Diy wood cut table

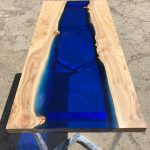

Nowadays, a rather fashionable trend is the use of furniture made from natural materials. This is a table made from a cut of wood. This unusual piece will add uniqueness to your interior.

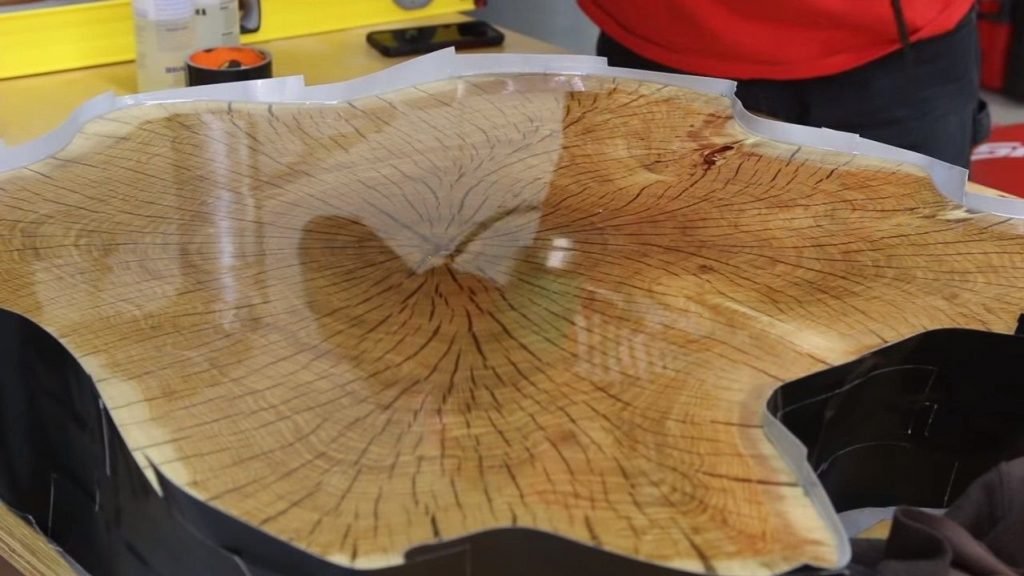

Since the pattern on the inside of the saw cut does not repeat in nature, the furniture made from wood saw cuts will be one of a kind, and you will not find such a table at anyone else.

How to make a wood cut countertop

To make this designer piece, you need a cut from a tree trunk, which is used as a table top. The legs can be made either also from wood or from metal.

To create such a beautiful and unique piece of furniture, you just need to set aside time and spend a little of your own energy. Of all the varieties, it is most advantageous to make a coffee table from a saw cut from a tree.

Choice of design

Choose what shape you need a coffee table:

- round;

- oval;

- rectangular.

The thicker the barrel you use for the round table, the larger the table you will get. In the case of a rectangular or oval shape, it is necessary to use longitudinal cuts of wood.

After that, you need to decide on the number of legs. Will the standard four-post solution work for you, or would you like to use three legs attached at a specific angle. There are tables with one support located in the center - then it must be massive and wide enough to provide stability.

There are options made from one piece, such as a stump or koryak. In this case, a suitably treated rhizome can act as table legs.

There are models created from several cuts, filled with epoxy resin.

Perfect material

Wood is the safest material in terms of health. In addition, it lends itself well to processing and can be easily combined with other materials.

By treating a wooden saw cut with special compounds, you can stop its rotting, as well as completely exclude the effect of water and insects.

A small drawback is that wooden furniture does not like direct sunlight, as a result of which it can change its shade.

Preparation

Of course, you can find a suitable cut of a tree on the Internet or in a hardware store, but a more interesting option would be a trip to the forest. It is necessary to find a dry, felled tree of sufficient thickness, while it should not be rotten.

Choose wood of those species that are less afraid of moisture. Suitable oak or walnut.

It is necessary to cut down several parts and choose an option among them that does not have any defects. It is best not to use pieces with cracks, chips or knots.

After that, you need to prepare other materials and equipment. In most cases, you will need a saw, plane, sander, and drill. From materials, epoxy, varnish, wood glue and fasteners can come in handy.

Stages of work

Consider a general work plan for making a table from one cut:

- First you need to prepare the tree. To do this, remove the bark and remove all irregularities with a planer, then process the surface with a grinder.

- If there are cracks on the saw cut, then they must be strengthened with wooden "butterflies" and filled with epoxy resin. Then sand the surface again.

- Using a brush, coat the entire piece with varnish or epoxy.

- Dry the resulting countertop.

- Drill holes on the bottom side and install the legs using the pre-prepared fasteners.

To make a table from several sections, the base is first cut out of chipboard or fiberboard. Temporary bumpers are made on the sides of the base. Cuts are placed inside the resulting form and everything is poured with epoxy resin. After drying, it is necessary to remove the sides and sand the resulting countertop. After that, it remains to paint the tabletop from the bottom side and attach the legs.

Than poured tables from wood cuts

As mentioned above, epoxy resin is used to make a table from several cuts. For a more original look, the countertop can be painted in other colors by adding some components to the resin:

- chalk to get white;

- the soot will turn black;

- cement makes the countertop gray;

- other colors of dyes are available in stores.

Where can you put such a table

A table made of saw cut wood will organically look in the kitchen or in the living room in a number of interiors, such as folk style, ethnic style, rustic, country. But, of course, it is most optimal to make it for a country house.

DIY furniture made of wood cuts will become a highlight of any interior. If you want to surprise your guests with an unusual furniture design, then a beautiful coffee table, made by yourself, will be the ideal solution, because every detail and decor element will be unique and convey your idea and mood.

Video: how to make a table from a saw cut yourself