DIY glowing table

The glow-in-the-dark table is an original solution, suitable for both home and garden. It is also quite practical, as the glow can last for 12 hours.

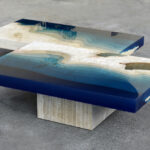

What is a light table

A light table is a table covered with epoxy resin and having various types of backlighting.

It has the following advantages:

- resistance to mechanical damage;

- moisture resistance;

- ease of care;

- resistance to sunlight and color retention;

- no shrinkage of the material after pouring;

- ease of decoration, the ability to implement a variety of design solutions and high aesthetics of appearance.

A number of disadvantages can also be distinguished:

- high cost of starting material;

- intolerance to low temperatures, from which the material begins to crack;

- with strong heating, there is a risk of release of toxic substances;

- the impossibility of placing hot dishes, which leads to the melting of the material.

In case of self-production, it is necessary to strictly follow the instructions, since any deviation from them can lead to the appearance of defects.

What are they

All luminous epoxy tables can be categorized according to the nature of the appearance of light:

- Resin with phosphor. It is a powdery substance that works on the principle of photoluminescence. After training with ultraviolet light or bombardment with electrons, this substance releases light energy, that is, it glows after exposure to sunlight.

-

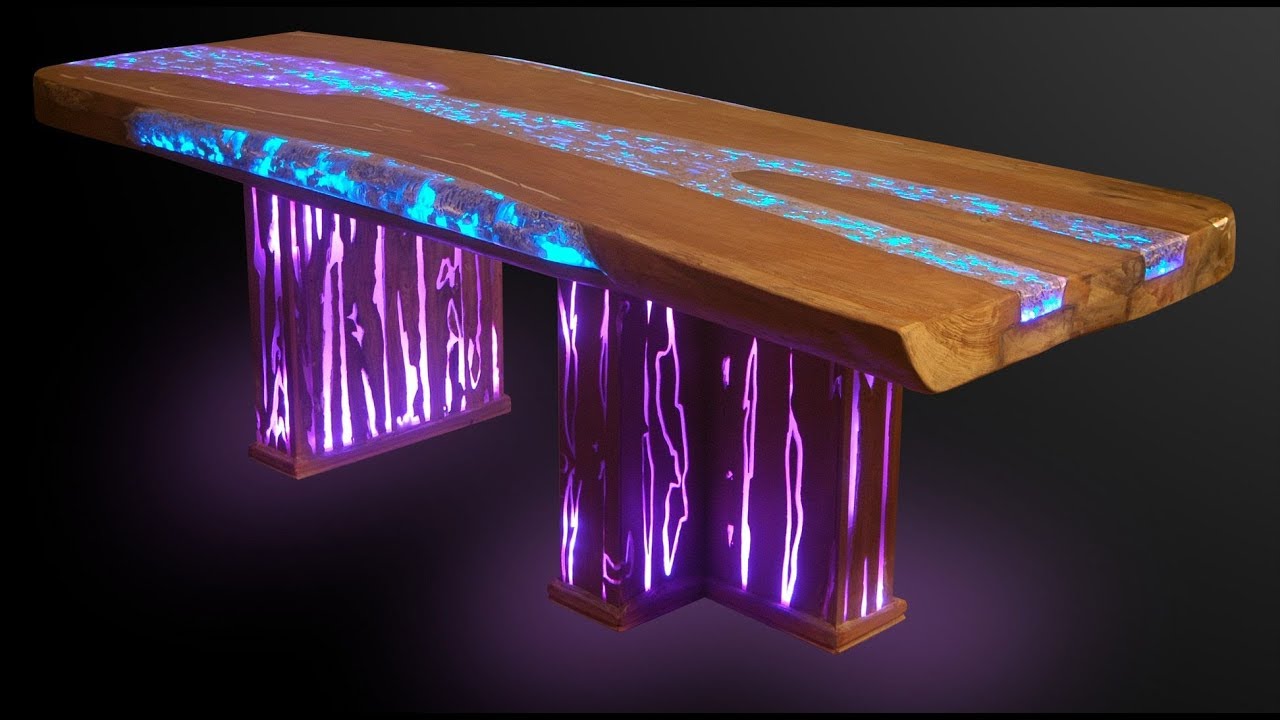

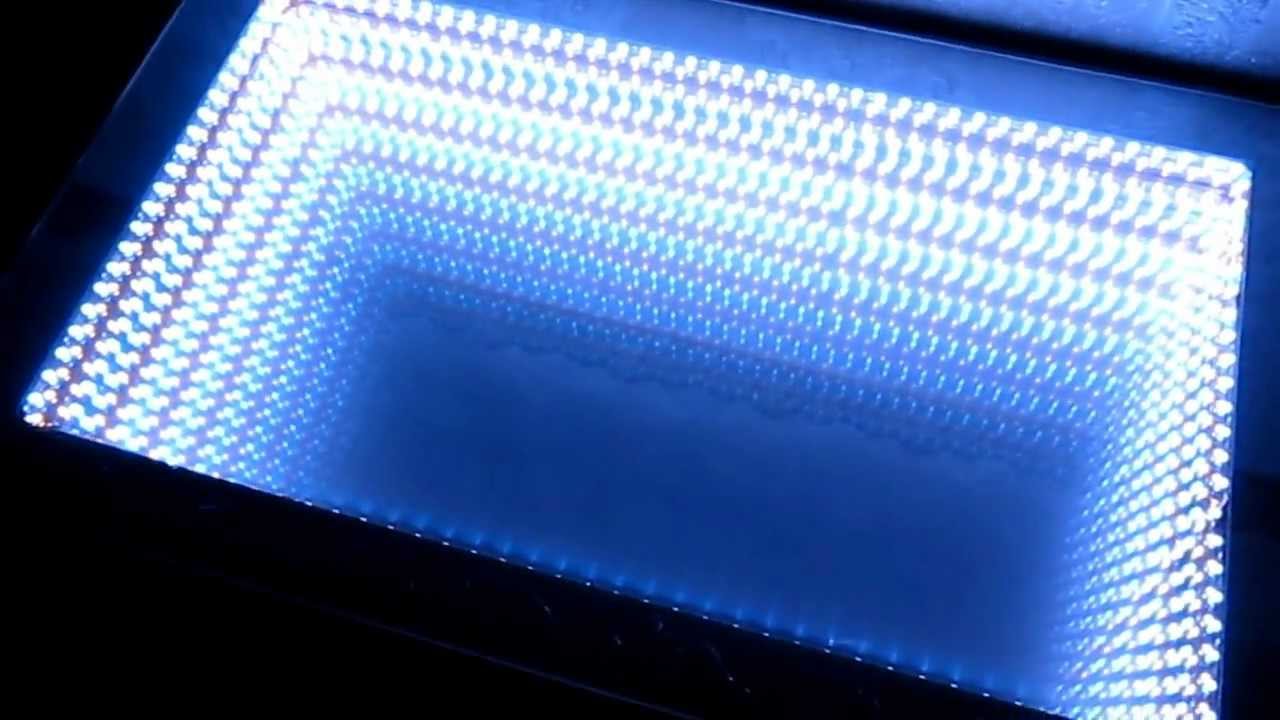

Electric lighting. It can be in the form of LEDs or incandescent lamps. In this case, the dielectric properties of epoxy resin are used, which can be used to fill the elements of the electrical circuit, thereby reliably isolating them.

The power supply for LED elements is usually filled completely, along with the backlight. This is due to its low power. In this case, it will no longer be possible to replace the failed element. More durable models are equipped with a current converter.

How to do it yourself

Scheme and drawing

The first step is to determine the size and shape of the table, which will later be reflected in the drawing.

In this case, it is worth considering some recommendations:

- the table should fit optimally into the space of the room for which it is intended;

- it is necessary to estimate the number of people who will use it, and allocate at least 70 cm in width for each;

- table height must exceed 70 cm;

- if the table is planned to be used both for a large number of guests and for a small family, then it is worth stopping at a folding model.

The table can have different shapes:

- square;

- oval;

- round;

- rectangular;

- uneven.

The form is determined by the possibilities of the space and the wishes of the owners. It is also worth choosing the number of legs:

- One is massive. Suitable only for small structures, for example, for a children's table or a table for a gazebo. At the same time, a reliable cruciform strapping is certainly performed, which allows you to cope with significant loads.

- Two massive ones. Must be located at a suitable distance. Most often they are chosen for rectangular or oval models, for example, a country table. Usually, the upper part of the legs is narrow, and begins to expand towards the bottom. This design allows you to fit freely at the table, without touching the legs with the legs.

- Four. The most common option used for dining or writing desks. Also suitable for tables with complex tabletop configurations. It is very important that the length of the legs is identical, and that their dimensions and length correspond to the overall design.

In most cases, it is most convenient to use four table legs, as they can easily provide sufficient reliability and stability of the structure. At the same time, they do not need to make specific calculations.

The choice of dimensions depends solely on the dimensions of the space for which the table is being made. For example, for a small kitchen, the size of the countertop can vary from 50x80 cm to 60x120 cm.Most often, the width fits within the range of 80-110 cm, and the height is 70 cm.It is very important to determine in advance the desired dimensions in order to correctly draw up a drawing.

The scheme is performed in several projections, depending on the complexity of the design. This is usually a front, side and top view. It indicates the external dimensions - height, width, as well as the thickness of the parts used. The drawing should include an indication of the distances between the elements, their width, dimensions from the part to the attachment point and the sequence of necessary actions.

Selection of tools and materials

To work, you need the following tools:

- an electric drill, which is used to form holes for cotter pins, as well as to create decorative recesses;

- hammer;

- a grinding machine, with the help of which the surface of the tabletop is brought to a perfectly smooth and even state;

- a set of clamps (clamps) required for the screed;

- jigsaw, with which the ends of the table top are cut;

- a plane with which the wood is pre-processed;

- a gas burner required to burn cavities in the wood;

- accompanying tools - chisel, screwdrivers, saw, construction knife, pencil, tape measure.

If all of these tools are not available, then they can be rented from workshops or some hardware stores.

The optimal material for making an epoxy product is wood. However, you should not make a glowing table with your own hands from expensive species like oak. Cypress or pine is ideal.

The following materials will be required:

- four wooden boards measuring 150x14x4 cm;

- two bottles of epoxy resin, 118 ml each;

- metal legs;

- joiner's glue;

- six plastic cups;

- Scotch;

- hardener;

- 100 g of phosphor;

- furniture varnish;

- a sheet of plastic or plywood measuring 60x150 cm.

Table creation process:

- Connect the boards with cotter pins, then glue them together. Pull the resulting shield with clamps and leave until the glue is completely dry.

- Work the side edges of the worktop with a plane, then sand.

- Cut the ends of the table with a jigsaw to a single level. Grind them.

- When using cypress, clean the resin chambers with a semicircular chisel. It is important not to disturb the natural structure.

- Blow out the cavities with a vacuum cleaner and dry with a hairdryer.

-

Prepare epoxy filler. To do this, mix the resin, hardener and phosphor in plastic cups. 10 g of resin accounts for 1 g of powder.

The resin must be handled with heavy rubber gloves.

- Glue the table around the perimeter with tape, and put plywood or a sheet of plastic underneath. This is to prevent resin leakage.

-

Fill cavities and cracks with prepared filler and leave for a day. This time is enough for the final solidification of the mixture.

The filling should be carried out gradually, starting with the filling of the cracks. Otherwise, during the drying process, air bubbles will be released from the latter, which will remain in the resin.

- Grind the surface with a grinder until a perfectly flat surface is obtained.

- Cover the countertop with three coats of furniture varnish, letting each of them dry completely.

- Form a support frame from a board whose width starts from 5 cm.

- Attach the table top to the frame and place it on the legs.

If pine (or still oak) is used for work, then the grooves in it are burned out with a gas burner. This allows you to create recesses of any shape. In addition, the fired surface accentuates the structure of the wood, which adds to the visual appeal.

Lighting and dimmer

In the case of using a phosphor, brightness control is achieved by changing the amount of this powder. It does not dissolve in the resin, but is distributed throughout its volume.

Therefore, you should not make too large an area glowing, as it will dry out much longer. During this time, powder particles can settle to the bottom, which will lead to uneven illumination. It is better to break the entire surface of the countertop into small areas.

Do not make this backlight too bright, as it can cause quick eye fatigue.

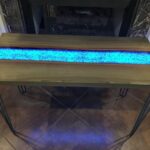

If an LED strip is used, then it is important to hide the light sources when laying it. To do this, recesses are made in the countertop, to the horizontal walls of which the tape is attached. In this case, the resin itself should be tinted to mask the LEDs.

Features of the children's light table

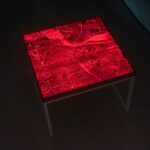

There is a special kind of luminous tables - a children's light table for drawing with sand.

Light tables for drawing with sand have become popular recently.

This is not just a beautiful element of the interior, but a full-fledged training system that allows you to develop:

- sensory abilities;

- fantasy;

- fine motor skills;

- compositional skills;

- artistic and aesthetic taste.

It is made without the use of epoxy resin. The simplest option is a plastic container lined with foil and filled with a garland or LED flashlight.

At the same time, the lid is covered with tracing paper from the inside. The assembled structure is provided with bumpers and filled with kinetic or quartz sand.

Where to put the table

If an LED strip is used to illuminate the table, then the power supply is usually a household network. Therefore, the table should be located in the immediate vicinity of the outlet. The power cord should not obstruct movement around the room.

Care rules

Epoxy tables require little maintenance. If dirty, they can be wiped with a dry and soft cloth. It is better to remove liquids and dirt from the surface immediately, to avoid the appearance of streaks or stains. Do not wipe the countertop with substances containing acetone or alcohol, as they destroy the material.

In general, caring for a luminous table does not differ from caring for a regular table top. It is worth keeping it clean and preventing the appearance of chips and scratches, as they will be visible on a transparent background. With careful handling, the table can last for several decades.

Making a glowing table with your own hands is not too difficult a task that requires a careful approach. If you follow the instructions carefully, you can get a high-quality, beautiful and original product.

Video: how to make a glowing table from oak and epoxy resin yourself