DIY solid wood table

Furniture made from a single piece of wood belongs to the elite category with a long service life. However, in a store, it is expensive, and it is difficult to find its elements that suit personal requirements and the design of the room. These problems can be solved if you make a table from solid pine with your own hands.

Pros and cons of DIY

The main advantage of a table made with your own hands from solid wood is the ability to independently determine its type, shape, design, and material. In this format, the finished product will cost its owner much less.

Of the general advantages, it can be noted:

- environmental friendliness, since the raw material is free of harmful and toxic substances;

- creation of a favorable microclimate due to essential oils and resins of natural raw materials;

- durability - the ability to use up to 50 years;

- ease of restoration of minor defects;

- harmonious appearance in a room of any design;

- expensive appearance;

- the ability to apply decorative elements - carving, inlay;

- ease of use.

The disadvantages of a self-made table include the massiveness and weight of the product. Some people think that he does not fit in an apartment, the owner of which dreams of furniture in bright colors.

Important! The varnished product has an unsaturated color, but it can be selected by focusing on the color of a special paint.

Is it possible to make a table from solid wood

Purchasing a table in a store can be a problem, since in retail outlets, furniture items are offered in a limited range. The owner may not be suitable for their design, color, style and price.

A dining table made of solid wood is easy to make with your own hands. To do this, it is enough to adhere to the algorithm of actions of step-by-step instructions. If everything is done according to the rules, the table will cost the owner inexpensively, but it will have a special value corresponding to his aesthetic and consumer needs. The technology of making a solid wood table can be dealt with even without specific knowledge and skills.

Varieties of tables

An element of furniture such as a table is found in almost every home. It performs different functions. It can be used for cooking, for work, for board games or just to be an addition to the interior.Tables are made from different materials and according to different design patterns. They differ in size, shape and style.

By appointment

For each type of furniture element, specific functionality is provided, which determines the format of its use. The general classification of tables implies their division into:

- dining rooms;

- magazine;

- transformers;

- written;

- computer.

By design

With a focus on design parameter, all tables are categorized into simple and complex models. The first category includes standard furniture elements, which consist of a table top and legs. Complex structures are characterized by the use of several massive countertops, located one below the other, while the top element is larger.

A separate category includes transforming tables. They are usually miniature, but if necessary, due to special mechanisms, they can be folded out, resulting in a large working surface.

Also distinguish between stationary and mobile tables. Wheels are provided for mobile structures.

By form

The shape for the table can be any - square, rectangular, oval or round. It is determined by the size of the room in which the element will be installed and its purpose.

When planning to install the table along the wall, its rectangular appearance will save space in the room. The square shape is relevant for small apartments and a small number of people who will sit behind it. Round and oval tables are installed in large rooms, but they do not involve many guests.

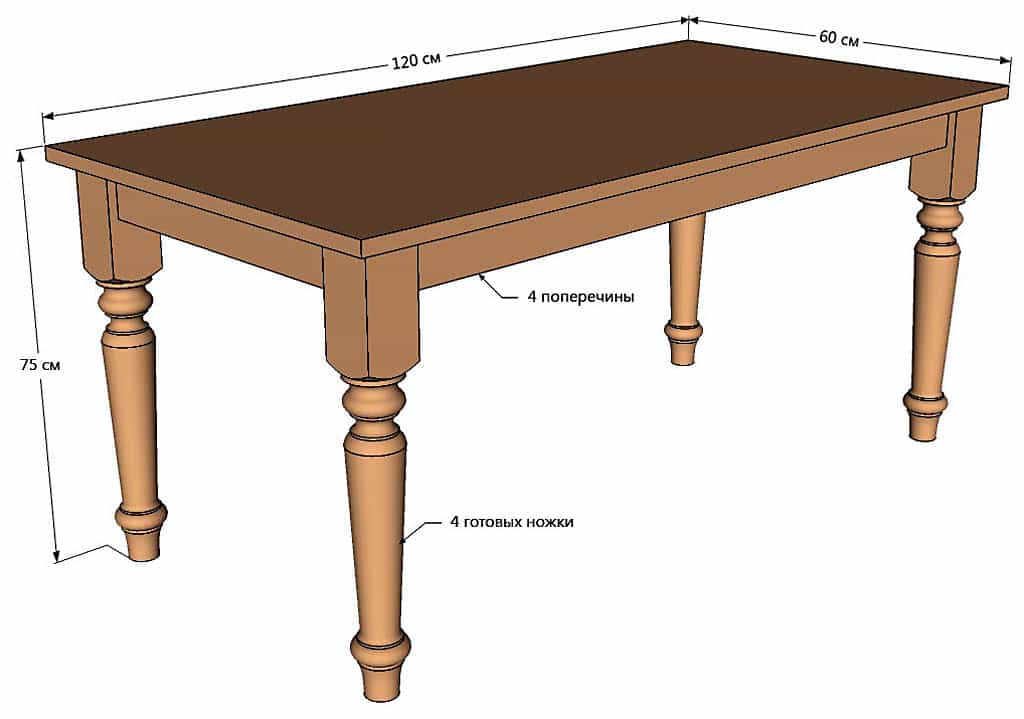

How to make a solid wood table with your own hands

The wooden table should harmoniously fit into the interior of the room where it will be located. To do this, you need to take into account its functionality and general characteristics at the planning stage.

For large rooms, a table of any size can be made. Miniature tables or multifunctional ones, suggesting transformation, fit into a small space.

Experienced craftsmen can work with hard grades of materials. The complexity of processing is compensated by the stability of the finished product to deformation effects. For novice craftsmen, wood is suitable, the processing of which is not difficult. You should also take into account such parameters as the shape and style of the table, which must match the interior.

Having determined the characteristics of the future product, you need to draw its layout and calculate the amount of material that will be required for work. Performing it strictly according to the algorithm of actions, one can hope for a positive result.

Selecting a table model

When deciding on the style of the table, you should think about in what room and in what place it will stand. It should also be taken into account that it fits into the overall design.

Additional Information! The width of the table top and the height of the legs are selected depending on the functional requirements.

If you plan to work at the table, then you should provide for its functionality in the form of additional drawers and shelves. You should also think about the adjustable table top height.

For a comfortable placement on a computer table, you should plan to manufacture a separate compartment for the location of the system unit, as well as holes for the cable. If an oak table is made for small rooms, you should not make a lot of built-in shelves and drawers in it, since in this format it will look bulky.

Selection of materials and tools

Before you start making furniture, you should prepare the materials and tools necessary for the work. The list, parameters and quantity of materials are determined by the dimensions of the finished product and its design. Of the general positions, it can be noted:

- boards for countertops, the thickness of which must be more than 40 mm;

- bars, sizes from 40X40, to ensure strength and stability;

- solid support legs, metal profiles, balusters;

- impregnation for wood to protect against fungal infections and eliminate minor surface defects;

- varnish for surface treatment will give the product a complete look and protect it from outside influences;

- confirmations for fastening elements.

For marking by a template and for measuring structural elements, you will need a ruler, a square and a level. To work with wood, you need an electric saw or jigsaw, a sander, sandpaper and a jointer. Clamps, screwdrivers, drill, screwdriver and mallet are needed to secure the individual parts.

Additional Information! To ensure the personal safety of the master when performing work, he must use protective equipment - glasses and gloves.

Choice of wood

For solid wood tables to be durable, you need to choose the right material of manufacture. In this case, factors such as:

- design features;

- functional;

- the style of the room in which the table will be installed;

- personal preferences and financial capabilities of the owner.

A piece of furniture is most often made from pine or bleached oak. Pine products are cheap to their owner. They are relevant for kitchen tables. To improve their performance, they must be varnished. In the more expensive segment, the tables are made of oak. They are characterized by an exquisite appearance that emphasizes the impeccable taste and status of the owner.

Other raw materials can be considered. To obtain a light product, birch, alder, ash, larch, apple and pear are suitable. Plum and wenge are used for dark furniture.

Table making process

The manufacturing technology of the table assumes a certain algorithm of actions:

- Preparing the countertop.

- Making a drawer side.

- Leg processing.

- Fastening legs and drawers.

- Connection of the structure to the table top.

Countertops

Note! The easiest way is to use a solid piece of wood as a countertop. In this case, it is enough to cut it to size and grind it.

In real conditions, it is difficult to find material for the entire work surface of the table.Therefore, it is often formed from several elements. In this case, you need:

- Prepare the boards - remove the bark, level the surface, grind and process with a special compound.

- Connect the boards in a convenient way for the master - gluing, on a spike, using the "edge-groove" method, on a key or on a connecting strip.

- Process the ends and surround them with a protective edge.

- Bring the surface of the future product into a respectable look - remove irregularities at the joints, varnish.

It is better to strengthen the stacked tabletop along the end with additional strips. This will give the product strength and prevent swelling and cracking from the end part, which is especially important if it is used as a table element.

Underframe

The drawers form the base frame of the product. They are made from beams by joining them according to a standard technique. Difficulties can arise when attaching them to the legs. To strengthen the structure, you will need another cross member. For connection, such elements are used as:

- confirmations;

- thorns;

- dowels - chopiki and dowel;

- groove-comb with insertable ridges attached to self-tapping screws;

- metal mounting plate.

Final assembly

After preparing the legs and the table top, you need to connect them. Parts are fastened according to different schemes:

- nails or self-tapping screws - the caps will spoil the appearance and create irregularities;

- secret fastening - placing a self-tapping screw below the plane of the surface of the product, followed by closing the hole with a plug or lifting part of the board fibers, followed by placing the fasteners and gluing the raised part into place;

- fasteners from the bottom of the tabletop to the corners or to self-tapping screws, which are driven into the wood in such a way that the tip does not reach the surface of the tabletop.

Decor

Decor elements for the table allow you to transform its appearance and the interior of the room in which it is located. There are several techniques that a master can do with his own hands:

- art painting with paint;

- stickers;

- decoupage;

- painting;

- craquelure;

- mosaic;

- ceramic tile.

Self-made tables do not differ in complex technology. If you delve into all the nuances, then you can make a durable multifunctional piece of furniture with your own hands, suitable for all the requests of its owner.

Video: do-it-yourself solid wood table