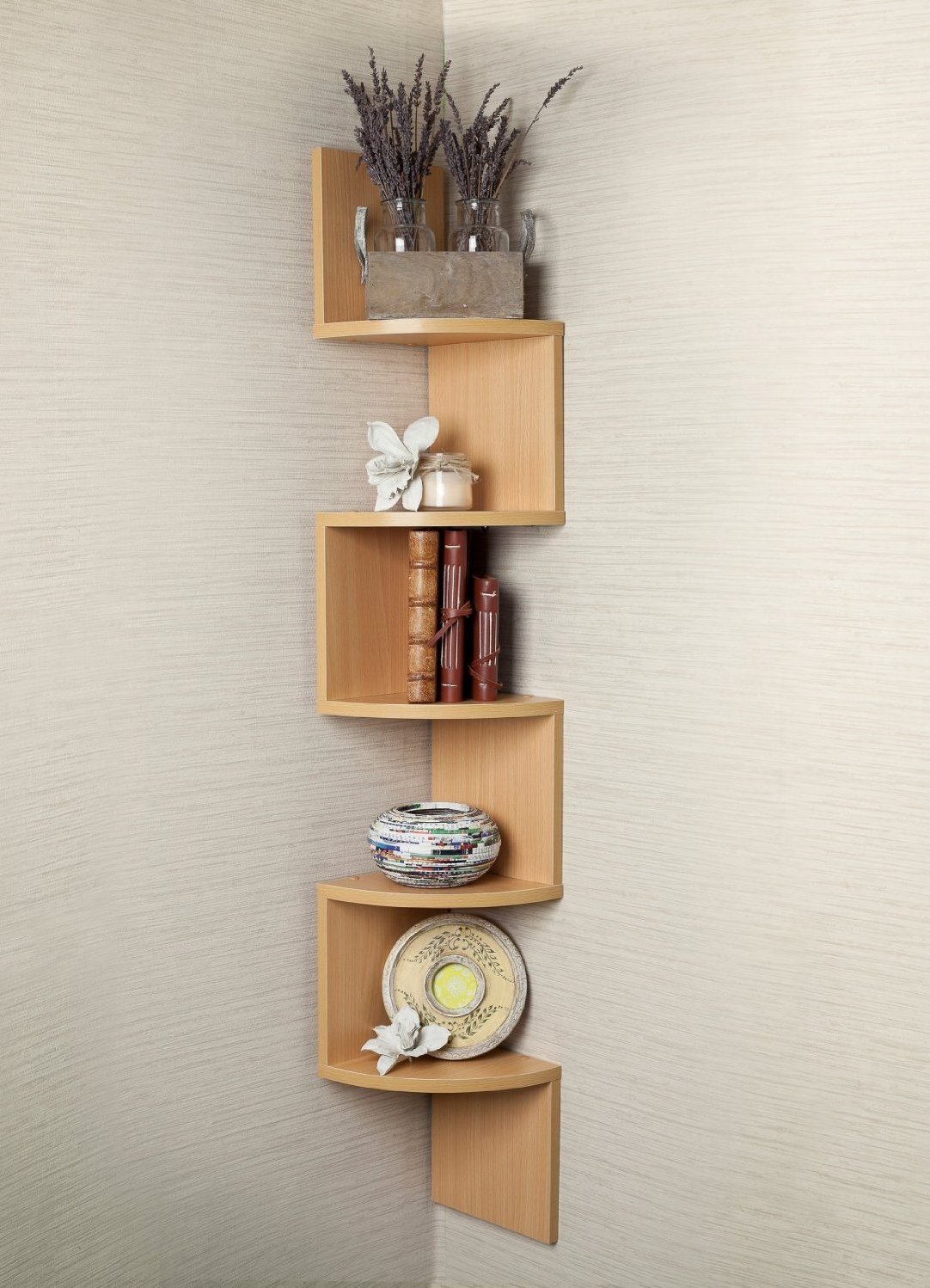

Varieties of corner shelves

In order to determine the type of product, it is worth studying the features and characteristics of various models that are used in certain rooms.

For kitchen

For greater convenience, it is necessary that all the necessary items are at hand. A comfortable and spacious shelf will help to cope with this.

For the kitchen, natural wood or materials containing it are best suited. Plastic, glass and metal should not be used due to their susceptibility to moisture. In terms of shape, it is better to give preference to the usual rectangular design with sides in the form of shapes.

In the kitchen, a shelf is used to store spices, cutlery or figurines. Therefore, it is not necessary to strengthen it strongly, since it is not designed for heavy objects.

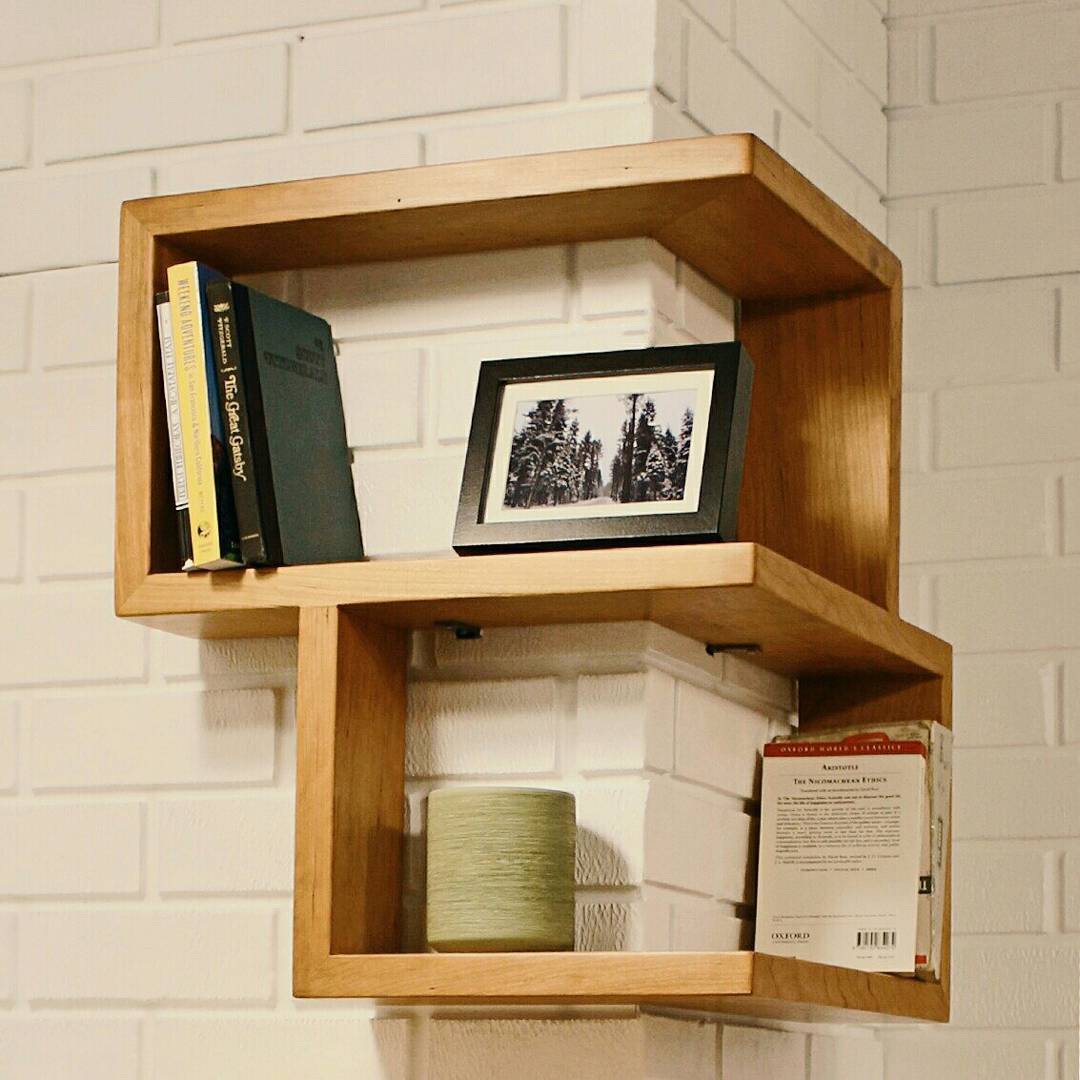

For the living room

This room is intended for relaxation and reception, so the shelves are mainly used for decoration. Here you can place photos of the family, figurines and decor items.

In order to choose the right model, it is important to be based on the load that is applied to the product. So, to store books from your personal library, you will need a strong and spacious enough shelf.

In this case, you can use any material: wood, glass, metal or plastic. The choice depends on the purpose of the product. When using a glass structure, do not overload the shelf, otherwise it will look too busy, and not gracefully, as planned.

Shelves made of drywall or wood will look great. Such products look sophisticated and in themselves are interior decorations.

For bathroom

This room is indispensable without a comfortable and spacious shelf. When choosing, keep in mind that there is high humidity in the bathroom and the material must be resistant to water; wooden and metal structures should be avoided.

The shelf should be spacious and roomy to accommodate all the jars and tubes. And also durable and reliable, since it must withstand heavy loads.

For the bathroom, it is best to choose:

- Glass with chrome-plated stands;

- Plastic with metal uprights.

Note! The simpler the design, the easier it is to wipe clean. In conditions of high humidity, this is a very important condition.

What tools are needed to work

To make your own shelf, prepare the necessary tools. Their set depends on the material to be used and the degree of complexity of the model.

For a simple corner shelf on the wall with your own hands made of wood you will need:

- Jigsaw;

- Ruler or meter tape;

- Hacksaw;

- Glue;

- Drill;

- Screwdriver;

- Level;

- Triangle;

- Sandpaper;

- Mountings.

When making a metal shelf, you will also need a welding machine. If the basis is glass, then you need to prepare a glass cutter. Materials for finishing are also required: varnish for wood, coating for metal, paint, accessories.

How to make a corner shelf with your own hands

Various materials and shapes are used in the manufacture of shelves. Consider the step-by-step execution of work.

Made of wood

It is best to take natural wood as a basis, since it is an environmentally friendly and safe material for humans. Working with wood is much easier than working with metal, which is also a significant plus for a beginner.

In order to choose the right material, you need to follow the following rules:

- Pay attention to the quality of the board. There should be no cracks or rot on it;

- There should be no deep scratches or gouges on the board;

- Oak, birch, or pine are best.

Now you can proceed to the direct manufacture of the shelf.

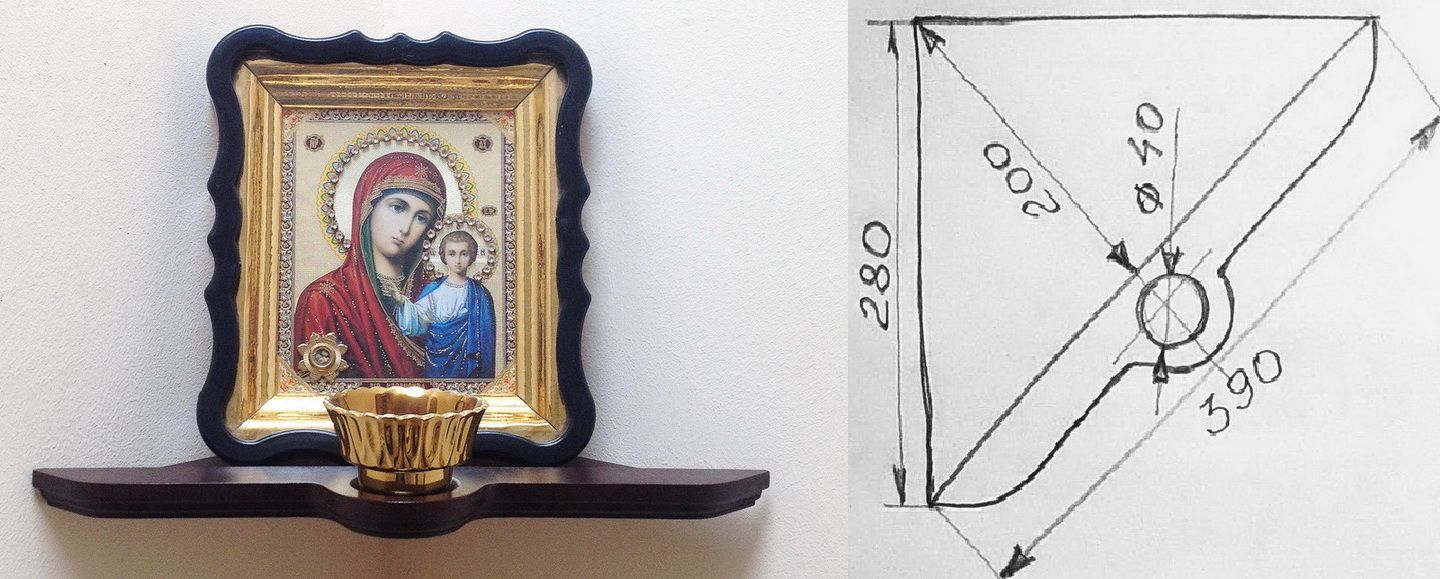

The first step is to create a drawing. On it, you need to clearly and in detail depict the appearance of the structure with all dimensions. If necessary, you can use the help of the Internet or special computer programs.

The second step is making blanks. Cut the boards diagonally and sand them. As a result, you should get two triangles. Make racks out of four planks and process them. Connect the triangles and uprights at right angles.

The third step is processing. With the help of sandpaper, you need to process all chips and roughness. After that, you need to cover the structure with a layer of paint or varnish.

The fourth step is to attach the structure to the wall. First you need to make marks on the wall so that the shelf hangs straight. This can be done with a pencil or marker. To do this, attach the stand to the corner and make marks. Using a drill, you need to drill holes in the wall where it was marked and attach the structure. Ready. For greater reliability, you can also use glue.

Chipboard

Consider the step-by-step manufacture of a chipboard shelf with rounded edges. First you need to create an accurate drawing with dimensions and the tools and materials used.

The first step is to mark the chipboard sheet. After that, cut out the fragment with a jigsaw. They need to be processed with sandpaper.

The second step is to make three shelf racks. Sand and drill holes with a drill for self-tapping screws. Now you need to treat it with varnish or paint and attach it to the wall with self-tapping screws and glue.

From laminated chipboard

Another wood-based material is chipboard. It is great for making shelves.

Note! For greater structural strength, you need to opt for boards with a thickness of two centimeters.

The first step is to make fragments in accordance with a previously drawn up drawing. Parts are processed with sandpaper or a grinding machine.

Second phase. Cut out the racks from the chipboard sheet and attach the previous fragments to them. Attach additional supports to the inside of the shelf.

Stage three. Product processing. To do this, you can use varnish, paint or some kind of decorating technique.

Made of metal

This will require metal pipes and steel sheets. A frame is welded from pipes using a welding machine, consisting of supports and supplies for future shelves.

Then fragments of a suitable size are cut from the sheets of steel. These fragments need to be welded to the frame. Now we need to process the resulting construction. First of all, you need to use an anti-corrosion coating, then a special paint for metal.

Corner shelf saves space and serves as an interesting design solution. For its manufacture, you need to choose the most suitable material, depending on the purpose.

Video: do-it-yourself corner shelf