How to make a cutting table with your own hands

The cutting table is one of the most important items in a sewing workshop. Making furniture yourself is not only pleasant, but also profitable. You can save a lot on interior decoration and make a model that will be comfortable and harmoniously fit into the space of your home workshop. We will tell you how to make a cutting table for fabric with your own hands.

- Features of the design of the cutting table

- Varieties of cutting tables

- What you need to make your own hands

- Step-by-step manufacturing instructions

- How to make a fabric cutting table

- Features of making a table for cutting chipboard

- Tips & Tricks

- Video: how to make a cutting table with your own hands

Features of the design of the cutting table

The main distinguishing feature of such tables is a large table top, on which a significant piece of fabric will fit. Also, the surface should be absolutely flat, the edges are well processed. Otherwise, the matter will cling to knots and protrusions.

Stable supports are important to withstand the load of heavy fabric.

Very often, built-in drawers for storing sewing accessories are located under the table top.

Varieties of cutting tables

The width of a standard table for home use is 150 cm, and the length is about 2 m. The standard height of the product is 80-90 cm. In conventional models, the table top is made of chipboard, and the end parts are sealed with slats and corners so that the edges do not cling to the fabric.

It is very important to be able to adjust the table legs, taking into account the characteristics of the floor.

It is logical that in the conditions of an apartment there is not always a place for such a "giant", therefore, most often, home craftswomen choose folding book tables or corner models with a dropping table top.

Inside, there are always shelves and drawers in which you can store tools, materials for needlework and the sewing machine itself.

By the way! The folding table is suitable for those who sew occasionally. Such a structure will not withstand regular loads, so craftsmen who work with fabric on an ongoing basis need to think about a stationary model.

What you need to make your own hands

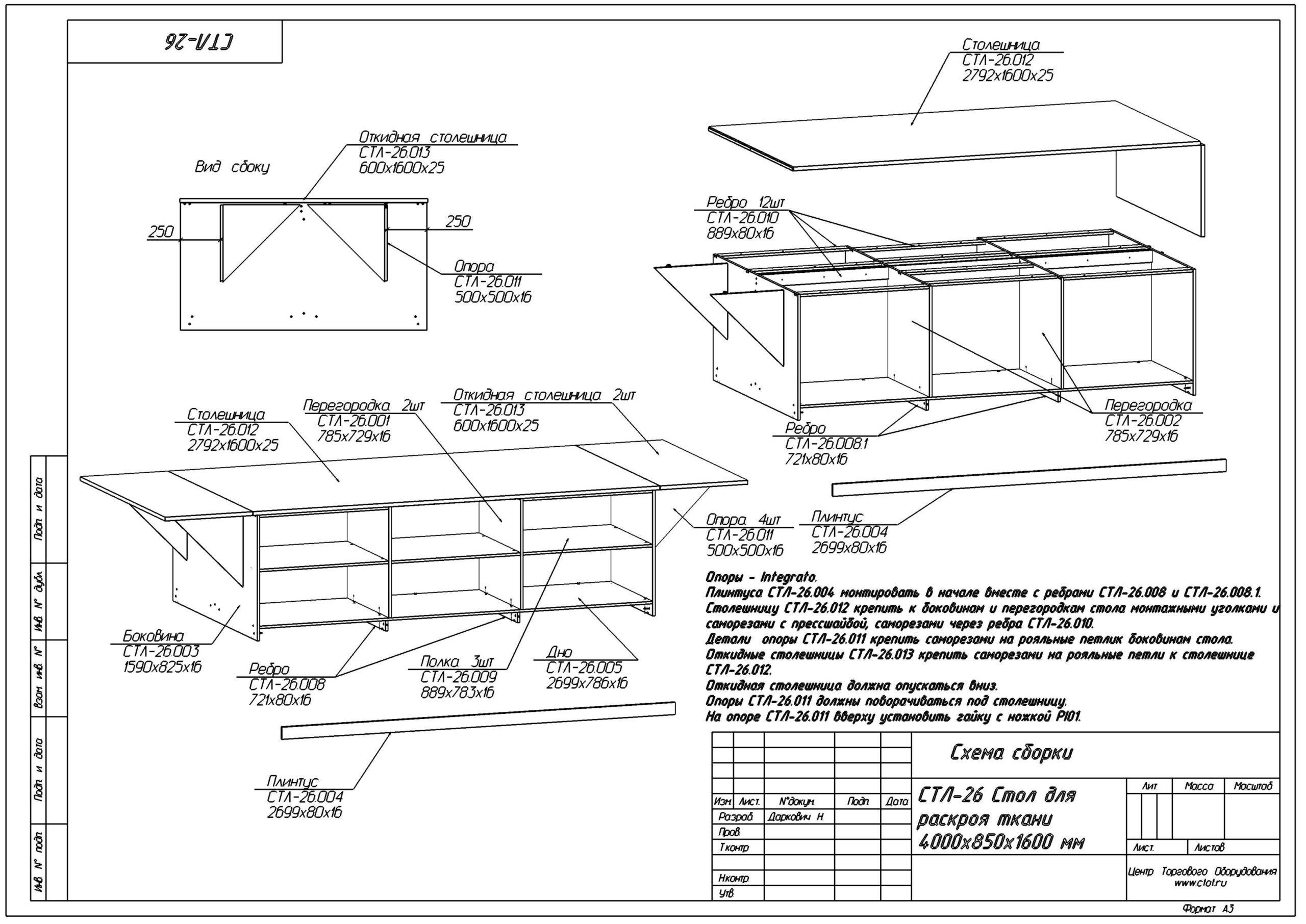

To make a cutting table yourself, you need to select a design drawing. Furniture can be mounted on ready-made legs, timber supports. However, the most convenient option is a folding table with a curbstone.

For work you will need:

- plywood sheets (chipboard, laminated chipboard, MDF);

- drill, screwdriver;

- grinder or sandpaper;

- jigsaw;

- tape measure, pencil;

- end strips and corners.

What accessories can be useful:

- piano hinges;

- gas lift;

- magnets;

- guides for drawers;

- rollers;

- self-tapping screws, confirmations, corners.

Step-by-step manufacturing instructions

The easiest way is not to make the whole table, but to prepare a tabletop that can be fixed to the existing furniture. This option is suitable for craftsmen who sew only occasionally and do not want to take up useful space at home.

The removable worktop can be placed in the closet, in the dressing room or hidden behind the closet.

How to make a fabric cutting table

To make a table for cutting fabric with your own hands, you need to prepare the base. It is best to make it from two cross posts. Screw the adjustable legs to the bottom of each plank so that the height of the table can be leveled.

Connect the supports to each other with an upper crossbar, the width of which coincides with the width of the racks.

Advice. In some cases, it is advisable to use not two, but three supports.

Further design may vary:

- On one side, make the back wall of the same or thinner material.

- Using rollers and guides, fasten several drawers (suitable for tables that fold out to the side).

- Do without drawers and make internal niches - at the very bottom, fix a shelf for a sewing machine.

Attach the retractable legs to the base on castors with stoppers or adjustable legs. They will serve as a support for the folding part.

The last step will be the installation of a processed piece of plywood or other material that will be folded back. It is attached to the hinges (you can use a gas lift).

Important! At the assembly stage, check the strength of the fittings.

A stationary table can be made from 6 pre-fabricated legs or beams and a sheet of plywood / MDF of a suitable size.

Features of making a table for cutting chipboard

Some do-it-yourselfers often work with chipboard boards, so they need a special table for operations. Making it at home is more difficult, since you will need the most durable and even tabletop that can withstand significant loads.

Practicing masters recommend not to make a table for cutting chipboard with your own hands, but to purchase two simple strong tables and connect them with ties.

Advice. You can cover the countertop with a metal sheet with a processed edge or thick plywood.

Tips & Tricks

The surface of the fabric cutting table must be well sanded, but not slippery. Otherwise, it will be inconvenient to work with light flowing materials: they will simply move off the table.

The joints of the slabs do not interfere with the cutting, provided that the ends of the sheets are well processed and are evenly joined together. During assembly, it is advisable to use a level to determine height differences and level the structure.

Video: how to make a cutting table with your own hands

Part 1:

Part 2: