How and with what you can make a glass table

Wooden tables need careful maintenance, plywood tables are unreliable. Glass is another matter. Tea spilled? Not scary! After wet cleaning, not even a trace will remain, and small scratches can be easily removed with regular polishing. And such a thing looks great in the interior.

That's just ... Budget options look too “simple”, and designer ones are much more expensive. But making a glass table with your own hands is not at all difficult. Is this not a reason to show skill?

Varieties and glass tables

How is one table different from another? Constructive and materials of manufacture. Let's dwell on the first point. It includes:

- the shape of the countertop;

- height;

- number of levels;

- structure (monolith, sliding, folding).

The easiest one for home-made is a monolithic single-level table. It is more difficult to make a folding or sliding one, since you will need a calculation and competent installation of sliding mechanisms.

The second point is the materials of manufacture. The choice depends on the design, the functional purpose of the future product and the skills of the home craftsman.

The easiest option is to assemble a glass tabletop with legs made of wood, metal, rattan. It is more difficult to make a table made entirely of glass. In this case, you cannot do without professional equipment.

For the manufacture of countertops, tempered, reinforced glass, triplex or lacobel (glass painted at the production stage) can be used. Ordinary thin glass is not suitable for work: it is less durable, which means that the product will not be practical.

What it should be and how to choose the right one

The main question that the master must answer is: what will the product be used for? If the ultimate goal is to decorate the room, then a simple table without additional levels will do. You can put souvenirs, dried flowers compositions on it, spread magazines.

Often these tables are installed in the corner / along the wall. In this case, the square shape of the table top is justified, but it can also be round. A coffee table, which will be used for tea parties, snacks while watching movies or get-togethers with a company, is best done with 1-2 additional shelves. This will add useful space.

The optimal shape is oval or rectangular. If the area of the room is limited, and a table is needed only occasionally, it is logical to consider a folding model. Dining tables have no fundamental reference to the shape of the table top.

You need to start from the shape of the headset, the number of people who will regularly dine with it. For greater convenience, you can make a sliding table, but it is worth considering: the strength of such a tabletop is lower than that of a monolithic one.

How to make a glass top table

The main element of the future product is the tabletop. It is worth starting work with its manufacture.So how to make a glass table with your own hands? Make calculations, choose a design, prepare materials, tools and get acquainted with safety precautions at work.

Choice of design

There is no need for a novice master to choose complex multi-level, sliding structures. It is better to focus on simple monolithic models with wooden or metal legs. The most convenient to manufacture are square and rectangular countertops.

To achieve an even oval, you will have to prepare a pattern (layout), and you can get a circle using a compass-shaped glass cutter. Depending on the style of the interior, the legs will fit the glass table:

- made of wood - for eco and country styles;

- chrome-plated metal - for designs in the spirit of modern minimalism or hi-tech;

- wrought iron - for classic styles.

If it is supposed to move the table around the apartment, then it is logical to equip the legs with wheels.

Tools and materials

Materials for making a glass table are sold in any hardware store. For work you will need:

- plywood or chipboard;

- a sheet of glass with a thickness of at least 6 mm;

- legs;

- suction cups for attaching the legs to the table top;

- transparent glue for glass and metal (transparent universal glue is suitable);

- sandpaper of various grain sizes (processing begins with paper with the largest and ends with paper with the finest grain);

- vegetable oil (for lubricating the roller glass cutter) and acetone;

- pencil / marker for marking.

Instruments:

- glass cutter;

- metal ruler;

- rubber hammer;

- grinder, drill with felt nozzles for polishing;

- emery bar.

Gloves and glasses will be needed to ensure safety during work. Perhaps the most important will be the choice of a glass cutter:

- the roller must be strongly pressed against the surface (pressure is not less than 2 kg), in one area of the glass you can cut several times until the desired result is obtained;

- diamond cuts glass in one movement, making stops and turns will not work.

Before proceeding with trimming a part, it is worth practicing on a similar material.

Glass cutting and processing

Before starting work, you need to prepare plywood or chipboard on which a sheet of glass will lie. It must be carefully processed from dust and dirt so that scratches and chips do not appear during glass processing.

The markings are applied to the underside of the glass (which is adjacent to the plywood). A thin metal ruler is used to work with a glass cutter. It needs to be applied along the line, and then the incision is made. After that, the line is tapped with a rubber hammer and the edges are carefully separated from the workpiece.

Several tools are used for edge processing:

- a file to remove large irregularities;

- grinder and grinding wheels for more accurate alignment;

- sandpaper for smoothing and shaping sharp edges.

The final stage is glass polishing with paste and a felt circle.

Assembling and decorating

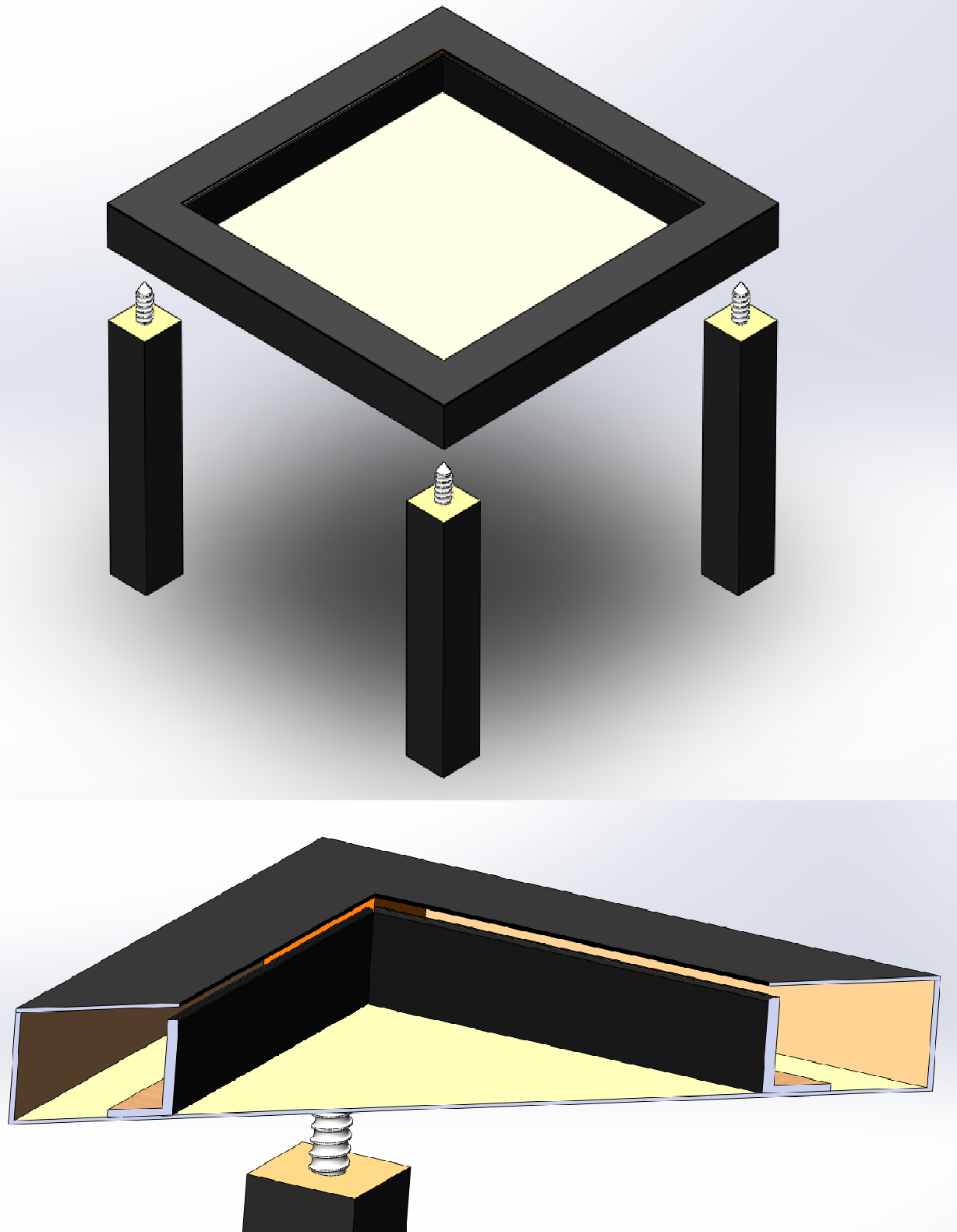

On the finished countertop, it is necessary to make markings for the place where the legs are attached. It is applied at a distance of 7-10 cm from the edge and 13-15 cm from the corner. Suction cups are attached to the upper part of the legs, on which the tabletop will be planted.

For added strength, clear glass adhesive can be applied to the suction cups.

The table top is attached to the suction cups, the remaining glue is removed.Self-adhesive tapes and film are suitable for decorating a glass table. The decorative elements are glued to the inside of the countertop.

Another option is stained glass painting. If you do not have enough artistic skills, you can make / buy a stencil and apply the pattern with paints or glass markers (also on the inner surface).

Pros and cons of the design

What advantages, besides beauty, does a glass table have? It is easy to care for: a household product for mirrors will do. Glass is one of the few materials that does not absorb odors, and there are no indelible marks from drinks or hot objects on its surface.

Transparent or dyed in the manufacture of countertops will not fade, even in direct sunlight. The only drawback is the need for polishing. If high-strength glass was chosen for the manufacture of the table, then the product is unlikely to break under the influence of ordinary mechanical stress.

How can defects be removed from the glass table

Any furniture needs maintenance, even “ultra-practical” glass. Therefore, periodically, the surface of the countertop will have to be polished with a paste and a felt wheel. But after processing, the glass table will once again shine with its original gloss.

If glue or other stubborn substance is spilled on the table inadvertently, you can remove it with a solvent and a hard sponge. Then remove the formed scratches with a soft cloth and paste or polish with a felt disc.

Video: how to make legs (supports) for a glass table with your own hands