Calculation of boxes on ball guides

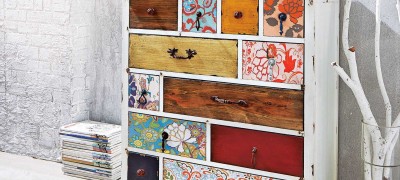

Remember how a wooden boy with a long nose turned out from a log? It was created by an old carpenter. Do you want to become the same master and learn how to make furniture with your own hands, create an original style. Start small, build a drawer. Today not a single type of cabinet furniture can do without them, from a sliding wardrobe to kitchen cabinets and nightstands.

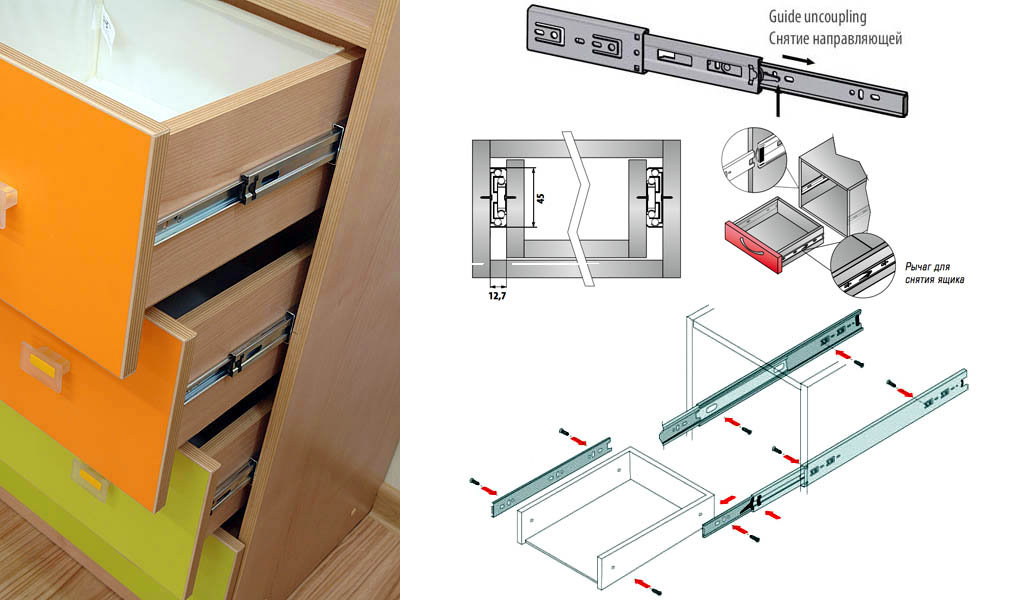

When calculating the parameters of a retractable accessory, it is necessary to take into account everything to the smallest detail, especially such a thing as guides. They provide free movement of the box inside the body. For example, ball guides for drawers, the dimensions of which depend on the length of the side walls.

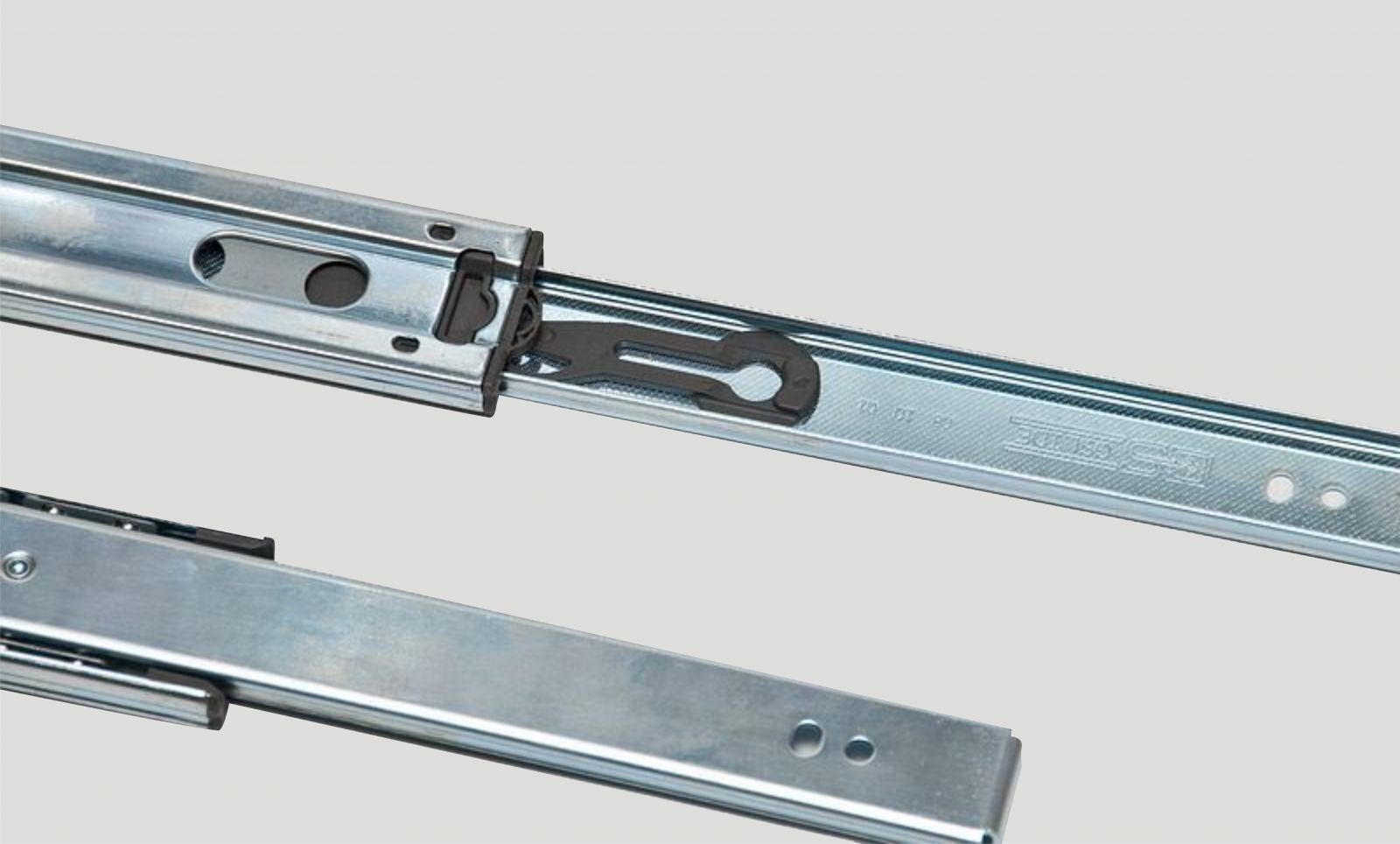

What is drawer ball guides

Before calculating a box for ball guides, you need to find out the features of their design, find out standard sizes and types. Their main purpose is to direct the movement and ensure smooth, silent operation of the mechanism. Until recently, furniture drawers moved along wooden grooves when they were pulled out. This process was quite noisy and required some effort.

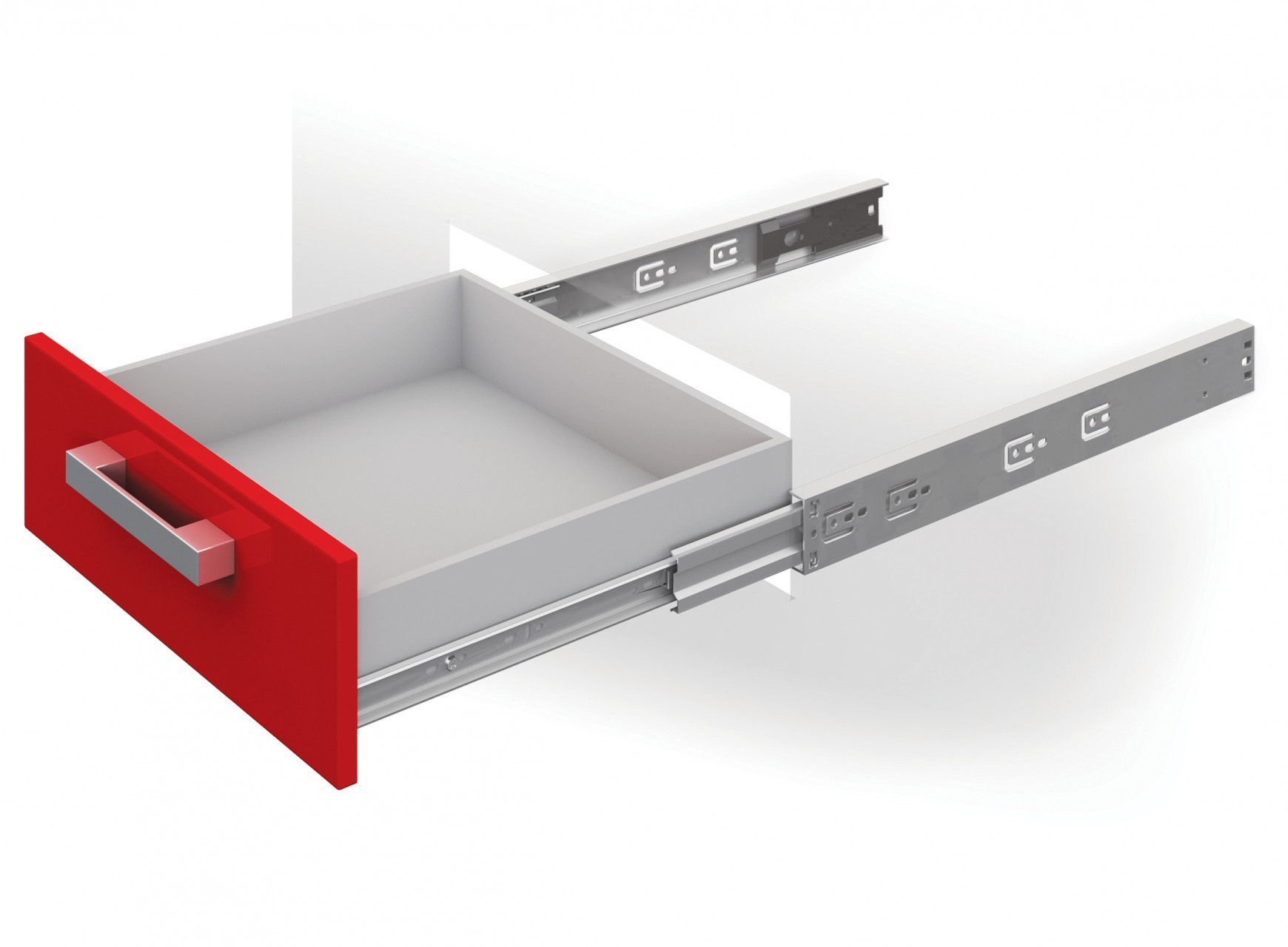

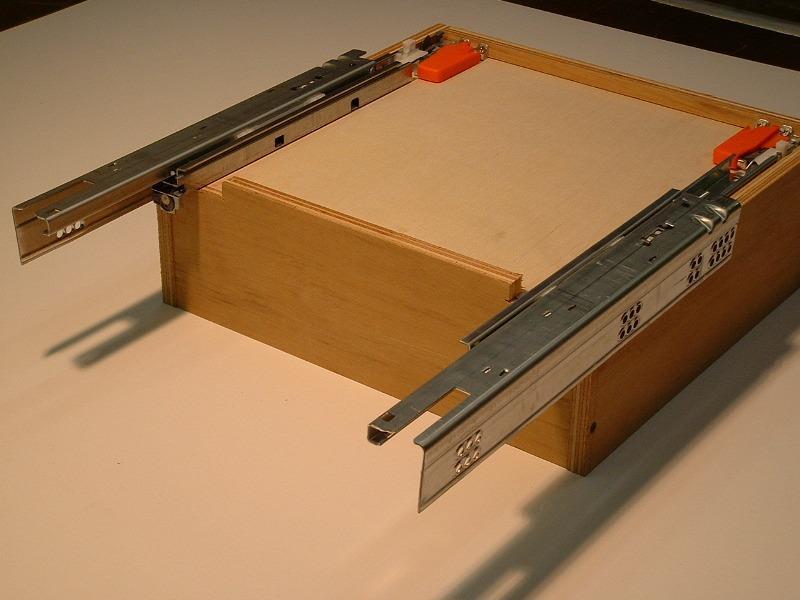

With the advent of retractable devices, the situation has changed radically. Structurally, they are made in two types - with rollers and with ball bearings. The advantage that the ball mechanism has is that it is quieter, smoother and allows the drawer to be fully extended. In comparison with roller ones, they require a little more effort during operation. They are attached to the side surface of the box.

The dimensions of the drawer guides have the following meanings:

- the reinforced structure differs in height, which is 45 mm, while the base height is 35 mm;

- the thickness of the device is 13 mm;

- the length of ball guides is always a multiple of 50 mm and, usually, varies from 25 to 60 cm for basic ones, reinforced ones - from 30 to 55 cm.

Types of furniture guides

There are two types of designs for pull-out mechanisms for furniture drawers:

- Roller - economy option. Wheels are used as a moving element. Furniture makers install them on economy class furniture. The main disadvantage is a small power reserve, almost a third of the drawer, when pulled out, remains inside the furniture body. But, they have an attractive price and a large margin of safety.

- Ball guides (telescopic). Provides full extension, smooth running. There are options for a reinforced structure and equipped with a closer. Balls are used as a moving element, which are silent when moving.

In addition, the retractable devices have a number of other design features.

Roller

Such mechanisms appeared about fifteen years ago and instantly became popular with furniture makers and furniture consumers. Today it is difficult to imagine drawers in a closet without guides.

The main advantages of this type of fittings are:

- work without lubricants;

- easy installation;

- smoothness and ease of movement.

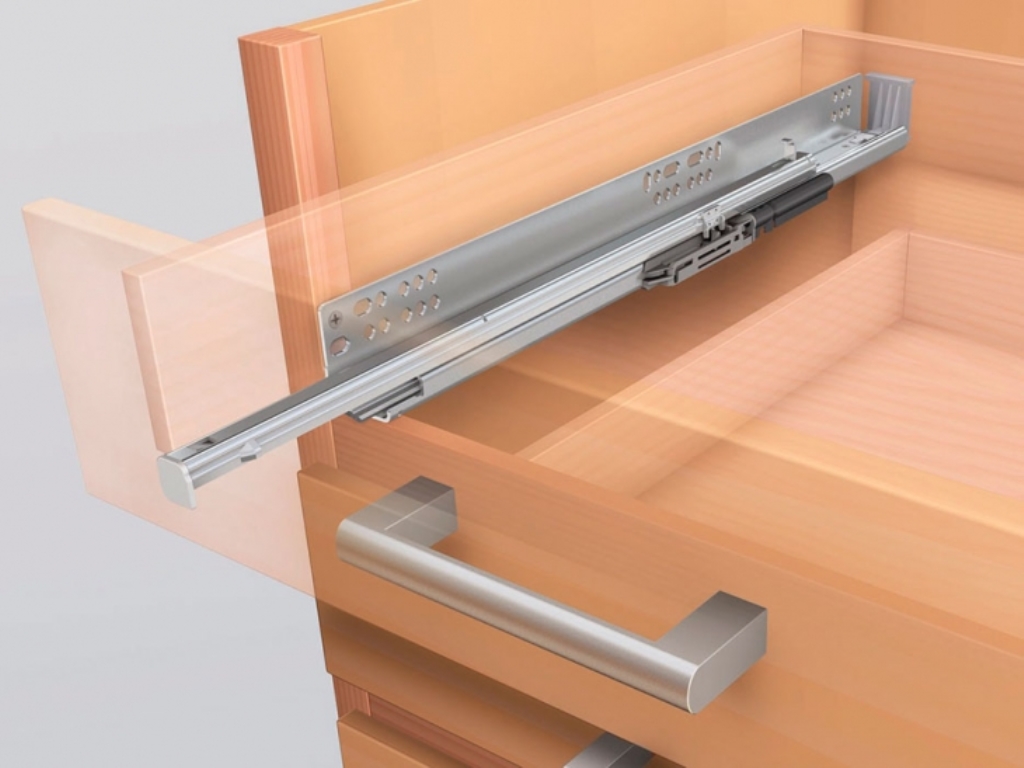

The pull-out mechanism consists of two parts, one of which is attached to the side of the drawer during assembly, the second is inside the product body, where the drawer is placed. There are no restrictions on the size of the furniture, while the roller mechanism has a length of 26-60 cm.

With a closer

More popular than other systems are pull-out mechanisms equipped with a closer and damper. They are more reliable in operation, durable and withstand higher loads.

Mechanisms equipped with damper devices open and close silently and smoothly. The damper itself works as a shock absorber. It is effective when excessive closing force is applied.

The closer picks up the drawer when closing, when it is already, almost, in the extreme position and gently returns it to its original state.

Ballpoint

Ball-bearing guides or telescopic mechanisms for opening furniture boxes differ in their shape and some design features. Taking into account such features, there are three groups of ball guides:

- The number of levels is one or more.

- The number of sections is one or more.

- The mechanism can be disassembled - non-collapsible and collapsible.

Non-collapsible guides have a lower cost due to the complexity of the production of a collapsible structure. The cost increases with increasing levels and sections. The balls in the bearing of the rail mechanism are steel or plastic, and the latter are quieter, but less wear-resistant.

Concealed installation

The rail mechanism for retractable elements of cabinet furniture with hidden installation is becoming quite popular among furniture makers. Such devices can be equipped with a door closer and a reverse action system. The main advantage is hidden installation, when assembled, it is installed on the bottom of the box. During operation. the retractable slats are not visible and the impression of the weightlessness of the box is created. Fittings of this design are highly reliable, providing soft and silent closing of the sliding furniture elements.

Reverse action

Reverse action systems operate according to the door closer principle. A distinctive feature of such fittings is that the mechanism is triggered in the direction of opening. To pull out the drawer on which the slats are installed, with the opposite action, you need to lightly press the front part. Hearing a click, release the force and the drawer will slide out on its own. The presence of a reverse system on pull-out furniture elements allows you not to install handles on them.

Full opening systems

When calculating boxes on ball guides in the manufacture of furniture with deep niches, the presence of full opening systems should be taken into account. The specific telescopic design of such rail sliding mechanisms allows the drawer to be fully opened, which is very convenient for viewing its contents. This functionality is provided by folding one-in-one rails and a ball bearing. Such systems are widely used in the furniture industry.

Which retractable mechanism to choose

The calculation of drawers is always associated with the choice of a drawer. Three points are fundamental in this question:

- Acceptable cost.

- Estimated load.

- Design - design features, color.

These points should be considered together, choosing the most compromise option. The most economical choice is standard roller guides. But, low cost is not always justified. If heavy loads are expected, then in order to avoid early destruction of the guides, you should pay attention to ball structures or the possibility of hidden installation of the rail mechanism.

For furniture design features that do not imply the presence of handles, it is best to use reverse acting systems, but they are not desirable in children's rooms. For furniture with deep niches, telescopic full-opening mechanisms will be most acceptable. If you don't have budget constraints, use tandemboxes.

Drawer guides

Ever since devices have appeared in the furniture industry that provide easy and soft movement of pull-out elements, they are constantly undergoing design changes, improving their functionality.

The most popular are roller-type guides. Simple design and installation make it easy to remove the box from the guides, which is very convenient for keeping it clean and finding lost items. Disadvantages - noisy move, difficulty with color matching, demanding maintenance.

More complex in design, installation and more cost mechanisms with a ball bearing. They work quietly, have a smooth ride, and cope well with heavy loads. They differ in design features:

- have a closer and a damper;

- with hidden installation;

- telescopic for full opening;

- with reverse directional action.

Tandemboxes are a complex design, which is both a guide and a side wall of the box. Such systems have a number of advantages:

- durability;

- ideality in work;

- a damper and a closer are installed on them.

The disadvantage is the high cost.

Installation of guides

The nature of the fastening of the bottom of the box is determined by the type of guides used. When installing roller mechanisms, the bottom can be secured with furniture nails.When the installation of ball guides is provided, fastening is carried out with self-tapping screws or the bottom is made loose.

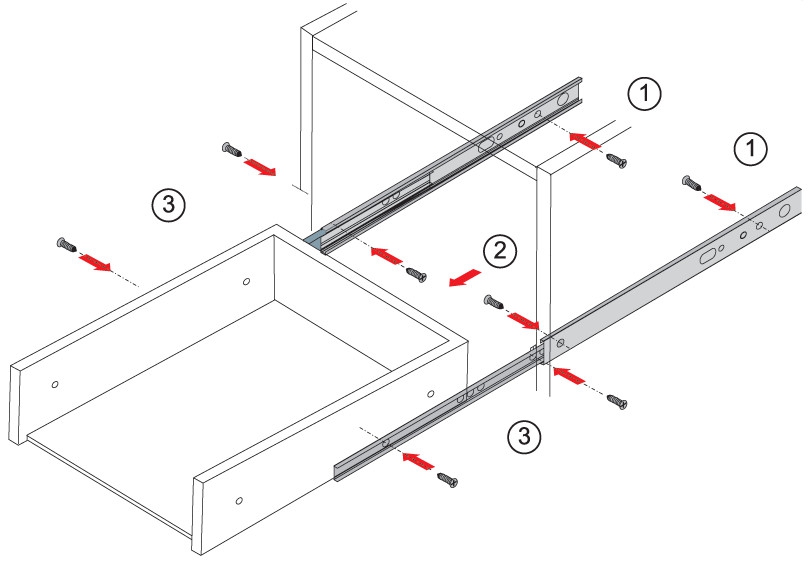

Consider step by step the process of installing rail mechanisms for pulling out a drawer:

- Disconnect the guide and place its inner part along the longitudinal axis of the outer side of the side of the box. We adjust the position along this axis using the technological holes on the rail.

- Align the front edge of the guide with the edge of the side wall from the facade side. Then we adjust the transverse arrangement of the plank and fix it with self-tapping screws.

- In the same way, we attach the outer part of the guide rail to the vertical surfaces of the niche. The longitudinal axes of movement are preliminarily marked.

- Before the final fastening of the rail to the wall, check that the drawer will close completely.

It is important to take into account when marking that gaps of at least 2 mm must remain between the facades.

Major installation errors

The one who does nothing is not mistaken, but that mistakes can and should be avoided. And we will learn from the mistakes of others. The assembly of the structure is the final part, for which mastery of the tools and care are important. Major inaccuracies are allowed at the stage of calculations and marking. The most common are:

- the depth of entry of the guide inside the niche is not taken into account;

- there is no gap between the facades of the boxes or between the facade and the upper part of the structure;

- incorrect calculation of the dimensions of the box;

- inaccurate measurement of the distance from the lower edge of the facade to the bottom of the box.

During installation, the main thing is to set the left and right parts of the rails at the same height to avoid skewing. Concealed slats require a very precise fit.

The choice of movable fittings should be approached taking into account the design features of the furniture and personal wishes. If you want the mechanism to work longer, refuse the cheapest offers. In terms of price and quality, ball, sliding mechanisms are an acceptable option.

Video: installing ball guides