Holofiber applications, pros and cons

Holofiber is an outstanding and successful representative of synthetic nonwovens. The first such materials began to appear in the 1930s in Europe. Russian manufacturers began using artificial nonwovens in the late 1950s.

Its history began in 2005 at the Moscow plant "Termopol" - the only manufacturer of this material, which developed and patented the technology for the production of unique fibers. The main feature of hollowfiber is clear from its name: the English name of the material is hollowfiber - in translation, hollow or porous fiber.

Hollow fibers of holofiber are made of high-quality polyester by thermal bonding, and the peculiarity of the structure of the material is that its fibers are sealed on both sides and twisted into spirals. Externally, the material is similar to cotton or down, but compared to natural fibers, it benefits from use:

- not afraid of mechanical stress

- does not form textile lumps and does not stray

- perfectly keeps its shape and volume

- not afraid of washing

We can answer the question “holofiber what is it” as follows: a universal synthetic sound-proof and heat-insulating material, widely used in various industries.

The key consumer property of this modern fiber is the ability to create a thermal barrier and maintain an optimal temperature: in cold weather, the material warms up and conserves heat (in clothes with such a heater, you can withstand temperatures up to -30⁰ C), in the heat, on the contrary, it saves you from overheating.

Types of holofiber and their application

Holofiber is produced in 3 types: granules-balls, sheets and plates.

- A pellet ball is the most common and common type of filler. The fibers twist to form balls ranging in size from a pea to a ping pong ball. This form of the material holds its shape well, does not get lost and does not deform - it is stuffed with pillows, toys, used as a filler for blankets and gives a three-dimensional shape to decor items.

- Non-woven fabric. Holofiber in canvases is produced in different thicknesses from 60 to 4000 g / sq. The thinnest canvas is used in landscape design. Cloths with a density of 100 to 300 g / m2 are used as a heater for clothes. Denser fabrics, due to their thickness, density and elasticity, are excellent for the manufacture of mattresses and upholstered furniture. There are three main types of furniture holofiber: there are also hard canvases (hard) for creating a frame and flooring, medium (medium) for the top layer and soft (soft) for quilted elements and decorative elements.

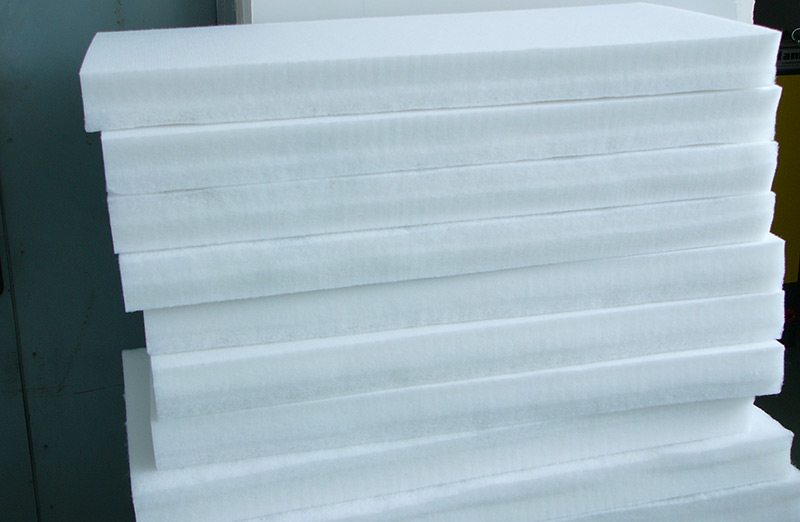

- Plates (layers, mats) are produced for construction needs, they are an excellent insulation and sound insulator. Both soft and hard pressed mats are available.

Various types of holofiber are also used in light industry, mechanical engineering, space industry and aviation.

The difference between padding polyester and holofiber

Both materials are synthetic and made from polyester (the most common polyester fiber today). The difference is in the structure of the material and the way the fibers are processed.

Fibers of synthetic winterizer are laid in parallel layers and are connected to each other by needle-punched method, glue or felting. Due to the use of adhesives in technology, synthetic winterizer can cause allergies and is not recommended for children's clothing and bedding.

The synthetic winterizer is a less durable material, it is short-lived and susceptible to deformation, when washing, even a well-quilted synthetic winterizer is knocked into lumps. The distance between the fibers of the padding polyester is greater, which means that the material is looser and retains heat worse. Clothes with padding polyester insulation are comfortable to wear up to a temperature of at least -15⁰ C. Due to its disadvantages, it is not intended for industrial use and is not at all suitable for use in construction.

Holofiber production technology is more complex. At the first stage, a non-layer canvas is obtained from hollow micro-spirals, the fibers in the formation are arranged in different directions, thanks to the use of a wind tunnel. On the second, the fibers are soldered together using temperature exposure. Such a connection of fibers is more durable, the final material is elastic, holds its shape well and is absolutely hypoallergenic. In comparison with synthetic winterizer, holofiber is lighter, warmer and more unpretentious in care, clothes with such a heater are very comfortable in winter.

How to distinguish when buying which material - holofiber or synthetic winterizer - is used in the product? Sintepon, unlike holofiber, is produced only with canvas. If you try to stretch it, you can hear the crunch of the sheared fibers, the stretched material does not recover. Holofiber is much softer and lighter than padding polyester. It does not split into layers and does not make sounds when stretched. Visually, holofiber fibers are always white, somewhat transparent to the light and have a gloss, while synthetic winterizer fibers are opaque, the material of poor quality can have a grayish or pinkish tint.

Pros and cons of holofiber

Holofiber is highly valued by manufacturers and consumers for a number of useful and unique properties:

- strength and resistance to deformation - due to reliable fiber splicing, the material cannot be torn by hand;

- durability and unpretentious care - products can be washed both by hand and in a washing machine.

- hygiene - it can be washed often, moths, mites, mold or fungus will not start in it;

- breathability and moisture resistance - products dry quickly and have a "breathing" effect;

- excellent heat-regulating properties;

- hypoallergenic and environmental friendliness during production and operation;

- lightness and softness;

- fire resistance - when exposed to high temperatures, the filler does not burn, but slowly smolders.

There are few downsides to holofiber products.Some consumers note that they feel hot in things with this insulation, this applies not only to clothes, but also to bedding. The reason lies in some of the individual characteristics of the organism. It should not be washed in aggressive modes and at high temperatures - it can lose elasticity and become tough.

Note! Holofiber is recommended for use for children's clothes, toys and bedding, as it is completely harmless.

Consider the benefits of using holofiber in different areas.

- In clothes

Holofiber clothes are warm, lightweight and absolutely hypoallergenic, which means they are suitable even for the smallest children. It can be washed frequently and will dry quickly after washing. In a jacket or down jacket, you will be warm even in severe winters at temperatures below -25⁰ С. the ability to retain heat, while it is much cheaper than thinsulate and is quite suitable for our winters.

- In pillows and blankets

Hypoallergenic and eco-friendly soft holofiber pillows will give a restful sleep to both children and parents, and under light breathable blankets made of this material it is not cold in winter and not hot in summer.

Such blankets and pillows are very hygienic - bed mites will not start in them, and washing them is no more difficult than a jacket. For this, the most common washing powder and a delicate mode at a washing temperature of 30-40 ⁰С are suitable. You can wring out and dry in the machine and after drying, the synthetic filler will not lose its shape and elasticity.

- For the production of furniture

In the furniture industry, all types of holofiber are used, as a rule, of special brands that have a denser structure and increased elasticity. Decorative pillows and bean bags are stuffed with soft elastic balls. Compressed fiber boards of the "hard" brand are suitable for the production of springless mattresses, including children's mattresses.

- In construction

In this industry, holofiber has an unlimited scope. It has proven itself as an industrial and household insulation - it can insulate a building from the foundation and basement to the roof. "Friends" with various building materials - concrete, stone, brick, wood. The material has become a godsend for insulating houses from timber and frame frames, including complex architectural forms in the form of domes, monocells, etc.

It is flexible and resilient, reliably filling all the necessary space, regardless of the weather and season. Separately, it should be noted the high soundproofing properties of sheet material and its incombustibility, which is important for frame and wooden residential buildings.

- In decorative items

Holofiber can be used wherever it is necessary to add volume to the product:

- decorative pillows and ottomans

- toys and souvenirs

- litters and houses for pets

- different types of handicrafts and hobbies

Proper care of holofiber

Any product filled with holofiber can be washed both in the washing machine and by hand.Jackets, down jackets, pillows and blankets, if properly washed and dried, will not lose their appearance and consumer properties. The filler will easily withstand intensive washing, steam treatment and mechanical stress, but when choosing a mode, do not forget that the upper material of the product may require a delicate attitude.

Here are the general rules for caring for products with holofiber:

- For light dirt, it is advisable to do without washing. Frequent washing can negatively affect the elasticity of the fiber, the product will begin to lose its shape and quality.

- If the item is heavily soiled, it is better to pre-soak it in soapy water. Wipe heavily soiled areas with a soft brush or cloth and rinse, and only then send to wash in the machine.

Important! Do not forget to familiarize yourself with the product label before washing or cleaning - the upper material can be natural or synthetic and require a more gentle washing cycle than the filler.

The best fillers for down jackets

In our climate, a down jacket is a must-have item in the wardrobe. An important characteristic that is important to consider when buying winter clothing is insulation - the service life of the down jacket depends on it, how light and warm it is. When sewing down jackets, both natural and synthetic fillers are used. What are the best fillers?

- Down of waterfowl (goose, swan, eider) is considered the best natural filler. It is lightweight, durable and warm, but there are also disadvantages - it requires special delicate care and may be an allergen.

Products with it are quite expensive in terms of price.

- Natural filler with a more affordable price - camel or sheep wool. Jackets and down jackets with such filling are warm, but heavy.

- Thinsulate is the warmest synthetic filler (twice as warm as natural fluff), it is lightweight, practical and hypoallergenic.

- Holofiber represents the golden mean among down jacket fillers, and its low price makes it the leader of our small rating. It is completely devoid of the shortcomings of natural materials and is second only to thinsulate in terms of thermal insulation properties (it should be noted that in Europe and Central Russia the ability of thinsulate to warm in frosts down to -60 degrees Celsius is clearly excessive and there is no point in overpaying for it).

So, a light, warm down jacket for Siberian frosts is thinsulate, inexpensive and practical - holofiber, and woolen and down fillers are suitable for adherents of everything natural.

VIDEO: How to wash holofiber in a washing machine.