How to drill porcelain stoneware

Drilling in porcelain stoneware causes difficulty and fear even for experienced craftsmen. It is especially difficult to do this without practice, understanding of the working material and special tools. Not every drill will take a porcelain stoneware slab because of its special strength and hardness.

Is it possible to drill porcelain stoneware

If ordinary tiles can be drilled with a drill or even self-tapping screws, then this will not work with porcelain stoneware. Unlike tiles, its surface is made of natural minerals and natural pigments that are firmly pressed and processed in a kiln at high temperatures. The resulting tile acquires special strength and resistance to mechanical stress. It practically does not absorb moisture due to the absence of pores in the structure of the material.

Porcelain stoneware tiles, despite their amazing durability and strength, can chip and crack when drilling. Why did it happen?

- Lack of practice in such work. Over time, the master unmistakably selects the right place for drilling, the necessary tool, intuitively determines the force of pressure and pressing on the plate. If you have no experience, read the related articles, watch a few videos, get acquainted with the process.

- Wrong choice of tool. Porcelain stoneware tiles require a special approach. The more scrupulous you approach the issue of choosing a tool and attachments, the better and easier the work will go. Do not ignore the helpful advice of experienced craftsmen.

- Observe safety rules. This is a prerequisite in any work of the master, especially if you are working alone.

How to drill porcelain stoneware at home

Before drilling any surface, you need to understand its characteristics and properties. Porcelain stoneware consists of several layers:

- Decorative glaze that can crack, become damaged or become unattractive.

- Soft ceramic underlay. It is malleable enough to cut. At this level of drilling, with careless work, chips and cracks can be obtained.

- The hardest layer of the composite is 8 units. For comparison, according to the MOHS scale, granite reaches 6 units. At this level, the drills break and the patience of the craftsmen.

- Soft ceramic layer.

There are porcelain stoneware tiles, which are a single sintered layer. And despite such seeming difficulties, you can drill a hole of the required diameter for an average person far from the construction industry. To drill porcelain stoneware at home, you need special drills with a carbide tip or with a crown.Only what kind of helpers penetrate through the dense structure of porcelain stoneware material.

The choice of a suitable tool directly depends on the diameter of the planned hole. Hanging a hook or installing a socket in a bathroom tiled with porcelain stoneware are different processes and different approaches to work. It is impossible to crush the material with a small drill to obtain a large diameter. This can damage the wall, get a lot of chips and ruin the appearance of the room.

Professionals know how to drill porcelain stoneware:

- diamond core bits as an effective and budgetary solution for the home craftsman;

- diamond-coated drills, as an option, are more expensive, but more durable than crowns.

Hand tool for drilling porcelain stoneware

Porcelain stoneware is a stubborn material. But even it can be mastered and drilled with due experience and skill, even with a screwdriver.

Press the tool firmly against the work surface so that the drill does not slide over the glazed tile surface. Pre-mark lines or points at the drilling sites to focus on the process.

Electric tool

Electric tools make work easier and require experience at the same time. It is easy to pinch, apply more force and break the tiles. Therefore, choose a tool with a center drill. The cut will be smooth, and the edge will be beautiful, without chips or cracks.

What are the drills

The quality of the future hole in porcelain stoneware will depend on which tool you choose. The more economical the drill option, the rougher the job will be. An impact drill cannot be used. It will damage the porcelain stoneware surface and may crack the tiles.

Victory drill

Winder drills can often be found in a DIY repair box. They are bought in large quantities, since the service life of such attachments is short. Drills often break, fail, do not like high temperatures. Made a victorious drill from a strong alloy, which can work with tiles, concrete and bricks.

Such drills are “not on friendly terms” with porcelain stoneware. But, if the master has no other choice, you can try to work with them. You will most likely need 2-3 pieces until you make the hole you want. After that, the drills will no longer be suitable for further work.

Diamond coated tools

A handy tool when you need to make many holes or grooves of the same diameter. For such works of the same type, craftsmen acquire a drill with a special spraying according to the sintering method technology. Cutting the surface of porcelain stoneware tiles is carried out using diamond chips. Such spraying is held by a special solder, which contains manganese and chromium. This makes the coating particularly wear-resistant and hard.

Diamond core bits

If holes of significant diameter are needed, craftsmen recommend using a special crown. Its edges are covered with diamond chips immersed in a layer of nickel compound. The electroplated coating is short-lived, but affordable enough for the job.

When working with porcelain stoneware tiles, it is recommended to work from the decorative, glazed side. To make the crown last as long as possible, start working at an angle, gradually moving the tool to a vertical position. Diamond core bits differ in manufacturing technology:

- sintering method, makes the nozzle more wear-resistant, allows you to drill up to 10 socket-outlets at a time;

- the method is galvanic, such a drill is enough for a maximum of 6 socket-outlets.

Steel feathers

Feather drills are needed for holes larger than 12 mm. You won't be able to get large holes, but you will be able to make a place for the dowel. The drill got its name due to its appearance, reminiscent of a bird's feather sharpened from the base. In work, a tool with such a drill requires skill and experience. The drill must not be pushed through with force, you can damage the tool. But even weak, insufficient pressure will not provide the desired result.

To drill through a porcelain stoneware surface, it is recommended to use two types of nibs. It is better to start with a diameter of 3 mm, and finish the work with 12 mm. Scotch tape is glued to the intended drilling site. This will help prevent the tiles from breaking down. A small feather on porcelain stoneware creates a hole, and a larger one expands it to the desired diameter. Do not forget to cool the interaction zone of the drill and porcelain stoneware with water during operation.

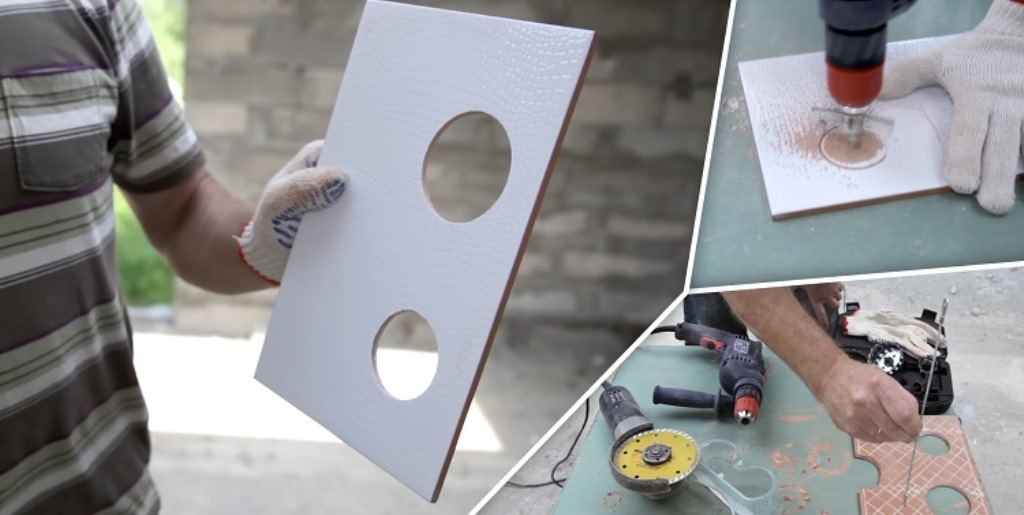

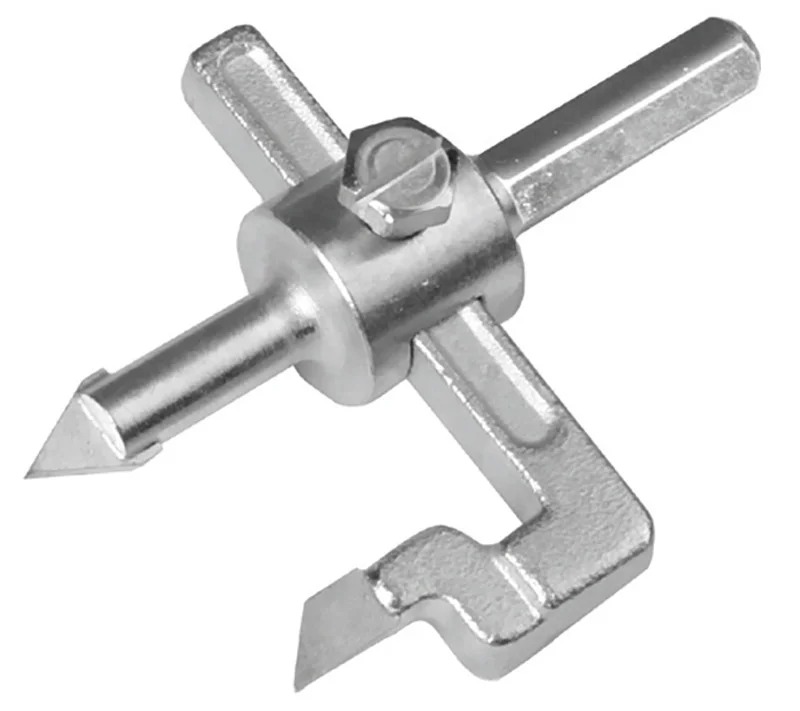

Ballerina

The circular drill got its name due to the structure rotating around the axis. The fragility of the tool in operation can be compensated for by the option with a replaceable cutter. This item is easier and cheaper to replace than to upgrade the entire kit. The ballerina's cut on porcelain stoneware turns out to be perfectly even. You do not have to draw the previously planned hole circle on the working surface, it will be set initially by the dimensions of the nozzle. It is enough to outline the central point of the work and concentrate on it.

Drilling instruction

Before drilling porcelain stoneware tiles, decide on the task. If you need a neat hole with straight edges, for example, for attaching a socket outlet, you need an even cut and exact observance of the diameter. This is a work for diamond crowns or for a ballerina.

If the place of drilling is planned to be masked in the future with a decorative element, for example, a painting, it makes no sense to observe jewelry precision in drilling. Drills, such as a winder drill, are suitable here.

Try not to drill on a concrete floor. Place plywood under the tile. It absorbs some of the vibrations and pressure, protects the tool from "sticking" into the concrete and helps to achieve smooth cutting edges.

Pobeditovy drill

Drilling porcelain stoneware at home will win - a matter that requires skill and accuracy. To make a hole, make sure there are no voids underneath the tile or it will burst. Tap all the places for future drilling with a piece of wood. As soon as you hear a ringing sound, an air lock has formed there.

The winner is not recommended to work in the joint space, so as not to spoil the appearance of porcelain stoneware. If absolutely necessary, stick tape exactly in the middle of the tile joint and work at speeds up to 500 rpm.

When working with a victorious drill, pre-fix the work surface.High-quality and accurate work rarely turns out on weight, especially if you are a beginner in this business.

Crown

Working with diamond core bits requires an axial or centering bit. If there is none, use an additional template jig. To do this, a plywood sheet is applied to the drilling site and fixed with tape so that it does not shift. As soon as the drill overcame the template and plunged into the porcelain stoneware by 1-2 mm, the template is removed and the work continues without it.

It is recommended to combine drilling with a diamond bit with swinging. That is, little by little, by a couple of millimeters, change the angle of inclination in relation to the working surface. This helps to cool down where the tile touches the drill and helps to avoid overheating.

It happens that the bit gets stuck in a partially made hole, its segment breaks or sludge gets clogged in depth. You can remove the nozzle or its parts with a reverse hammer.

Ballerina

The ballerina is convenient when you need to make many holes of different diameters. Drill a hole with a nib or steel nib before using the circular nozzle. So the ballerina will not move and spoil the front of the decorative tiles.

Helps to lubricate the glossy work surface with machine oil. The process will run smoothly and evenly, there will be no sudden jumps and unplanned tool displacements.

How to drill

There are several ways to drill a hole in porcelain stoneware tiles. Each has its own pros and cons.

Wet surface

Wet drilling is the regular wetting of the nozzle and tile surface with water or oil to cool it down. When wet working with the diamond bit, gently swing the tool from side to side. This is necessary for uniform removal of wet sludge from the drilling zone. It is recommended to carry out such manipulations every 5-7 seconds.

Always wear safety glasses for personal protection. Wet waste can fly around. Covering your eyes or dodging regularly will prevent you from making a perfectly straight hole.

Don't pour too much water. A small, thin trickle is enough, and sometimes a couple of drops. It is necessary to add moisture with this drilling method as soon as you see the first haze of dry dust rising.

Dry surface

Turn on your home vacuum when drilling this way. It will help remove dust and sludge generated during operation. The dry process is best done with diamond core bits, the cavities of which already contain cooling oil. This will help to avoid "blurring" the edges and will give the final result a neat finish.

It is important that there is sufficient free space between the packing segments for the cuttings to escape. Otherwise, the operation of the tool will be blocked.

If there is no vacuum cleaner, try to interrupt work and remove fine dust. You will spend more time, but the result will exceed expectations.

The dry drilling method is used when a large number of holes need to be drilled in a short time.

On the floor

If the tiles are already installed and glued to the floor and you need to drill a hole to install, for example, partitions, there should be no difficulty in working. In this case, the tile surface does not move or vibrate, especially if it is glued onto it.

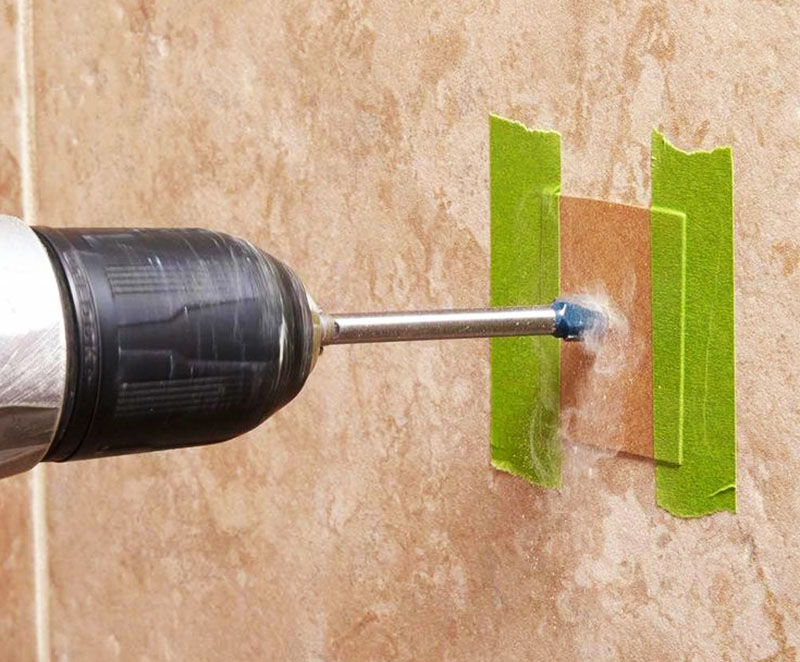

The main condition for quality work is to ensure that the drill is accurately positioned in the selected place so that it does not move.To do this, stick the tape, and the tool will not slip on the glossy surface. Make sure that there are no voids under the tiles, otherwise cracks will appear. And it is important to bring the drill already plugged in to the floor, and not to apply it while it is stationary.

It is convenient to drill with a wet method on the floor.

On the wall

If, before gluing the tiles to the wall, drill it from the matte, seamy side, this will lead to the destruction of the surface. When working with porcelain stoneware, it is important to maintain the angle of inclination of the tool. Then the wall will become your assistant. Work at low to medium speeds, avoid sharp knocks and jolts, and apply the same force during work.

As in working with floor tiles, mark the center of the future working circle and stick a piece of masking tape. This will prevent the tool from slipping.

Vary the drill diameter. If possible, first create an initial recess with a small diameter bit. And then modify it with a larger one. These simple manipulations will help you quickly make a hole of the desired diameter.

How to cool the instrument

Tool cooling plays an important role in the DIYer's work. Regular overheating of the drill will significantly shorten its life and can lead to serious damage. Reducing the temperature at the point of contact between the tool and the working surface reduces the likelihood of chips and cracks on porcelain stoneware tiles.

There are situations when water cannot be poured onto the drilling surface. In this case, interrupt work frequently and water the drill. This will reduce the degree of incandescence and help you work further without overheating the tool. Helps hold a wet sponge under the drill. This also cools the drill during operation.

If the work is carried out on a horizontal plane, you can build a side-fence from ordinary plasticine. A small plasticine well is fashioned around the future hole, into which a little water is poured. During drilling, the bit will automatically cool down. Do not pour too much liquid at one time to avoid splashing.

To ensure a regular supply of water, use a regular plastic bottle. Make 1-3 holes in its lid and pour water as needed. If you don't have a suitable plastic container on hand, a medical syringe will do.

Despite the seeming difficulties, it is quite possible to work with electric or hand tools with a porcelain stoneware surface. The main thing is to first familiarize yourself with how to avoid possible difficulties and follow simple, effective tips.

Video: how and how to drill porcelain stoneware