Making a press for squeezing juice from apples

Every gardener knows that in addition to planting and growing, it is important to ensure proper storage of the crop. And it doesn't matter in what form you store, for example, apples: fresh, canned or as wine and juice. The latter option will also require special equipment. How to choose an apple press?

How the press works

All presses, regardless of their type, work according to the same principle - creating pressure on the crushed raw materials. Pulp (crushed berries or fruits) is placed in a container with holes or special bags. When squeezed, the juice flows into the pallet, and the spent pomace is removed after the end of the work.

The main distinguishing feature of each device is the way in which pressure is generated. On this basis, the press is divided into:

- Mechanical - pressure is created manually;

- With partial use of manual power - jack hydraulics;

- Electromechanical - hydraulic with water supply, pneumatic, electro-hydraulic.

The most productive are the combined structures (using electricity and hydraulics). Such devices allow processing a large amount of raw materials in a short time. And the yield of the drink is not bad - 70% of the fruit mass.

Mechanical presses are popular because they can be used in any conditions, even without sources of electricity and water.

Presses of any design are made of high quality durable materials and do not have a negative impact on the raw materials used.

Construction types

The design is chosen depending on personal preference, as well as the amount of juice that you plan to receive. For example, mechanical models are ideal for daily use when you need to get your family drunk at a time. But the hydraulic apparatus and models with an electric drive give a larger volume of juice, it is no coincidence that such structures are used for blanks for the winter.

In addition, it is important to know what kind of maintenance each model will need, to assess their advantages and disadvantages.

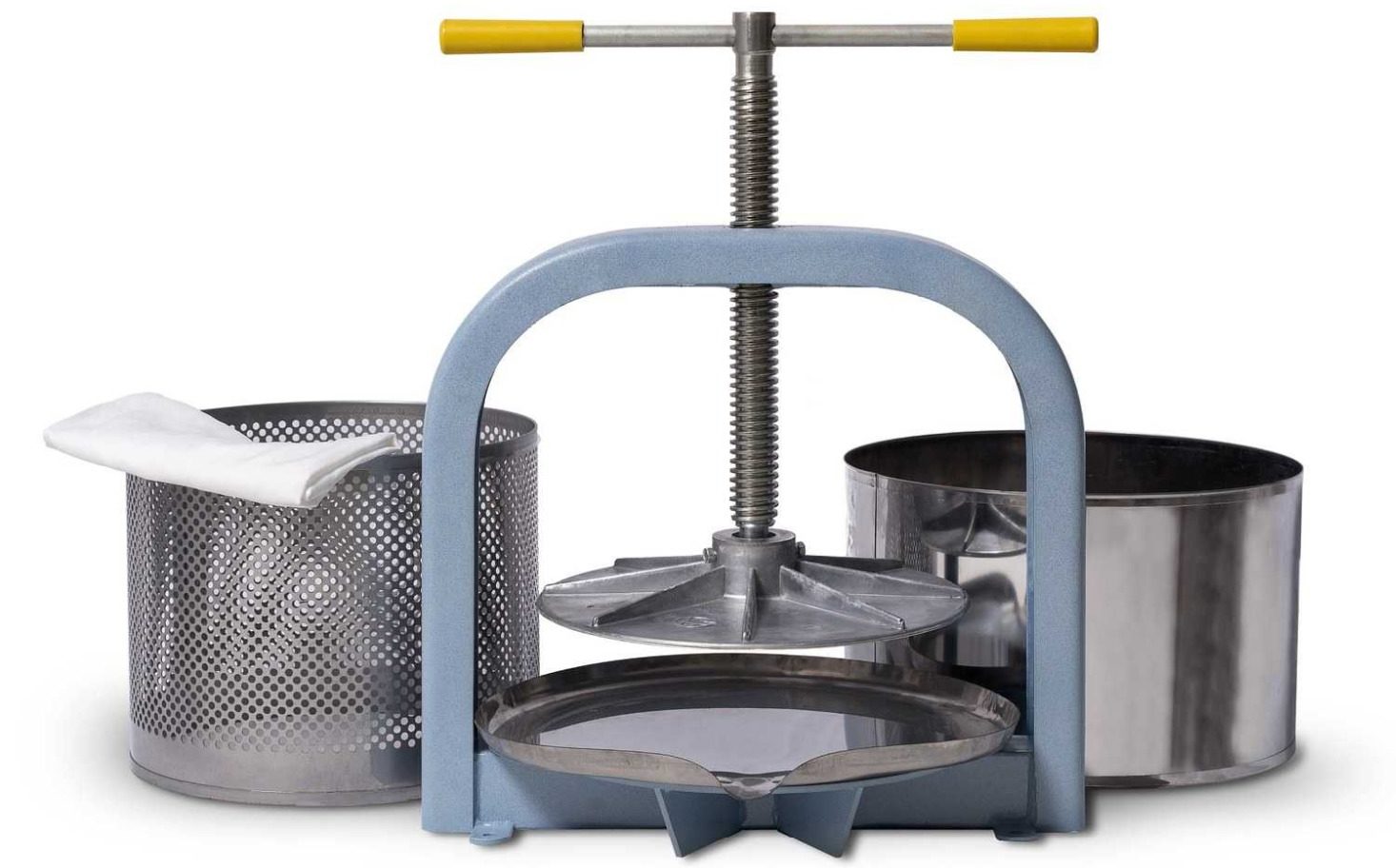

Mechanical press

This is a budget option that was invented decades ago. We can safely say that the mechanism of its action is debugged to the smallest detail. Apples are placed in a container with perforation. In the process of rotation of the handle, the piston is lowered and the screw mechanism of the press is activated. Juice is squeezed out of the apples under pressure. In the lower part there is a container for "collecting" juice. Such a press requires serious physical effort and is not very productive - you can get from 10 to 30 liters per hour (depending on the effort and the variety of apples).

Mechanical options are available in two designs:

- No frame.The screw is attached to the base of the press.

- With a frame. The handle rests against the lid, and it is much more convenient to twist it, but more effort is required.

Such presses have many advantages: they do not take up much space, they are ideal for daily use (0.5-3 liters you can prepare quickly enough). If you are the proud owner of a wooden mechanical press, then the structure will also become a worthy decoration for your kitchen. Finally, they are appreciated for their versatility: with the help of a mechanical model, you not only get juice from apples, but you can also process other fruits and berries, as well as extract honey from the honeycomb. In addition, you can even make cheese with this press.

Pneumatic

In pneumatic presses for pressing apples, the pressure is a consequence of the work of compressed air. For this, each unit is equipped with a mains-powered compressor.

Advantages of pneumatic presses:

- In the process of work, no physical effort is required;

- The device is equipped with safety valves, which means that the working process is completely safe for humans;

- During one working process, you can get a sufficient amount of ready-made juice without disassembling the unit, and without adding raw materials;

- The design has no moving mechanical parts, which usually fail quickly. This ensures long-term operation of the device.

The housing for such models is made of very durable materials, and the pneumatic actuator can be purchased separately. This design is ideal for processing large quantities of apples, other fruits and berries. Such presses are often used in agricultural enterprises. The main difference between pneumatic and hydraulic structures is the absence of a water membrane.

Hydraulic

These models use water pressure to spin. Such units are the most expensive of all of the above, but thanks to them you can get the largest volume of juice - up to 70% of the weight of the raw materials used. Instead of a metal container with perforation, wooden frames are used. Apples are crushed and placed in special bags, which, in turn, are placed between frames.

The following designs are available:

- Jack on hydraulics. Even the representatives of the beautiful half of humanity can cope with such a design, minimal efforts are required.

- Models without a jack. The pressure is created by water. The liquid, accumulating, presses on the decomposed fruits, and the juice flows into a special container.

The capacity of the hydraulic jacks is large enough to process large quantities of fruit. When purchasing a device without a jack, you need to provide for the possibility of connecting to the water supply.

Electrohydraulic

Hydraulics are combined with electricity to fully mechanize the juicing process. The water from the pipes is supplied to the membrane, and the high pressure is provided by the compressor. The cake remains in the basket.

Advantages of electro-hydraulic models:

- High performance;

- Electronic control system;

- Ease of cleaning after use;

- Juice can be obtained from any raw material.

The main disadvantage is the high cost. Most often, these models are used for industrial production.At home, such a unit is justified only in cases where you need to process a large amount of raw materials. By the way, it is often used to make raw materials for home wines. Even the fairer sex will be able to cope with the electro-hydraulic press to obtain juice.

The spinning process

It takes place in two stages:

- Preparation of raw materials. For grinding apples, special devices are used, reminiscent of graters at meat grinders. Thanks to the electric drive, such units work quite efficiently, and the "semi-finished product" is quickly prepared.

- Placing raw materials in the press and spinning.

After work, the press must be disassembled, rinsed and dried well. Remove the cake, clean the perforations. Containers made of wooden frames require especially careful attention to themselves, since they are stained, absorb juice and odor.

Since the apple is a fairly hard fruit, additional methods are used to increase the yield of liquid. For example, cloth bags that filter juice, or drainage devices such as wooden slats or perforated stainless steel discs.

How to choose a press

If you have decided to purchase a press for squeezing juice from apples, pay attention to the following criteria:

- Loading capacity. This indicator determines how much raw material you can process in one cycle.

- The material from which the basket is made. Preference is given to stainless steel containers, since it is easier to care for it, and it will last longer.

- Design features. Find out if you need a water or electrical connection. Otherwise, it may turn out that you will purchase a unit that will be useless in your conditions (for example, in a country house with an incomplete "set" of utilities).

- The size. The convenience of storage and operation depends on the parameters.

- What physical effort will be required to work. In some situations, it is better to purchase a model without mechanics.

A press is an opportunity to regularly produce a new batch of products without boiling or sterilizing the product, which helps to preserve useful properties and vitamins. - Press productivity. How much juice can you get in a certain time. For large volumes of raw materials, choose a model that can produce 100-200 liters of juice per hour.

- Price. This criterion is, of course, relative, but nevertheless it should be taken into account. Mechanical presses are the most affordable. The factor that determines their cost is the volume of the basket: the larger it is, the more expensive the press. If there is no desire to exert physical effort and incur serious financial costs, then choose hydraulic presses with a jack.

Before buying a large device, you should think about where to save it during the winter. Some machines are very heavy and difficult to transport.

For most, a press for juicing is not a luxury, but a necessary unit that will provide seven vitamin drinks. Moreover, modern designs allow you to do this quickly, efficiently and with minimal physical costs.

Homemade press for fruits and vegetables