Description of the tabletop postforming procedure

The working surface of the kitchen unit is exposed to the maximum impact of various harmful factors, and must be resistant to them. In the production of furniture, materials that lose their original properties after the first days of operation have not been used for a long time.

And in order to give the countertops the durability of decorativeness, there is postforming.

What is countertop postforming

Modern postforming for kitchen countertops - what is this technology, what is it?

Postforming is a specially developed way of laminating chipboard, MDF to give them strength and any design. Layers of kraft paper and plastic are applied to the boards, the front edge of the tabletop is formed, if necessary, the back plinth is formed in the U or L type.

The material that has undergone this treatment is the most popular for kitchen countertops and countertops, there are no alternatives with equal properties.

Varieties

So what is countertop postforming and how does it happen?

- For the manufacture of plates of the economy option, thin sheets of chipboard with a thickness of 26-28 mm or 32 mm (consisting of two sheets of chipboard 16 mm each) are used.

- Chipboards with a thickness of 38 mm or 60 mm are more resistant to moisture, they are heavier in weight. On the cut, such plates are green - this is the result of processing to increase moisture resistance.

Lightweight versions of chipboard boards with postforming are also available. First of all, these are countertops made from a combination of sheets of thin and thick chipboard, when the thin part is in the middle of the table, and the thicker part is at the edges.

There are also slabs with a cellular filler inside (the so-called tamburat), which have an equal thickness, but by weight, they are much lighter than slabs made of solid chipboard.

It is important! Lightweight stoves with a tamburat are not at all suitable for use in a kitchen, they are damaged by steam, temperature changes and moisture, they can deform as a result of this effect! Tabletops for office tables, furniture at the reception of hotels - where the influence of harmful factors is excluded, is made of slabs with a tamburat.

The postforming tabletop can be made to order, or you can purchase ready-made factory options with standard sizes. Chipboard sheet with postforming processing has a standard width of 60 cm, its length can be 244 cm, 300 cm, 400 cm. You can also find ready-made one-piece corner modules.

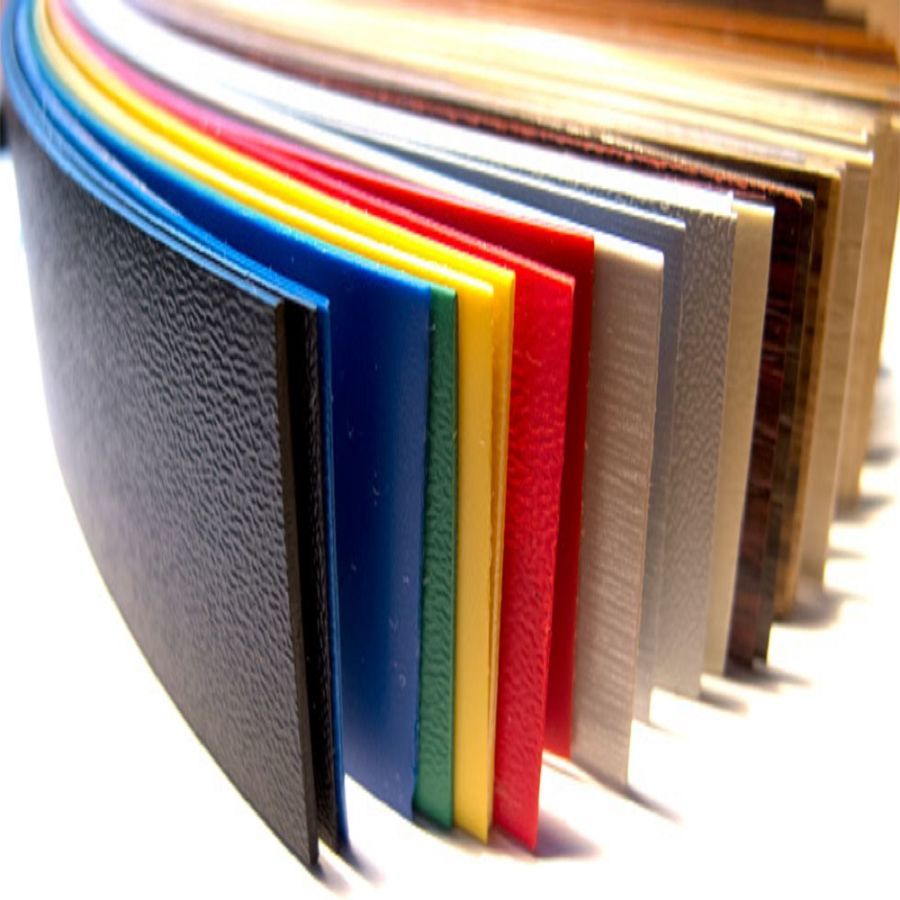

There are a lot of postforming countertops colors. They can be monochromatic, of any color and shade, or with a printed pattern for wood, stone, canvas, and other interesting materials. The surface can be glossy, smooth or matte, and the surface can be applied with a texture like stone or wood, making the material indistinguishable from its natural counterpart.

Such textures look expensive and give furniture a noble look.

Note! One of the indicators of the quality of the postforming worktop is the presence of a drip tray under the edge, on the side opposite to the working surface - it looks like a strip with bulges.

Procedure steps

In order for the postforming tabletop to acquire the specified properties, the technological process has several mandatory stages.

- First, craft paper impregnated with special resins that impart strength and resistance to moisture is applied to a chipboard sheet of the selected width (or MDF for some manufacturers). It also provides better adhesion to the subsequent slab surface.

- Then a layer of plastic is applied to the plate. The work is carried out on special equipment, under a press and when exposed to high temperatures, which ensures better formation of the material and the connection of layers. The plastic layer can be 0.6-0.8 mm thick. The thicker the plastic layer, the higher the strength of the countertop.

- The final stage of processing involves the application of melamine or acrylic resins. This layer protects the surface from scratches and moisture, resists fading.

How to choose and care for your countertop

Durable and beautiful postforming worktops are well suited for the kitchen and differ in some properties. How to choose the right material?

- The thickness of both the countertop itself and the plastic on it is of great importance - the thicker the better.

- For the kitchen, it is better to choose matte surfaces, they will not show streaks.

- Countertops that are too bright will become annoying over time.

Postforming surfaces are very undemanding in the care of the surface - it is important to wipe them from moisture and wash them with soapy water.

Advantages and disadvantages of the procedure

The advantages of postforming countertops include their availability, high operational properties and resistance to harmful influences, a wide variety of textures and colors, and ease of installation.

There are also disadvantages:

- Synthetic materials. Manufacturing cannot be called environmentally friendly.

- Without protection of the ends of the headset, as well as in the case of chips on the surface, moisture can penetrate into the base and contribute to delamination, swelling.

- Even if the surface is slightly damaged, it cannot be restored - it will need to be replaced.

But, despite the shortcomings, postforming countertops have no alternative, and with the right choice and operation, they can serve for decades.

Video: what you need to know about postforming