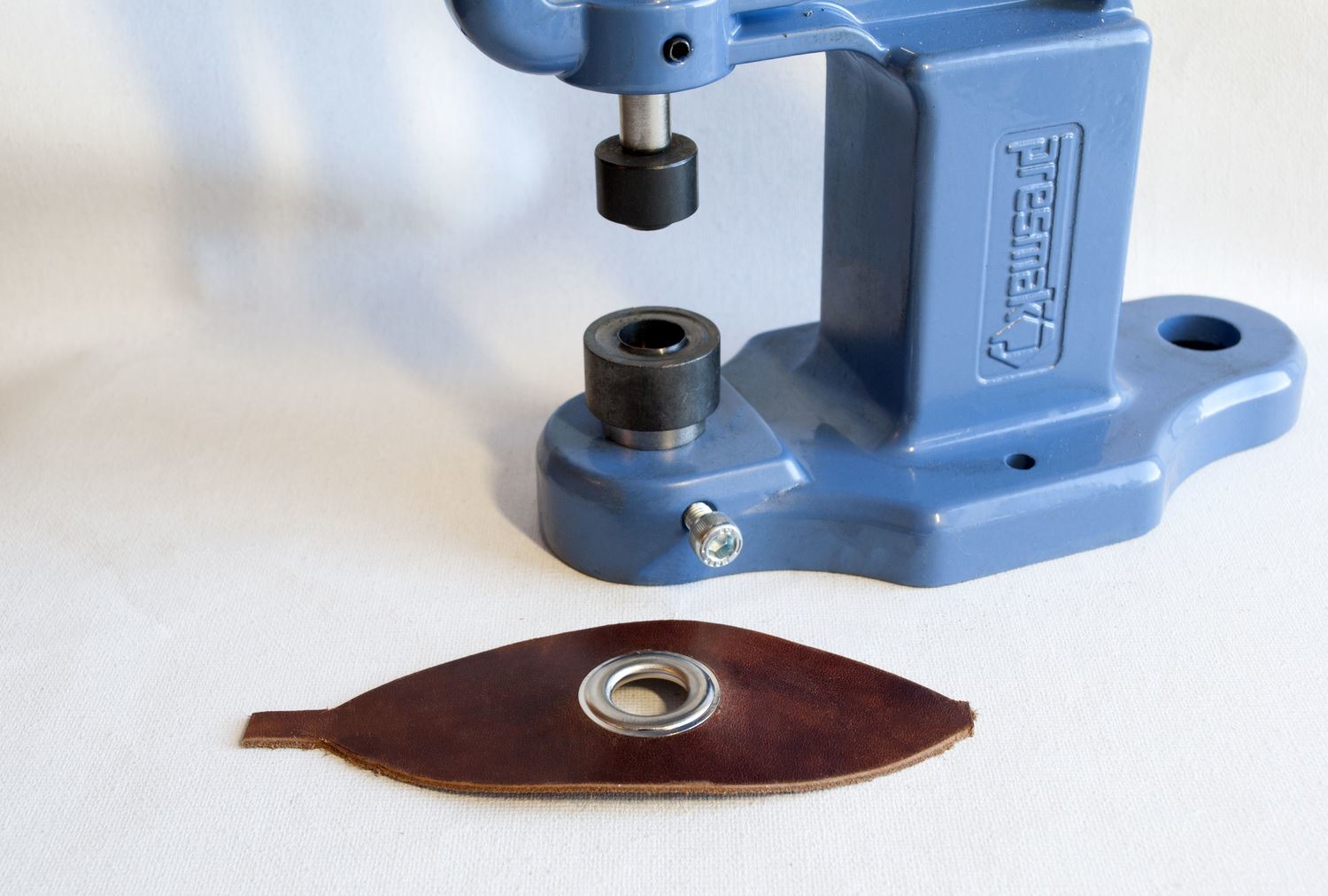

Machine for installing buttons and eyelets

A press for eyelets or a press for installing fittings is a special tool, the main functionality of which includes just fastening fittings (in particular, eyelets) to various materials.

Usually this is needed for decoration (clothes, shoes, children's toys) or has a specific function - for example, it helps to fix curtains on the cornice (the rod is threaded through round eyelets) or to put up a tent (a special strong cord is used with eyelets).

Advantages and disadvantages of a press for installing eyelets

The main advantage of the press for installing the eyelet is the principle of its operation - using this tool, you can simultaneously make a hole in the base fabric and fix the sleeve and washer (they are also called metal trim). When using a press to install fittings, you can forget about any other tools - they are simply not needed, everything you need is done in one move.

Of the minuses, it is worth highlighting the cost of such equipment - the most modest model of a pneumatic press will cost at least 150,000 rubles. The cost of the most expensive options on the market would be better tactfully kept silent.

How to use the fixture correctly

It is quite easy to use the press correctly for installing eyelets (it is also called a machine for installing buttons and eyelets) if you strictly follow the attached instructions, which, however, are sometimes written in too abstruse language and introduce ordinary users into a stupor.

To begin with, it is worth choosing the most suitable option - manual, pneumatic or electric, since the method of application is not very much, but it differs.

A pneumatic press is commonly used in sewing shops and is powered by compressed air. It is designed to be fastened to fabric-based buttons and eyelets.

First you need to place the grommet in the place chosen for it, then place it under a metal press and start working. The press itself will punch a hole, fix the eyelet on the fabric and connect its two parts to each other.

Hand press

The manual press, which is used for the same purposes as the pneumatic press, differs in many ways from the previous model reviewed. This tool can not only install eyelets, it can also be used to easily punch holes in fabric.

To make the hand press work, it is necessary to place the fabric with the fittings already applied in a special place above the "punch" and press the press lever, then in a second the hole in the frame of the metal ring will be ready.

To simply perforate the fabric, you need to do the same thing, but at the same time remove both parts of the eyelet (sleeve and washer) from the base.

Universal

Why are some hand held eyelet presses called universal? The answer is quite simple - such machines can be used if you need to install holders, buttons or eyelets of different diameters. The main thing in this business is to choose the right attachment.

There are a wide variety of attachments for hand presses:

- Attachments for eyelets of different diameters.

- Bits for double-sided holniten.

- Nozzles for one-sided holniten.

- Button caps.

Depending on the fittings at hand, you need to select the appropriate attachment that will be most suitable.

IMPORTANT! You should not use a nozzle with unsuitable fittings, so you can break not only the grommet, button or clamp, but also the tool itself.

Varieties of tools for installing eyelets and buttons

In addition to various types of presses, you can use a punch or a collapsible hammer to install fittings. The undoubted advantage of these tools is their lower cost than the presses.

A press for eyelets or a machine for installing eyelets and buttons is equipment that must be available in various workshops, but at the same time it is not so urgently necessary for home use and it can be quite easily replaced with the tools at hand.

Video: installing eyelets using a press