How to make a massage table with your own hands

When going to a massage session, people expect to receive not only quality service, but also high service. One of the components of the latter is a couch on which the client will lie during the procedure. A really high quality model is very expensive. But you can make it cheaper if you do it yourself. A do-it-yourself massage couch is made for a short time, and it will serve no worse than a factory one.

Features of the design of the massage table

Externally, the models can be radically different in color design, content and format of execution. But the key feature of all massage tables is their design, which consists of 3 main parts:

- Frame. Made of metal (aluminum, steel) and wood. The material is selected based on the required table strength. The strongest are considered models made of aluminum. Sometimes, transverse arcs are also added to strengthen the structure.

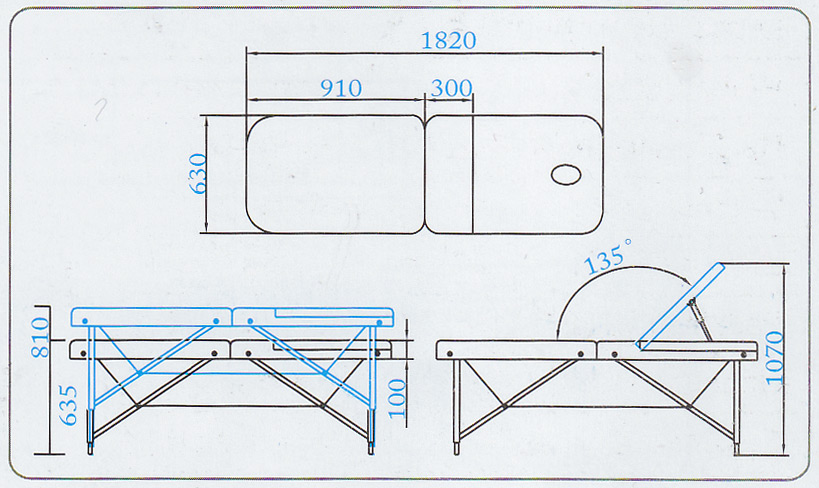

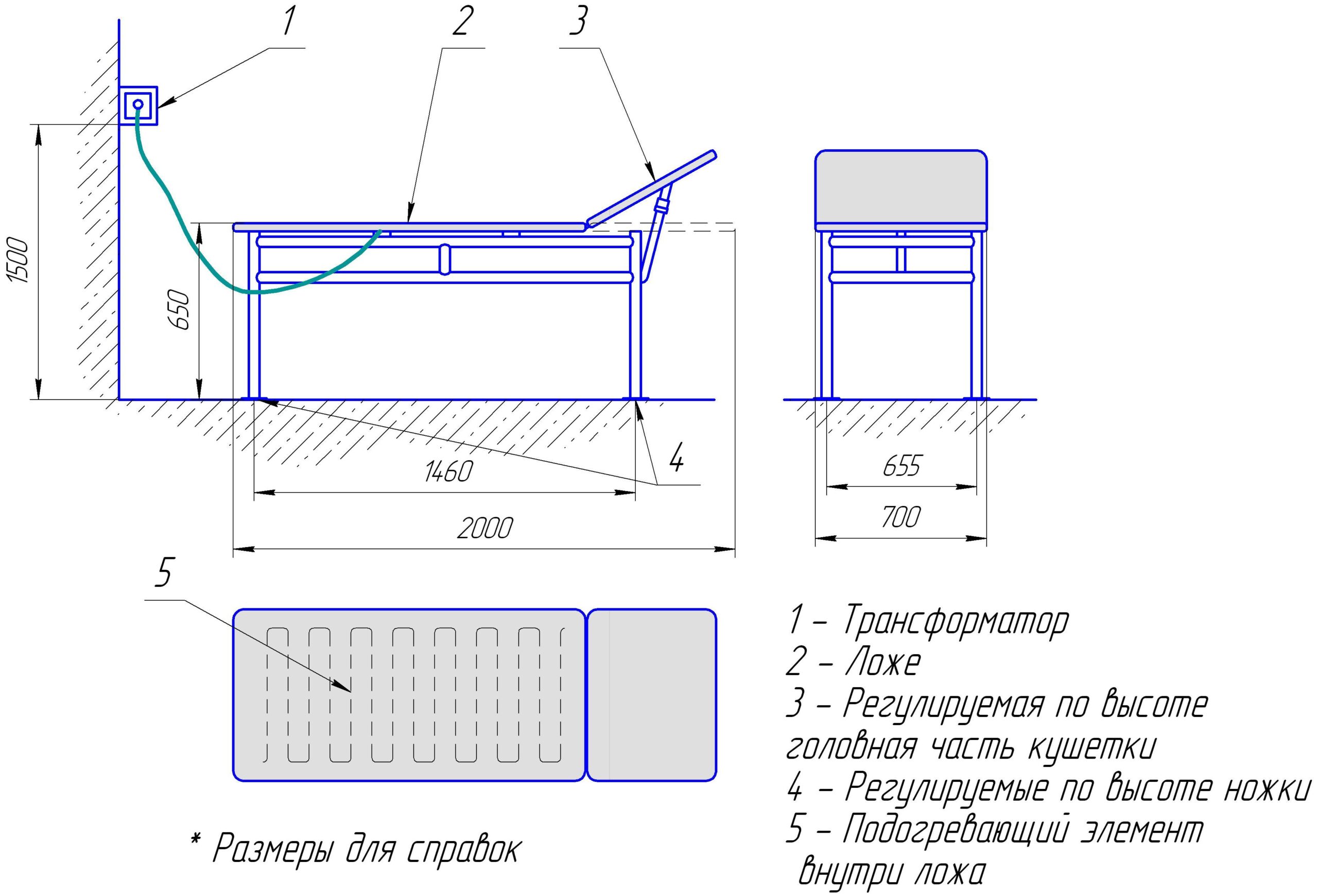

- Table top. This part of the structure consists of one to three sections. The first option should be chosen if the couch is planned to be used only for massage. If in the future you want to introduce nursing procedures into everyday life, you need to choose a folding option for several sections. It can be transformed into a chair.

- Headrest. This design element makes the procedure more comfortable for the client. The best option for massage is with a cutout for the face.

These elements are the basic component of any massage table model. But, during the manufacturing process, they can be significantly upgraded or supplemented with other useful options.

Varieties

Despite the fact that there are a lot of massage table models on the market, they can be divided into only two categories:

- Stationary. This type of table does not fold out and weighs not a single kilogram - it is categorically not suitable for regular transportation. The constructions are durable and can be used not only for massage, but also for other cosmetic procedures.

- Foldable. The model is easily assembled into a small bag that can easily fit into the trunk of a car. Such a table weighs a little, therefore it is insanely popular. The folding type of construction is lightweight, therefore it has limitations in loading.

How to make a massage table with your own hands

There is nothing difficult in making your own massage table, even for people with minimal construction skills. All that is required is to correctly select the material and preliminary sketch the product. The last point needs to be given key attention, because the quality of the constructed drawing directly depends on whether it will be possible to assemble the table at all.

Choice of design and construction

When making a massage table, you need to take into account several main points: where it will stand, the design of the room and how you plan to use the selected model.

Also, when choosing, you need to consider a few simple tips:

- It is better to choose the upholstery in a neutral color - beige or coffee with milk. It doesn't matter if it doesn't fit into the interior concept - it should always have disposable sheets on it that can be matched to the tone of the room.

- Do not rely on trendy models with retractable headrests, handles, etc. Such tables are 2-3 times more expensive than ordinary tables, and their functionality is rarely used to the full. The only additional feature worth paying attention to is the height adjustment of the couch.

- The most convenient upholstery material to work with is leatherette. It is easy to clean, there are rarely traces on it. The fabric cover, under the influence of detergents and oils, will become unusable in just six months.

Important! When choosing a material, you need to focus not only on quality characteristics, but also on the convenience for the client. The couch should be moderately soft and not slippery.

Selection of tools

Initially, to build a drawing, you need a sheet of paper, a square, a pencil and a ruler. Of course, you can implement your plan with the help of computer programs, then no stationery will be needed at all.

For the direct manufacturing process, you will need:

- a hacksaw for metal or a saw for working with wood (depending on the material chosen for the frame);

- screwdrivers;

- marker or pencil;

- screwdriver;

- screws, nails and staples.

If you also plan to drag the table at home, you should also stock up on artificial leather. You can add softness to the product by making a foam rubber layer inside.

Material selection

The main challenge faced by the manufacturer is the choice of material for the structure. There are not so many options - wood or metal. Each of these materials has its own advantages and disadvantages, so you need to focus only on how the product will be used in the future.

Wood

Wood is a rather heavy material, so only stationary tables are made from it. The design can be foldable, but visually it is still bulky. Wood can support a lot of weight, but still cannot compete with metal.

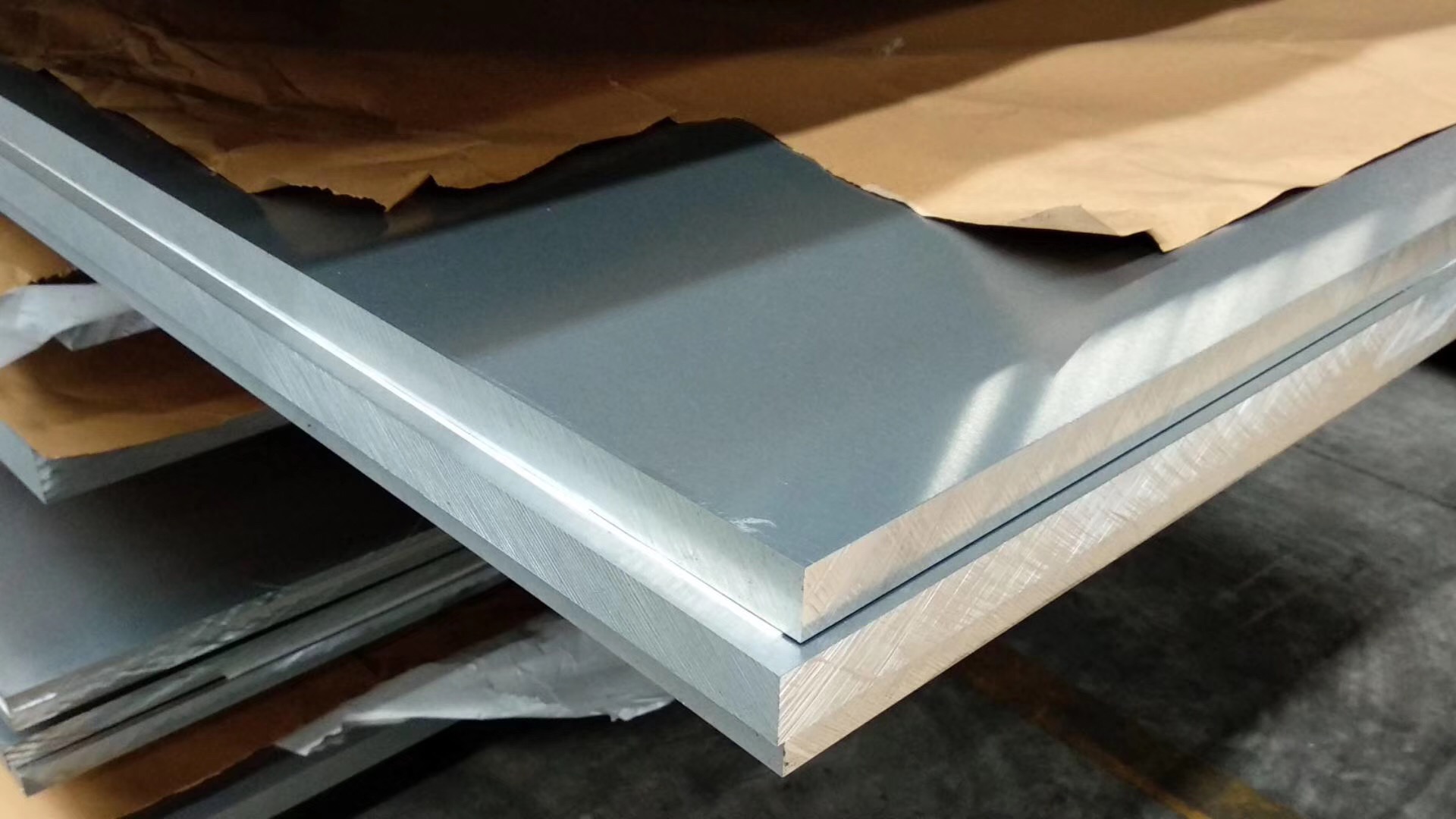

Metal

The most demanded metal for the manufacture of massage couches is aluminum. It is durable and lightweight, so it can carry more weight than the most resistant wood. For the manufacture of a table, it is better to take aviation aluminum - with impurities. For the product that is planned to be transported, this is the best option. The metal legs should be made tubular.

Making a massage table

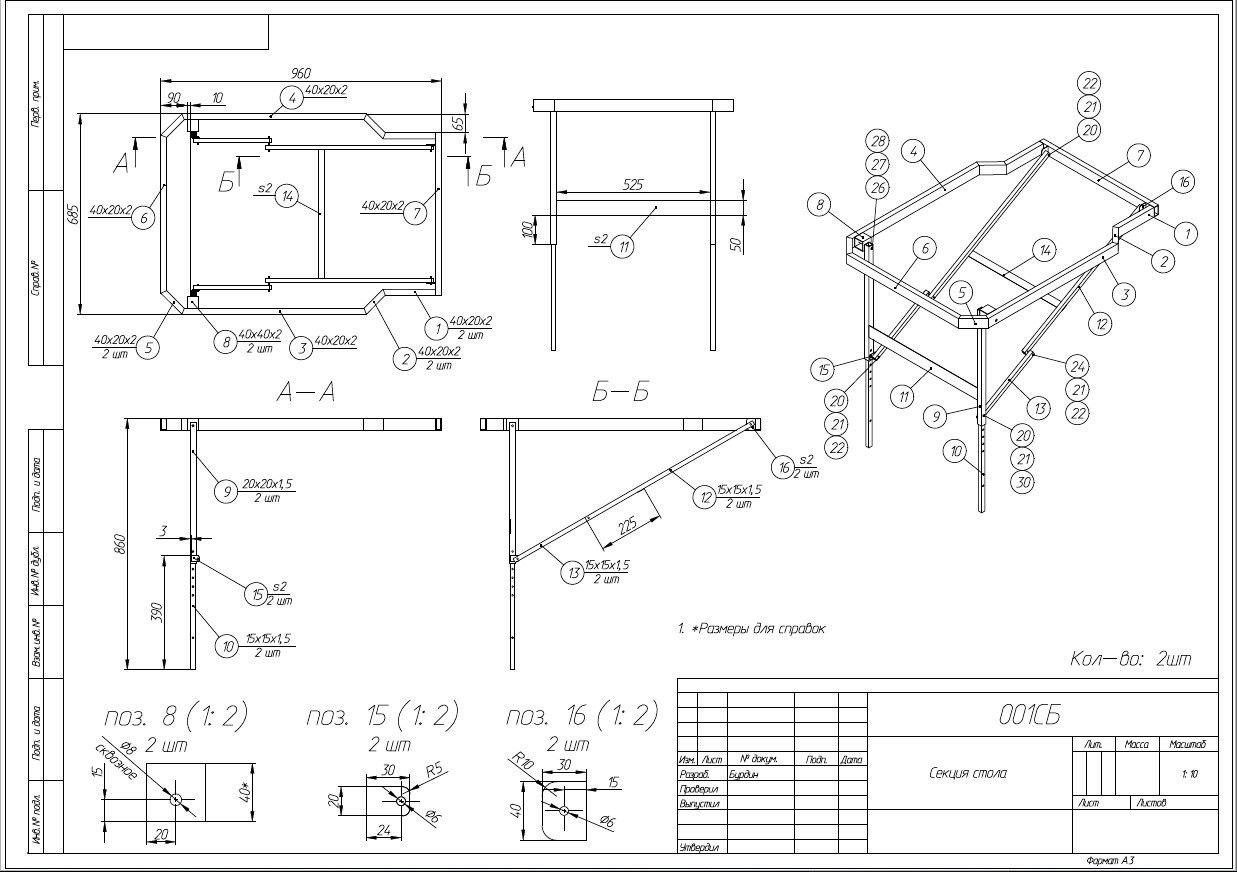

Manufacturing is carried out strictly according to a drawing made in advance. It is on it that the optimal dimensions of each element are already outlined.

All work should be carried out in stages:

- Tabletop manufacturing. For these purposes, you will need plywood 0.9 cm thick. You need to take two sheets, each measuring 60x90 cm. In one of them you need to make an oval cut - this will be a recess for the face.

- To strengthen the structure, a frame is made, which can be either wooden or metal. Its dimensions should be identical to the dimensions of the countertop. Both workpieces are fastened to each other with self-tapping screws.

- To make it comfortable for clients to lie on the couch, it must be softened with foam rubber. It can be attached to the countertop with construction glue. After it dries, the couch needs to be covered with a leather substitute. It is attached to the wood with staples and a special pistol. The optimal spacing of the fasteners is 10 cm.

- To make the legs, you will need 2x5 cm bars and 85 cm long. They must be screwed to the frame, and not the tabletop itself, and fixed with spacers. If you want to strengthen the structure, the spacers can be made along the length of the couch.

After the completion of the manufacturing work, you need to do the decoration - cover the wooden parts with paint or varnish. The couch should definitely be free of burrs!

Features of assembling a folding massage table

A flexible structure is more difficult to manufacture than a stationary one, but it is quite possible. The first difference is that the frame is not made for the entire tabletop, but for each of its parts. These components are attached with self-tapping screws. Everything else will be hinged. In order for the couch to be conveniently transported, it is advisable to attach handles and a latch on both sides, like on a suitcase.

Where can the table be placed

The best placement option is near the wall, but not close, but with a small gap. It is desirable that the room has more natural light, which has a beneficial effect on the condition and mood of clients.

Designing and arranging a folding or stationary massage table is a very real task for those who can calmly and step by step perform the assigned tasks. The main difficulty is to make the drawing correctly and choose the material that will be guaranteed to meet all the requirements during further operation.

Video: homemade wood massage table