Making a table for a manicure with your own hands

A comfortable and high-quality workplace is not the last component of a successful business. Sometimes it can be very difficult to explain to the master or to purchase the necessary thing ready-made. It remains only to make it yourself.

A manicure table can also be made by a person with the basic skills of a furniture maker: it is enough to delve into the process, correctly draw up drawings, carefully cut and fasten all the details together.

Varieties of manicure tables

The manicure table is selected based on the total area of the master's office, his main specialization (manicure or pedicure) and the physical characteristics of the body structure (height, weight, etc.).

The most popular options are:

- Foldable. Such tables are suitable for novice craftsmen who do not yet have their own office. At the time of manicure, this transformer turns into a full-fledged table, after the end of the work it can be reassembled into a compact cabinet. The foldable model is usually equipped with shelves for varnishes and other manicure accessories.

- With built-in elements. A hood or additional lighting can be provided at the stage of designing the table. As a result of this solution, more work space will be freed up and there will be no clutter in the form of additional equipment.

- Corner. These tables with maximum capacity allow you to remove almost all consumables from prying eyes and save space. The only drawback of this design is its cumbersomeness.

- T-shaped. The models include a large number of built-in compartments, which is very convenient for the master. At the same time, the T-shaped table takes up a lot of space and is categorically not suitable for small offices.

To make the selected version of the table more mobile, castors can be installed on the legs. This will allow the master to independently rearrange and change the position of the table at any time.

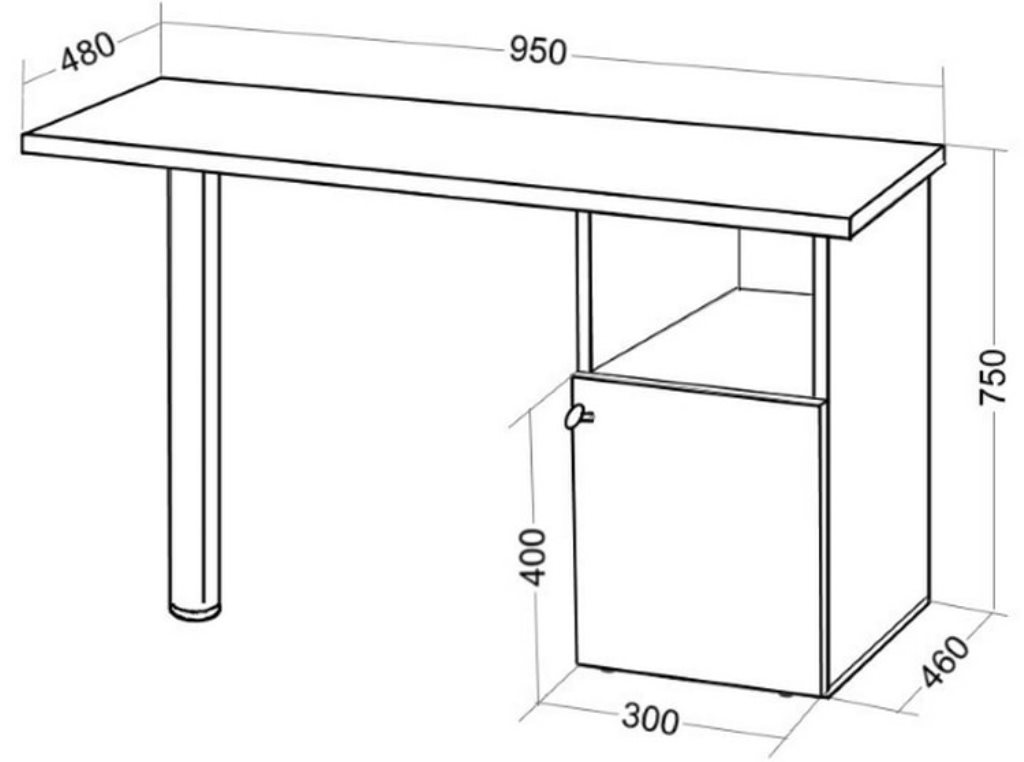

Drawings and table dimensions

The parameters of an average table have the following indicators:

- height - 70-75 cm;

- width - 100-150 cm;

- depth - 40-60 cm.

Important! During work, the legs of the master and the client under the table should not interfere with each other, and all working movements should not require additional back bends.

Drawings can be done manually or using graphic programs, made by yourself or taken from the free Internet access. The main thing is to put on them all the dimensions and fastening points of the parts, separately display the types of fasteners used. This is done so that at the cutting stage, the corresponding grooves are made on the material and the table can be simply assembled like a designer.

What materials and tools are needed for work

Before starting work, you need to stock up on the appropriate inventory:

- screwdriver, hammer;

- six-sided wrenches, screwdrivers;

- roulette;

- construction pencil;

- glue;

- jigsaw (preferably electric);

- iron;

- the selected material (most often these are chipboard sheets).

Step-by-step manufacturing instructions

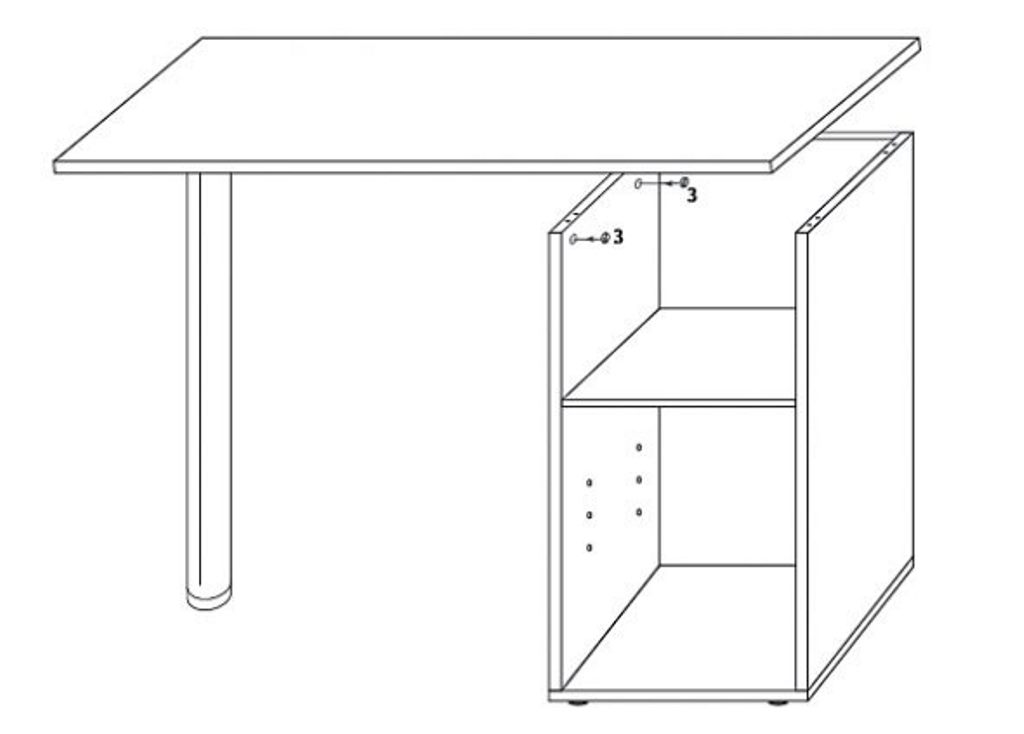

The easiest way to assemble the table will be if all the parts have already been cut on the cut - the parts will just have to be connected together. If the project is carried out independently from start to finish, you will have to work hard: first cut out all the parts and fasteners, and only then assemble them into a single structure.

How to make a manicure table with your own hands:

- The chipboard sheet must be laid out on a flat surface and cut into components. You should try to carry out this procedure with a minimum of waste.

- All ends are covered with veneers. Having connected the main part and the decorative strip with the help of glue, you need to walk over the surface with a hot iron. This will achieve better material adhesion.

- In the places marked according to the drawing, you need to drill holes where the fasteners will go.

- After the preparatory work is completed, all elements must be connected together. If the table is not planned to be disassembled in the near future, you can pour glue into the grooves of the fasteners - this will make the structure stronger, and situations with shelves falling out (often found among beginners) will automatically be excluded.

If you plan to install a built-in hood, even at the cutting stage, you need to drill a corresponding recess for it. There is no need to glue it with veneers - the cut of wood will be closed by the device itself. It is possible to make a hood for a manicure table with your own hands, but its cost is not much less than that of a finished one. That is why the built-in model is easier to purchase ready-made.

Important! For attachment points from the edge of the walls, an indent should be made - at least 20 mm.

What should be on the table

For the convenience of the master, there should be a minimum of items on the table - everything is only the most important and necessary. Do not lay out the entire base of colors and design elements on an open surface - they will fit perfectly in internal drawers.

On the table must be present means for disinfecting and stopping blood, napkins, a demonstration palette and a set of brushes. For those who constantly control the time, you can set the clock on the desktop.

It will not be difficult to cut and assemble a manicure table yourself with your own hands, even for a person with basic construction skills. It is not necessary to take the standard as a basis, you can create an object according to individual criteria.

The main thing is to choose high-quality material and not rush to assemble. The more accurately the chipboard sheet is marked, the less waste will be. And this, in turn, will reduce the cost of the final product.

Video: DIY folding manicure table