Making a kitchen dining table with your own hands

Walking through the major retail chains, you can see a huge variety of new and modern kitchen tables. However, pricing always leaves questions. Citizens do not understand why they have to pay 15-20 thousand rubles for a seemingly ordinary table. Those who understand how prices are determined know that out of these 15 thousand, 30% goes to pay rent and salaries for employees, the rest is transportation, and only a small part is spent on material.

To eliminate a number of unnecessary expenses and get a high-quality table, the cheapest way is to do it yourself. Below you can find information on how to make a kitchen table with your own hands, what drawings you can use and much more.

Varieties of kitchen tables

In apartments, the dining area takes up 50% of the entire kitchen. Manufacturers make new convertible models that help save space. You can also support ergonomics and make a comfortable area for the whole family with your own hands. It is recommended that you familiarize yourself with the forms and materials.

By form

There are two common shapes for a dining area:

- Rectangular - most often they undergo transformation due to the use of sliding mechanisms. Ideal for room design where corners are used. They are chosen more often by large families, where it is customary to get together.

- Round - for a young couple, this shape is best suited. However, it will not work to put the table in a small room, since the circle initially gives the impression of a dedicated area. He focuses on himself when guests enter the kitchen. There is another advantage, if square meters allow, you can make a large round table, decorating with dishes, flowers and beautiful glasses, you will always have the impression of luxury.

- Oval is a compromise between round and rectangular. Well suited for large families with small children. They are often made folding out of round ones.

- Non-standard shape - made based on the creative design of the kitchen. You can find triangular, rhombus, trapezoids on the Internet. They are done quite simply, the main thing is to stock up on glue and clamps.

Additionally, it is worth highlighting the types of mechanisms that allow you to change the size and even the shape:

- Sliding - part of the table top is pulled out, an additional part rises from below, increasing the table by 30%. For a small kitchen, this is a real salvation;

- Swing-out - the mechanism has been used for 70 years, the tabletop was initially folded in 2 layers, when turning, you can fold back the second part, while creating 50% of the dining space.

There are two drawbacks to tables with a mechanism: they are heavy and the joints are visible, which will affect the aesthetics. If the family is large and the kitchen is small, this option is ideal.Despite the fact that the joints are visible, you can always choose a structure that will successfully fit into the design of the room.

By material

The material of the table top is of great importance, if the legs can still be corrected, then the work surface cannot.

Tabletop material options:

- MDF is cheap, you can choose any texture and even color. The main disadvantage is a short service life. The weak point of such material is water and dampness, the plate swells, loses its appearance;

- The tree looks impressive and rich. If properly soaked and prepared for operation, it will last a very long time. The cost depends on the type, the best option is ash or birch;

- The stone is natural or artificial. A practically durable option, when using an artificial one, it is possible to choose any color. Easy to clean, does not accumulate dirt, does not allow mold and mildew to develop;

- Glass - used in modern design, it looks very organic and visually enlarges the space;

- Ceramic tiles - texture is additionally selected (wood, stone). Easy maintenance, just use a damp cloth. The tabletop is decorated with mosaics, painting (combined with a kitchen apron);

- Plastic is gaining popularity. The main plus is a wide selection of colors and shapes. Modern material is resistant to temperature changes, cuts, and is not susceptible to bacteria.

Important! You can make your own MDF countertop. However, it should be understood that this is not the best material option for a surface that will be wet cleaned.

To create a product from a different material, you can contact a specialized company. If you can still make glass at home using a glass cutter, then with plastic things are more complicated. Alternatively, the plastic can act in the form of legs. For this, PVC pipes are used.

How to make a kitchen table with your own hands

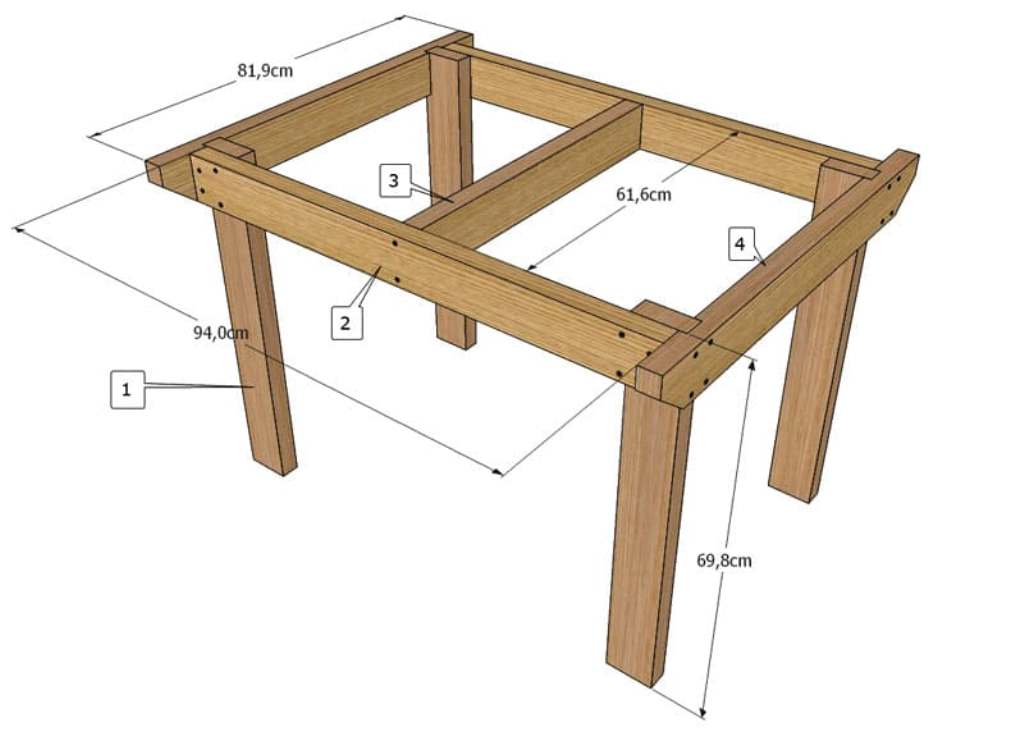

The production of a table for the kitchen will not take a lot of time and effort. Below are instructions and drawings to simplify working with a do-it-yourself dining table made of quality wood.

Round or square kitchen table

It is easiest to make a round or square table without the use of extension mechanisms. To do this, first, wood is selected, then the master follows the highlighted instructions. The drawings can be found below.

When making a list of what is needed, it is better to give preference to the best materials and components. In this case, the master saves on a lot initially, so the funds should be spent on improving the appearance and quality of the table. The size lends itself to change, you can change it yourself when drawing up your own drawing, the highlighted one is more suitable for creating a basic view of the future structure. Using the same technology, you can make a square copy.

The round table is more difficult to make. To do this, you need to have a grinding machine, clamps and find high-quality glue. The drawing can be taken as a basis, the legs can also be changed, at the discretion of the master.You can see the detailed information in the photo.

Small instruction:

- First you need to collect tools - a furniture compass, a jigsaw, a screwdriver, metal corners, wood varnish, wood glue.

- To make a sturdy tabletop, it is enough to glue the planks in several rows. You only need to use wood glue for this, be sure to resort to clamps. When the base is ready, a circle is drawn with the help of a compass, then cut with a jigsaw.

- The processing process is equally important. You should not skimp on the material, you will need at least 3 layers of varnish for the entire product.

For inspiration, it is recommended that you familiarize yourself with the photo of ready-made tables for the kitchen.

Folding table

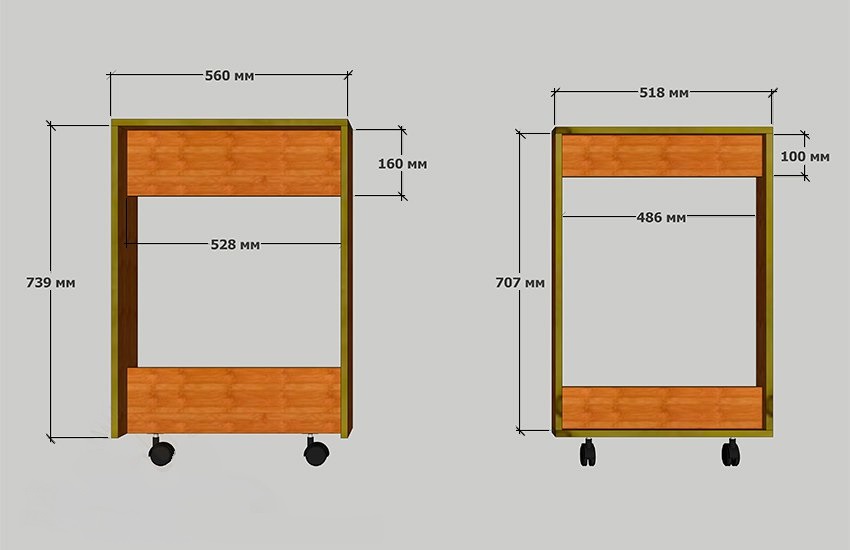

Making a folding table with your own hands is much more difficult. Here you need to figure out how the mechanisms work (by the way, you can buy a ready-made one). The original can be made using 2 sides.

If you connect them even with simple loops, you can achieve an equally successful result at minimal cost. Below you have to consider the diagram. To make the table more mobile, wheels are attached to the legs.

Small table for a small kitchen

For a small kitchen, it makes sense to use a folding table that is easy to hide when not needed. It is quite simple to make it, it is worth paying attention to the scheme. By the way, in the assembled version it may look like an ordinary picture on the wall. Suitable for a small family of 2-3 people.

Tiled table

This method is perfect for restoring an old table. Even if there are only a few tiles left after the repair, you can not give it to your friends. Step-by-step master class:

- For laying, you will need a standard 20 * 20 tile (the master can use any size).

- The surface of the old table is leveled by grinding - by hand or with a typewriter. This is done to remove the old coating.

- Next, the tile is calculated based on the dimensions of the countertop. Size - 105 * 65. For the seam between the joints, usually 2 mm is left.

- The markup is created, the tiles fit into each cell.

- Create a frame - you can take a regular wooden baseboard.

The product dries for about a day. Next, the seam is rubbed with a spatula. After 12 hours, residues can be removed with a damp sponge. On such a table, you can safely leave a hot kettle and cut meat. The drawings can be seen below.

Important! If you don't want to buy a cutting tool, then you can use mosaic tiles. The parts are easily detached from the web using simple scissors.

An additional plus - you can lay out a whole panel from a tile, using even broken parts of the tile. If there are scraps left after the repair, they should also be used in work.

Large dining table

Buying some material and accessories is much cheaper than buying a ready-made table. Moreover, sitting at the product made by the owner of the house is much more pleasant. Below you can see the drawings and instructions that will help with the assembly. The countertop can even be purchased in a ready-made version at any hardware store. Further, it is processed using impregnation and varnish, after which the legs are attached to it. How to make them and which ones to choose, you can find out below.

Kitchen table legs

If the countertop can be ordered or made during the day with your own hands, then with the legs everything is more complicated. There are several options for the kitchen table.

Balusters are architectural elements that are often used in the arrangement of stairs. Even if the tabletop is made of inexpensive material, the legs will correct the situation. You can make them yourself if you have the equipment. It is proposed to consider several types:

- combined - performed in several styles;

- screw - the middle part of the structure looks like a screw;

- chiseled - anyone who has minimal experience with a lathe can do it.

In hardware stores, they sell wooden blocks of different sizes. You can safely purchase them to make legs for a large kitchen table. Additionally, you will need sanding (equipment or sandpaper), a jigsaw, impregnation and varnish. The material plays an important role, since the main load falls on the legs. Experts recommend using birch, pine, ash bars. For each, a different type of impregnation is used, the tree should be chosen scrupulously, it is advisable to purchase it in closed stores, where the material is in a dry place. If in the future it is planned to simply cover the tabletop and legs with varnish, it is advisable to make parts from the same type of material. For example, pine and ash are very different in shade, which will immediately catch your eye.

What other table legs are there:

- Stand legs - this option is not endowed with the ability to change the height of the table. They function as a support, the cost is very low. Most often used for an office or coffee table. If the kitchen or living room is large, then they can be made on the dining table.

- Decorative - for lovers of creativity. If you use ready-made schemes, you can create an interesting table for modern kitchen design. You can make it out of wood, having a lathe at your disposal.

- Folding - this option will help make the kitchen table more mobile, it is possible to adjust the height. Metal supports are often sold ready-made. By the way, a wooden alternative can also be made using a lathe.

- Telescopic - they will help to change even the level of the tabletop tilt. Ideal for studios where a table cannot be placed for a child or study. The schematic can be found below.

- PVC legs - an economical option, suitable for a temporary option. A diagram of such legs can be found in the photo.

Which legs to choose for your table, everyone decides independently. The most important thing is not to skimp when choosing a material. Tools that you may need for assembly can be rented. A homemade table is a worthy alternative in cases where there is not enough money for an expensive product. The master saves up to 70% of the cost of the option you like.

Video: how to make a kitchen table with your own hands