A step-by-step description of making a table-bench with your own hands

Multifunctional furniture has become increasingly popular lately. At the dacha, where people leave to take a break from work, everything should be as simple and easy as possible. A bench-table will be the best solution for a summer cottage and a great rest.

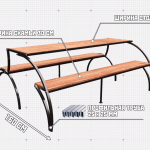

Description of the design and principle of operation of the table-bench

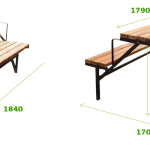

The principle of operation is very simple: the structure can be easily transformed into a table and benches, and when folded it is an ordinary bench. Let's take a closer look.

There are three types of benches that can be transformed into:

- A table with two benches (when assembled it can be one or two benches);

- Small table with chairs on the sides;

- Angular.

In most cases, the folding structure when assembled looks like a bench with a high back. In its manufacture, pipes and wood are usually used.

A significant drawback is the large weight, which makes it impossible to move the structure freely. But the advantages, in the form of versatility, reliability and durability, play a significant role.

What material can be made

In order to make a folding table-bench with your own hands, you need to choose the right materials. The most commonly used wood and metal.

The latter can be executed in the form of straight pipes or artistic forging. The first option is more stable and much easier to manufacture, moreover, it is convenient to use. But over time, the pipes begin to bend and deteriorate, which requires replacement.

Wrought iron is more attractive in appearance, but an excessive amount of metal makes the structure heavier and creates some inconvenience (more difficult to re-paint and repair). In addition, special skills are needed to create artistic forging, if there are none, you will have to contact a specialist, and this is quite expensive.

The seat and backrest should be made of wood for greater comfort. It is recommended to choose spruce, as it does not deteriorate under the influence of temperature changes, does not lend itself to destruction under the influence of fungi.

In the absence of spruce, the following varieties can be used:

- Maple. Durable and reliable material that withstands corrosive environments.

- Birch. She has an attractive shade and unique patterns. It is easy to process, but requires frequent coating with a special solution to extend the service life.

- Ash. Does not deteriorate when exposed to moisture, but exposed to woodworm.

In addition to wood, you will need a bar and a special treatment tool.

Required consumables and tools

To work with materials, you will need tools: a grinder with discs, a screwdriver and screws, a drill, a level, iron corners, nails, screws and self-tapping screws. To process wood, you will need sandpaper of various hardness. In addition, you will need a tape measure, compasses, a simple pencil, and a ruler.

For finishing, you will need varnish, paint and a special agent that protects against fungi and beetles. If necessary, you can make galvanizing, which will protect the metal from corrosion.

Design and drafting

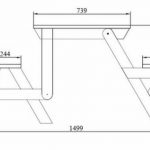

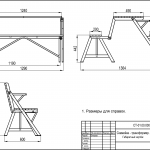

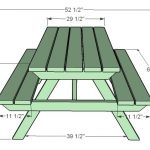

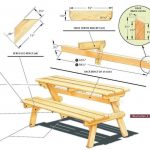

In order to correctly and accurately make a folding bench-table with your own hands, you need a drawing. You can do it yourself or find a suitable one on the Internet.

The drawing details dimensions, parts, materials and tools. It is also necessary to take into account the fact that a certain load will be made on the bench-table. The exact drawing should be in several planes: from the side, from above and from the front.

It's easier to create a do-it-yourself transforming bench with a drawing using a special computer program. It will help you easily and quickly create an accurate sketch.

Step-by-step instructions for making a transformer bench made of wood

Consider the step-by-step production of various models of transforming benches.

The easiest and most popular assembly method is a simple large table and two benches on the sides. It is lightweight and can be moved around. The design drawing is quite simple, so it can be mounted without special skills. First you need to cut (the length is chosen independently) and sand the boards.

Connect the boards with screws and self-tapping screws so that you get a back and a seat. Connect the legs together using iron plates. The second bench is constructed in the same way. Another crossbar is cut out of the tree, after which the seats are connected to the base.

The tabletop must be placed on a support and pressed firmly against the legs. Make a 0.7 cm hole in the bursa piece and attach this piece. Secure the supports with washers.

The bolt heads should be slightly buried in the wood so that they do not cling and interfere with the use of the structure.

The joint on the sides should be made so that it is slightly movable so that the table top can move. Wiggle the stove to make sure it is secure. Cut out the armrests from the timber and glue them to the base.

After that, you need to install a special lever so that you can easily change the position of the structure. They need to be attached to the legs with furniture bolts.

Now you need to finish. For this, wooden elements are varnished, and then painted, if necessary.

You can make a small coffee table. To do this, you need to make legs in the amount of 8 pieces. Two frames for the benches are cut out of the board. With the help of a bar, the frame is strengthened. For greater reliability, you need to fix the boards for the back. Screw the legs to the frame. Connect all the details into a coherent whole. After that, you need to cover the structure with varnish or paint.

There are some features of making a shop with your own hands. These include:

- Welding a metal frame should be done only with the skills.

- Holes are best done with a variety of drills.

- Check the strength of the structure in advance.

- Consider the purpose and who it will be used by.

It is best to assemble with two people, so the process will be easier and safer.

A transforming table-bench with drawings and dimensions can be made by hand. This design will perfectly complement the interior of the garden area. To make it, you need to follow the instructions exactly and carefully choose the materials.

Video: how to make a transforming table with benches with your own hands