Overview and Applications of Glass Adhesives

Glass objects are very fragile and therefore require repair more often than their "counterparts" made of plastic, metal or wood. For gluing parts, it is important to select such a composition so that the junction is almost invisible. And when it comes to joining glass with another material (wood, metal), the primary focus is on strength.

Requirements

Of course, a lot depends on the materials and the scope of use. But there are requirements that are relevant for any glass adhesive:

- High degree of adhesion (or, adhesion) of surfaces.

- The transparency of the composition.

- Minimum setting time.

- Elasticity.

- Viscosity.

- Fluidity.

- Resistant to temperature changes.

- Resistant to humid environments.

- Possibility of long-term storage.

- Environmental friendliness.

Adhesion manifests itself primarily in "contact" with surfaces. In the process of applying the adhesive, there should be no problems. If you want the seam to be as invisible as possible, use a transparent compound. Glass products of the correct geometric shape can be fixed with a clamp, but this is not always effective, therefore it is important to take care that the "setting" occurs quickly.

The degree of viscosity or fluidity depends on the surface of the parts. For example, when gluing earthenware and porcelain surfaces, it is important that the adhesive spreads in a uniform layer over the surface. When it comes to joining glass sheets, a higher degree of viscosity and a lower degree of fluidity will be required for the substance to be on the surface before adhering to the second part.

There is another requirement for glass products that are subject to high stress. The fixation must be strong and at the same time elastic enough so that the product does not break again during use. The composition of the glue should remain mobile after drying.

Often, glass products are used in different temperature conditions (for example, boiling water is poured into teapots and custards), which means that the glue must be appropriate. And the vases and glass shelves that decorate the interior of your home simply have to be also environmentally friendly, that is, not emit harmful substances.

Types of glue

Today you can easily find the glue that meets your requirements. Let's get acquainted with the main assortment.

Cyanoacrylate

This adhesive can be safely called universal. It is also used for bonding glass to glass, as well as for bonding glass to wood, plastic, iron and other materials. Speaking about the professional use of such glue, it should be especially noted that it is in demand in the field of electronics production.

The advantages of cyanoacrylate glue are numerous.First of all, this is a budgetary cost, it is also appreciated for its liquid consistency, which facilitates the process of distributing the composition over the surface. Finally, it is distinguished by its fast setting and seam strength.

For home use, the glue is available in aluminum or plastic tubes. The advantage of using such glue is the ability to store it for some time after opening, so there is no need to use all the glue at one time. Stored tightly closed and at room temperature. Outwardly, this glue looks like a transparent liquid. It does not require the addition of a hardener, as it is one-component. At room temperature, the adhesive hardens within three seconds. In the process of work, it is important to observe safety precautions: be sure to work with gloves. The dried joint can easily withstand temperature drops from -60 to +80 degrees. The only disadvantage of the composition is incompatibility with some types of plastic.

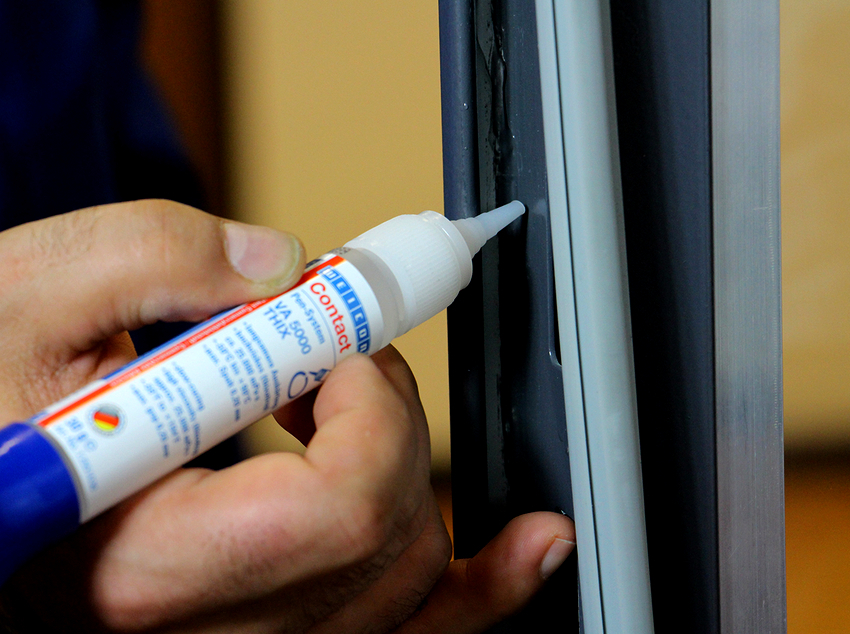

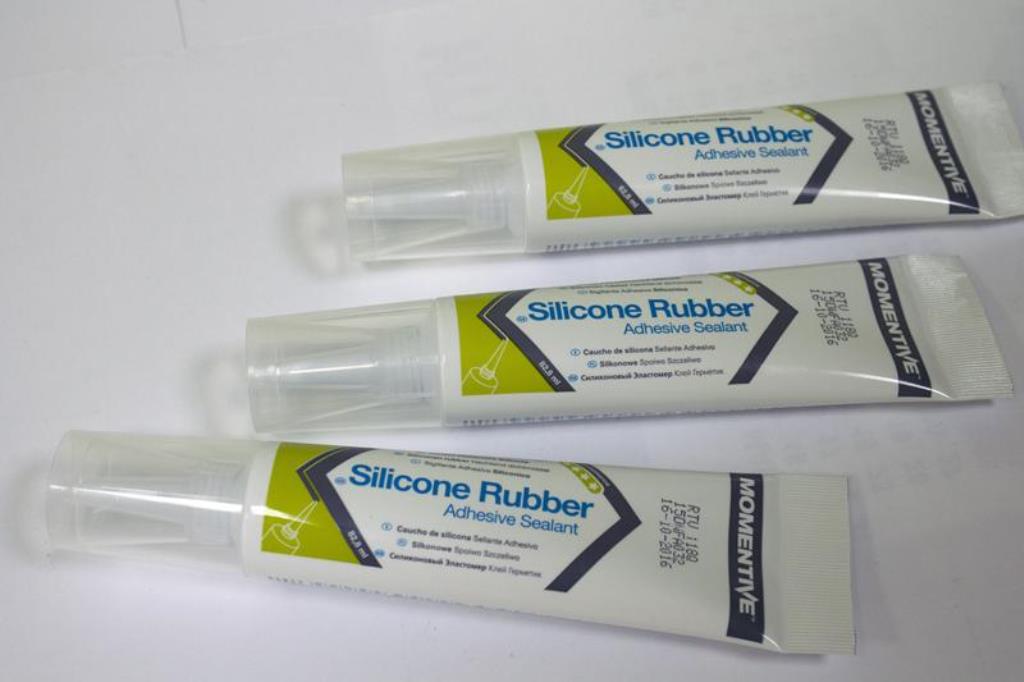

Silicone

Silicone glue is the most commonly used adhesive for bonding glass or ceramic surfaces. The composition contains a high molecular weight polymer, rubber, solvent and hardener. The proportions of the above components may be different, and this determines the way of interaction with materials and the properties of the composition.

The main advantage of silicone glue is its inertness to chemical and biological influences. There are antibacterial compounds that are necessary when working with plumbing, when various kinds of dirt accumulate in the seams and bacteria develop. The silicone composition does not dissolve under the influence of water, therefore such glue is often used to repair products that are used in a room with high humidity. Since silicone is an environmentally friendly substance, some of its types are even used in the food industry. Outwardly and in consistency, this composition resembles a thick cream. The drying time of the glued surfaces directly depends on the air temperature and the degree of humidity.

Silicate

Silicate glue is also called liquid glass, as it contains substances that are used in the production of glass. Outwardly, this glue is a transparent, slightly viscous liquid. The composition is very common as it is affordable and easy to manufacture. It acquires its "stickiness" due to potassium, lithium and sodium silicates. The glue interacts with any materials and provides fire safety.

When the composition is applied to the surface, it penetrates the pores of the material, releasing moisture and holding it together. When used on metal surfaces, the silicate adhesive guarantees anti-corrosion protection. "Liquid glass" conducts heat well and is characterized by resistance to temperature extremes. One of the few drawbacks is the impossibility of painting surfaces glued with silicate glue.

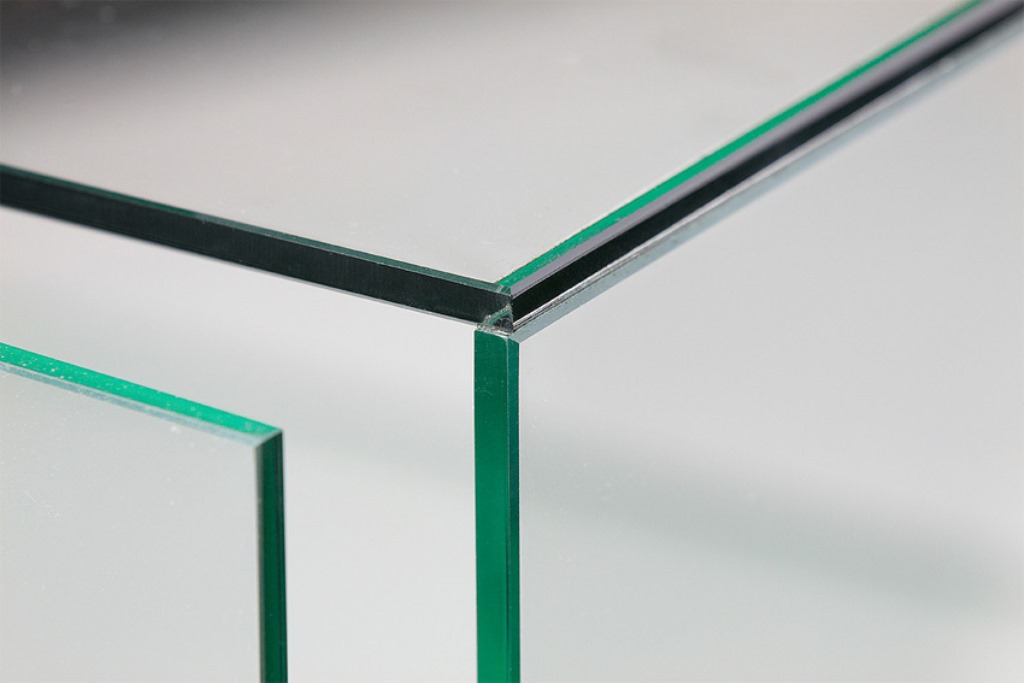

Polyurethane

The composition easily copes with the connection of smooth surfaces, and therefore is indispensable for gluing glass. This adhesive can be one-component or two-component. The one-component polyurethane compound is ready to use.The second option can be used for different cases, since the polymerization time depends on the amount of hardener applied. Sometimes composites are used as additives to increase the strength of the seam.

Heat resistant

This composition can be made on a natural or synthetic basis. The natural composition involves the use of silicates, as an aqueous solution of liquid glass, there is also refined sand, chamotte fibers, and minerals. When heated, no harmful fumes are released, and the composition can easily withstand temperatures up to +1200 degrees. This glue is especially in demand for glass or oven seals.

Synthetic heat-resistant adhesive is made from inorganic compounds. The composition can withstand heating up to 3000 degrees, easily tolerates an acidic environment and high humidity. Ideal for bonding glass to metal or graphite surfaces.

Important! If you are looking for a heat-resistant adhesive for repairing electric stoves, check that it has dielectric properties.

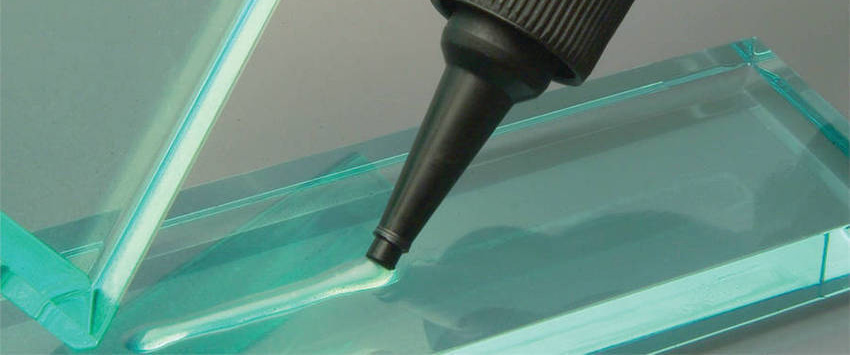

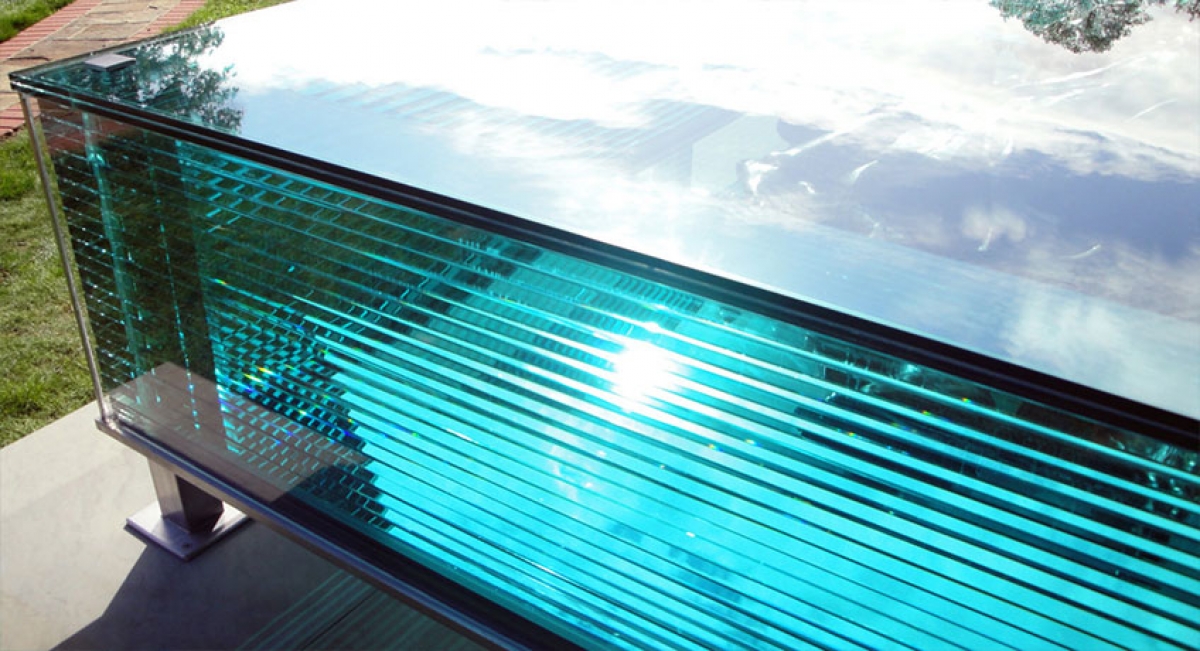

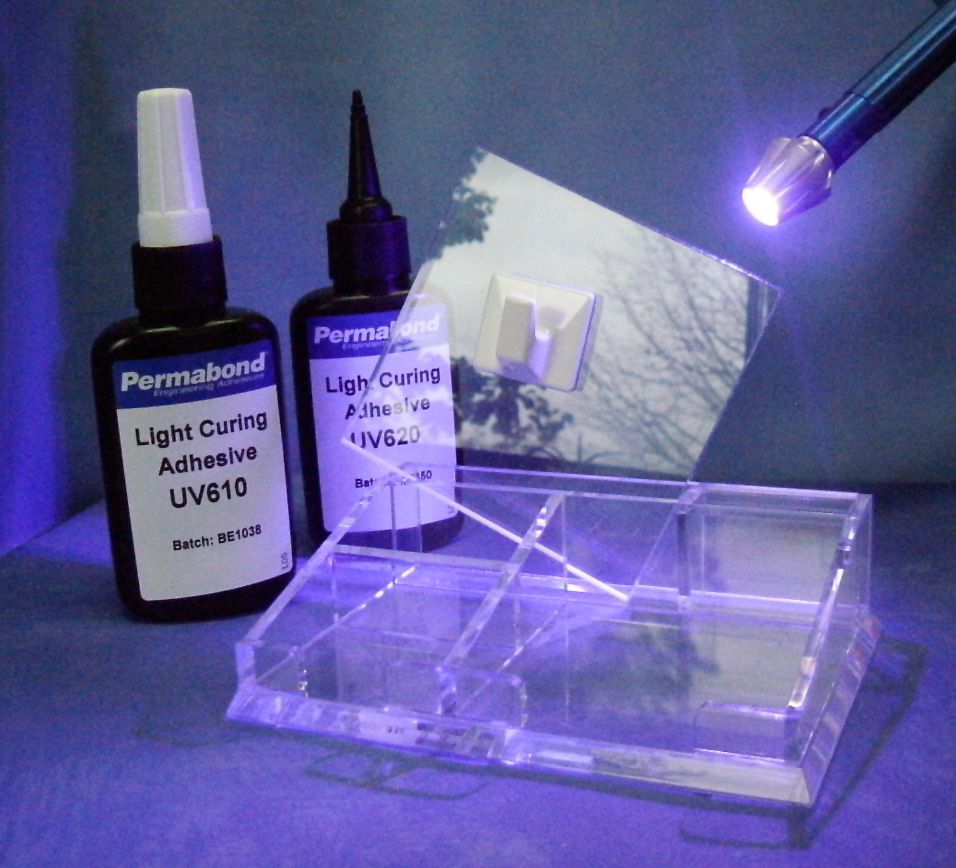

UV adhesive for glass surfaces

The catalyst for the process using this glue is ultraviolet rays. The composition is used for gluing glass surfaces to each other and to other materials (metal, plastic, wood, etc.). Moreover, glass can be both organic and natural. Methacrylic acid is used as a base for the glue.

Most often, UV glue is used for gluing aquariums, solar panels or furniture stained-glass windows. It also finds its application in the jewelry industry and in the manufacture of electronic devices.

The connection turns out to be glued, as they say, tightly, and the seam is resistant to temperature extremes (withstands from -40 to +150 degrees). Not afraid of humid environments. Since no solvent is used in the production of UV glue, the product is considered environmentally friendly. The cured adhesive can withstand shock and vibration.

How to glue

It turns out that this is only at first glance, gluing - a process without much wisdom. In fact, it is important to know exactly what to do and how to do it, otherwise the result will disappoint you.

First of all, before starting work, prepare the parts to be glued, latex gloves and adhesive. Cover the table (floor or cabinet) on which the work will be carried out with a film, then it will be easier to remove the drops of glue. Wash the surface of the parts to be glued with soapy water or degrease with alcohol. If you are glueing broken pieces, be careful not to injure yourself on sharp edges.

After drying, apply glue to one of the parts and press the other firmly against it. If you are using a cyanoacrylate compound, then the pressing time is a few seconds. If the glue is silicone, it will take a few minutes.

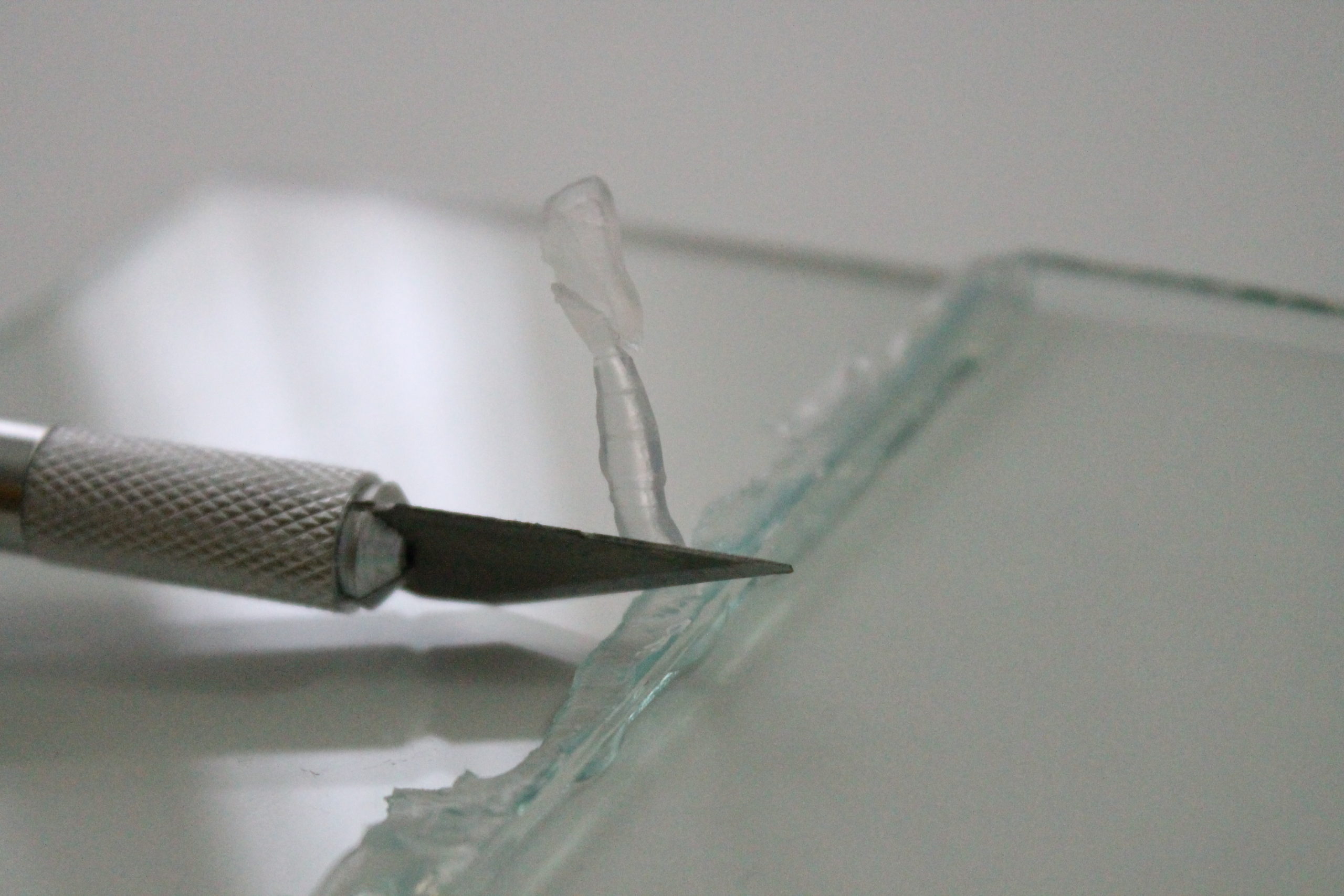

If you use UV glue, then after the above steps, you will need to heat the parts to 40 degrees. To do this, you can use a hairdryer.It is important to position the part so that the glue does not drip from it, firmly fix the surfaces to be glued, and then place it under a UV lamp for 30 seconds. If you do not have a special lamp, leave the aligned parts in direct sunlight. Of course, in this case, it will take more time, but the quality of gluing will be decent. If excess glue appears at the edges, then they are cut off with a knife or removed with a special scraper, but only after hardening.

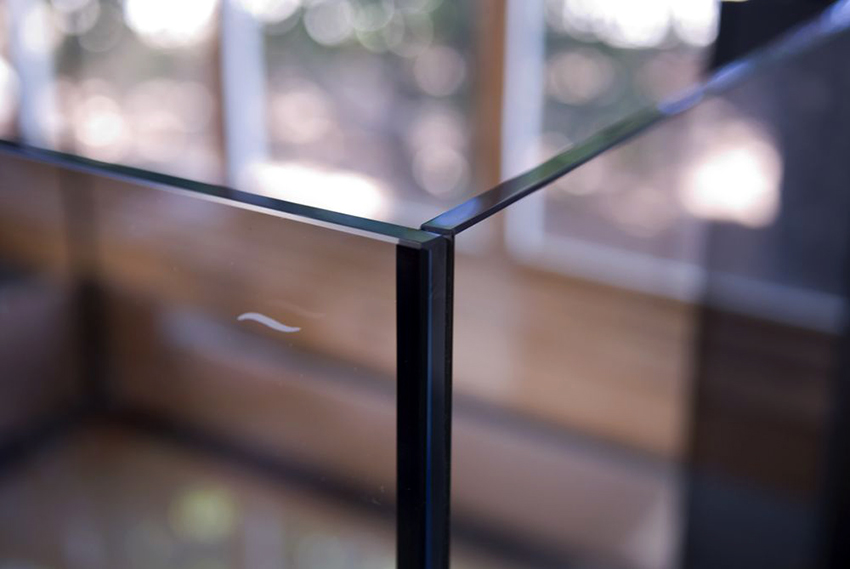

For bonding glass and metal, the main thing is to choose the right composition. Either UV glue or another adhesive is suitable, but always with a gel-like consistency. This will prevent the glue from flowing around the edges. The surfaces are degreased and heated up to +40 degrees. The seam is positioned horizontally and glue is applied to it. After that, the parts are tightly pressed and fixed with special clamps.

Practical advice

And finally, a few important recommendations:

- Do not rush to glue the parts with the first composition that comes across, choose the one that is suitable for your specific situation;

- Read the recommendations carefully when buying glue;

- If you need to glue large areas, then it is better to apply the composition with a brush, and then the glue must be poured into a convenient container;

- During work, you can not be limited to the use of gloves, but also wear a protective mask or goggles;

- If the adhesive contains a solvent, ventilate the room.

The well-known saying: “You cannot glue a broken cup” is no longer relevant today. There are many different compounds with which you can glue all kinds of parts, and this can be done almost imperceptibly.

VIDEO: How to use UV glue for glass.