Making a drywall wall with your own hands

Often there is a desire or a forced need for redevelopment. The easiest way to change the space is to have a new plasterboard wall that divides it.

But how to make a drywall wall yourself. Where to start and how to end.

How to make a drywall partition with your own hands

It is possible to start work on the manufacture and installation of a plasterboard partition if the plaster and screed have dried in the room, that is, all the "wet" work has been completed. The air should not be humid. Otherwise, this will lead to the fact that the material will become damp and deformed.

It is not recommended to start working immediately after the plasterboard is purchased. The warehouse in which they are usually stored is not heated and the gypsum plasterboard must be allowed to dry for about 24 hours, and preferably several days.

Scheme and drawing

It is quite simple to make a drywall wall with your own hands. It is worth starting with the layout drawing of the room. Namely, you need to determine the optimal placement of the partition and its dimensions in order to avoid mistakes during installation.

The drawing should carry all the information. This includes not only the size, but also the gap that will need to be observed. If grooves, shelves or "windows" are planned on the product, then it is also better to mark them on the diagram.

After marking on paper, the lines will be easy to transfer to the gypsum board, floor and ceiling. You should not skip this stage, since the quality of further work depends on it.

Materials and tools

A lot of materials and tools will be needed, so it is worth preparing them immediately before work.

- Plasterboard of the required thickness.

- PN and PS profiles

- Mineral wool

- Wood screws

- Dowel-nails

- Reinforcing tape

- Sealant and sealing tape

- Primer

- Putty

- Level

- Painting cord or chalk thread

- Locksmith pencil

- Gon

- Metal scissors

- Screwdriver and hammer drill

- Several drill bits

- Drywall knife

- Plane

- Brush

- Putty knife

Partition markings

For marking, you will need a level (laser or bubble) and a painting cord (chalk thread). First, a schematic place for the partition should be noted, following the previously prepared drawing.

Using the level, transfer the contour to the walls and floor, you should get a flat line, the outline of the future structure. A locksmith's pencil and a square will help in this. If the partition implies a recess for the door, then on the line it is necessary to mark the place where it will be located. The profile will be fixed there.

Transferring marks from floor to ceiling

When it's time to move the bottom lines from floor to ceiling, it's best to call someone for help. It will be difficult to cope with this alone, since you will need to simultaneously control the location of the plumb line and set the points of the contour.

One person holds a plumb line, the other puts down points, as if using a ruler. After checking for a match, they can be connected to create a straight line.

Layout of plasterboard partitions

The marking should be completed by checking the coincidence of all lines. Even with the smallest irregularities, the design will be unreliable and crooked. All guides are aligned using a laser level.

You can also check whether the drywall sheet itself is even.

Profile installation

It is better to start attaching the profile guides from the floor. The installation site is glued with a sealing tape to ensure good sound insulation in the future.

You will need dowel-nails or self-tapping screws for fastening.

Guide

After gluing the sealing tape to the back side, align the PN along the line of the internal markings on the floor, which was made earlier and fix it.

Fixation takes place with dowel-nails, if it is a concrete base and self-tapping screws, if it is a wooden base. Holes are drilled through the profile in the floor. You can cut off excess length using metal scissors.

Stoichny

The vertical post is fixed at the edges of the profile. They should be cut so that there is a 1 cm gap for building shrinkage between the top of the support and the profile on the ceiling.

Upon completion of the cut, each strut is attached to the lower profile like a cylindrical fixed support and carefully tucked into the upper rail with the free ends. This is followed by vertical alignment and screwing to the guide profile.

The same installation technology for the doorway forming the base and ordinary pillars. The axial marking of an ordinary post starts from the edge of the wall, then to the center of the first post and the central axis of the other supports, 600 mm each. If the chamfer of the extreme gypsum board is cut off, then the distance will decrease to 550-500mm.

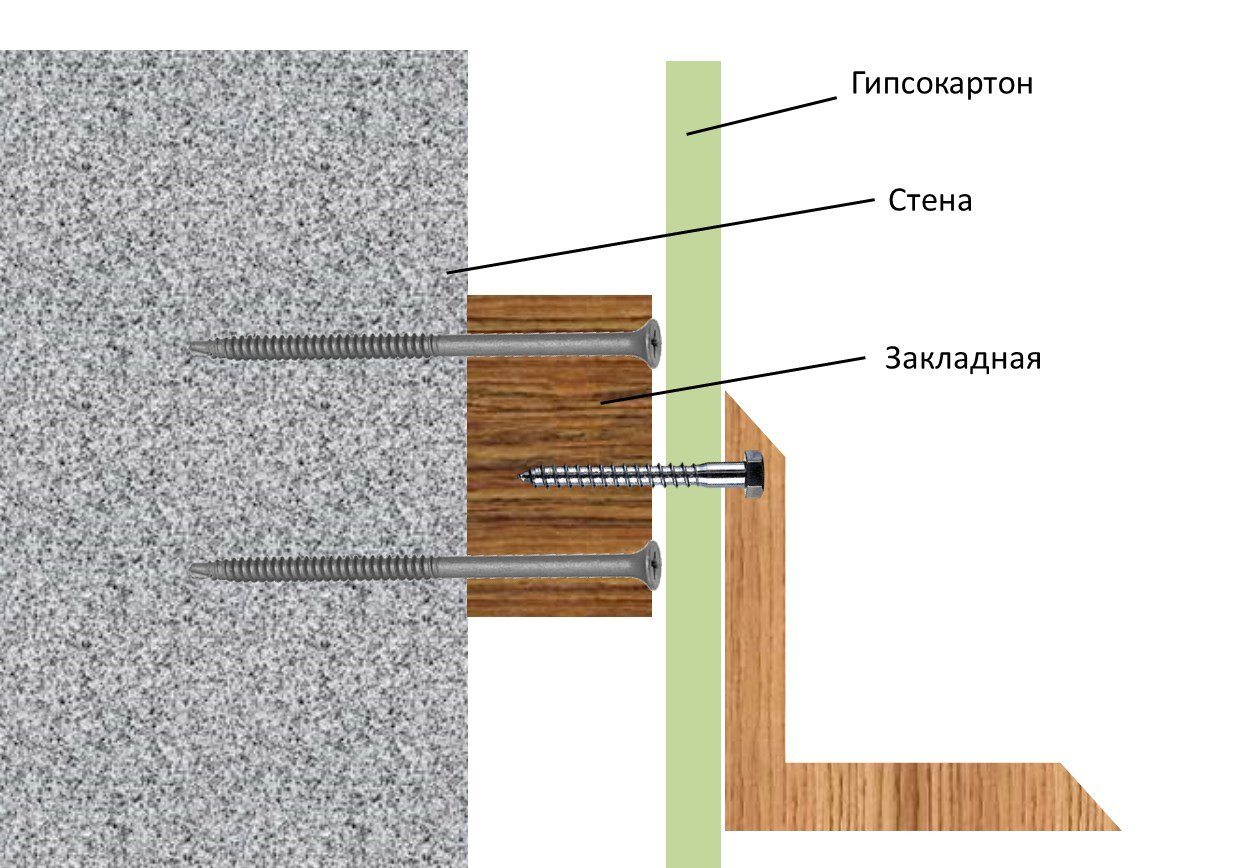

Features of strengthening the frame

You can strengthen the partition if you connect two profiles of the vertical rack for fastening. So the structure will become much stronger and can withstand a weight of up to 50 kg. They are connected with self-tapping screws, or dowel-nails. But this method is not always reliable, since not all materials retain their practicality and stability.

For the next method, you will need wooden blocks of the same size. The bar should be slightly smaller in width than the profile, since they are placed inside. For greater reliability, it is better to fix them with self-tapping screws. It is important to monitor the support, it should not deform during the strengthening process.

If you do not want to experiment, then it is better to use the third method. It implies reinforcement with ready-made certified parts that are made specifically to increase strength. They look like wider and thicker metal profiles. The method is good in that when choosing the most durable ready-made amplifiers, a structure from one sheet of drywall will be stronger than from two.

Making a doorway and installing crossbars

With the help of a guide profile, the upper part of the doorway is formed. It is cut off by 25-30 centimeters more than the design length. The outer side is marked at a distance of 15 centimeters from the edges of the cross member.

Risks should be visible on the side profiles.A cut is made along them from the edge of the sidewall to the marks on the bend. After that, the profile edges are bent on both sides at an angle of 90. The end result should be a crossbar in the shape of the letter "U". It can be easily moved along the racks and attached with self-tapping screws. The plasterboard joint should be at some distance from the rack on which the door frame will be attached.

The horizontal cross members are made according to the same principle. They perform the function of sealing the frame and joining the gypsum board, if the height of the partition is large. In this case, 2 to 3 rows of horizontal crossbars are used.

The tails of adjacent planks need to be bent in different directions and the crossbars should be staggered. So the adjacent horizontal joints will not match, and there will be no cross-shaped seams.

Frame sheathing

The most difficult thing is behind, it remains only to sheathe the frame with drywall. If the previous steps were performed correctly, then there should be no problems during the installation of the gypsum board.

Installation begins from one of the sides, which is closer to the wall or corner. One side of the drywall sheet is trimmed 4-6 centimeters. This is done to ensure reliable joint formation.

A knife or saw will help to cut qualitatively. For a smoother cut, it is better to perform the procedure on a table. It will not be possible to completely cut off the fragment, since it can move unevenly, it is better to trim on both sides and break.

Next, a drywall sheet is applied to the frame so that the lower edge is at a distance of 1 centimeter from the floor. With self-tapping screws, the drywall sheet is fixed to the frame, a step of about 14-15 centimeters, from the edge 1-1.5 centimeters of indentation.

Correctly tightened self-tapping screws will ensure reliable fixation, therefore, this moment must be strictly monitored. It should enter the sheet by 1 centimeter, while not breaking through it.

For easier puttying of joints, it is important to monitor the connection of the edges of the gypsum board. They are connected only on the substation. Correct docking is that the attachment point and seams do not match. Self-tapping screws are twisted apart, the panels are laid, displacing the seams. There is an alternation of whole sheets and individual stripes.

When the upholstery on the first side has come to an end, it's time to move on to the second. But first, a panel is placed in the resulting space, which will perform the function of sound insulation or heat preservation. Places for sockets and switches are outlined, taking into account the further wiring. The second side is mounted according to the algorithm of the first.

What else can you make a partition

In addition to GCR, you can use other materials, for example:

- Finishing brick

- Foam concrete

- Gypsum block

- Glass block

Design advantages and disadvantages

The benefits include:

- Reasonable price. The cost of a drywall sheet is less than for other materials and it is easier to find it in the store's assortment.

- Thermal insulation and fire resistance. The material is not inferior in these parameters to gypsum or foam concrete structures. At the same time, it allows air to pass through and it is not stuffy in the fenced off room.

- Smooth surface. Sheets do not require additional alignment. After installation, they are immediately painted, pasted over with wallpaper, and tiles are laid.

- Good flexibility. Thanks to this, structures of various shapes can be made from gypsum board.

- Easy installation. It is much more difficult to build and remove a brick partition than from a gypsum board.

The disadvantages include:

- Moisture resistance. The material does not deteriorate from a slight increase in humidity, but direct ingress of water has a negative effect. Therefore, the gypsum board is not suitable for installation in bathrooms.

- Insufficient strength. Sheets cope only with objects of medium weight and in this they are inferior to concrete and brick partitions.

Video: do-it-yourself plasterboard partition