The choice of glue for gluing shoes at home

It is usually much easier to buy new shoes than to carry them to the workshop, as this option is cheaper. But it is often difficult to part with a loved one who has served for so many years. To save the item, you can buy or prepare shoe glue. You can carry out the gluing procedure at home on your own without the help of specialists. To do this, you need to study all the subtleties and features of the issue.

It is difficult to choose a good shoe glue without sufficient experience. Experts recommend purchasing adhesives exclusively from well-known manufacturers. Otherwise, there is no guarantee of reliability. An optimal adhesive should have the following properties:

- cold resistance;

- elasticity and bending strength;

- high water-repellent properties;

- durability;

- strength;

- maintaining the integrity of materials;

- the thickness of the elements to be glued should not affect the quality of the gluing.

All these properties are characteristic of good products. There are many different products on the market, so it is often difficult to make a choice. It is necessary to understand what types of adhesives exist, as well as their purpose and application features.

Types of shoe glue

All products are divided into several large groups. They are distributed according to the type of adhesive and purpose.

Depending on the purpose, the following varieties are distinguished:

- Fixing the base. Designed for attaching heels or soles. Possesses high reliability, provides strong fastening of all basic elements.

- Ancillary work. They are used for connection with threads, nails, staples.

- Secondary gluing. For gluing labels and non-essential items. This does not require a high bond strength.

Note! Before purchasing products, you should carefully study the instructions. The purpose and application features are usually written in it. Different materials require different adhesives.

There are also universal substances. They can be used for gluing various materials without losing quality indicators. It is also important to take into account the durability of certain components, as well as exposure to external influences - humidity, temperature and other factors.

Also, the glue is divided according to its composition. They all have their own advantages and disadvantages. There are the following varieties:

- Universal. A common type of adhesive that is used for a variety of tasks. Suitable for repairing minor damage or major connections of torn elements. Differs in high elasticity and resilience.At the same time, it is not recommended to use it in places of strong bends, since it can quickly break down, which will lead to serious damage.

- Combined. The composition may contain various components depending on the requirements of the manufacturers. It is preliminarily recommended to study the instructions. Most often it is used for gluing small parts, nose, insoles.

- Nairite. It does not differ in high strength indicators. Mainly used for gluing shoe insoles. Good for joining rubber outsole. It is characterized by resistance to moisture and cold. Cannot be used for pasting polyurethane coatings, as this will only ruin the surface.

- Polyurethane adhesive for shoes. A professional composition of high quality. The advantage applies in workshops. When using, do not pour in a large amount of adhesive, as it increases in size during drying. The product hardens in a matter of seconds, so it is recommended to be careful when working with it.

- PVC. The composition contains resins. They make the composition flexible, which allows you to glue the bending points. Does not differ in high quality indicators. When used correctly, refurbished shoes can last for years. Among the special properties, the glue is distinguished by good moisture resistance.

- Pervinyl chloride rubber. Not a durable adhesive. It is used exclusively for joining insoles. The composition is not stable when exposed to low temperatures or moisture. It is recommended to fix the details exclusively on summer shoes.

To choose the best shoe glue for home use, many indicators must be taken into account. You need to decide what you will use it for. This will help you make the right choice.

How to make shoe glue yourself

If you do not want to spoil your favorite pair of shoes with a poor-quality composition, you can try to prepare the glue yourself at home. This is a rather difficult process that will take time. It is also advisable to look at the training materials in order to understand all the intricacies.

One of the recipes for preparing an adhesive is as follows. You need to take nylon or nylon (women's hosiery is suitable for this). After that, they are sent to soak in acetic acid. It must be cooled beforehand.

There is another option. It is necessary to prepare soft rubber and gasoline. The workpiece is cut into small pieces and soaked in fuel. The mixture must be left for two days. After that, the resulting mass is poured into a container made of glass or plastic. Stored in a dark, cool place. The finished mixture has a thick consistency that can be used for gluing shoes.

In order for the composition to be of high quality, you must have sufficient experience. It is recommended to consult a professional. If necessary, it is better to purchase ready-made glue of well-known brands.

How to choose the right shoe glue

There are many parameters to consider when choosing an adhesive. The main ones are listed below:

- Target. First you need to decide what the glue will be used for. This can be a major overhaul or gluing of individual elements.Select which materials need to be glued (leather, suede). If a large amount of work is required, it is better to give preference to expensive brands of products that have proven themselves in the market. The result will last much longer.

- Types of work and materials. Before purchasing any product, you must carefully read the instructions. It usually indicates the possible amount of work to be performed, as well as the materials that are allowed to be glued. Universal adhesives are not always suitable. In some cases, they only exacerbate the problem.

- Specifications. The adhesive must be resistant to moisture and low temperatures.

- Tube size. If you are planning a small repair at home, it is better to buy a small package. If you store the adhesive for a long time, it dries quickly.

- Price and quality. The main thing is to correctly assess the price-quality ratio of the product so that the purchase does not hit the budget hard.

- Efficiency. The strength of the composition is indicated by the reliability of the fastening, the service life of the product. Parts should not deform or peel off immediately after pasting.

These characteristics must be considered when buying shoe glue. The modern market provides a wide range of different products.

The best all-purpose shoe adhesives

Often the composition of all adhesives is the same. Moreover, the quality of each product is different. Below are the most common options that should always be at hand with a home craftsman.

KENDA FARBEN SAR 30E

Differs in universal properties. Can glue a wide variety of materials. Suitable for repairing shoes made of natural or artificial leather, rubber, textiles. Differs in fast bonding of different surfaces. The seam is durable, resistant to high humidity and low temperatures. It will take two days for the adhesive to dry. After that, you can use your shoes.

Among the advantages are:

- application in professional workshops and at home;

- high efficiency and quality indicators;

- resistance to temperature extremes;

- there is no unpleasant odor when gluing.

Disadvantages:

- rather high cost of one tube.

Moment "Marathon"

Quickly glues different surfaces, therefore it is suitable for quick gluing of shoes. Differs in ease of use. The composition does not spread, as it has a gel structure. Not intended for gluing polyethylene or PVC. It is used for gluing fabric, wood, rubber and other materials from which shoes are made. Freezing possible. After that, it heats up quickly enough at room temperature, without losing its quality indicators. The packaging looks red.

Pros:

- there are different volumes of tubes;

- allows you to quickly repair the desired product;

- economically distributed over the work surface;

- characterized by high strength and efficiency.

Minuses:

- unpleasant smell when gluing.

Nairit

Designed to work with a wide variety of materials. Differs in high quality bonding of rubber, fabric, leather, wood. It has elasticity, therefore it does not break the seam. There are two methods of surface treatment. With cold pasting, it will take a day for the adhesive to dry, with hot - about four hours.In order to give the mixture the required viscosity, you can use additional components (gasoline, acetone).

Advantages:

- there are no harmful toluene-based solvents in the composition;

- it is reliable and durable;

- it is used to perform various household tasks.

Disadvantages:

- high price.

Glue "317"

Household universal glue. They can glue a variety of materials: leather, rubber, glass, synthetic substances. For example, it is used to create landscaping decorations. Available in 40 ml tubes. Among the features, it quickly freezes.

Advantages:

- creates a strong connection;

- no need to wait a day for gluing;

- has a dense consistency;

- affordable cost.

Disadvantages:

- leaves yellow marks.

The best adhesives for shoe sole repair

To repair the sole, you need to select special compounds. They must have high durable performance, as well as be resistant to moisture and aggressive external influences. Below are the most durable adhesives.

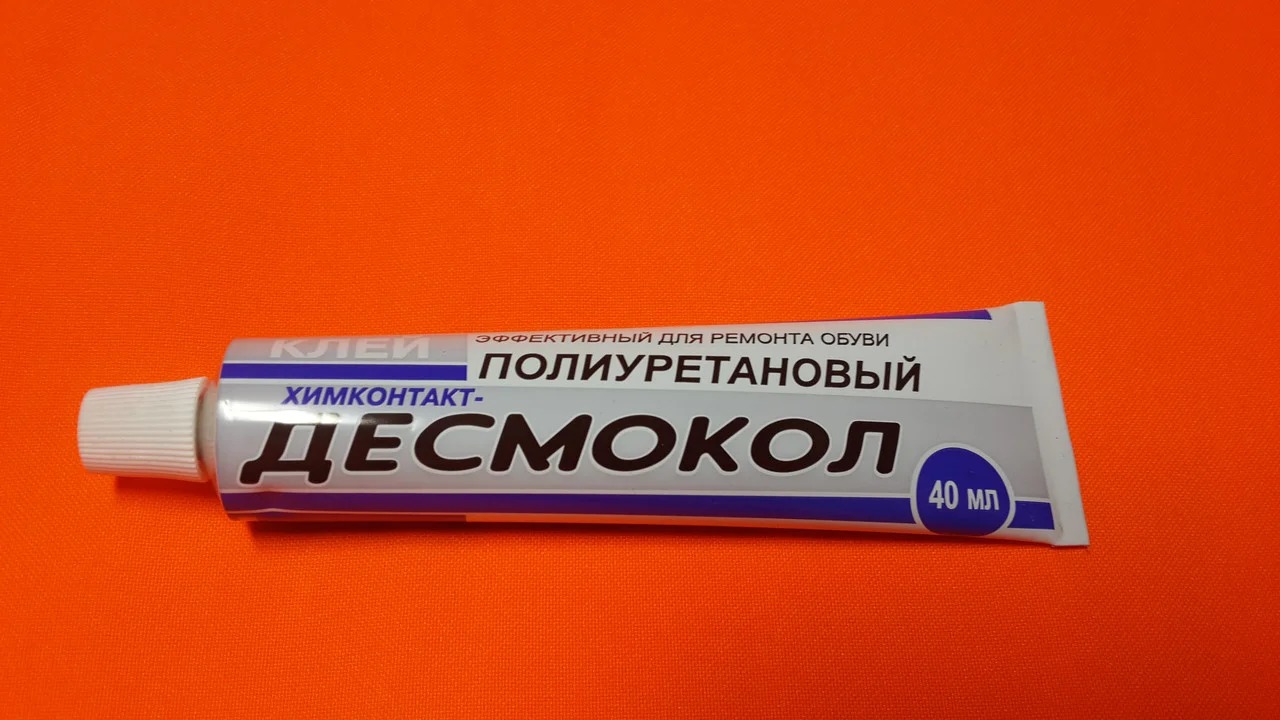

Desmokol polyurethane

The composition contains polyurethane resins. Also contains organic solvent, which is popular for repairing a wide variety of shoes. It is characterized by reliability and high durability. The seam is transparent, even, almost invisible. Cold resistant. It increases in volume upon drying, therefore it requires a small amount for pasting porous surfaces. Combines a wide variety of materials. Sold in large packs, as it is often intended for use in workshops. Sometimes sold in small tubes. You can use analogs.

Advantages:

- affordable cost compared to other substances;

- can be used instead of sealant if necessary;

- Suitable for gluing products for fishing and boats.

Disadvantages:

- excess glue is difficult to remove.

SEAM GRIP

Polyurethane based adhesive. Differs in universal properties. It can be used for gluing fiberglass, leather, rubber. Dries quickly, is characterized by elasticity. The substance does not spread over the surface, it adheres well. It is better to apply with a brush so that the composition is evenly distributed, gluing all the elements. It takes about twelve hours to dry.

Advantages:

- quickly glues;

- dries up in 12 hours;

- it is easy to use at home;

- resistant to moisture and cold.

Disadvantages:

- may be damaged at the seams.

Shoemaker

Nairite glue. It is used for gluing shoes made of a wide variety of materials. Differs in high performance properties. It is sold in different tubes, which is convenient for home use.

Pros:

- suitable for various surfaces;

- universal properties;

- ease of use.

Minuses:

- quite high cost.

Type-top

High-quality polyurethane glue that reliably connects the sole to the main surface of shoes, sneakers, and other shoes. Differs in strength and durability. Resistance to various atmospheric phenomena is manifested.

Advantages:

- affordable cost;

- reliability;

- high quality;

- glues well.

There are no disadvantages. This is the best product for its value.

How to repair shoes without glue

In this case, the shoes can be stitched. It is not recommended to perform this procedure yourself. Better to see a specialist. Otherwise, you risk ruining your favorite pair of shoes.

The choice of glue for repairing shoes at home is a rather difficult process. There are many parameters to consider. When gluing, you should strictly adhere to the instructions.

How to quickly and correctly glue shoes