How and how to saw off a countertop without chips

It is generally accepted that without professional equipment it is impossible to cut sheet materials evenly. However, there are several ways to do this on your own.

We will tell you how to cut a countertop without chips using household tools.

- Basic rules for cutting plywood or chipboard

- How to cut a countertop without chipping using a hacksaw

- Is it possible to cut with a jigsaw

- How to cut with a circular saw

- Sawing with a milling cutter

- Sawing with a panel saw

- Undercut sawing method

- What can not be sawed

- Video: sawing a countertop without chips

Basic rules for cutting plywood or chipboard

The most suitable tools are circular or band saws.

To get a clean cut, you need to follow the rules:

- fine-toothed saws are suitable for work;

- first of all, the material is sawn across the fibers, then along. This method will save you from splitting corners;

- from the front side, the material is sawn with a hand or band saw;

- from the seamy side - saw with a contour or disk tool;

- when working with a circular saw, it is necessary to monitor the high speed and low feed rate of the material;

- saw blade teeth should penetrate shallowly into the surface;

- so that fewer creases appear on the board, you need to guide the saw along the cut line, with light pressure and insignificant recoil;

- adhesive tape attached along the cut line will protect the material from chipping.

In a home workshop, you can achieve an even cut. But it is better to entrust work with dimensional sheet materials to professionals with specialized equipment.

How to cut a countertop without chipping using a hacksaw

A regular hacksaw is fine for cutting through a countertop. However, when working, you need to take into account that you need to leave a margin of at least 100 mm. The tool must be fine-toothed. Better if it is a hacksaw for metal.

Attention! Teeth should be hardened and set 1/2 of the material thickness.

To work, you need paper duct tape, a rough cut file, and fine sandpaper.

How to properly cut a tabletop with a hacksaw:

- mark the cutting line with a sharp tool;

- stick paper adhesive tape along the marking to protect the top decorative layer;

- direct the movements of the hacksaw at an acute angle to the surface of the sheet (no more than 30 degrees);

- cut smoothly, with medium pressure.

If chips appear, they need to be processed with a file, moving from the edges to the center. Sand the remaining minor defects with fine-grained emery paper.

Can I cut with a jigsaw

The tool is suitable for making small cuts. You will need a tool for working with metal, with fine teeth. The incision is made on the front side: this way there will be fewer chips on it, and there will be small irregularities on the seamy side.

During operation, the instrument is built not at maximum speed, but slightly above average. It is necessary to move the tool in smooth movements, with light pressure.

Important! The method is not suitable for cutting long materials, as it is difficult to maintain a straight cut line.

How to cut with a circular saw

The tool can make long cuts, however, more chips are formed during operation (compared to cutting with a jigsaw). You will need a fine-toothed saw blade.

As a rule, the side from which the teeth cut in remains clean, while the opposite side is chipped.

It is more convenient to work with a saw fixed on the table. Thus, the tool is not occupied and the guide can be used. This will increase the accuracy of the cut, allowing you to make several parts.

The chips that form after the cut can be processed with a file and sandpaper.

Sawing with a milling cutter

A great way to get a clean cut. First, the material is sawn with a jigsaw with an indentation of 2-3 mm from the marking line. Then the line is aligned with a cutter according to a previously prepared template. A cutter with a bearing is suitable for work.

In this way, you can make not only straight, but also curved cuts, make radius parts.

Among the disadvantages of the method: it is necessary to apply accurate markings, file the blanks in advance and set the template under the router. That is, it is inconvenient to cut off several identical parts with a tool.

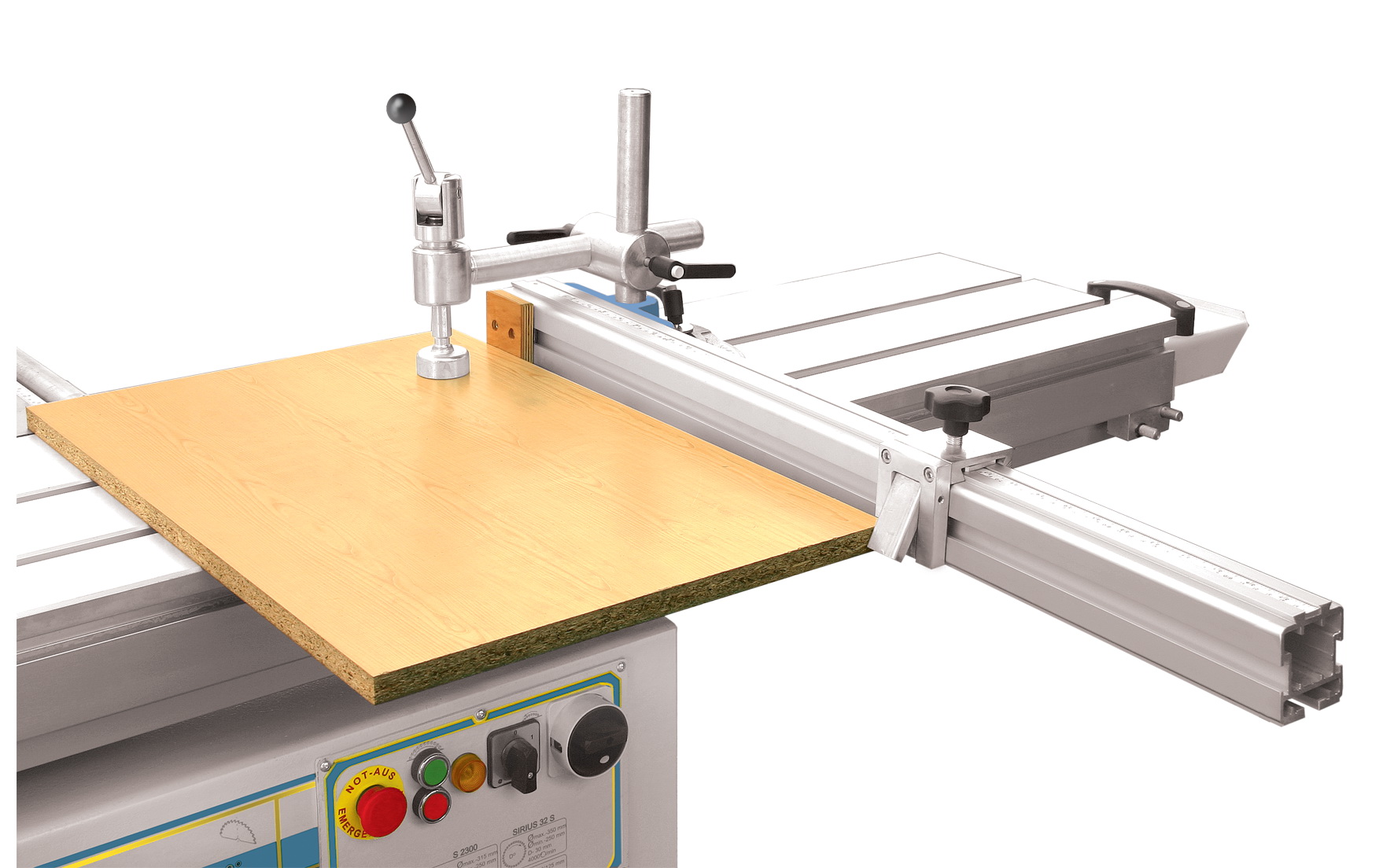

Sawing with a panel saw

The most suitable tool for cutting boards and pressed materials of various thicknesses. The cuts are accurate and multiple parts can be stamped.

They have a small size and weight (up to 20 kg), easy to install. If necessary, the machine can be removed and moved to another location. The tool is suitable for ripping to a depth of 8 cm. Also in the home workshop, you can saw the tabletop with a circular saw with an extended table.

They are more convenient than household ones, since they allow you to cut not only along the longitudinal, but also along the transverse lines. The maximum cutting depth is 9 cm. When working, you need to apply accurate markings and observe safety precautions.

Undercut sawing method

This method also involves using a circular saw, but a plunge-cut is more suitable.

You will need a double ruler: it is fixed with clamps to the workpiece. The principle of operation is the same as that of the panel saw: two cuts are made along the same line.

This is what the bus bar is used for. It is installed along the marking line, the laminate is slightly cut without disturbing its texture. Then the material is cut along the marked trail.

By the way! Due to the notch in the laminate, no chips are formed during the second deep cut.

This method can be used to saw a worktop into one or more parts. Minimal chips are possible, but they can be easily removed with regular sanding or hidden with a decorative overlay.

Disadvantage: This method can only make a straight cut.

What can not be sawed

A grinder or an angle grinder is something that you should not cut a tabletop with. Some masters advise this method to save time. However, it has more disadvantages than advantages.

Firstly, the quality of the parts is low: due to the sharp movement of the disc, many chips appear. Second, if large discs are used, there is a high likelihood of injury.

In addition, a lot of dust remains after work, which is unacceptable at home.

Video: sawing a countertop without chips